Patents

Literature

32results about How to "Efficiently wipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

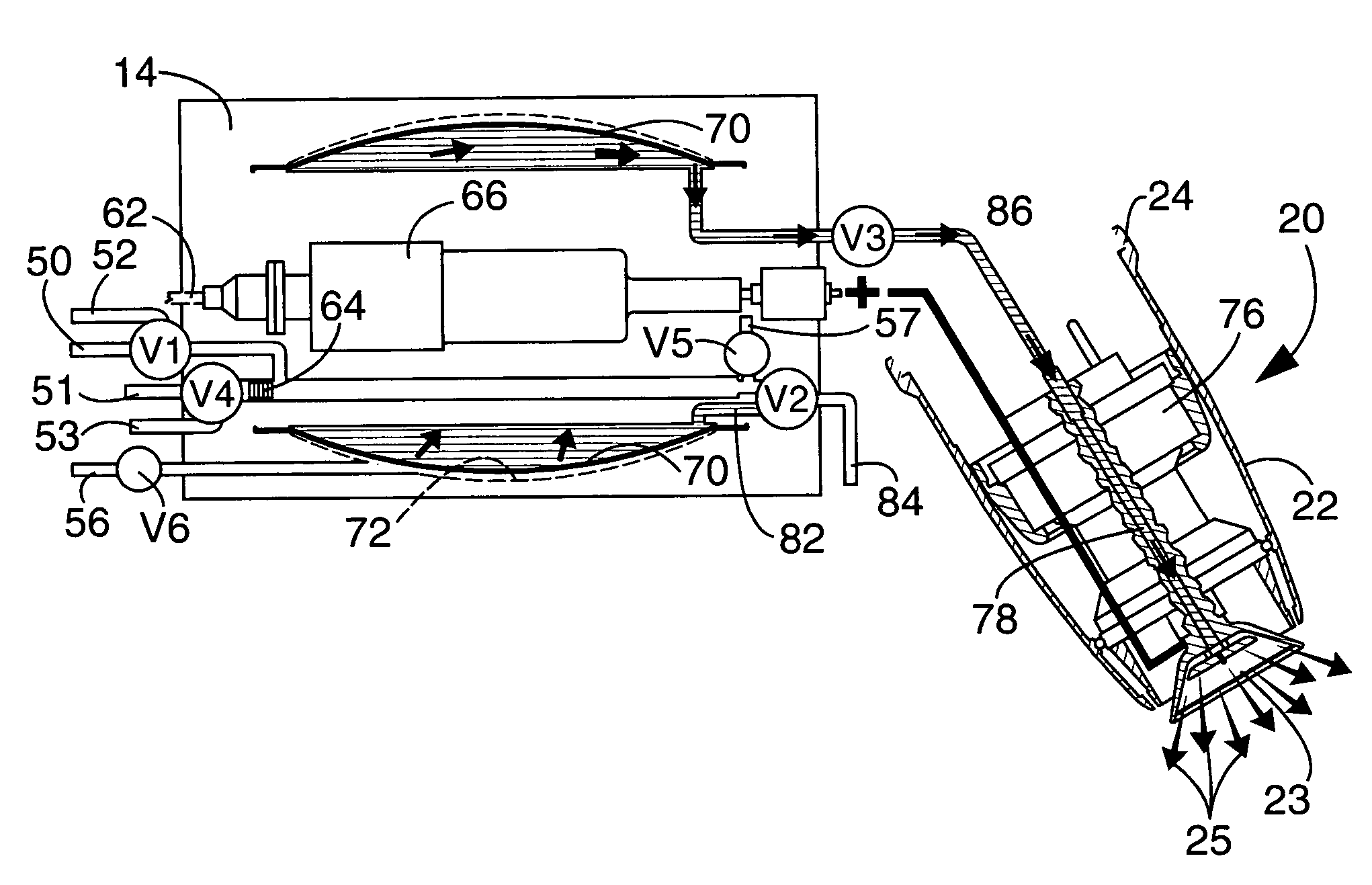

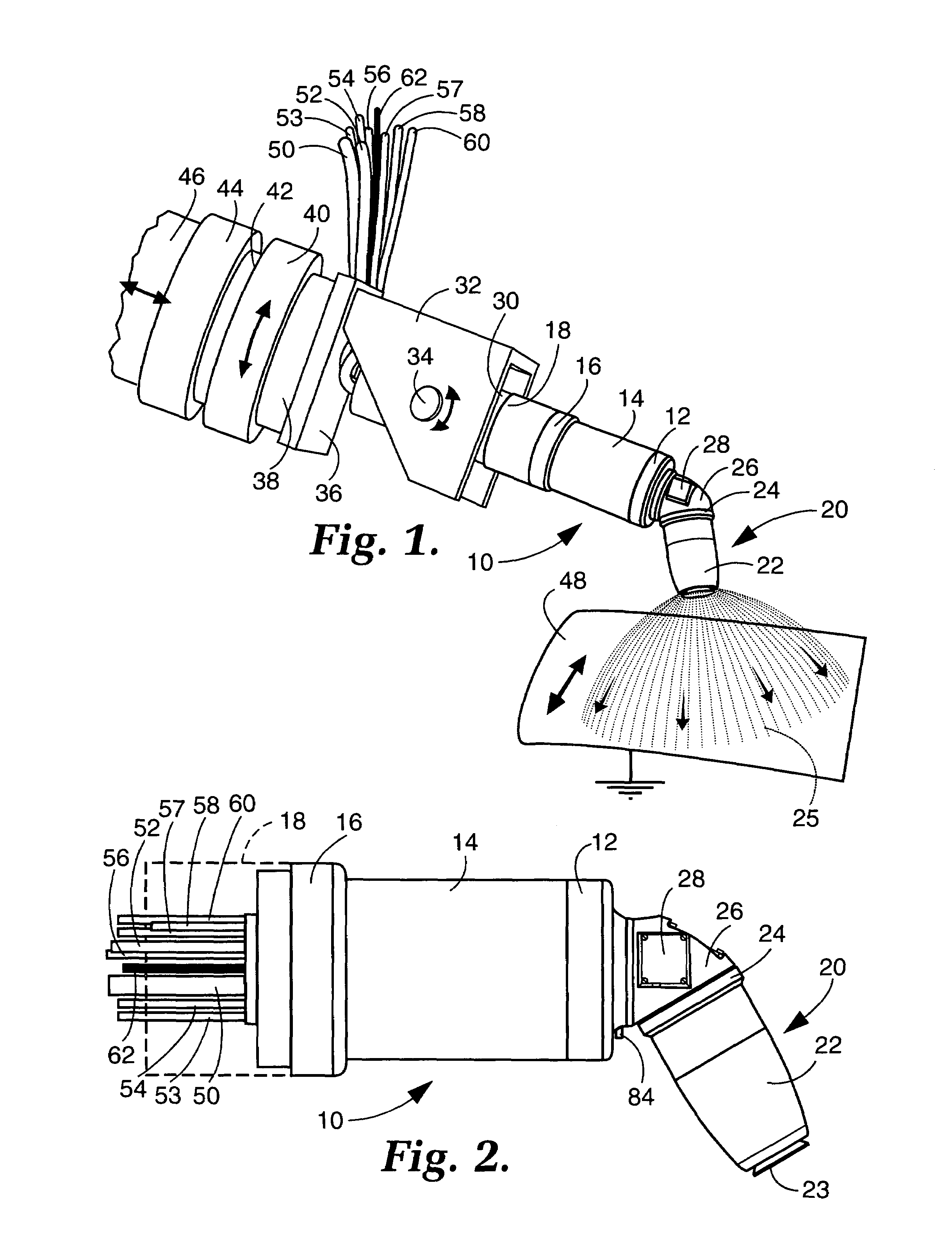

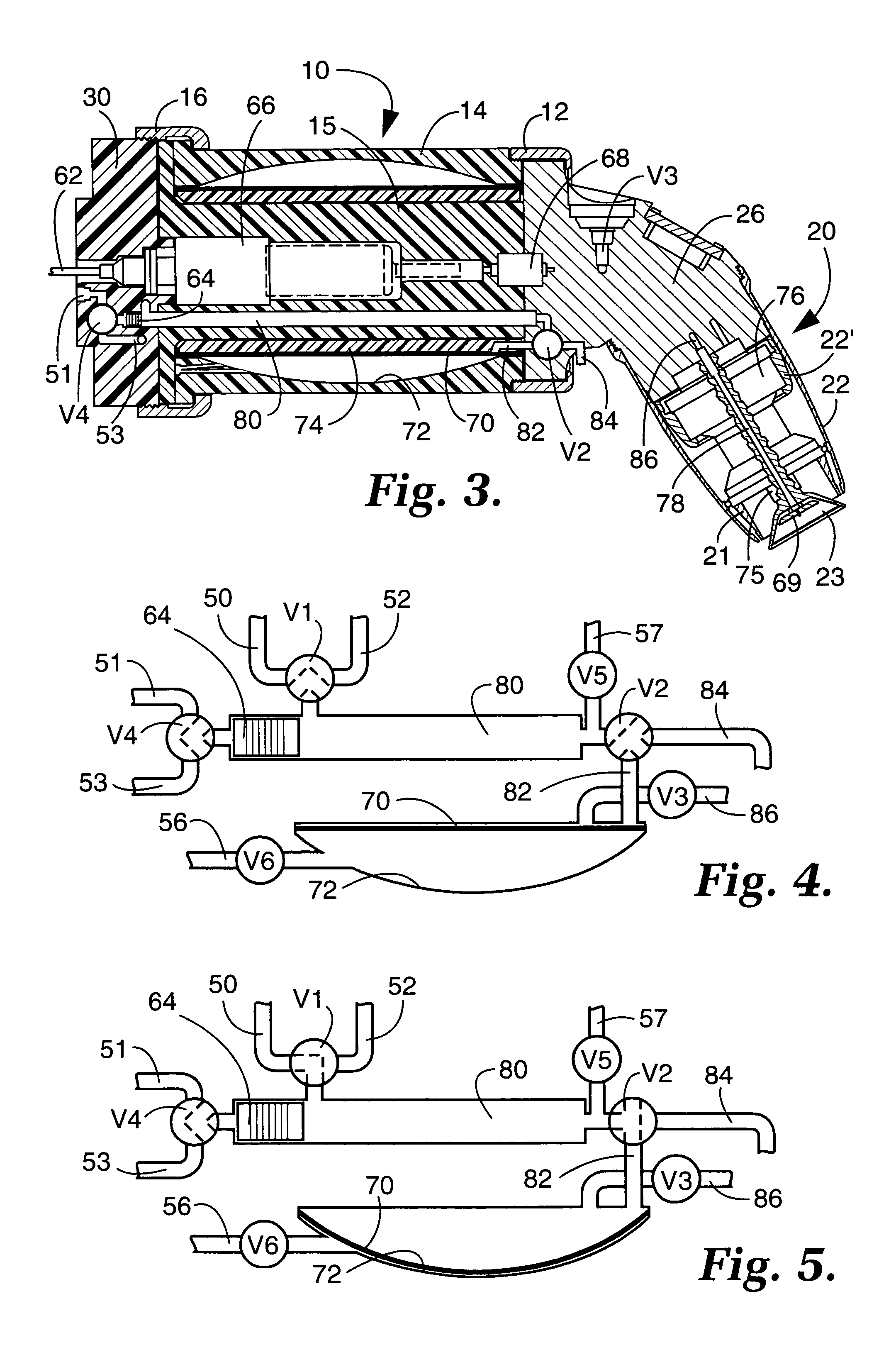

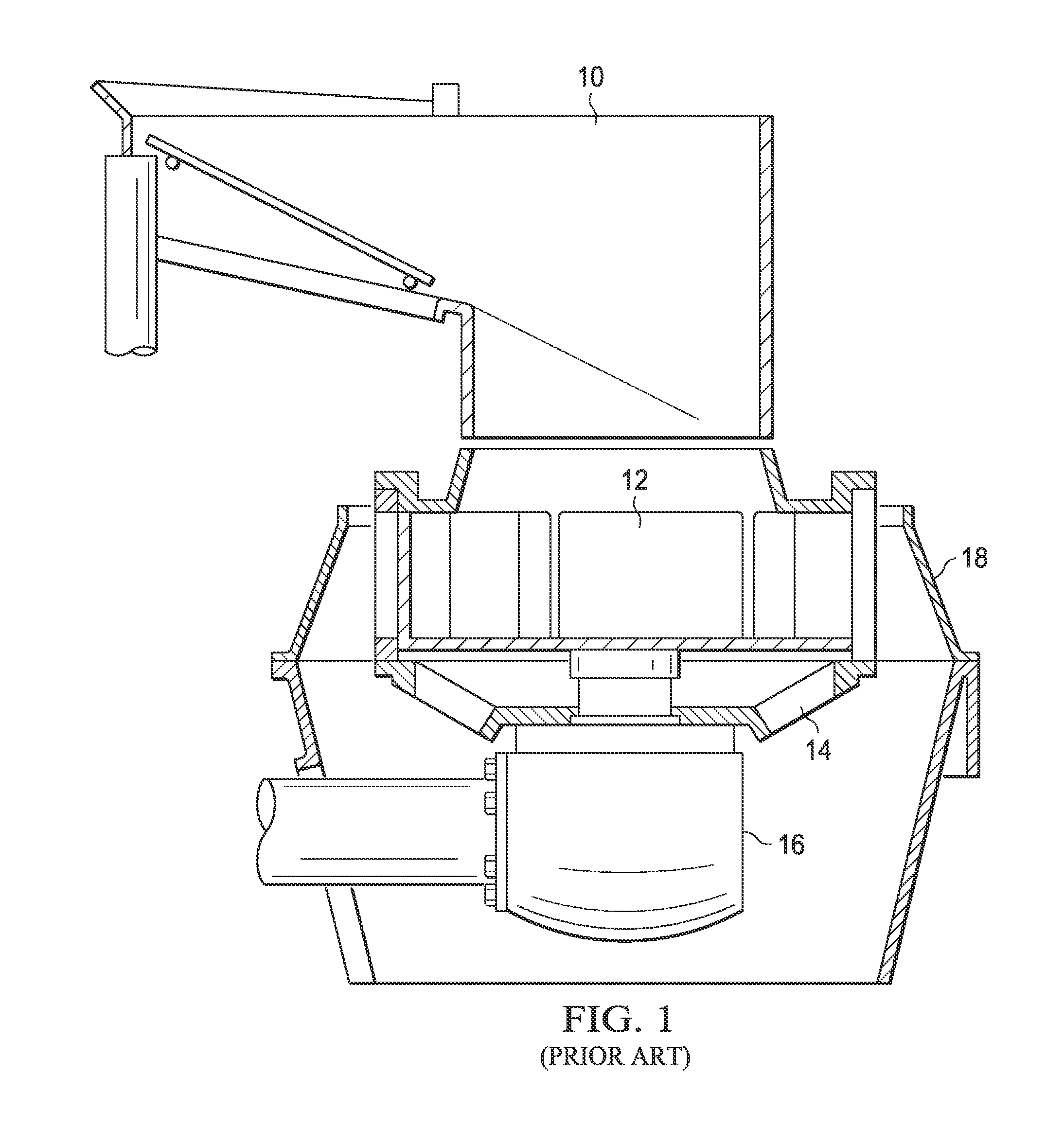

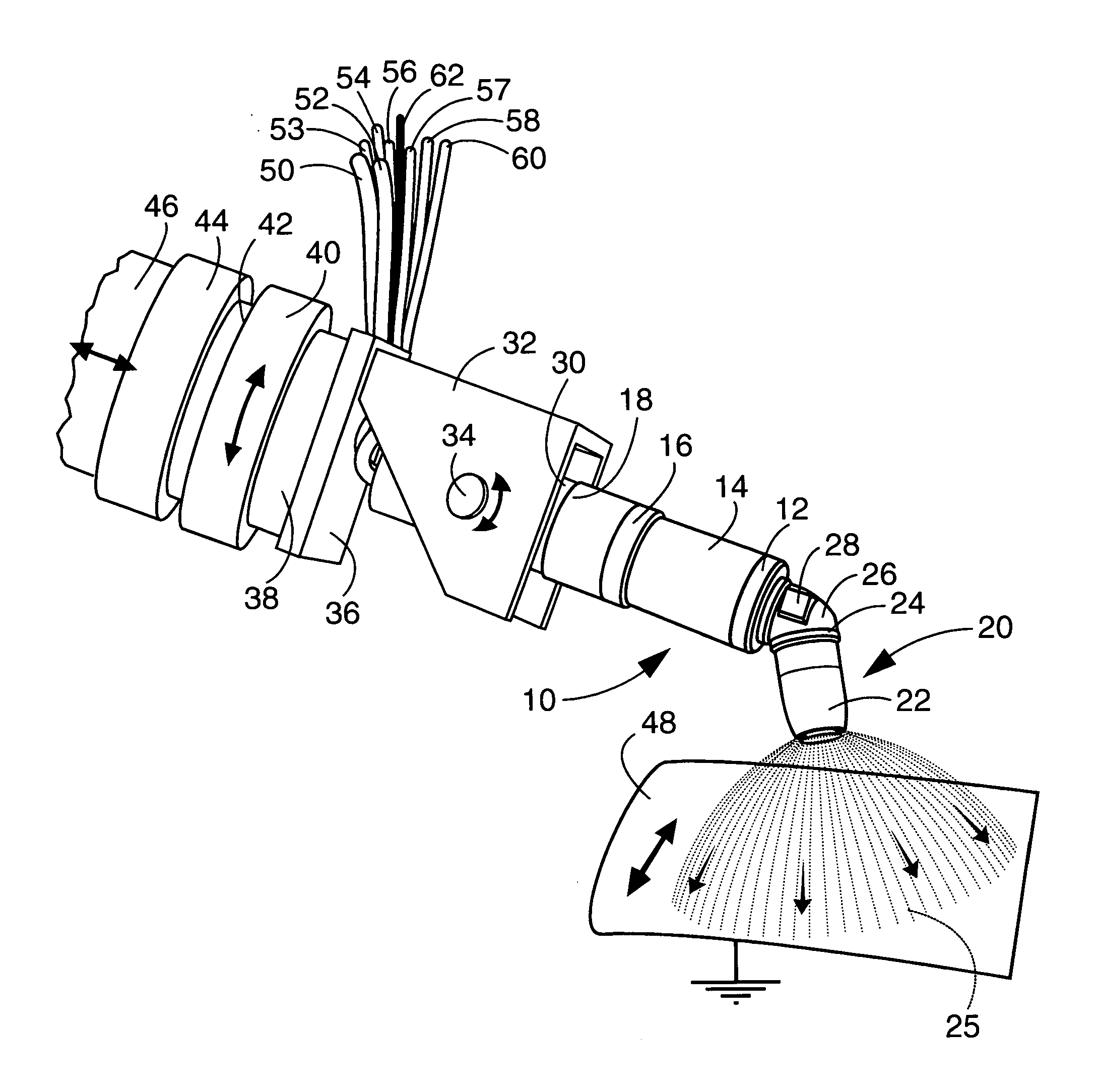

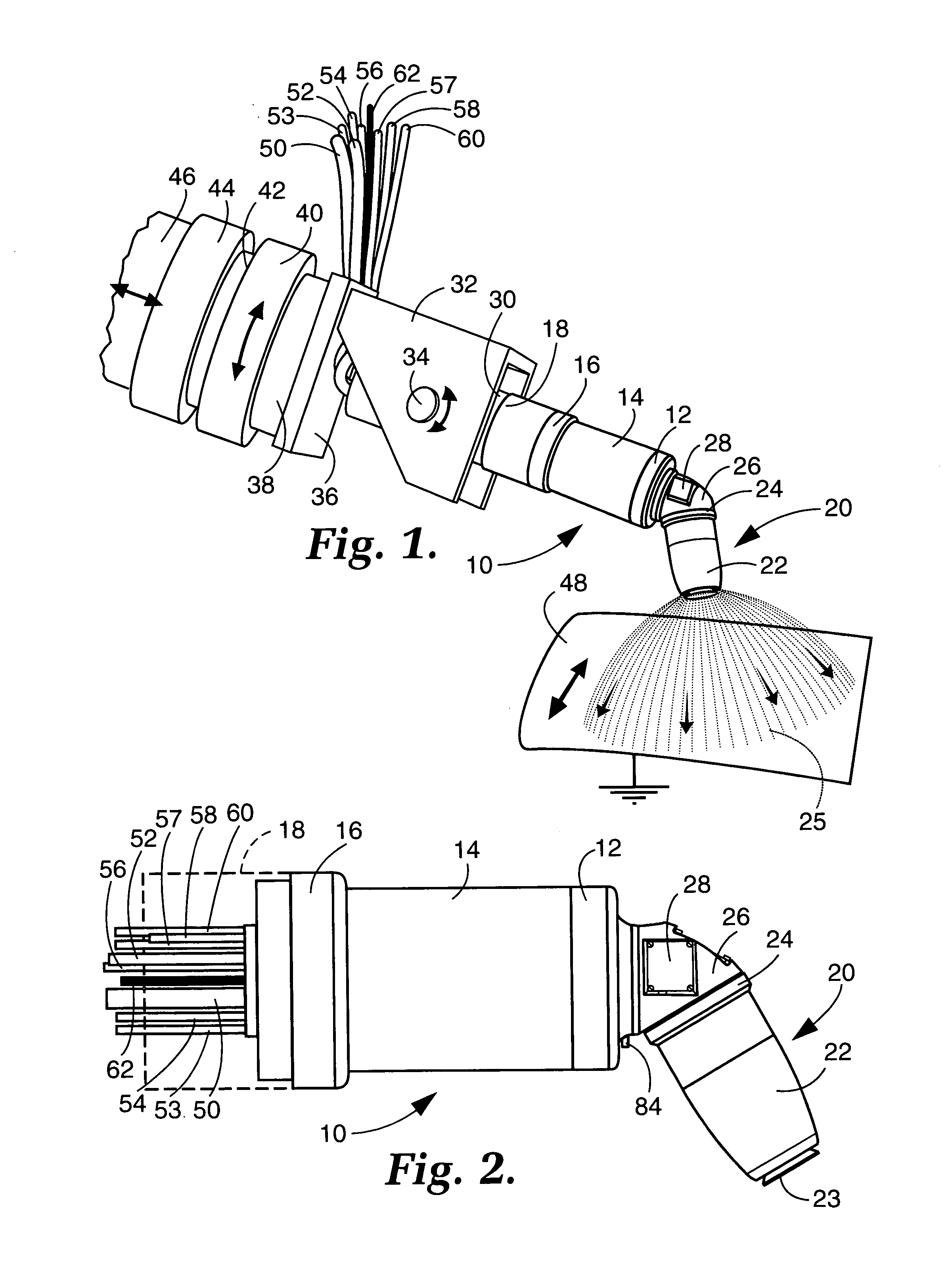

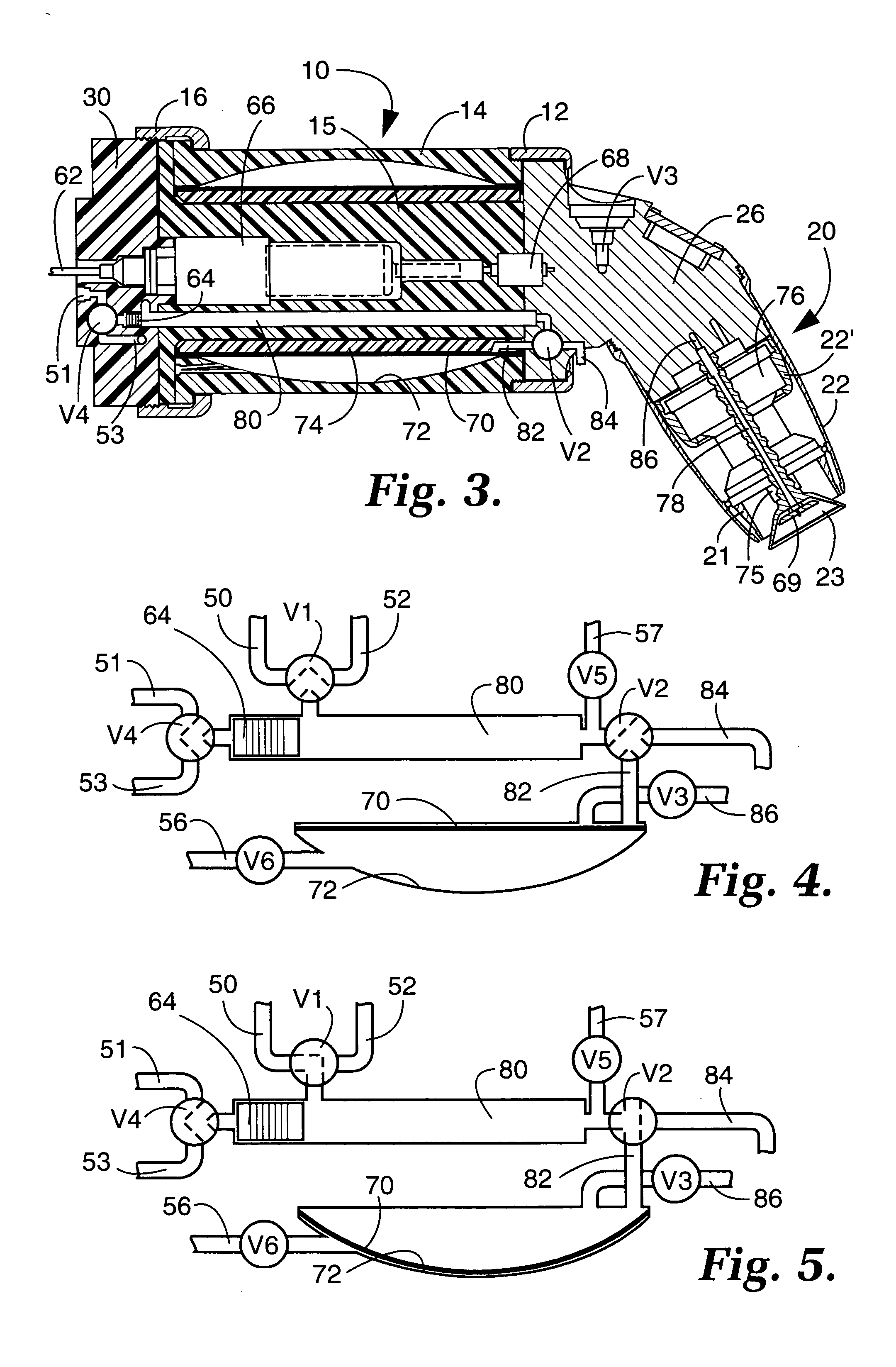

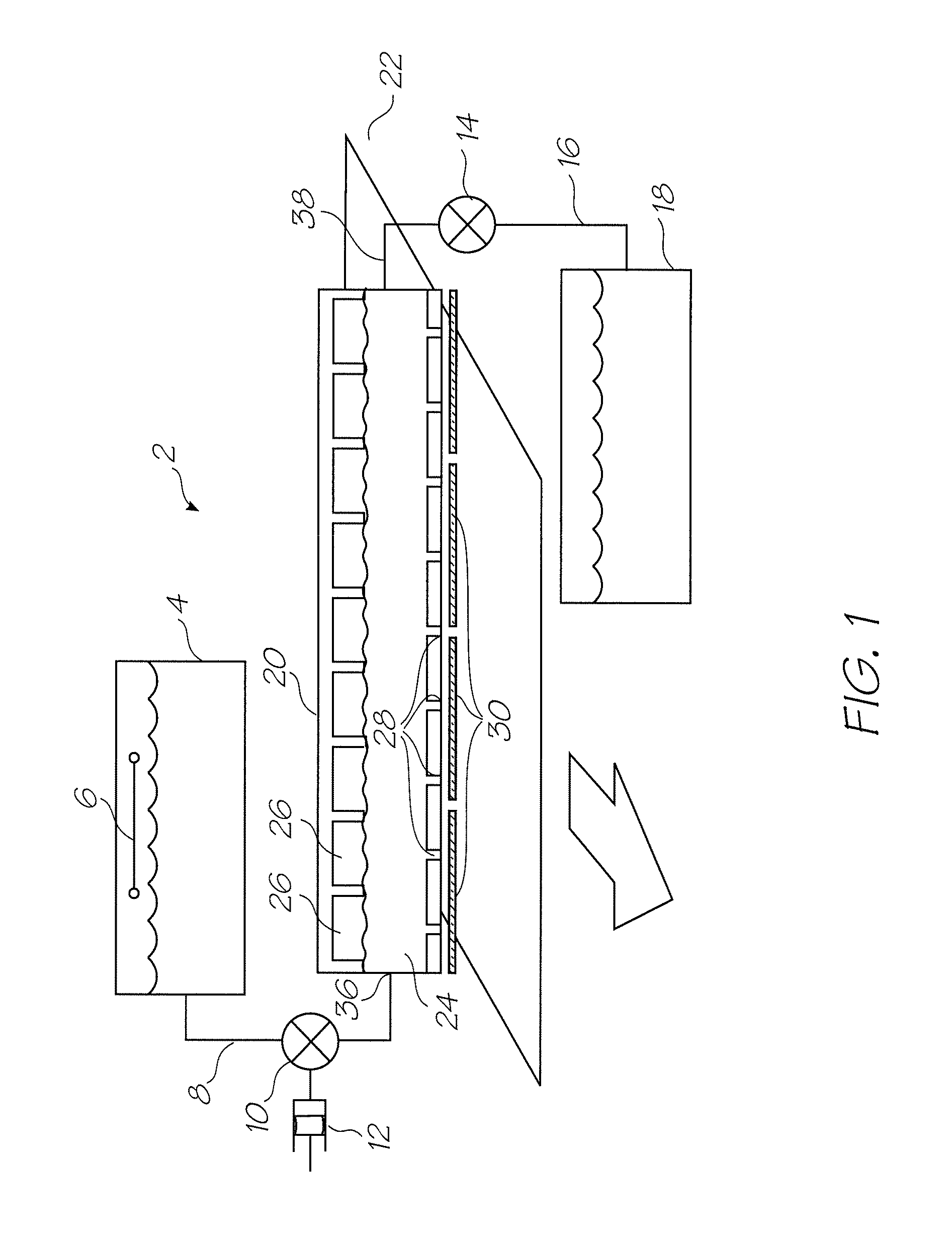

Apparatus and method for electrostatic spraying of conductive coating materials

Apparatus and a method are provided for isolating an electrostatic sprayer from an electrically grounded coating product distribution circuit connected thereto. The apparatus includes an electrostatic sprayer carried by a maneuverable robot arm, the sprayer capable of spraying an electrically conductive coating product such as water-based paint onto a workpiece passing in adjacent proximity thereby, on command. The coating product is supplied from a remote source of supply through at least one distribution circuit connected to the sprayer. The apparatus includes therein, carried by the robot arm, an electrically insulative storage tank for the coating product in valved fluid communication with the sprayer. The insulated storage tank is connected to and positioned downstream from a length of electrically insulative supply conduit connected to the distribution circuit and also carried by the robot arm. This conduit includes a cleaning mechanism for cleaning a portion, including all, of this length of supply conduit, in situ, after filling of the storage tank with coating product and before spraying. In this way, substantially all of the conductive coating product is removed from the portion of supply conduit, thereby completely isolating the sprayer electrically from the distribution circuit.

Owner:EFC SYST

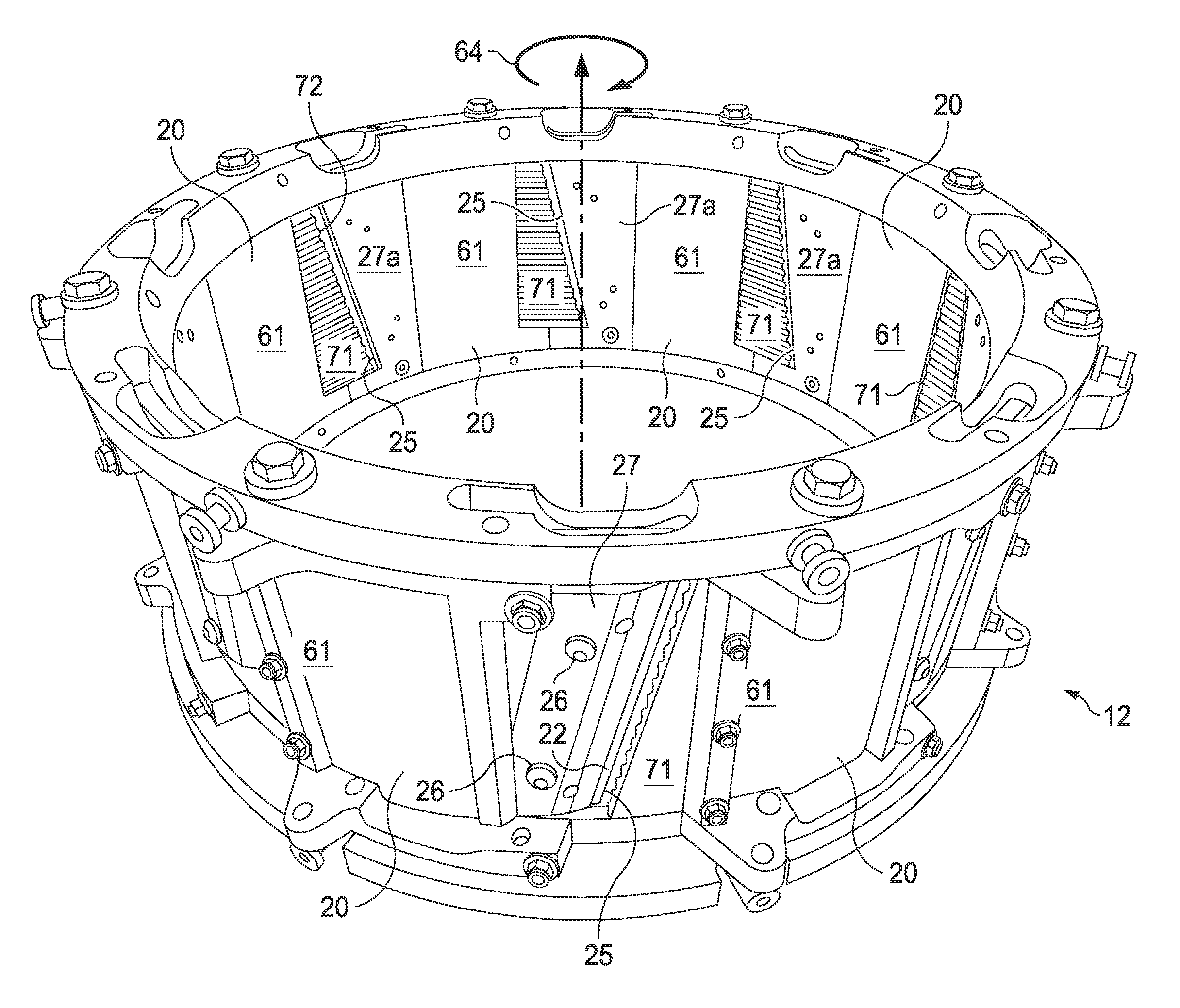

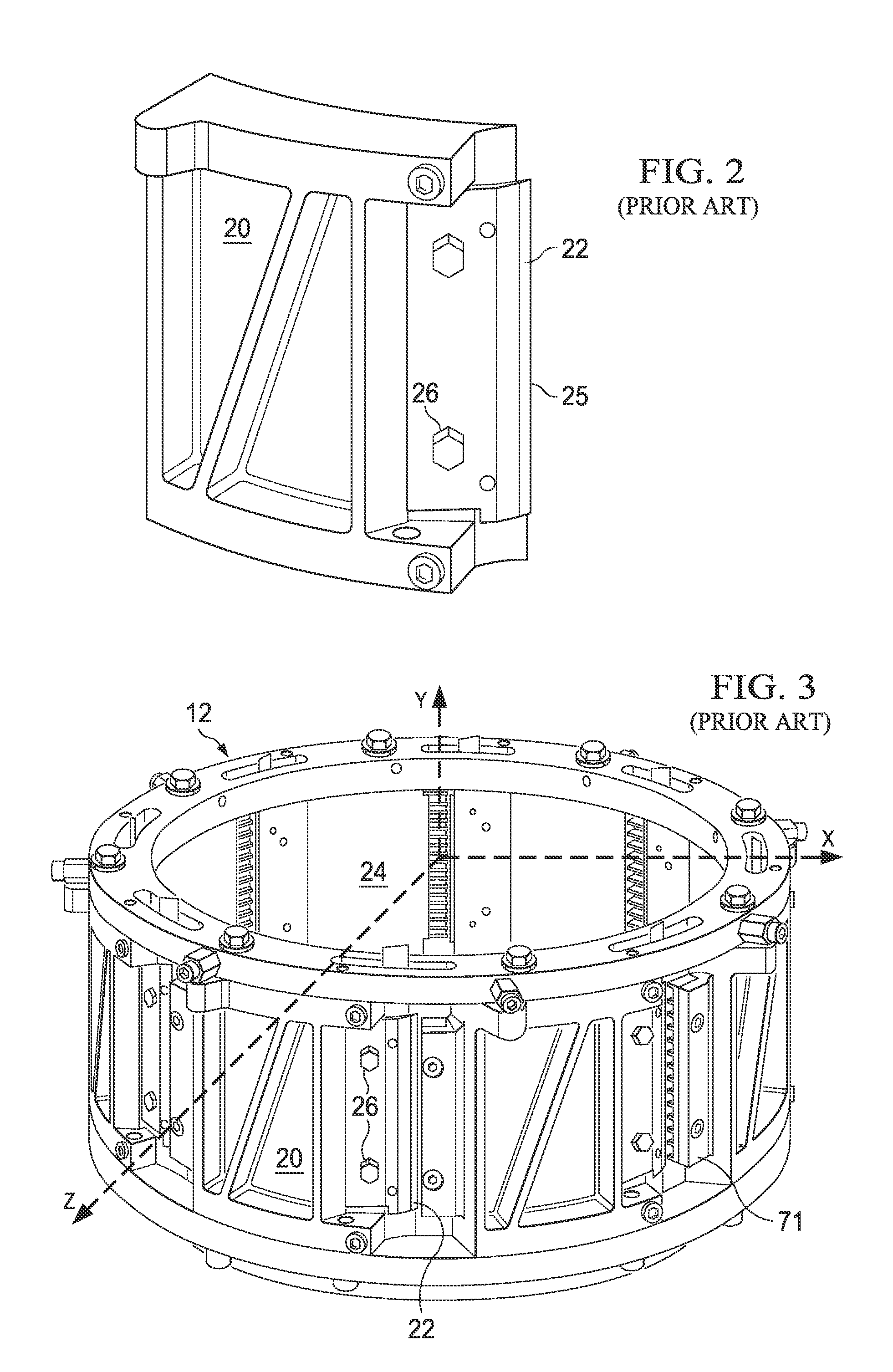

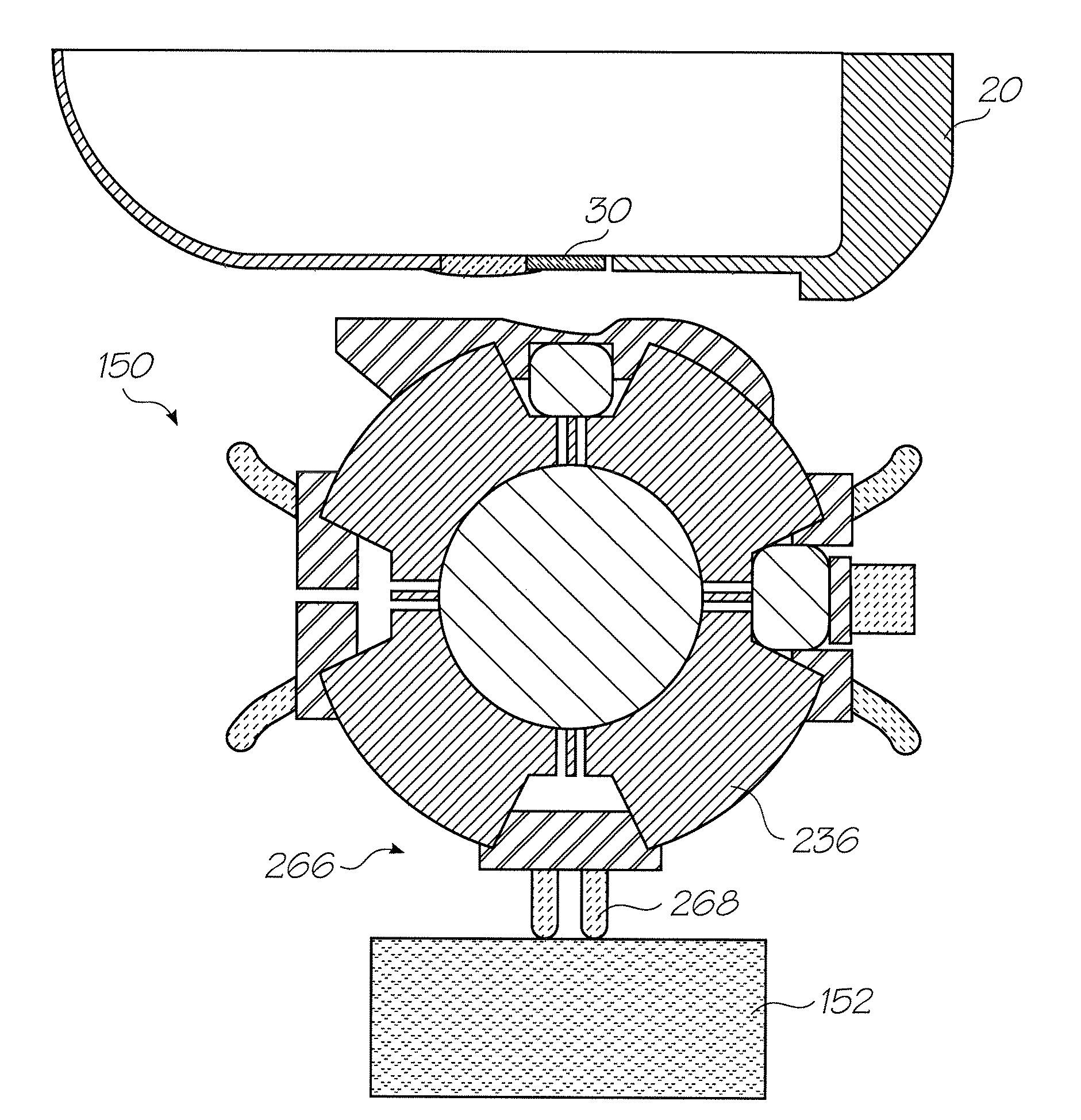

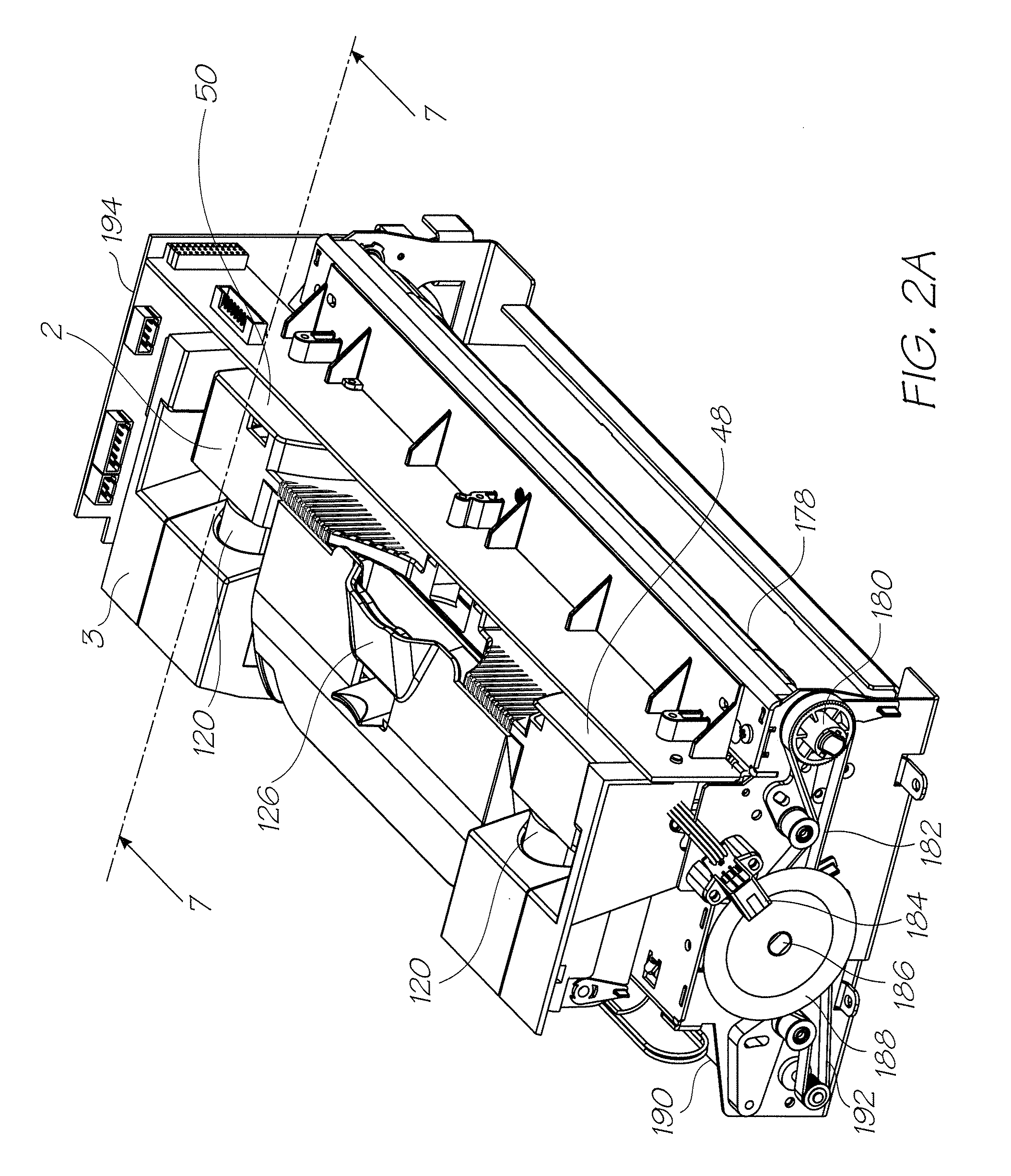

Cutting Head Assembly For Slicing Food

InactiveUS20160067877A1Increase productionMaintaining and increasing yieldMetal working apparatusSaw chainsEngineeringKnife blades

An improved cutting head assembly with an angled blade for slicing that can be used with a centrifugal-type slicer to provide an increased yield. The blade comprises a cutting edge that cuts a product, for example, a potato, in a cutting direction. A tangent to the cutting edge is at an angle away from the normal plane of a cutting direction for the blade. For example, if the cutting edge is a straight line and the cutting direction is horizontal, then the cutting edge is at an angle away from vertical.

Owner:FRITO LAY NORTH AMERICA INC

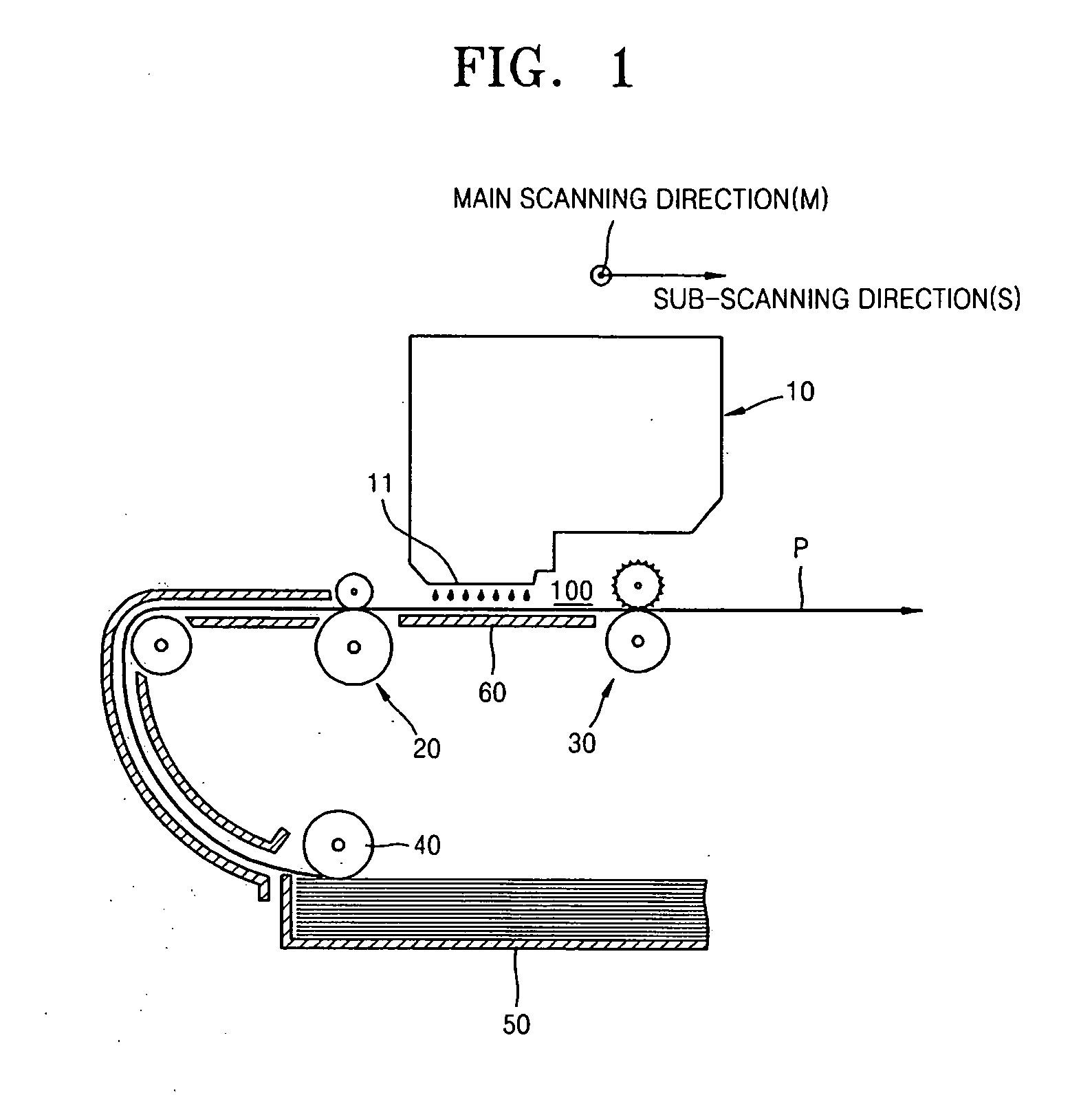

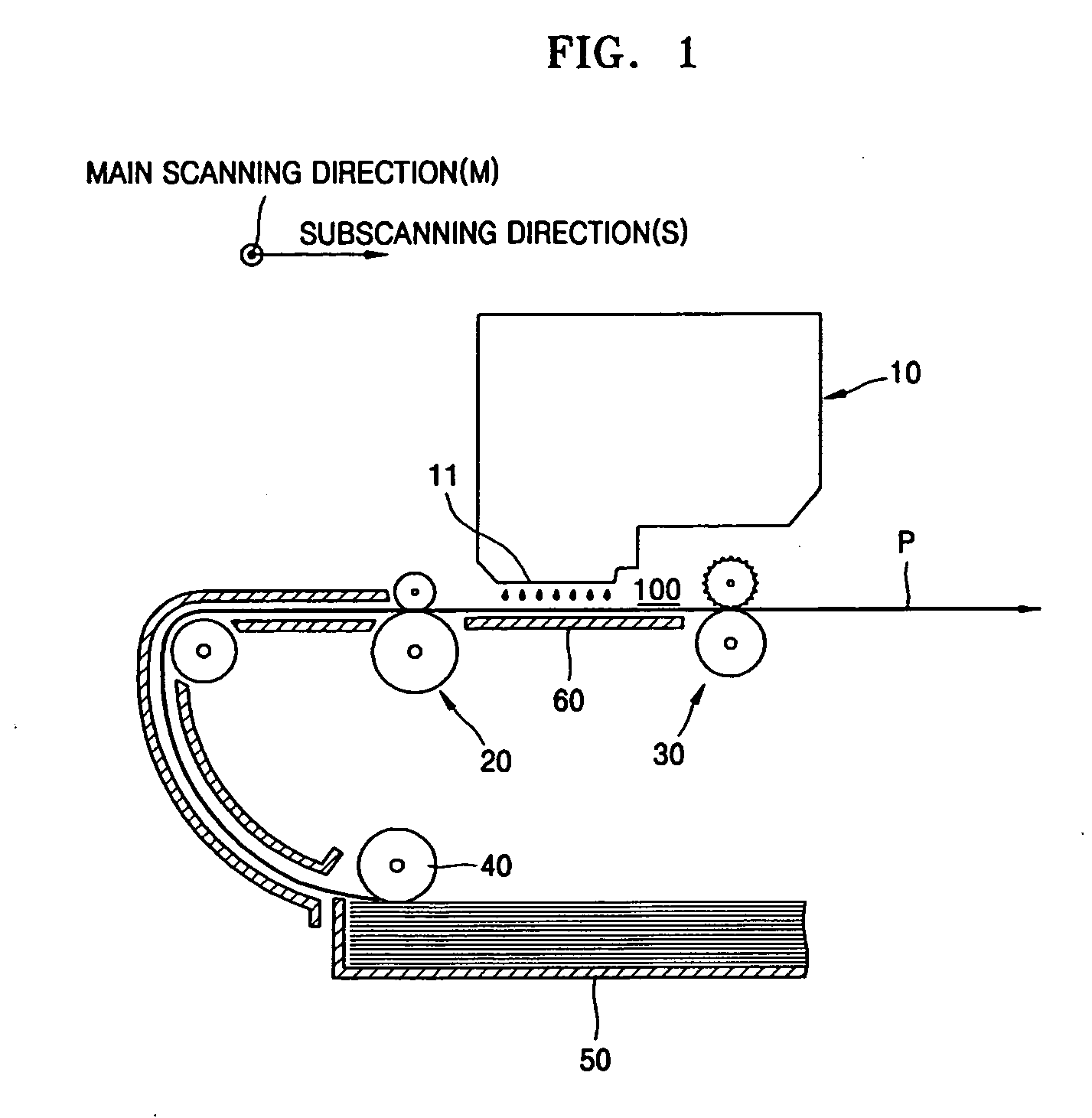

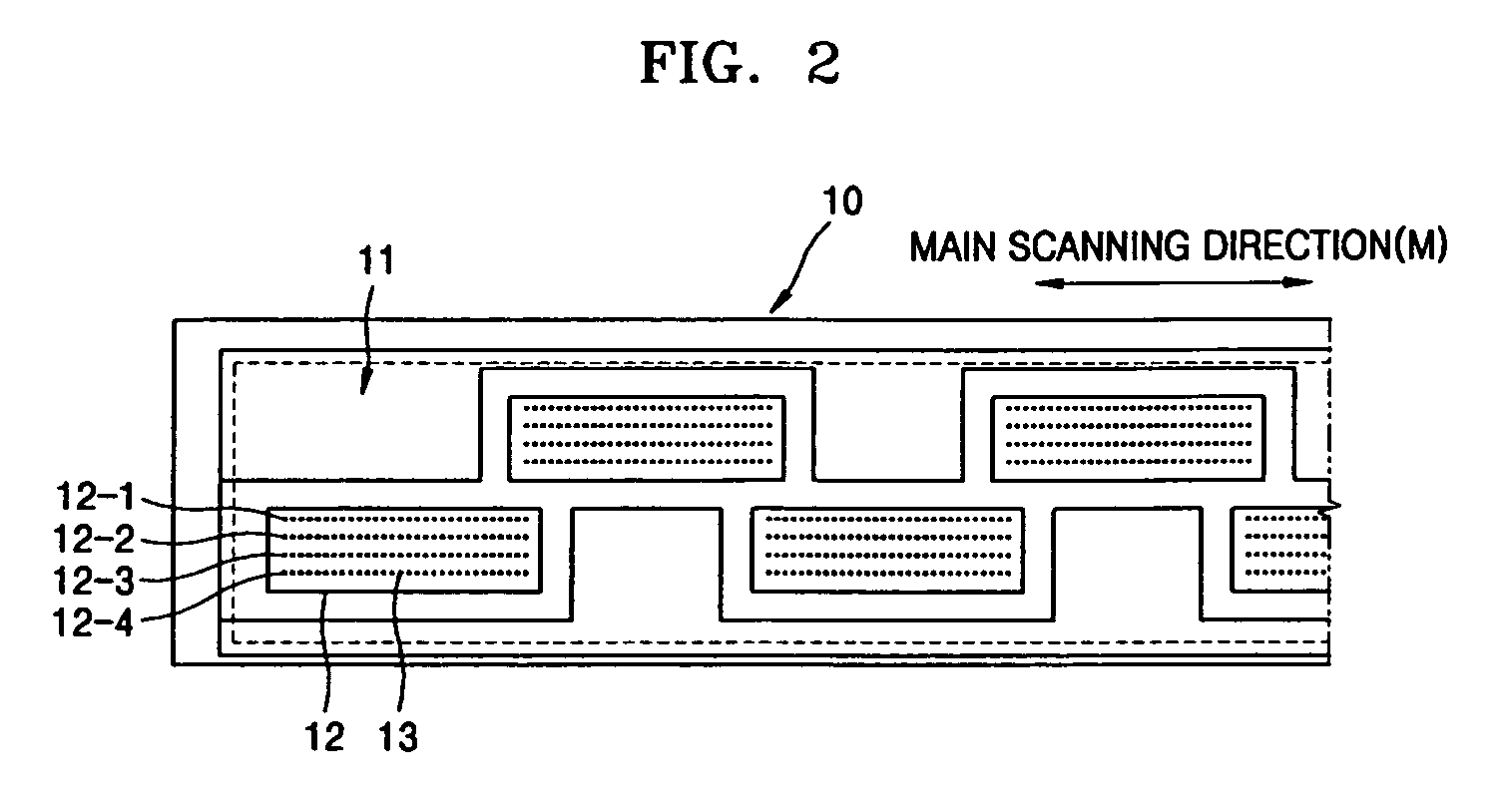

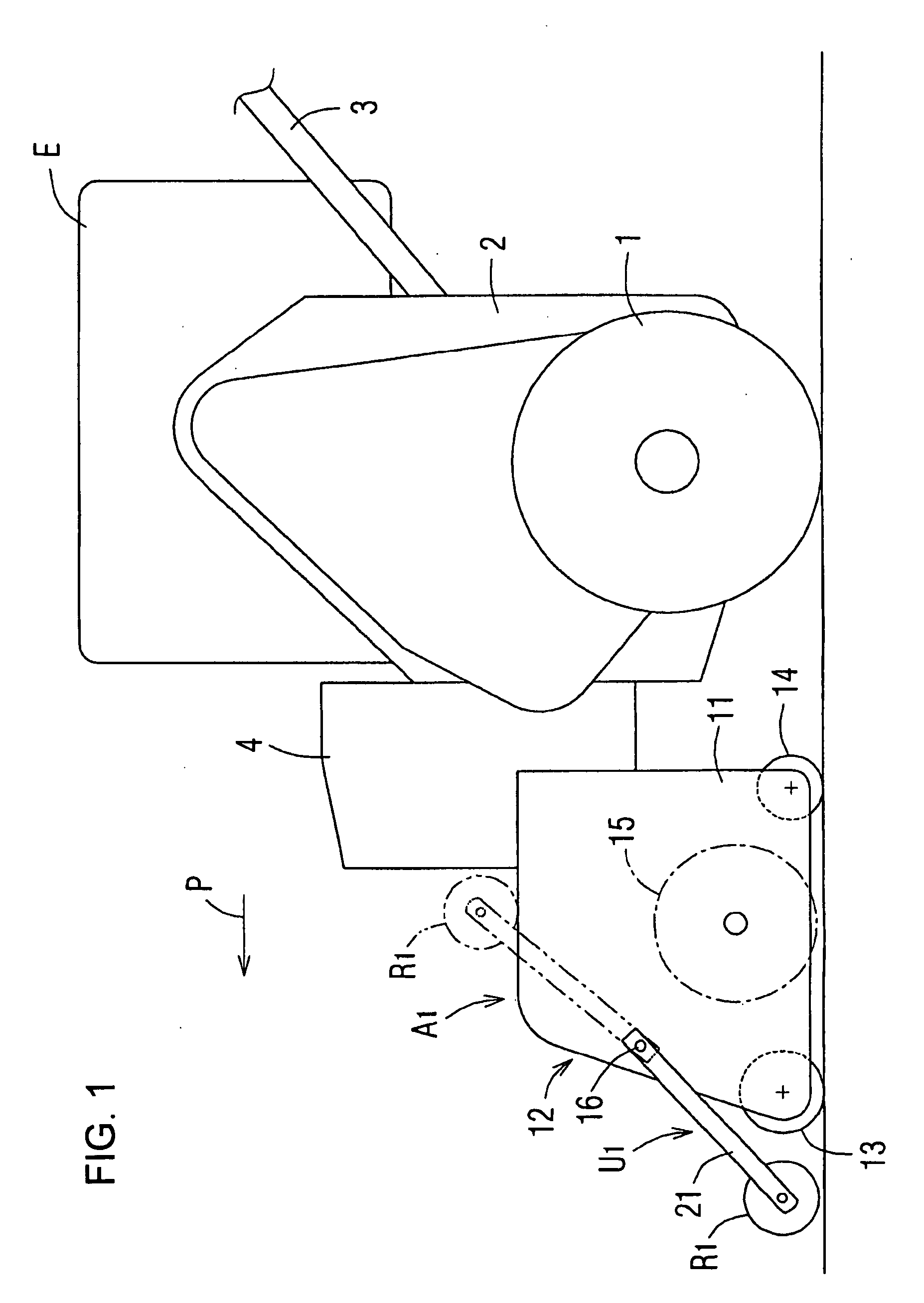

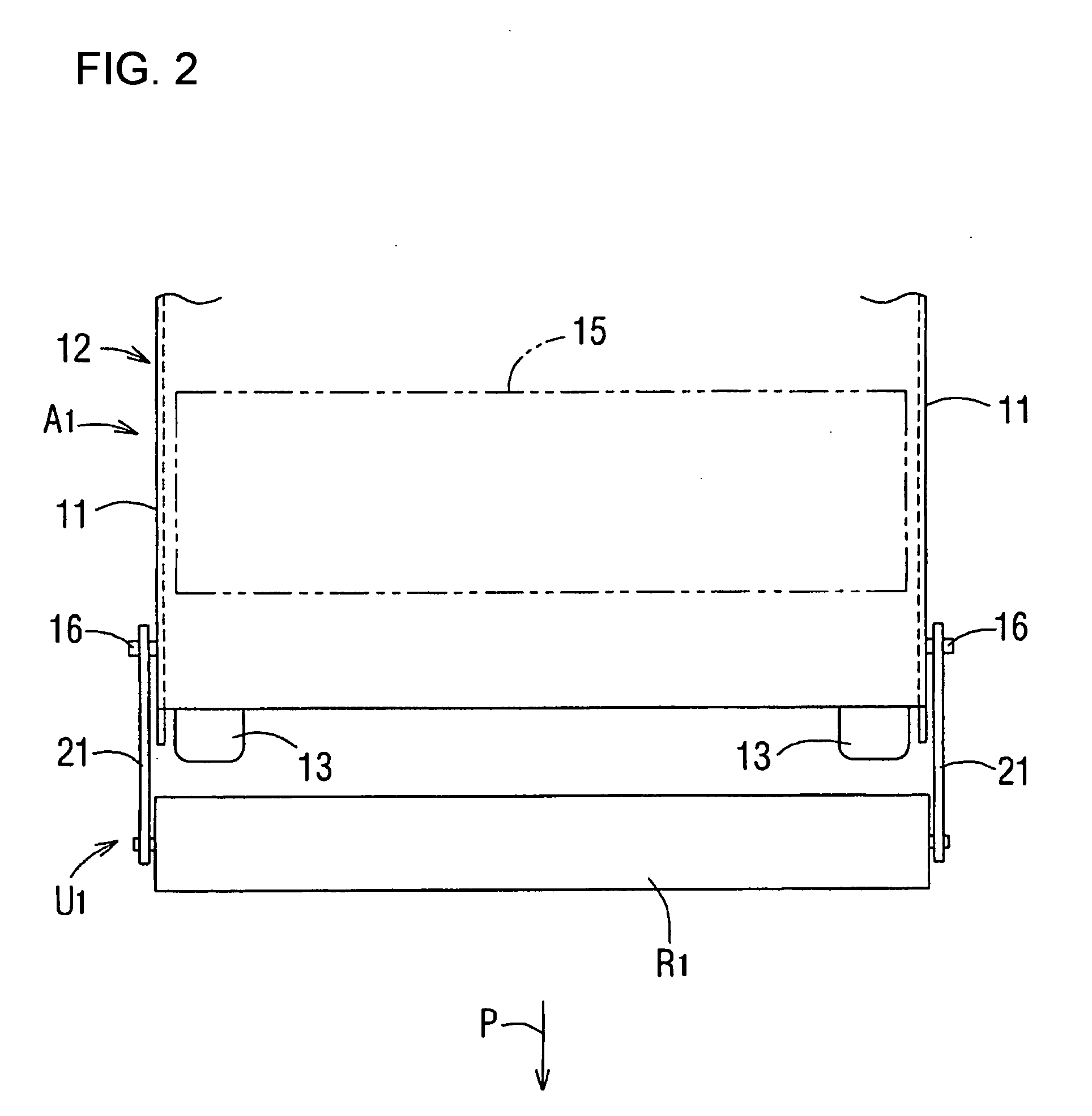

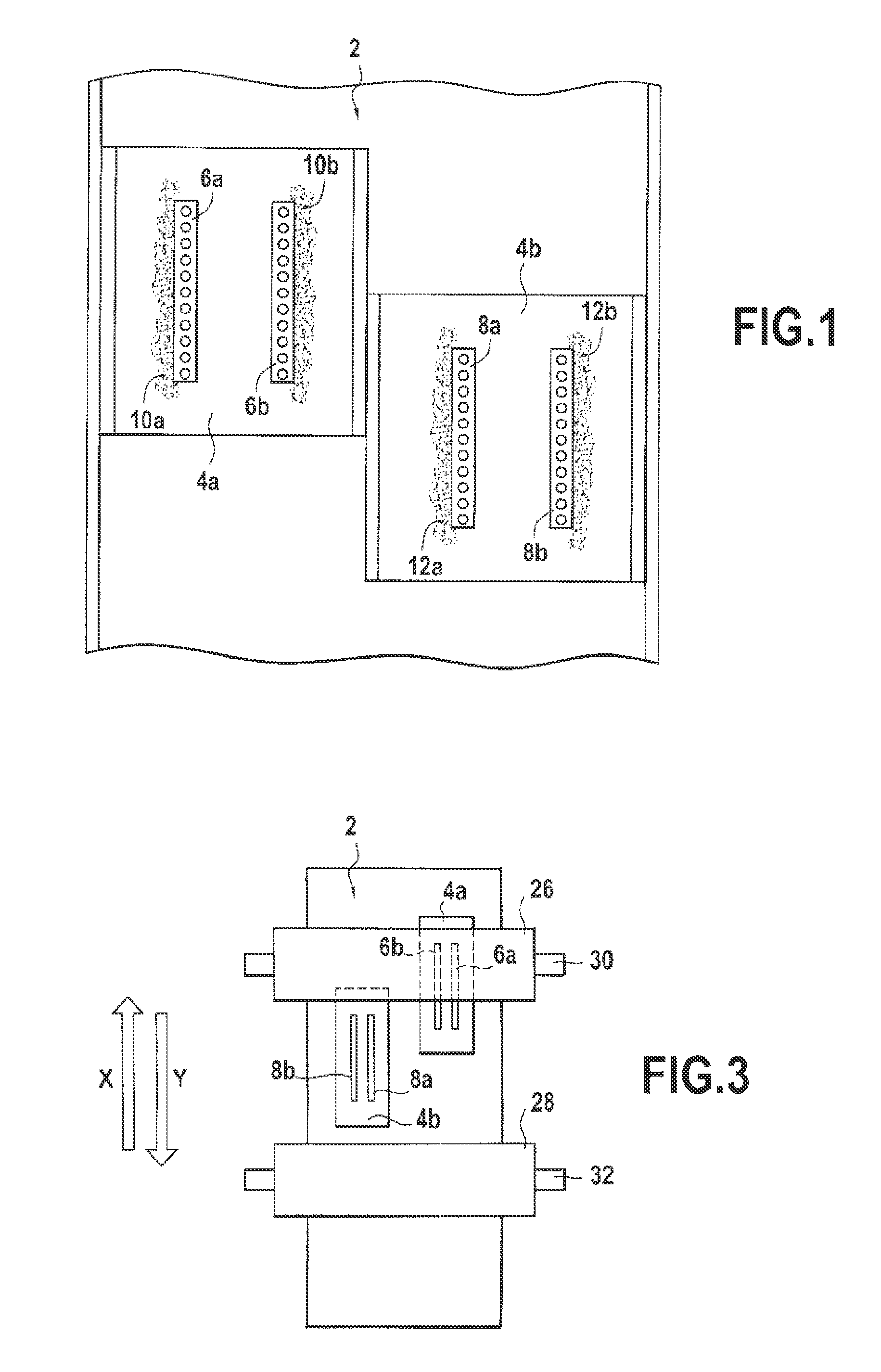

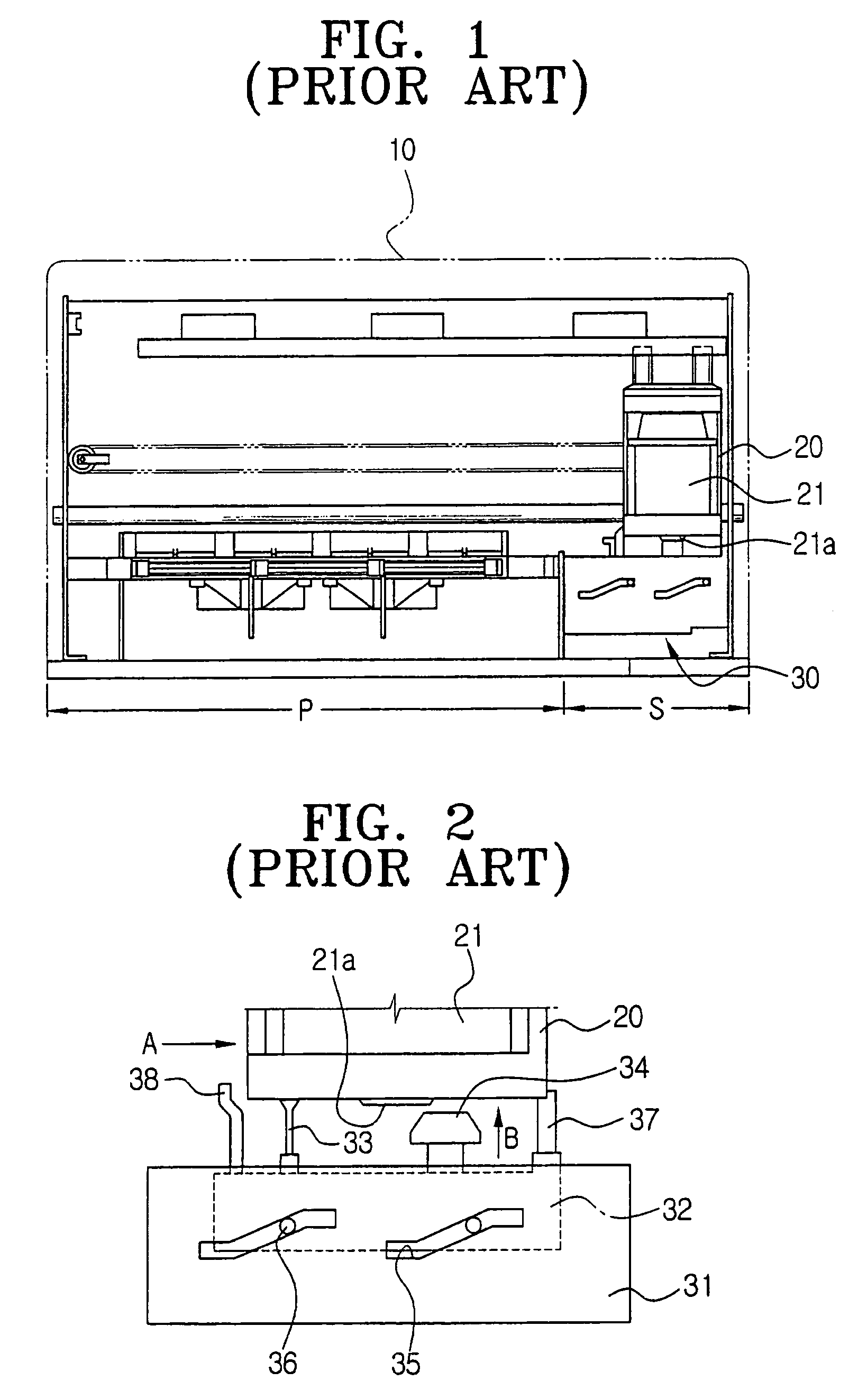

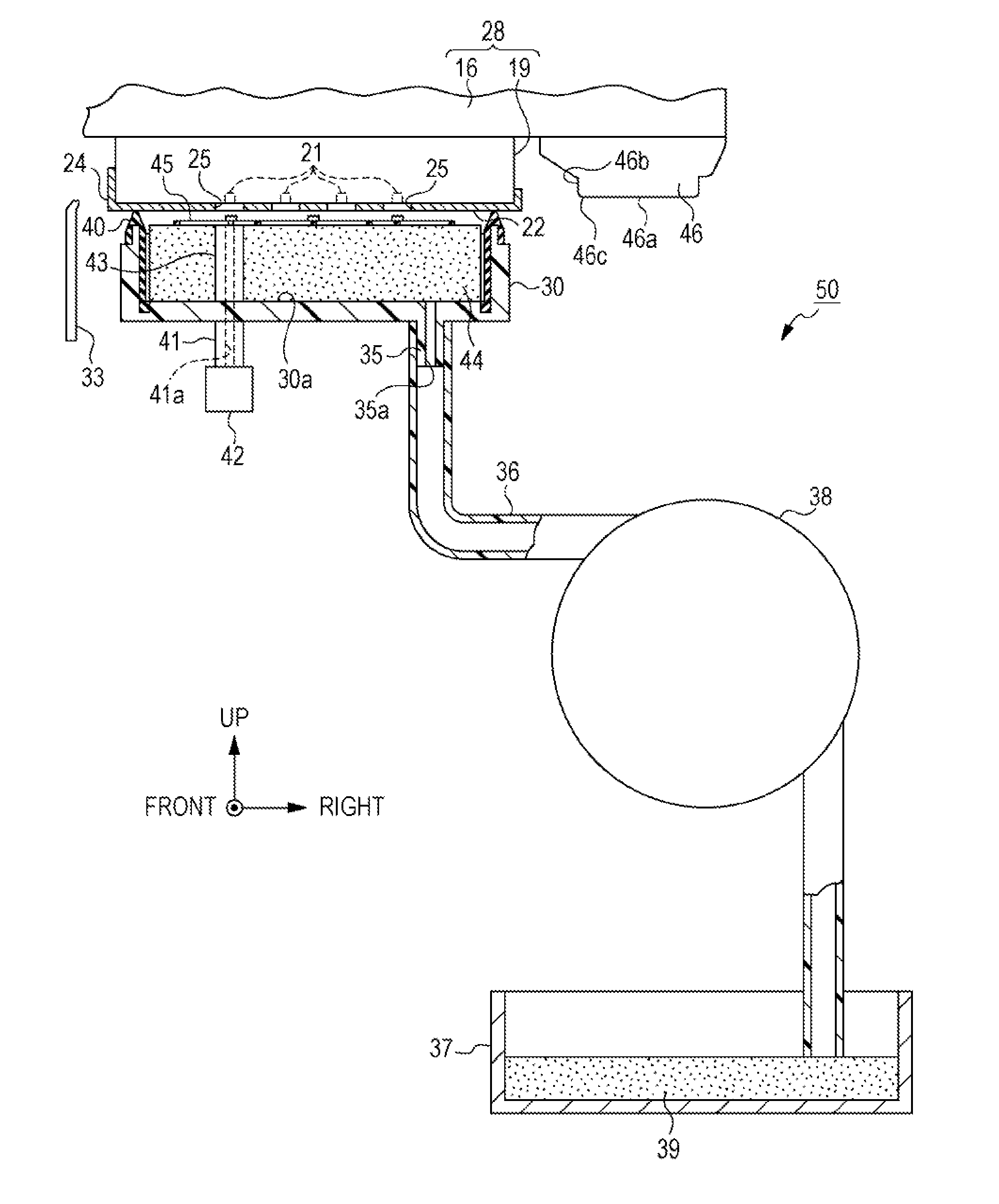

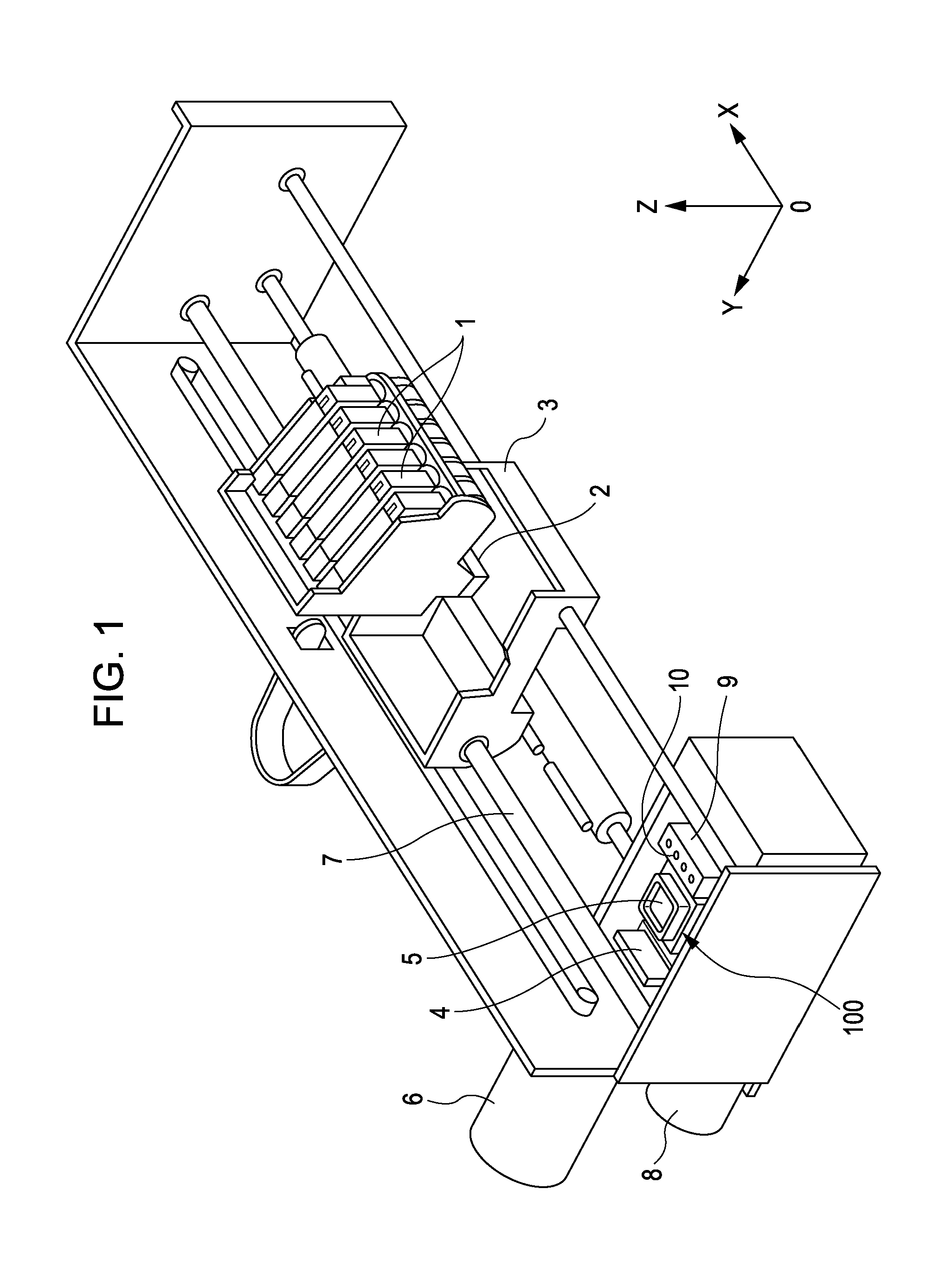

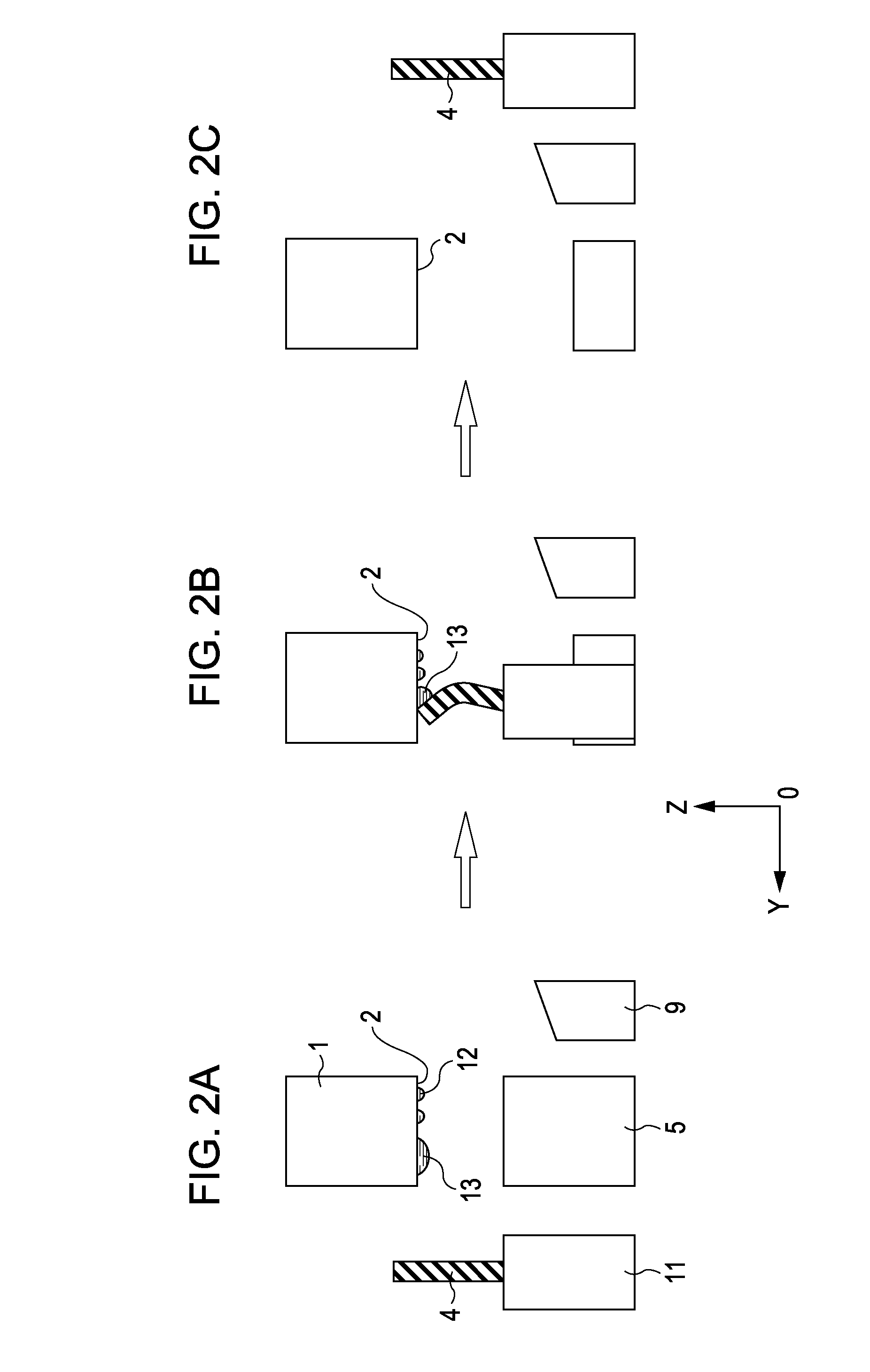

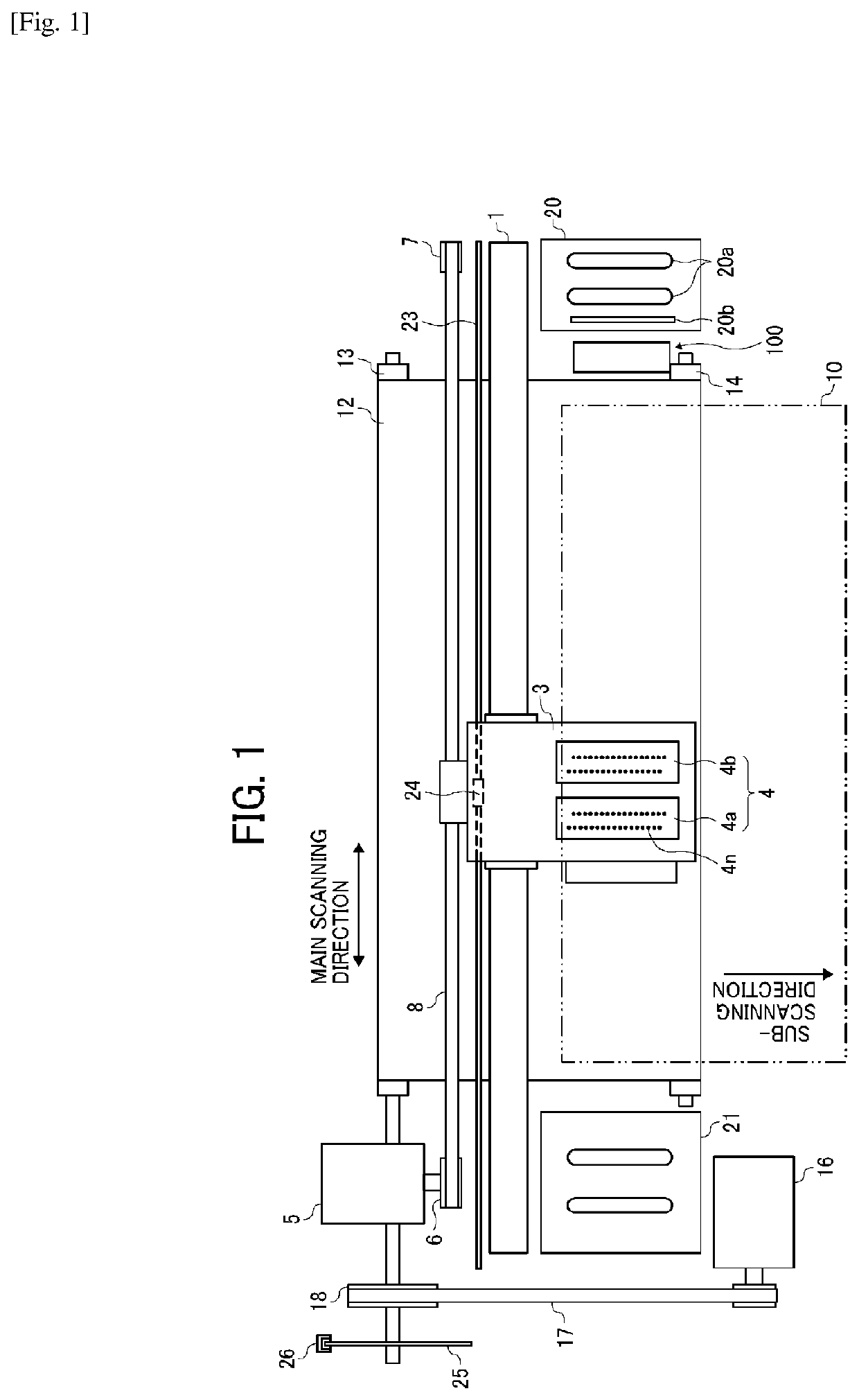

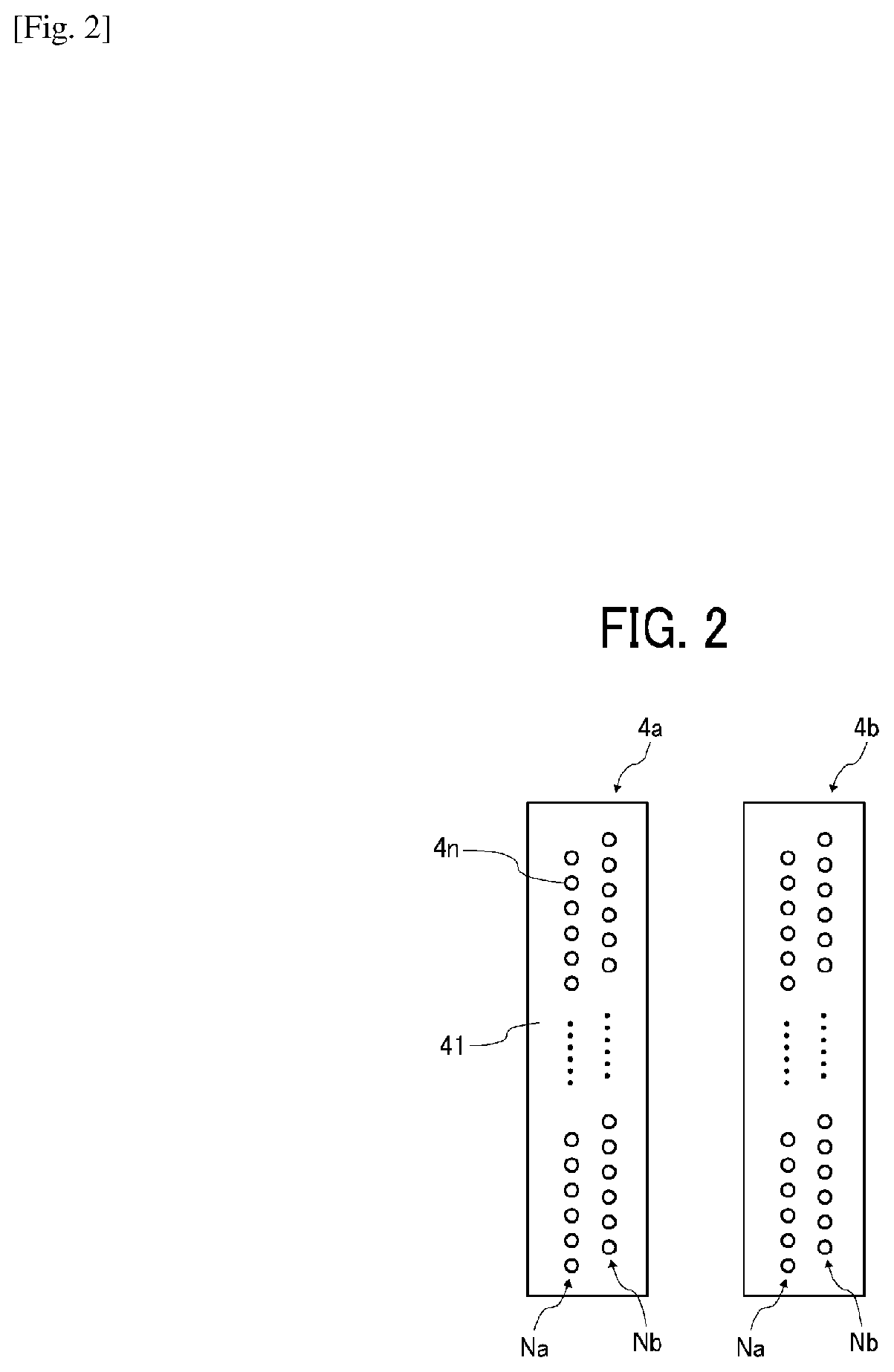

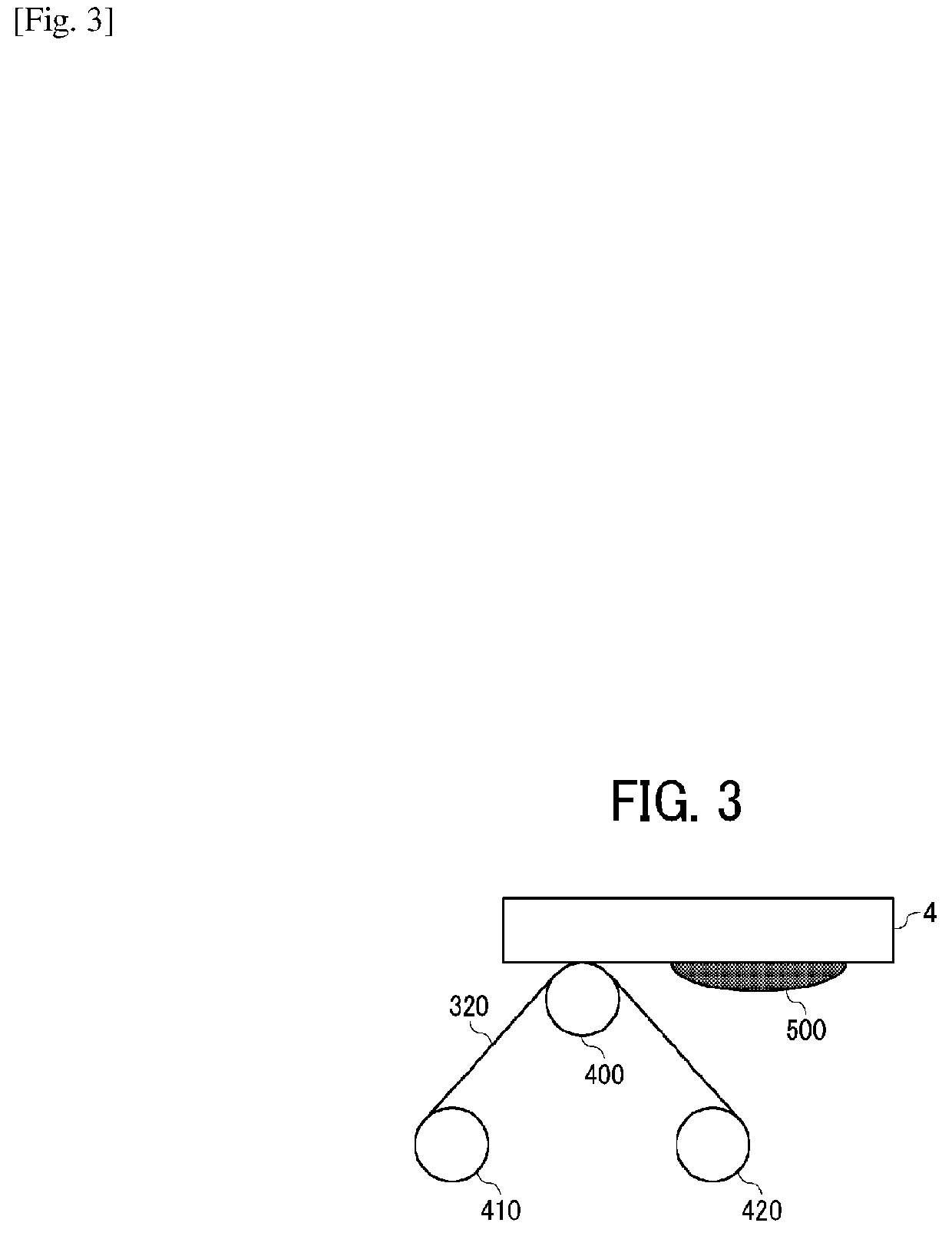

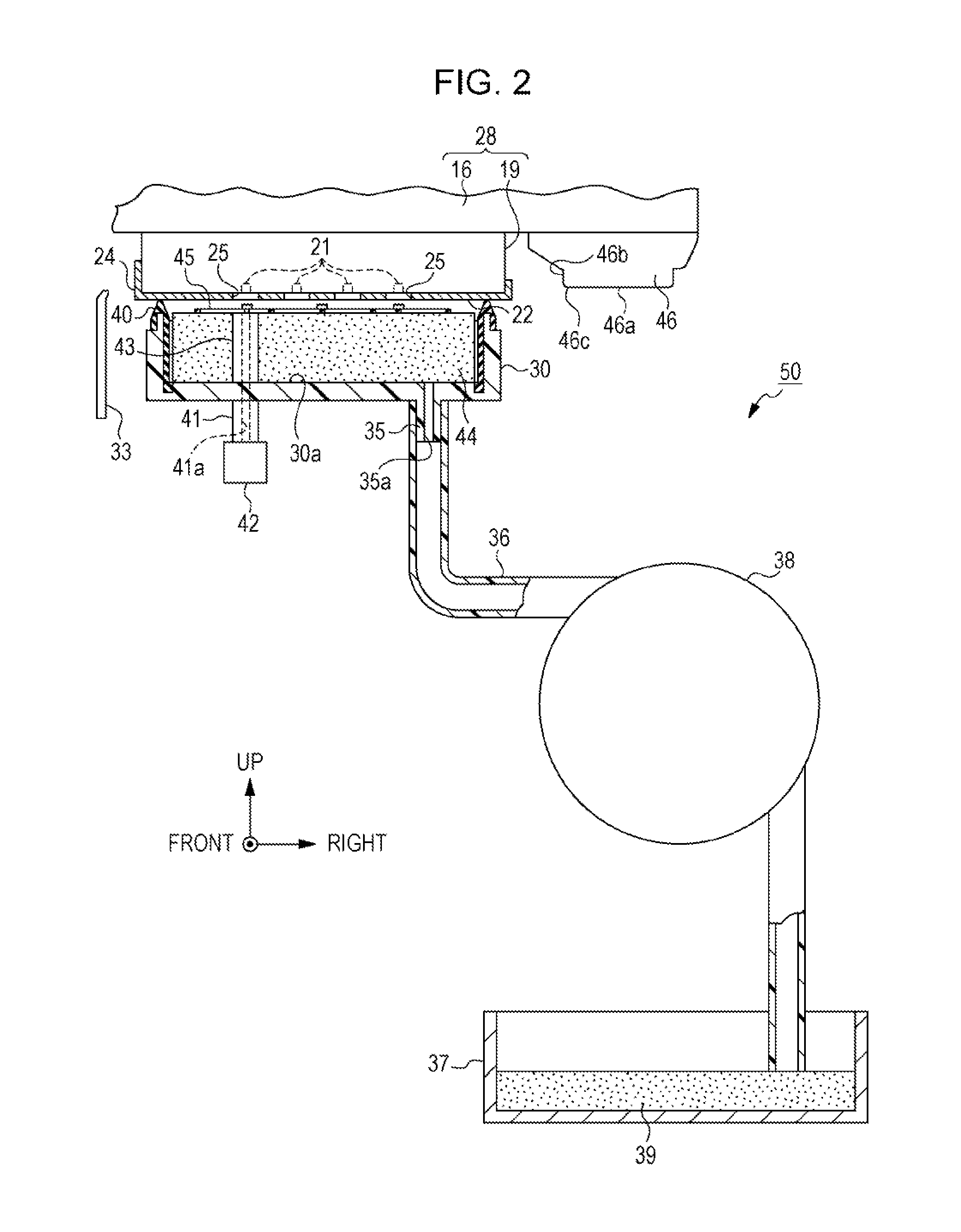

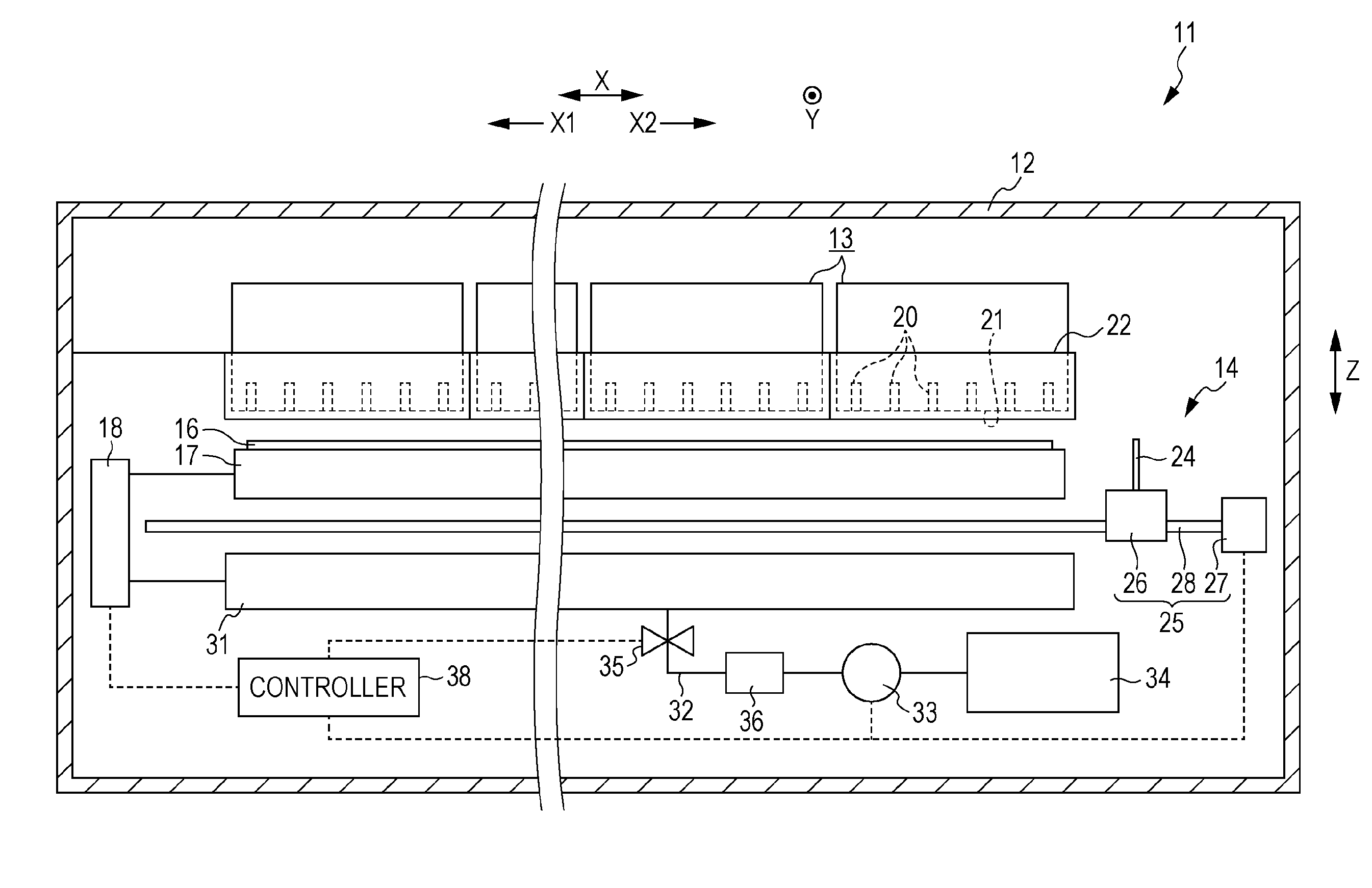

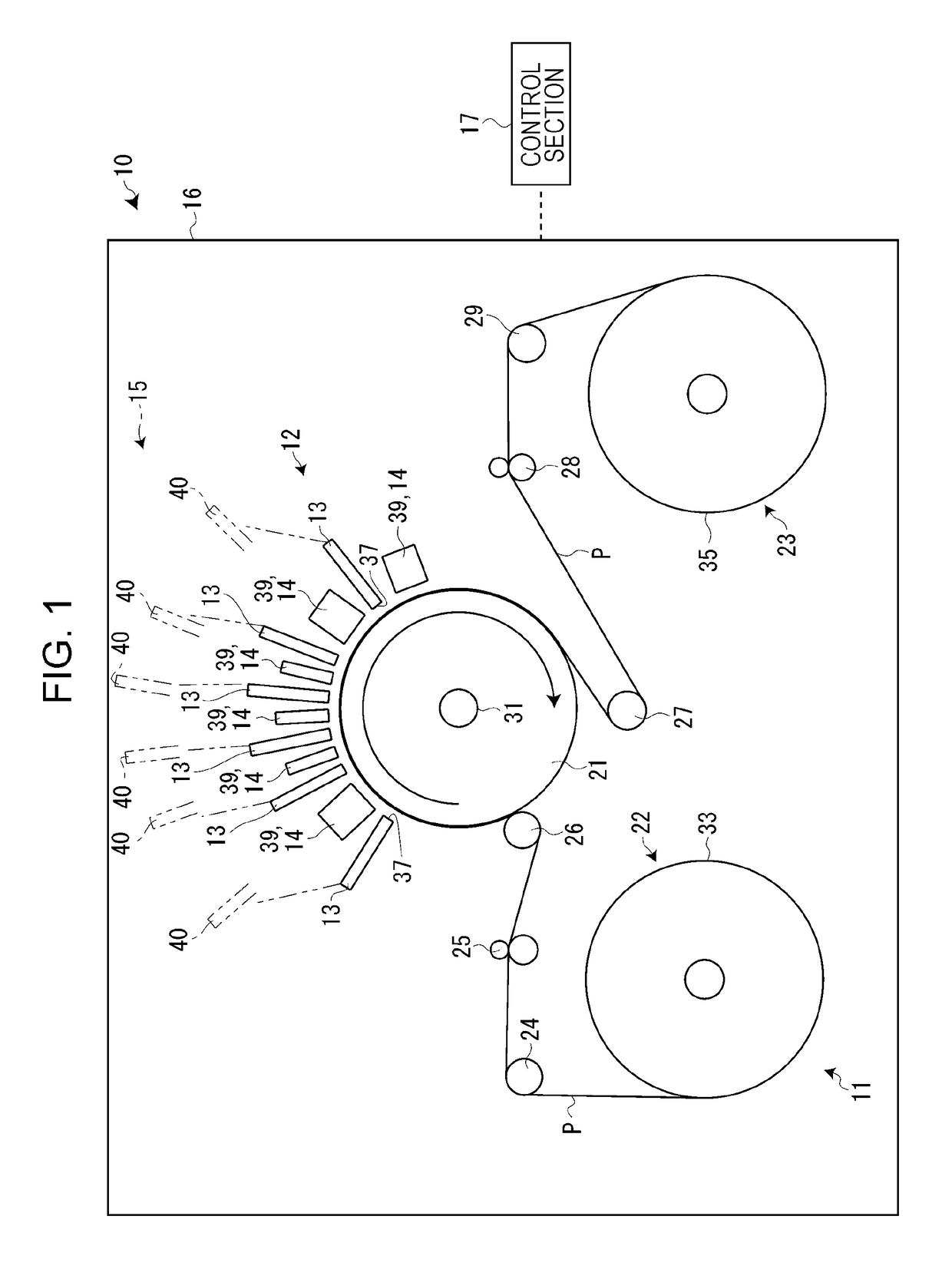

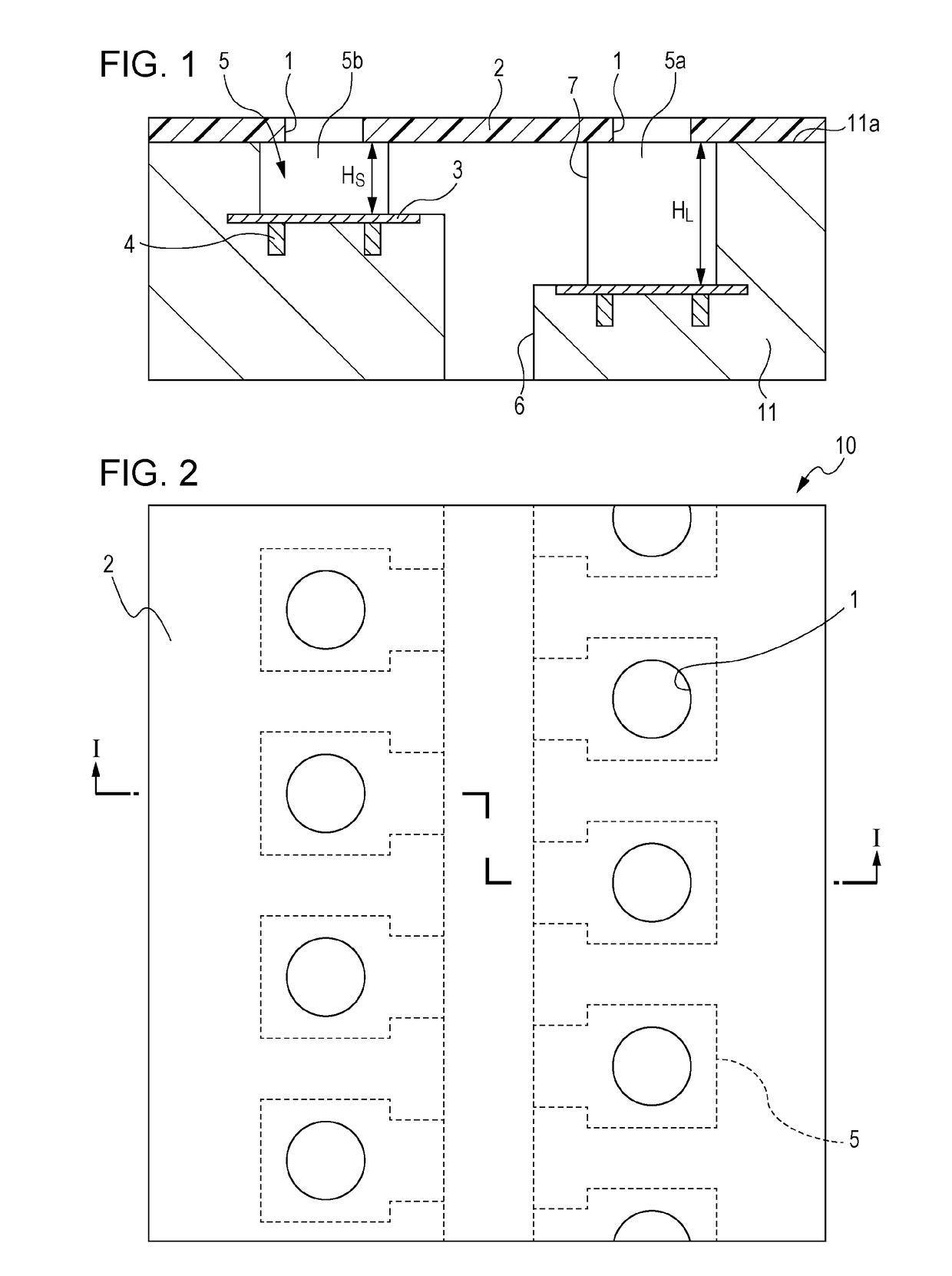

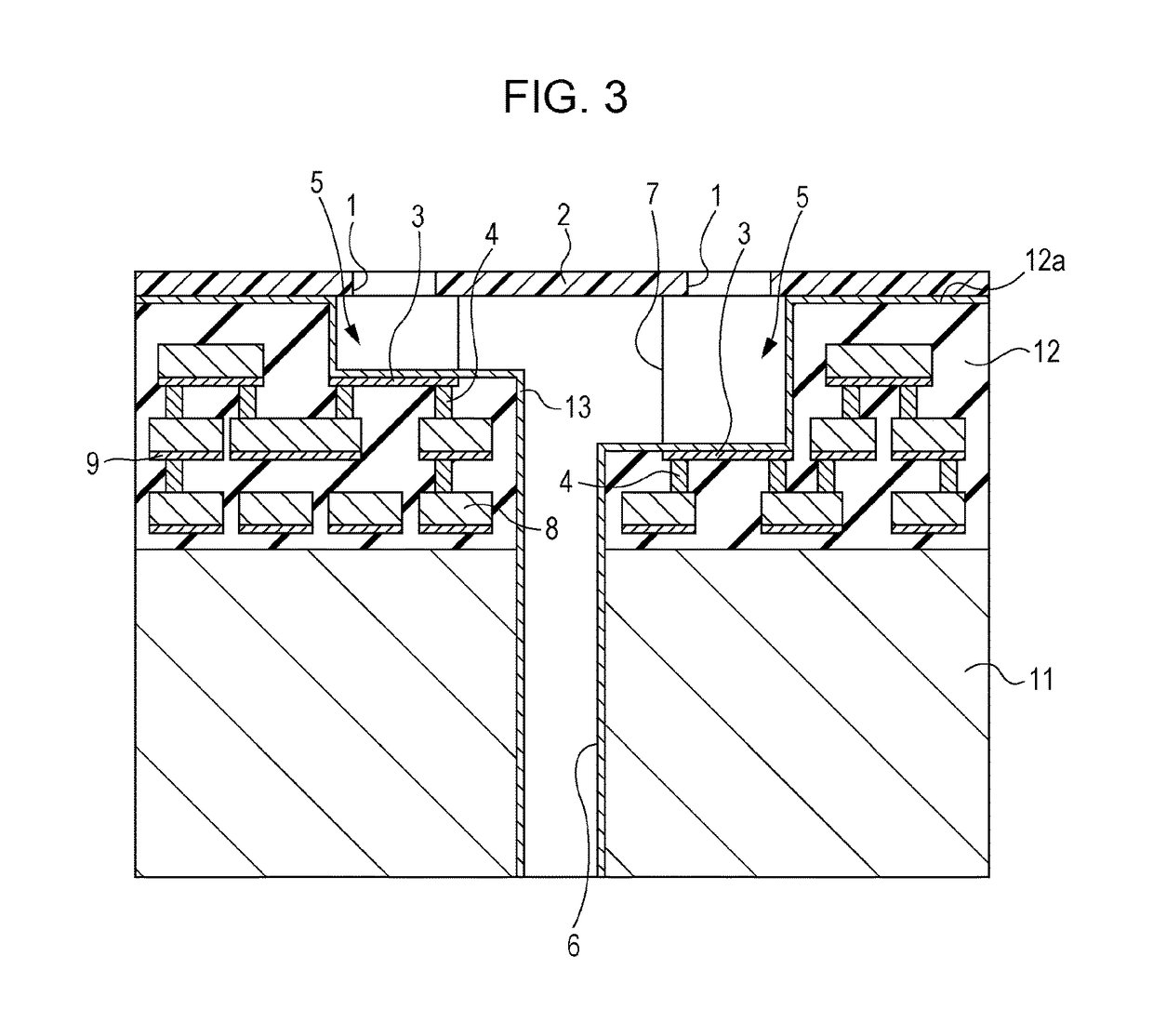

Inkjet image forming apparatus having a wiping unit

An inkjet image forming apparatus includes an inkjet head including a nozzle portion having a length in a main scanning direction that is at least equal to a width of a sheet of paper, a platen to move between a printing position where the platen faces the nozzle portion and supports a rear surface of the paper, and a maintenance position spaced-apart from the printing position in a sub-scanning direction, a wiping unit including a wiper to clean the nozzle portion, and a link arm having a first end portion that is rotatably connected to the wiping unit, and a second end portion that is rotatably connected to the platen. A first angle formed by a first line that connects the wiper to the first end portion and a second line that connects the first end portion and the second end portion when the platen is located at the printing position is smaller than a second angle between the first line and the second line when the platen is located at the maintenance position.

Owner:SAMSUNG ELECTRONICS CO LTD

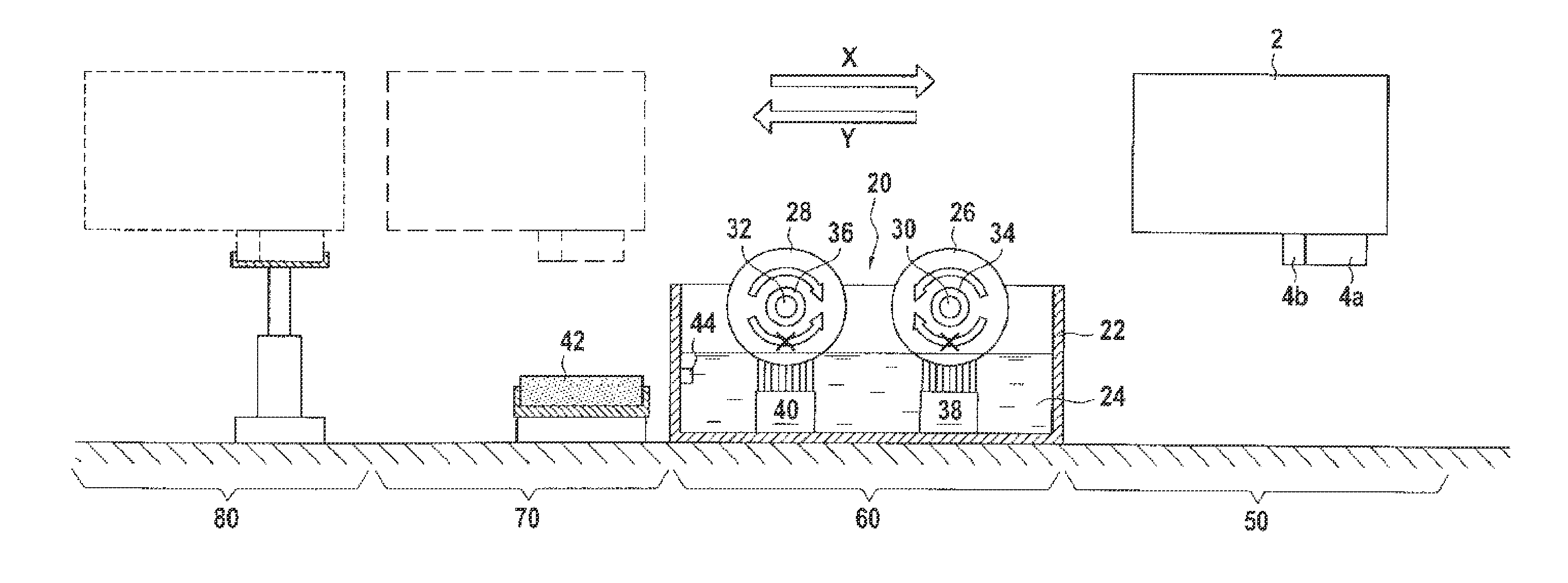

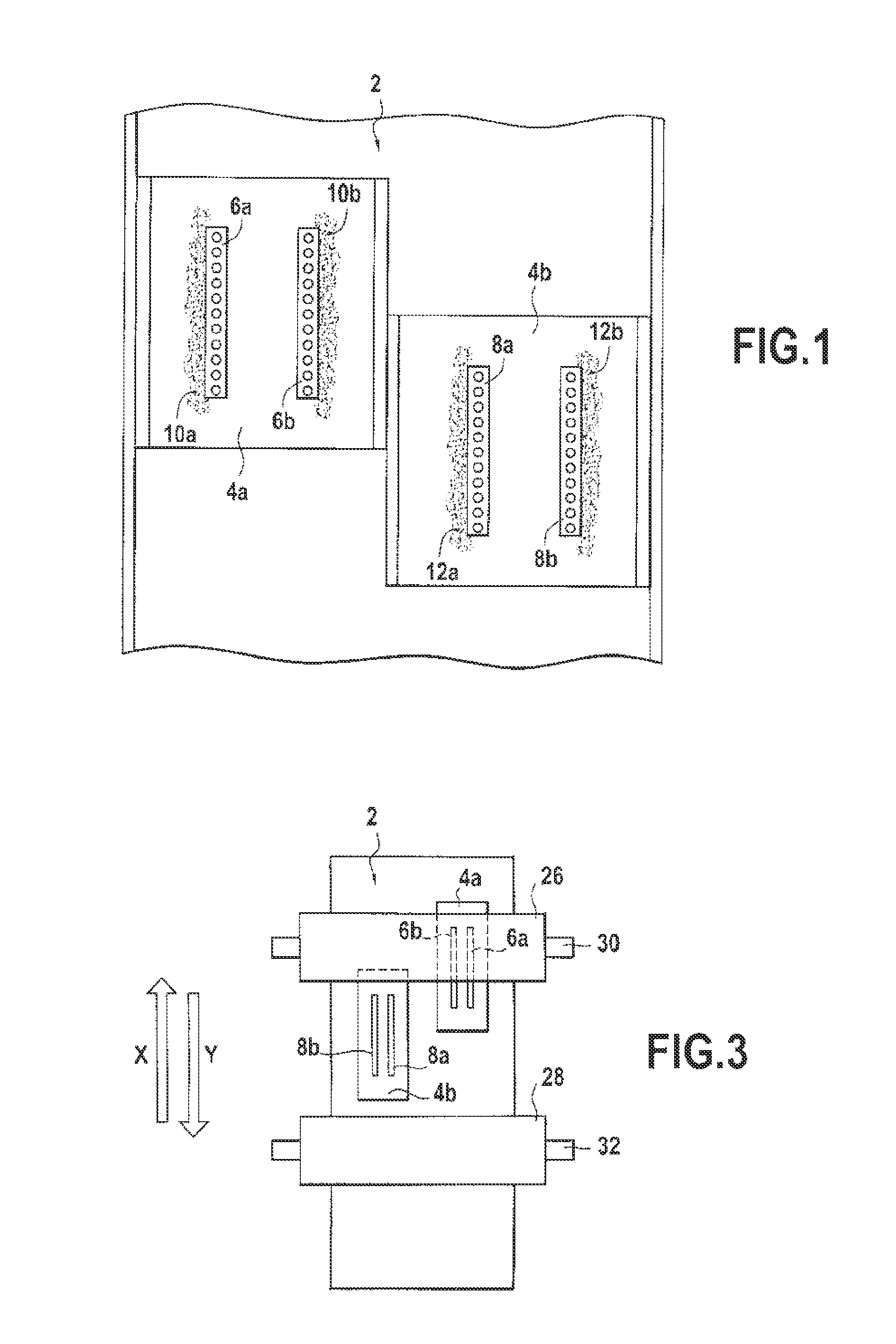

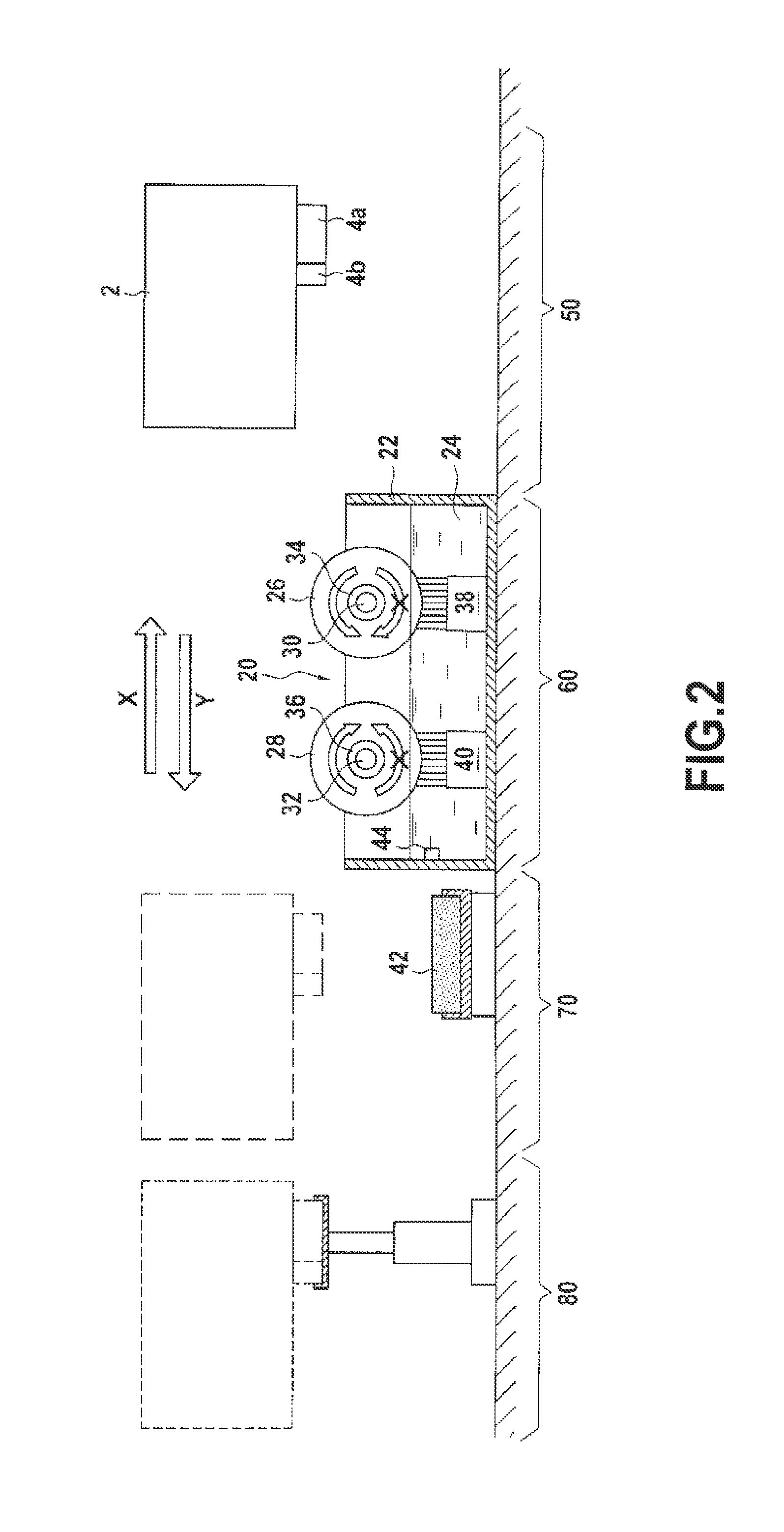

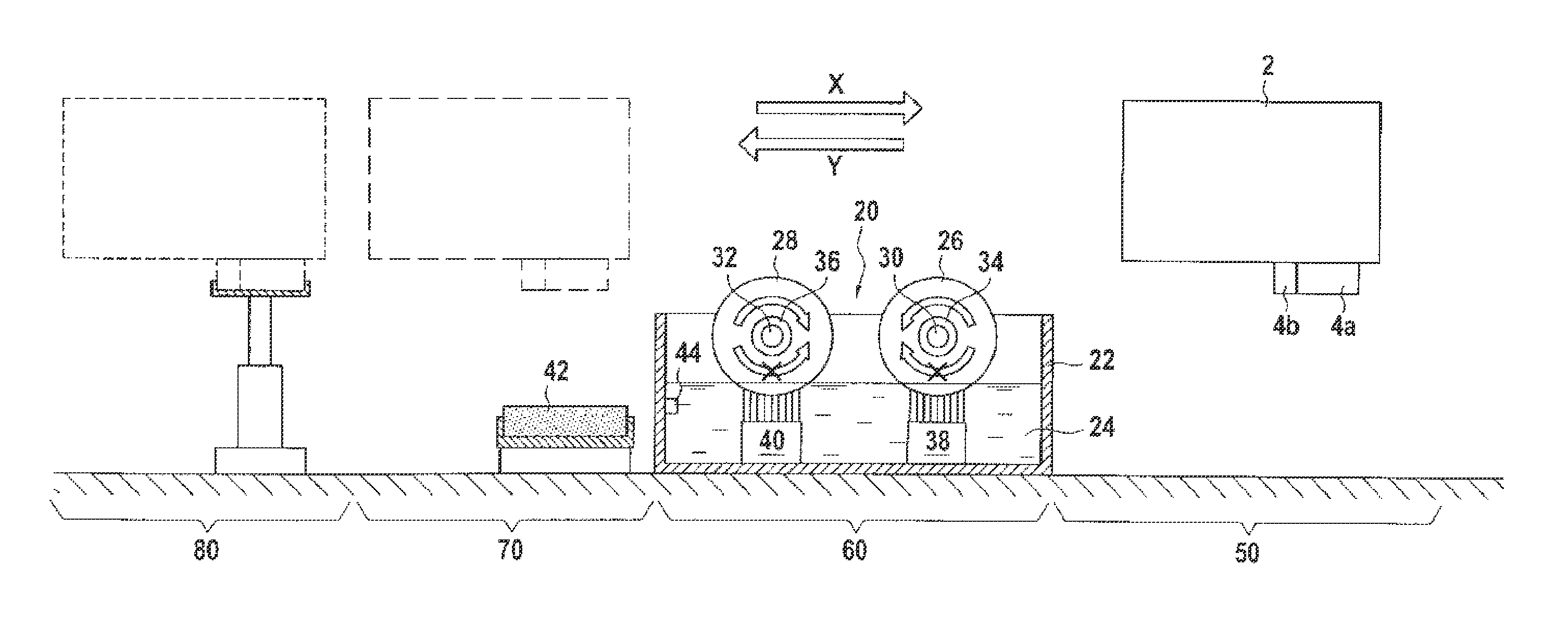

Wiping device for an ink jet franking machine

ActiveUS20130187979A1Efficiently and periodically cleaningEasy to cleanFranking apparatusPrintingEngineeringNozzle

A wiping device (20) for cleaning outer surfaces of at least one row of ejection nozzles in at least one print head (4a, 4b) of an ink jet printing module (2) of a franking machine when the module is moving above the wiping device in first and second directions (X, Y), comprising two wiping rollers (26, 28) located one behind the other in the first direction and adapted to rotate in opposite directions around respective fixed shafts (30, 32), the two wiping rollers being permanently dampened in contact with a cleaning fluid (24) contained inside a container (22); and the two wiping rollers are adapted via a one-way bearing (34, 36) to remain stationary alternatively, one during the moving of the module in the first direction and the other during the moving of the module in the second direction.

Owner:NEOPOST TECH SA

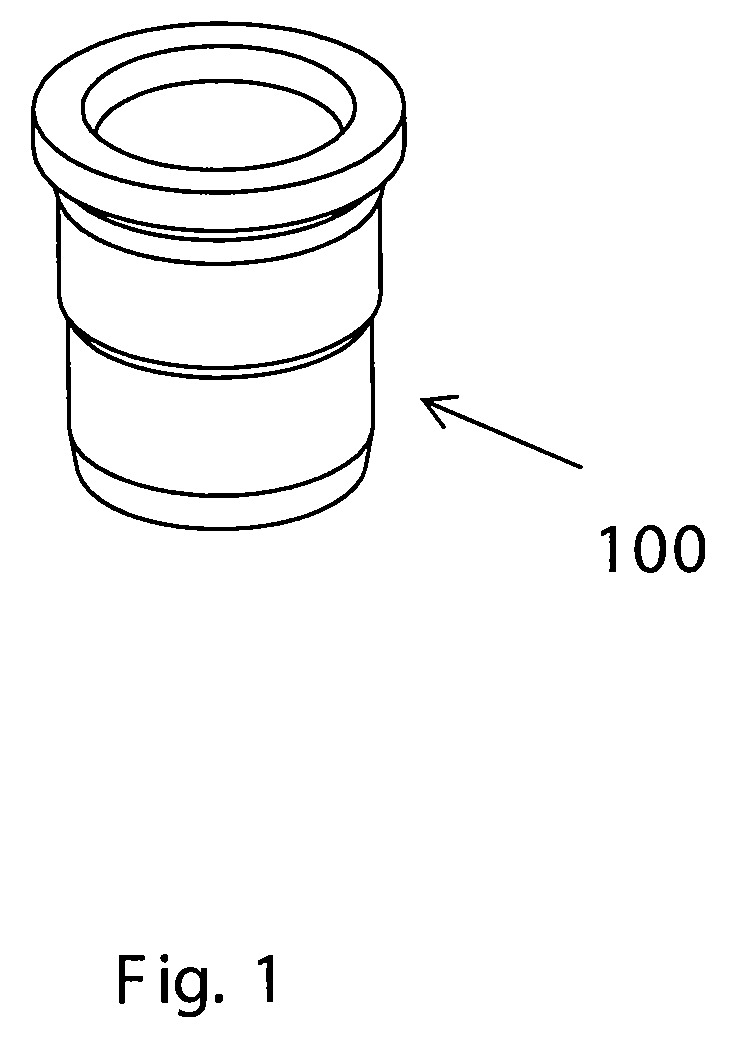

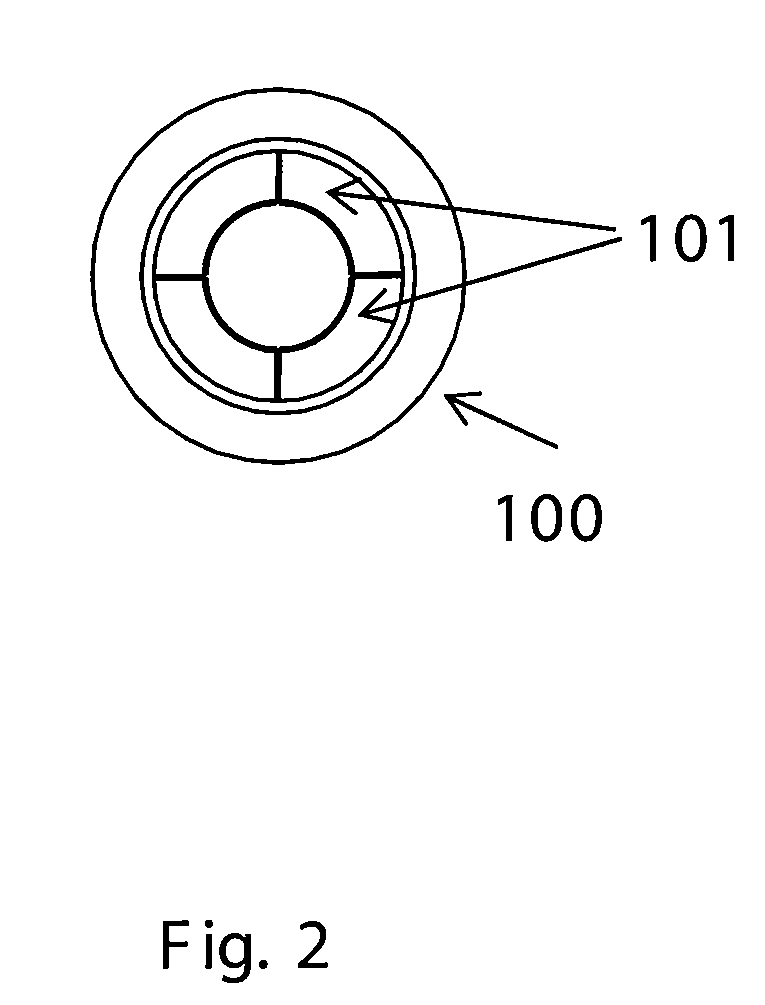

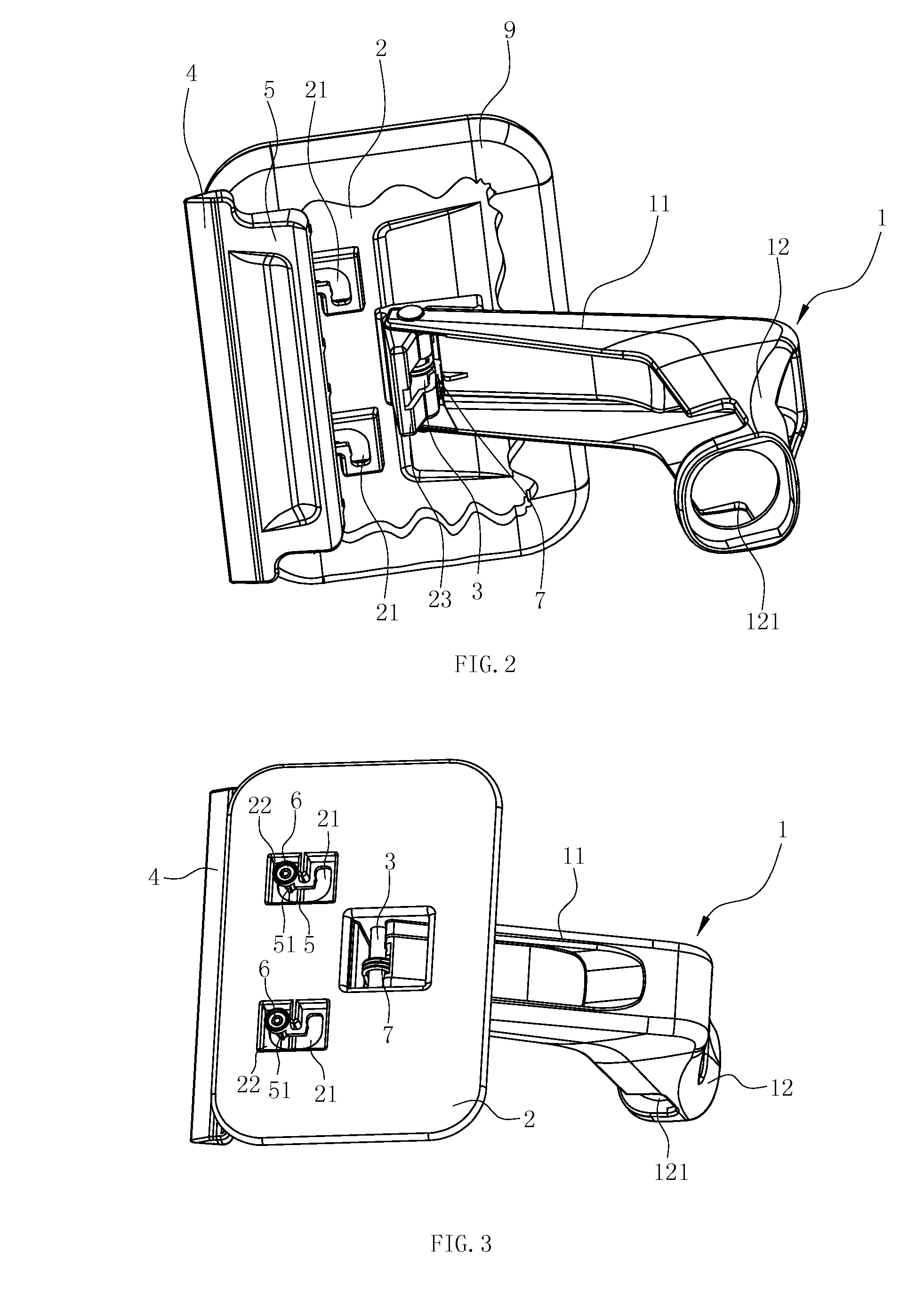

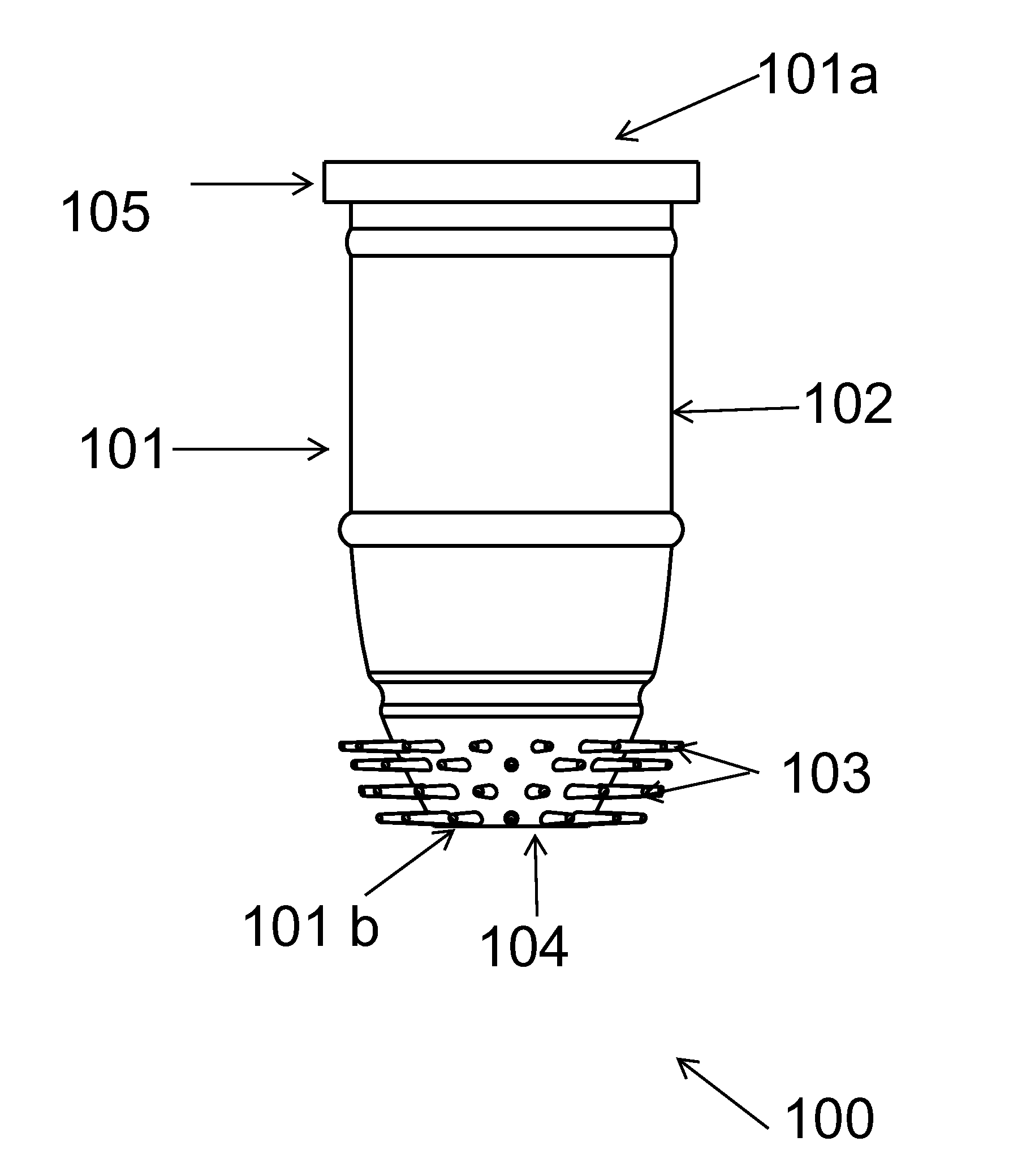

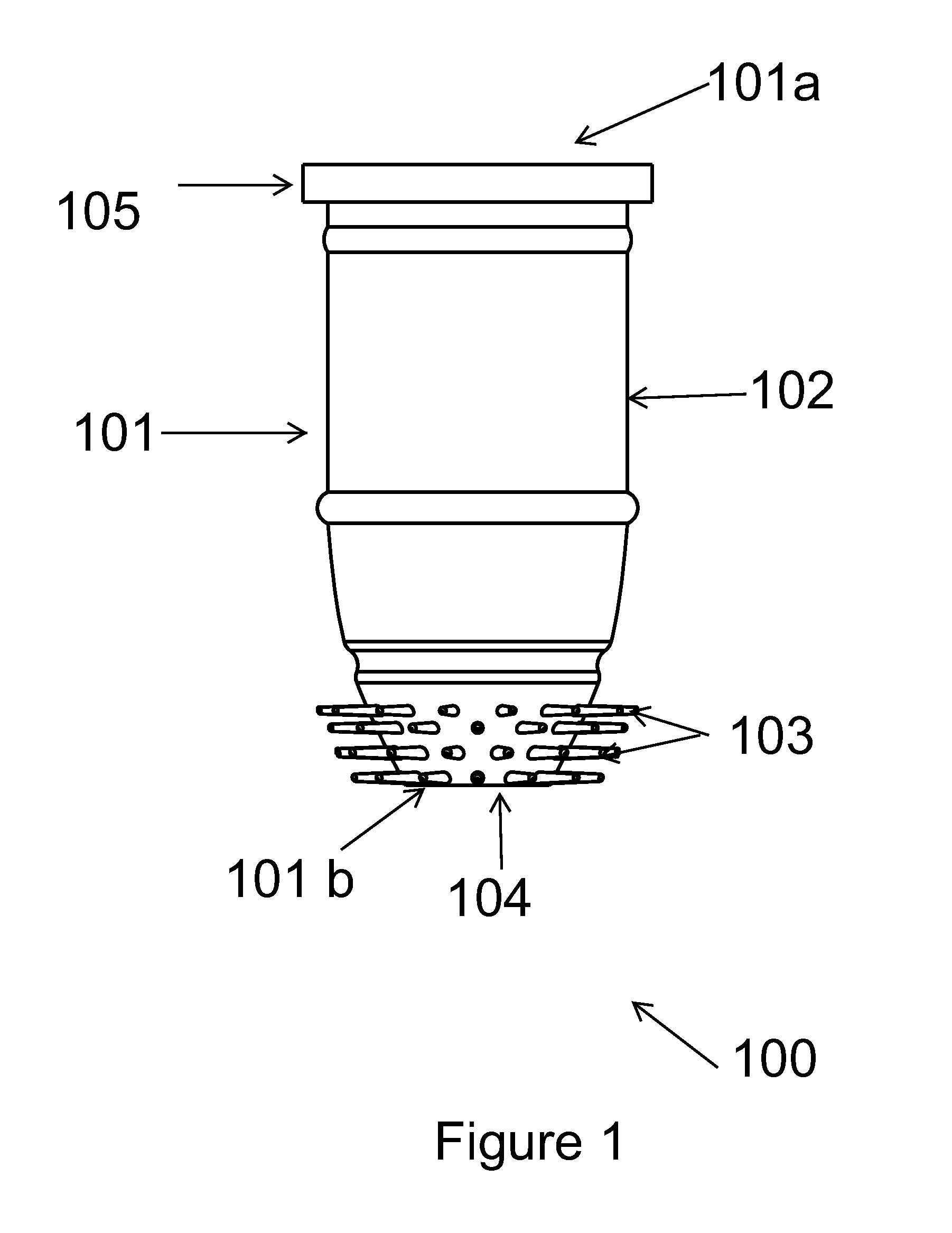

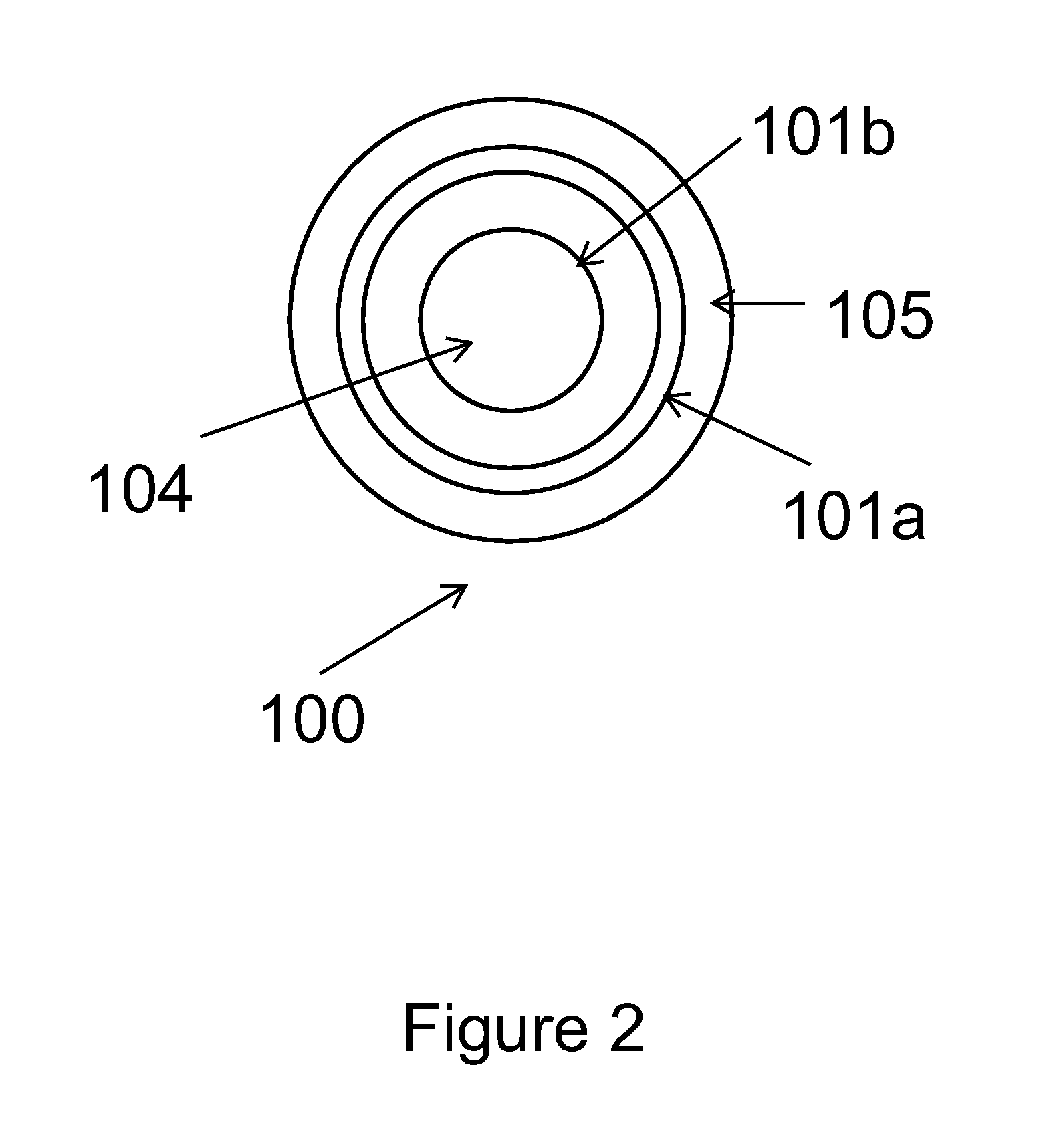

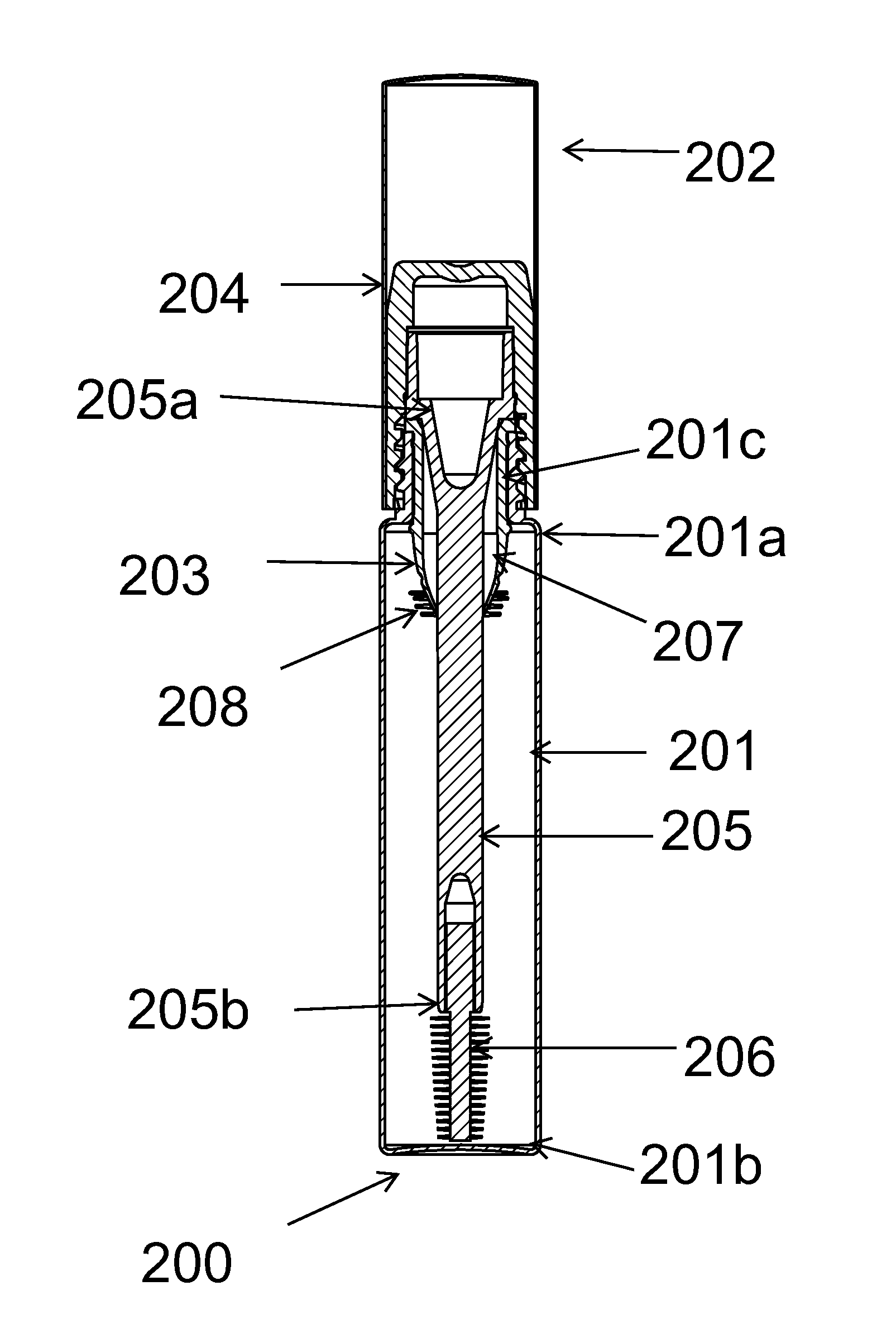

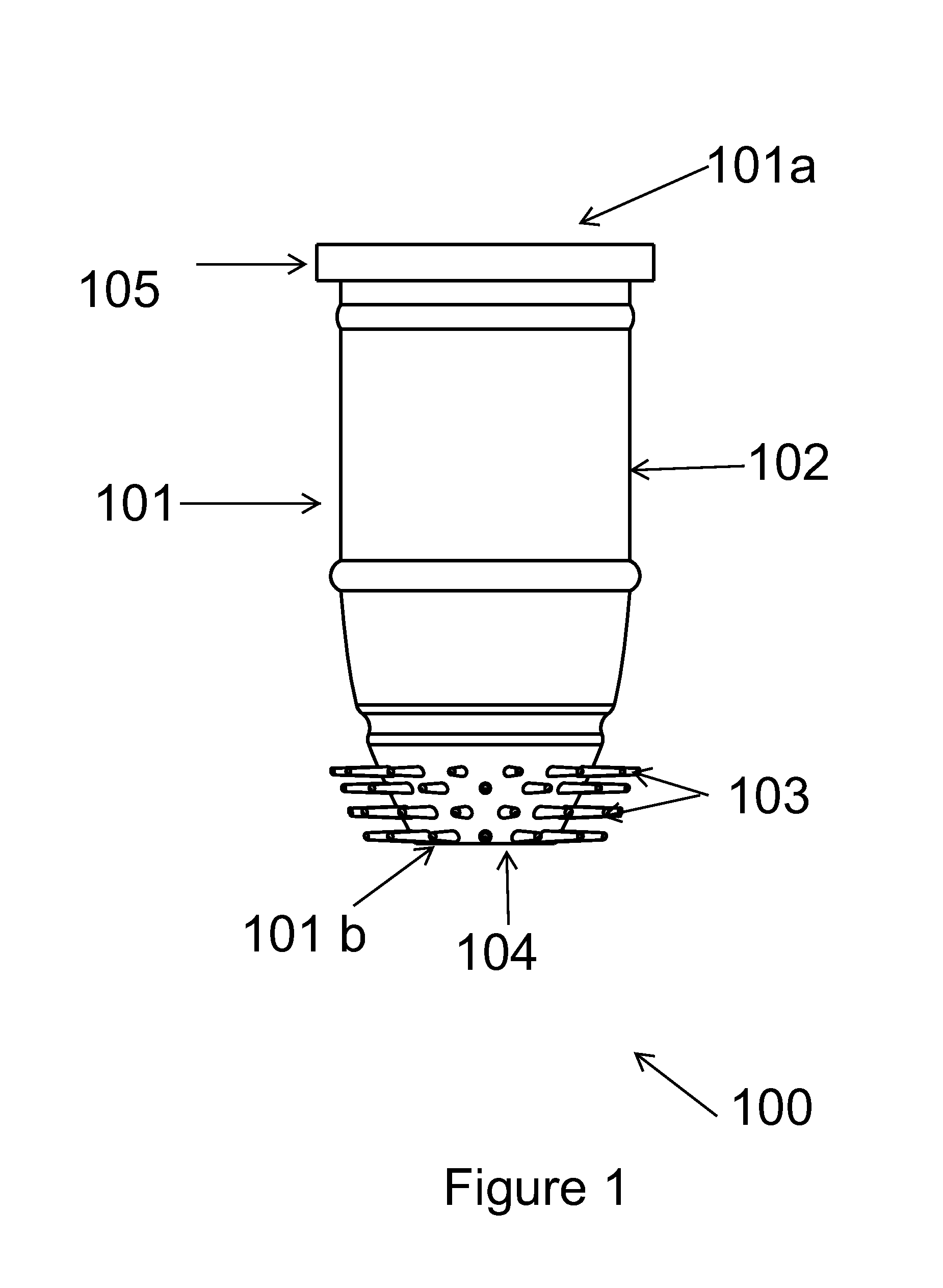

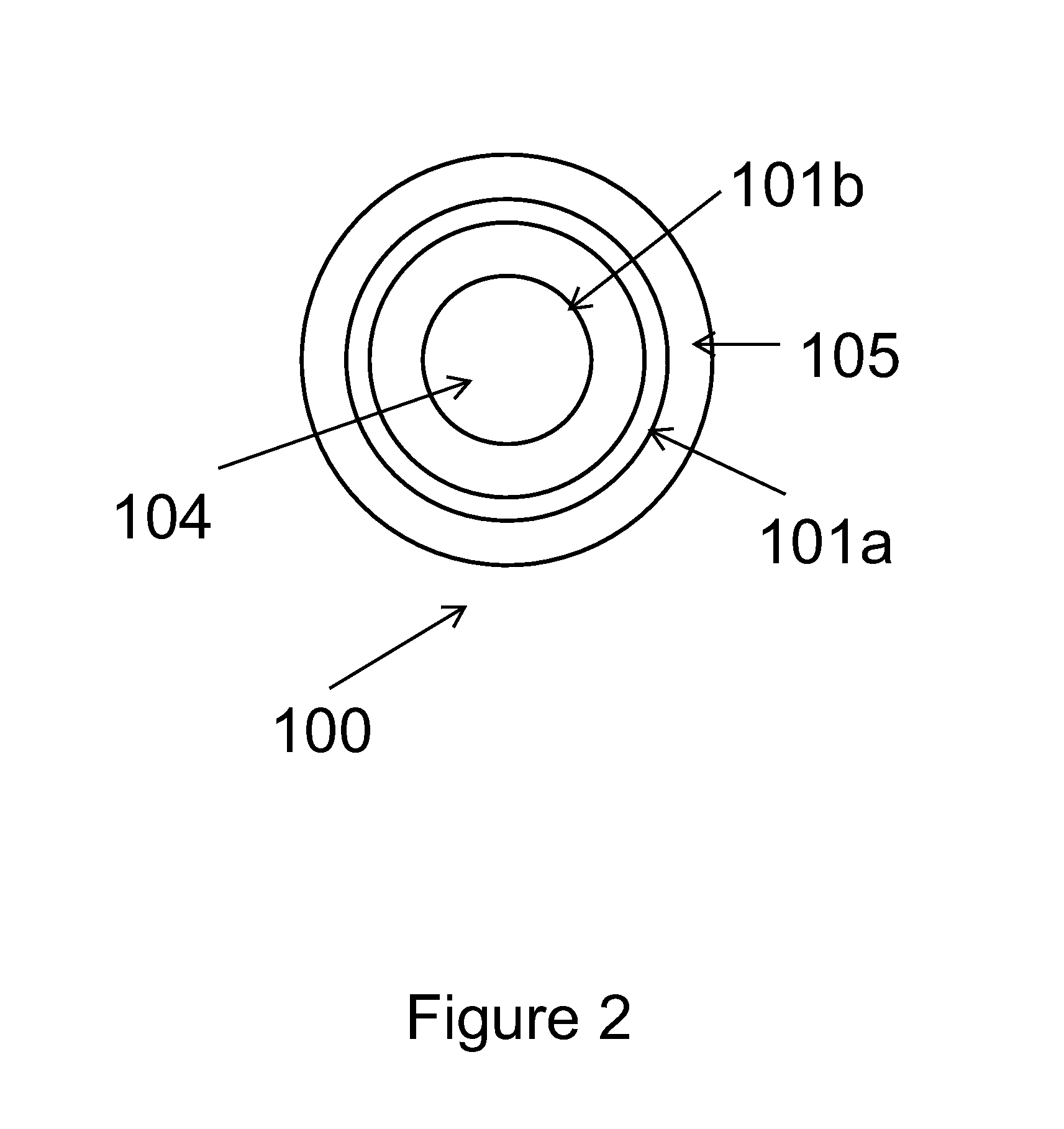

Wiper member for a container for packaging and dispensing products

InactiveUS20100129132A1Prolong lifeEfficiently wipeBrushesPackaging toiletriesEngineeringBiomedical engineering

The present invention generally is a wiper for a container for dispensing and dispensing cosmetic or care products. More particularly, the invention relates to a wiper member that is novel and inventive by way of its construction such that it prevents air from getting pumped / entrapped inside the container during usage. There is provided a wiper member that helps in increasing the life of the product by allowing it to remain in its original fluid state and prevents drying out of the product. Further, the wiper member by virtue of its internal configuration results in efficient wiping of the applicator element and at the same time provides an anti-pumping action by allowing the air to pass through the air vents in it. Also disclosed is a wiper member that is able to regulate the amount of product retained on the applicator when a force is either applied or removed from its central axis.

Owner:ZEN DESIGN SOLUTIONS

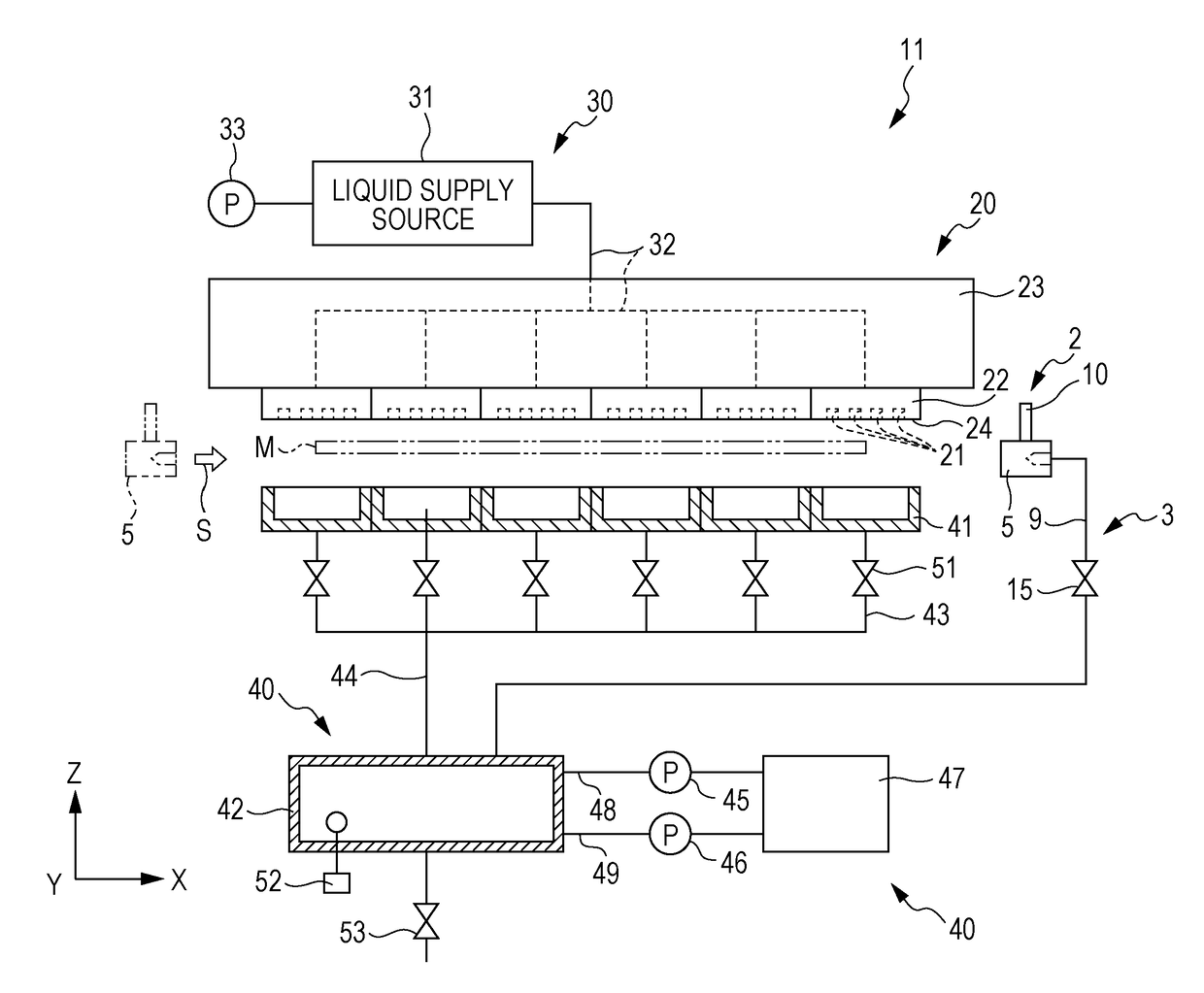

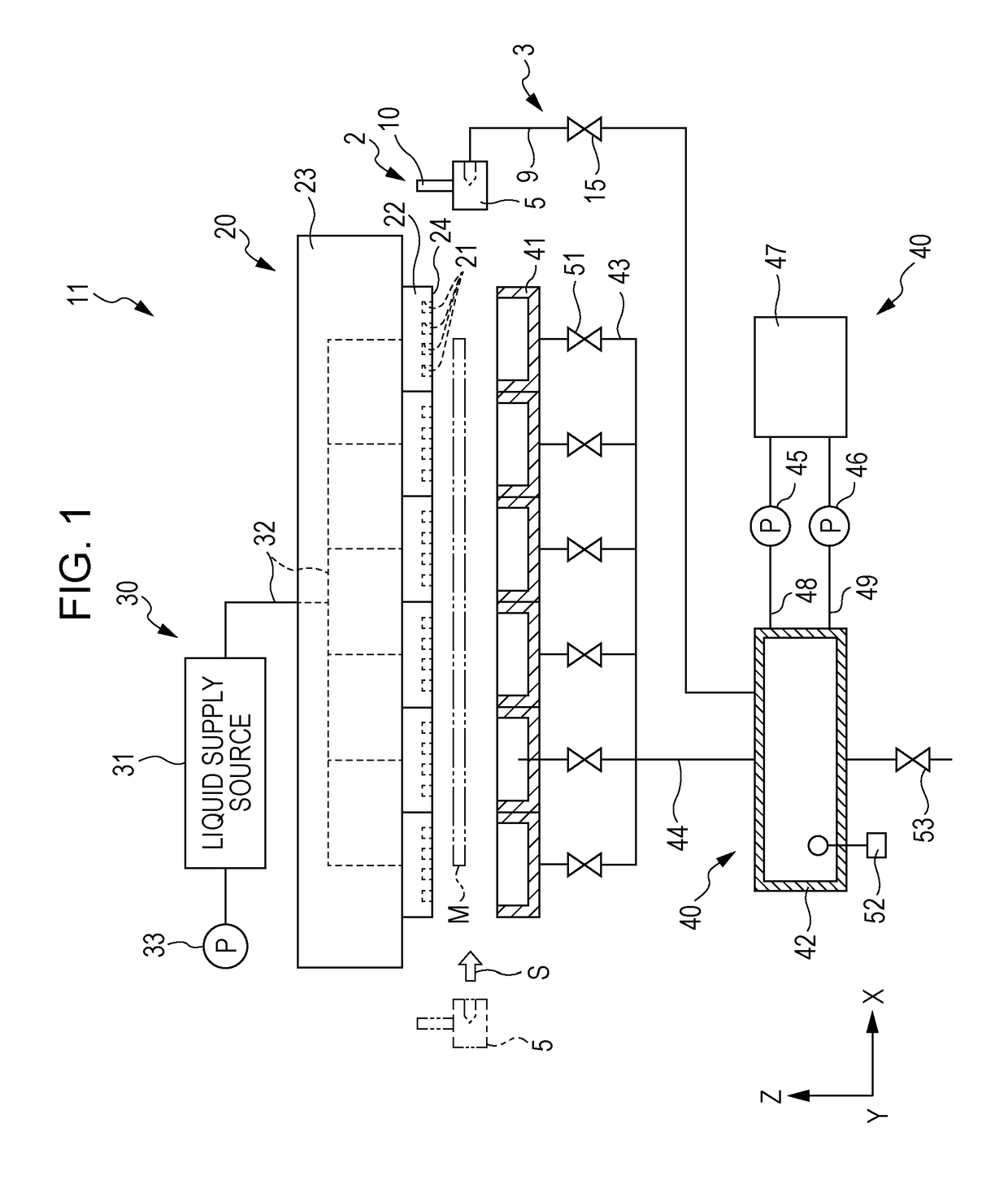

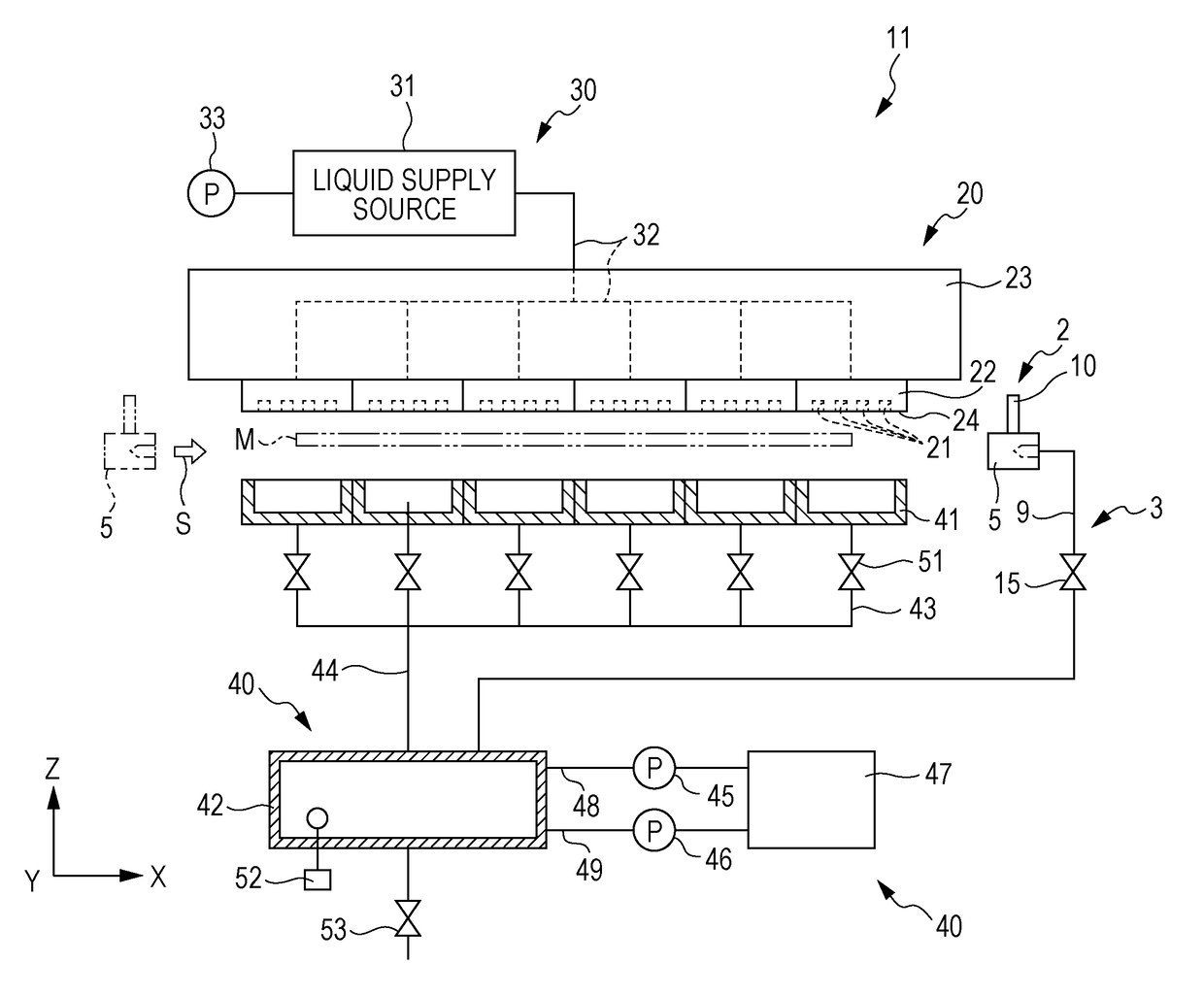

Apparatus and method for electrostatic spraying of conductive coating materials

ActiveUS20050129872A1Efficiently wipeBurnersLiquid supply arrangementsConductive coatingAutomotive engineering

Apparatus and a method are provided for isolating an electrostatic sprayer from an electrically grounded coating product distribution circuit connected thereto. The apparatus includes an electrostatic sprayer carried by a maneuverable robot arm, the sprayer capable of spraying an electrically conductive coating product such as water-based paint onto a workpiece passing in adjacent proximity thereby, on command. The coating product is supplied from a remote source of supply through at least one distribution circuit connected to the sprayer. The apparatus includes therein, carried by the robot arm, an electrically insulative storage tank for the coating product in valved fluid communication with the sprayer. The insulated storage tank is connected to and positioned downstream from a length of electrically insulative supply conduit connected to the distribution circuit and also carried by the robot arm. This conduit includes a cleaning mechanism for cleaning a portion, including all, of this length of supply conduit, in situ, after filling of the storage tank with coating product and before spraying. In this way, substantially all of the conductive coating product is removed from the portion of supply conduit, thereby completely isolating the sprayer electrically from the distribution circuit. The cleaning mechanism is preferably a chemically resistant plunger fitted in the conduit and adapted to reciprocally traverse the length of the conduit on command, effectively wiping it clean of coating product and thereby galvanically isolating the sprayer from the distribution circuit during the actual spraying operation.

Owner:EFC SYST

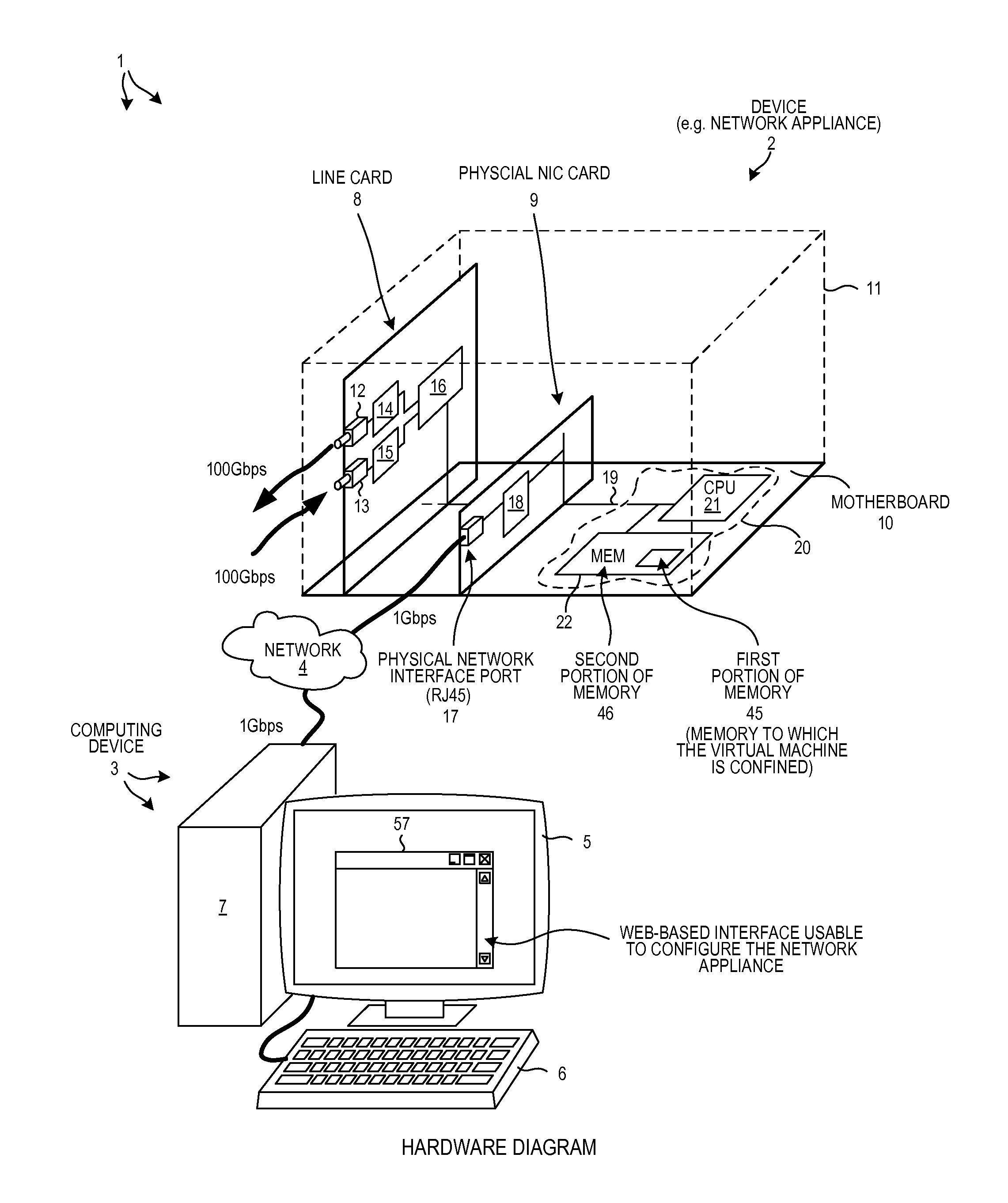

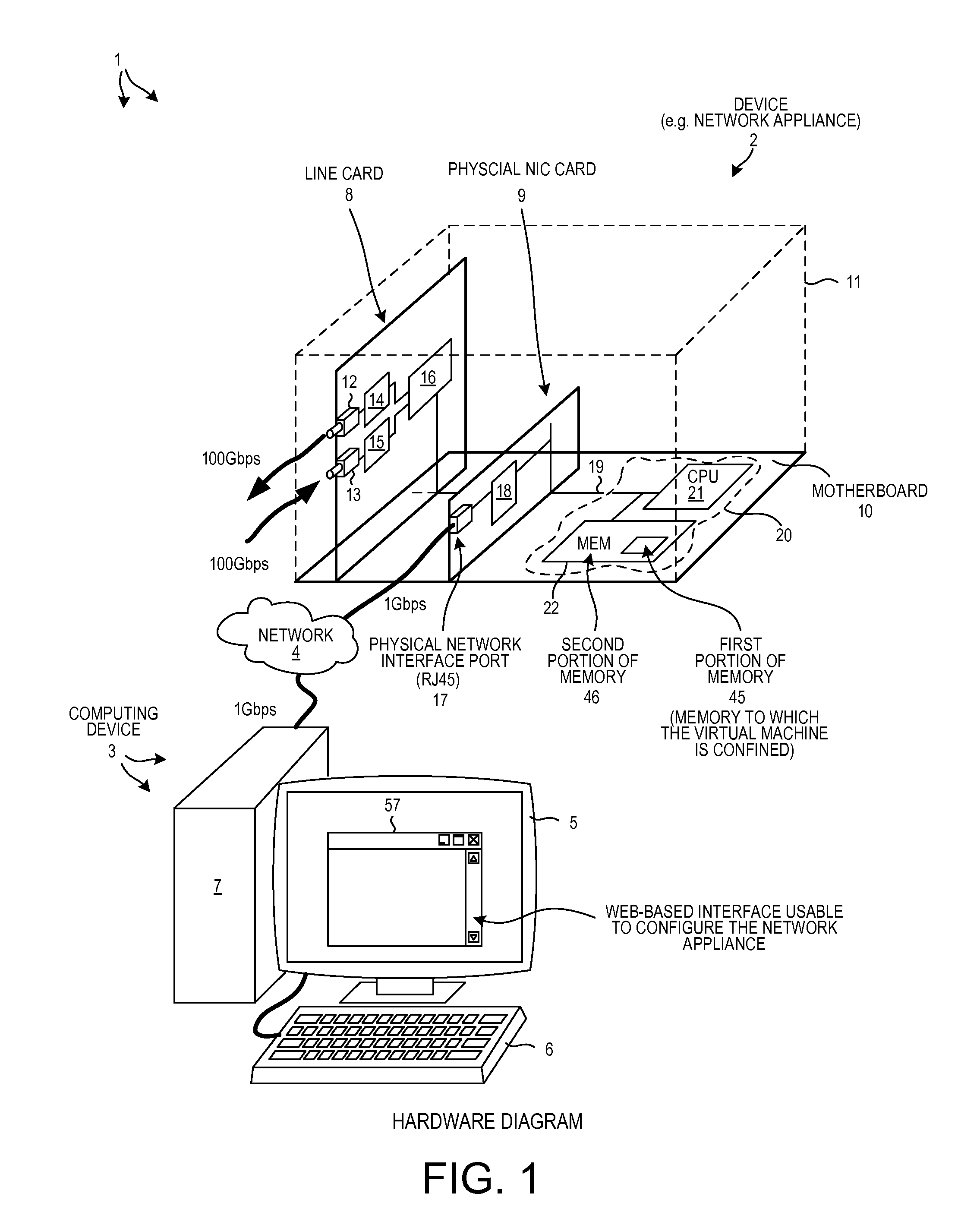

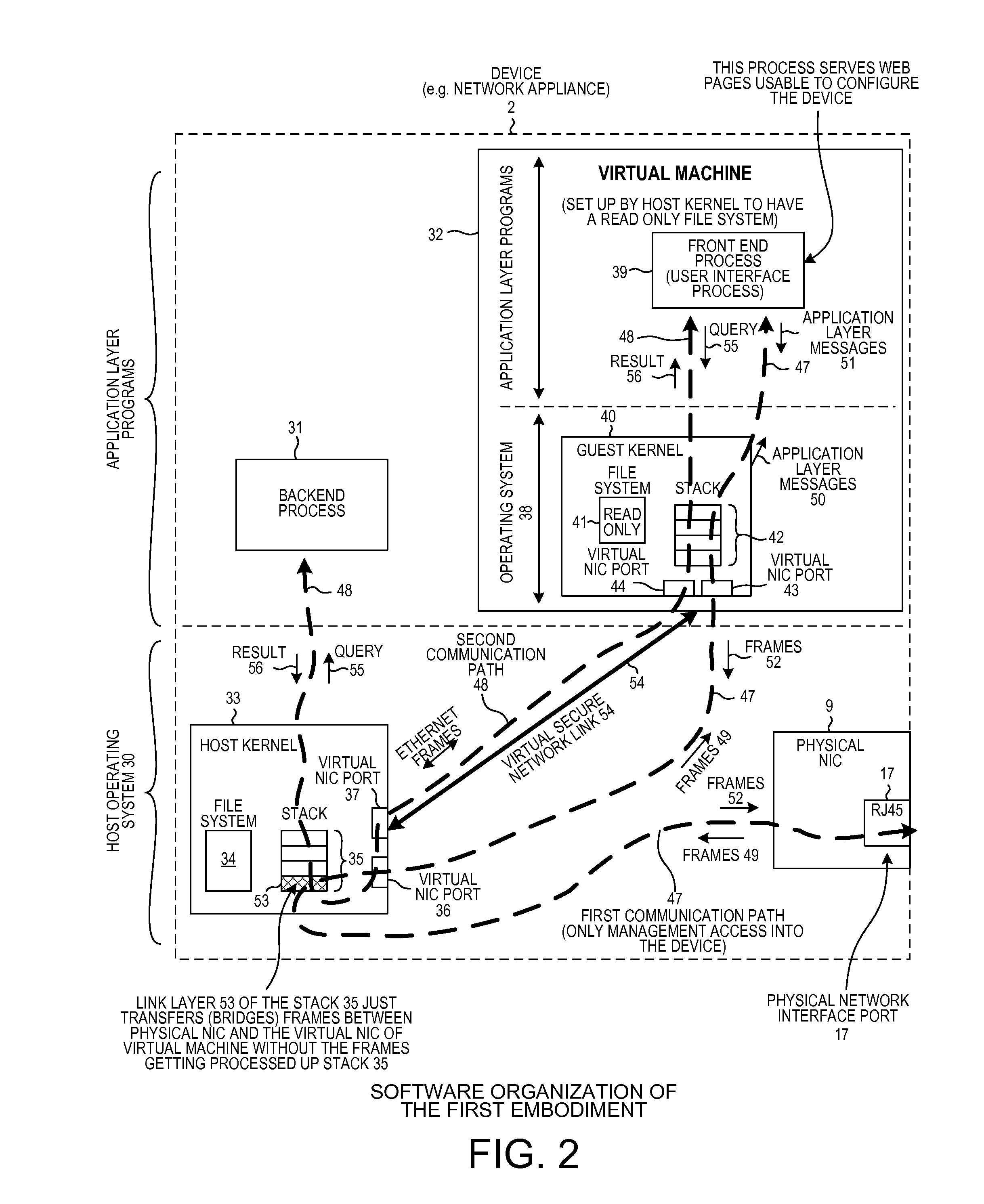

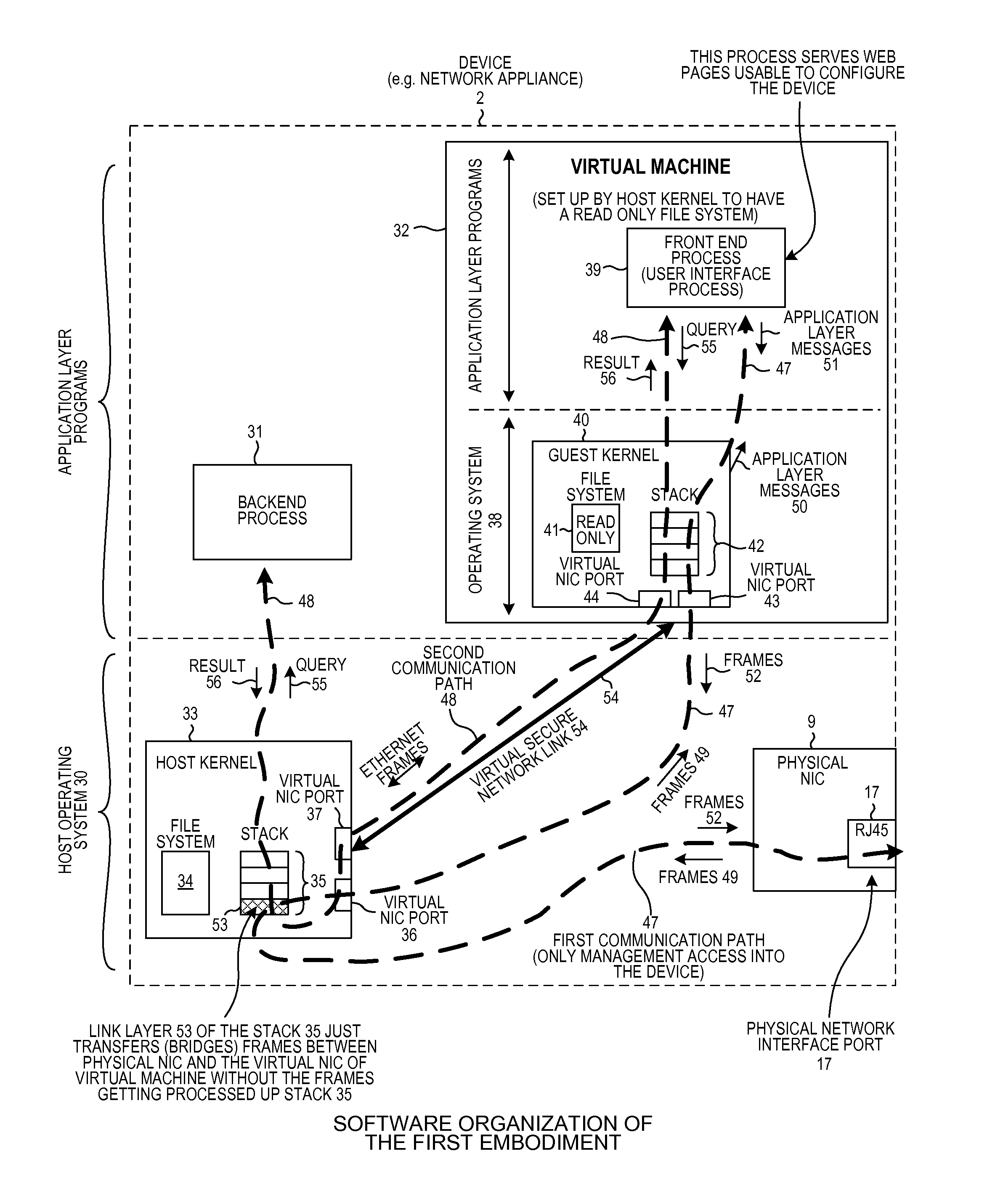

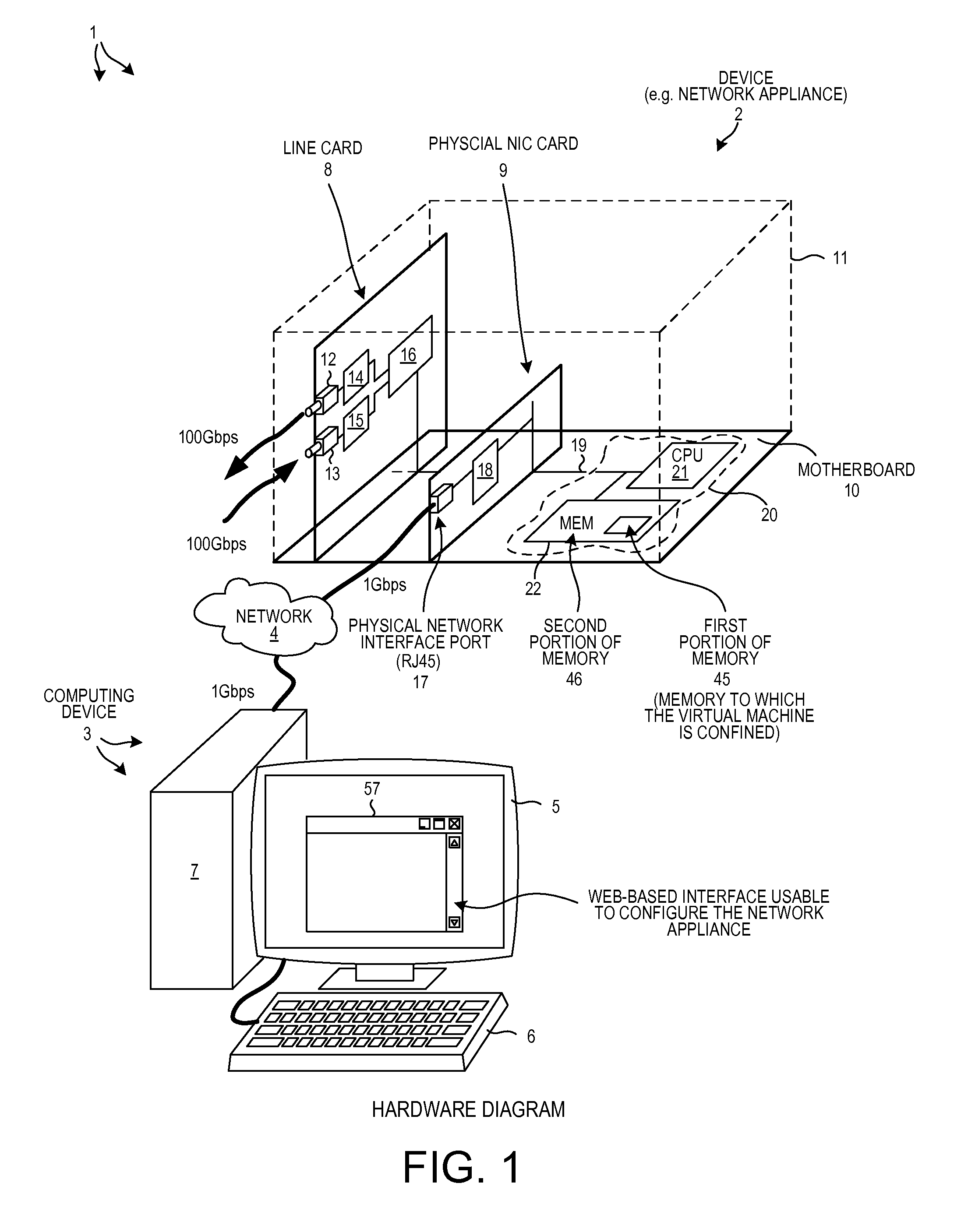

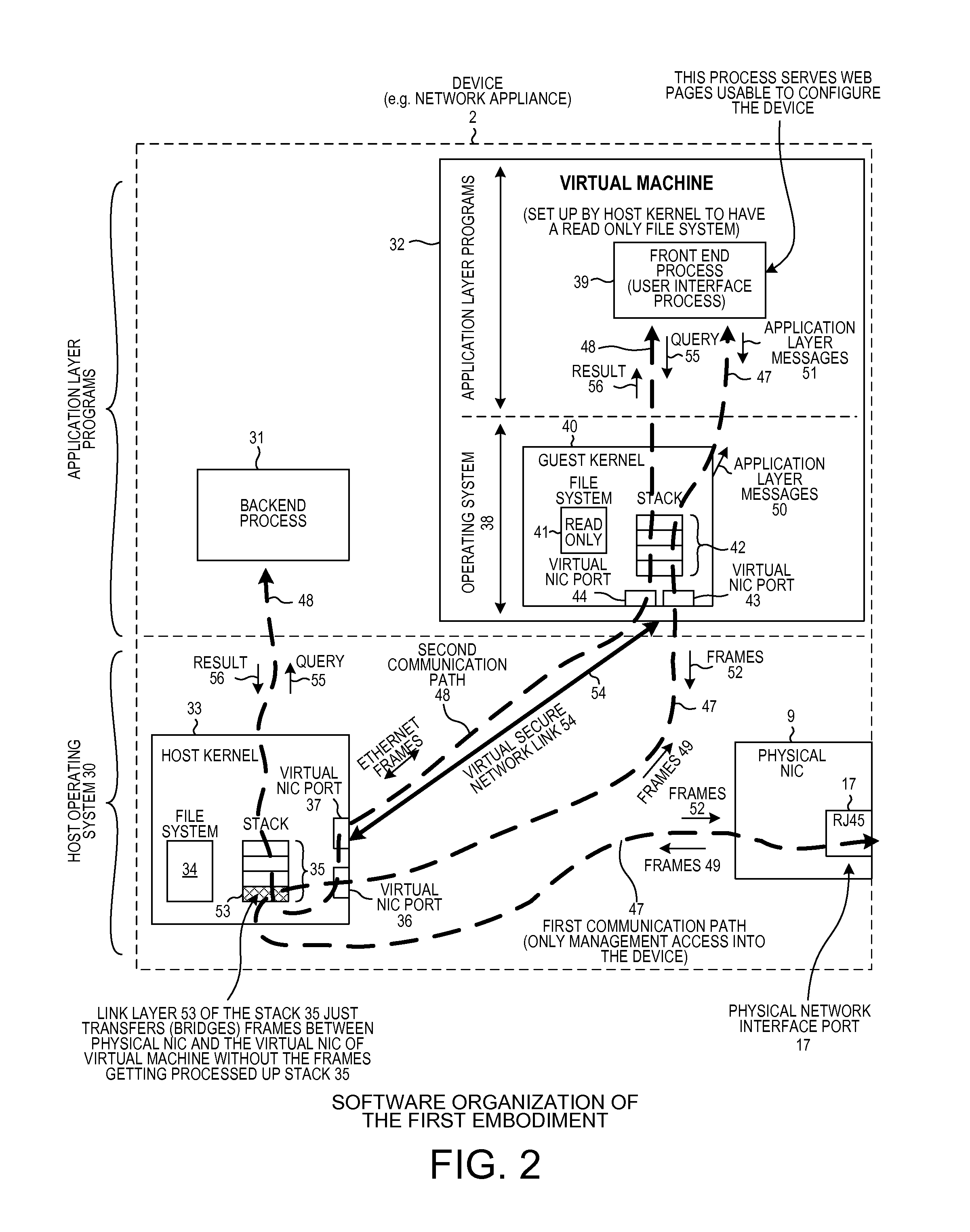

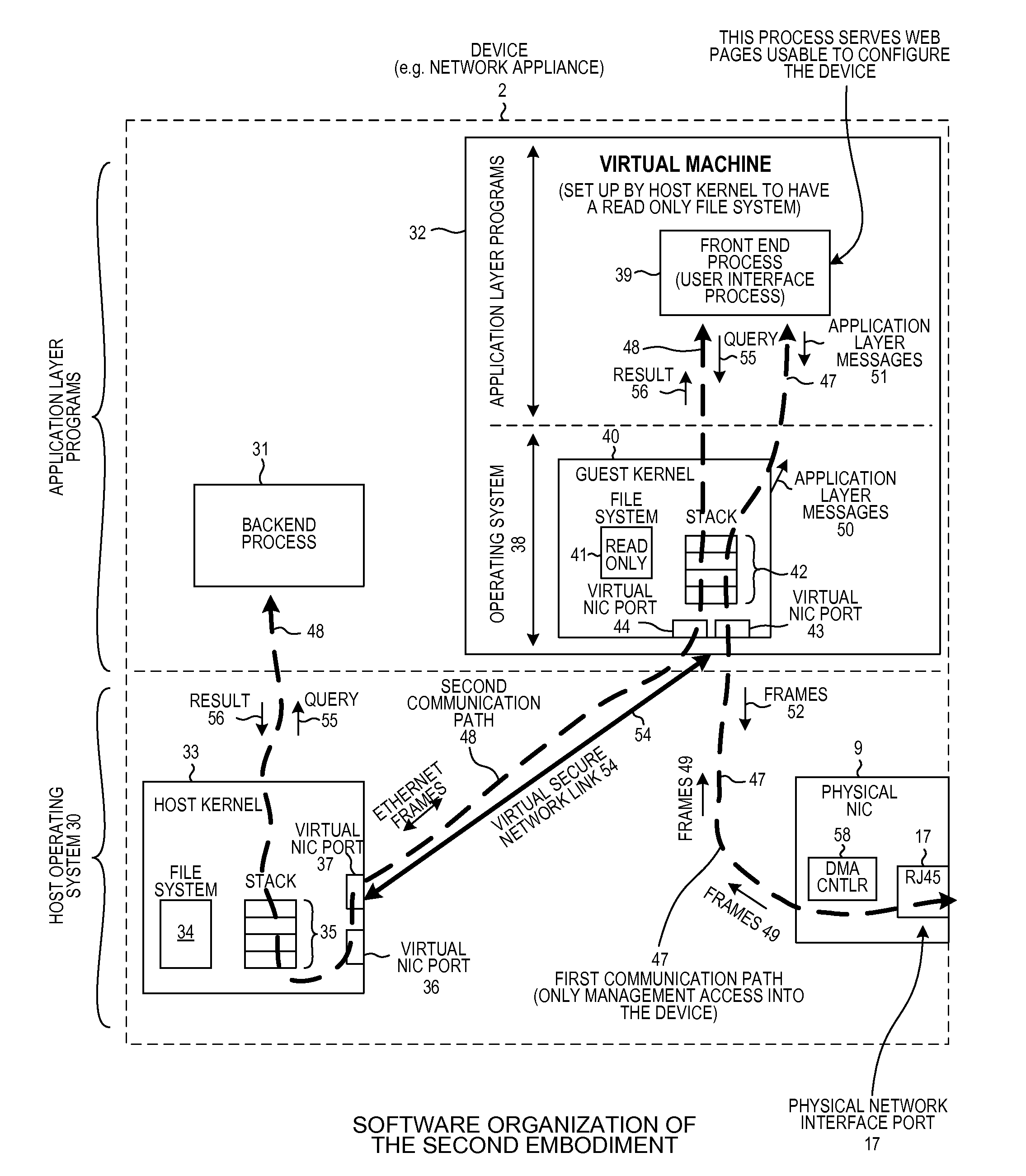

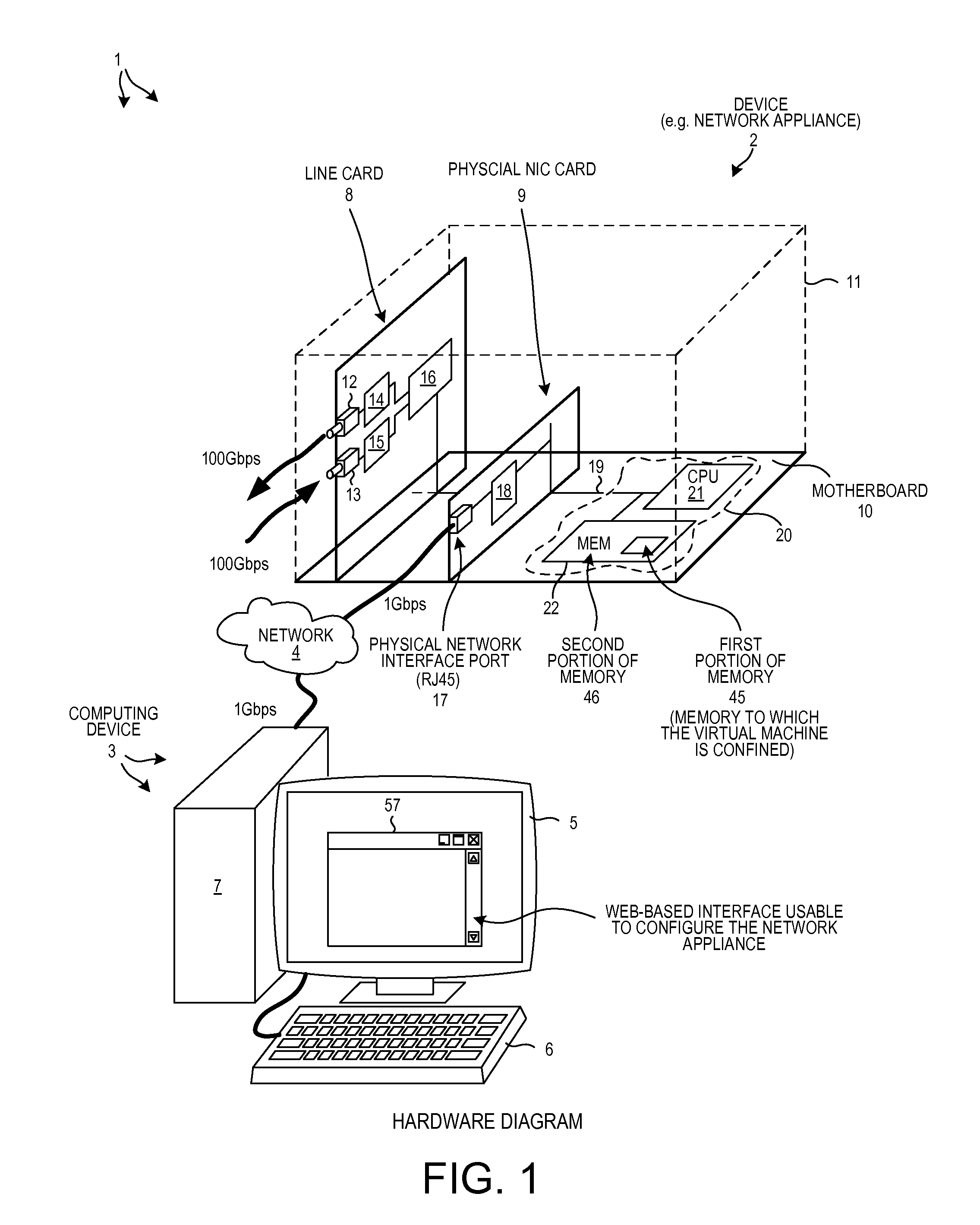

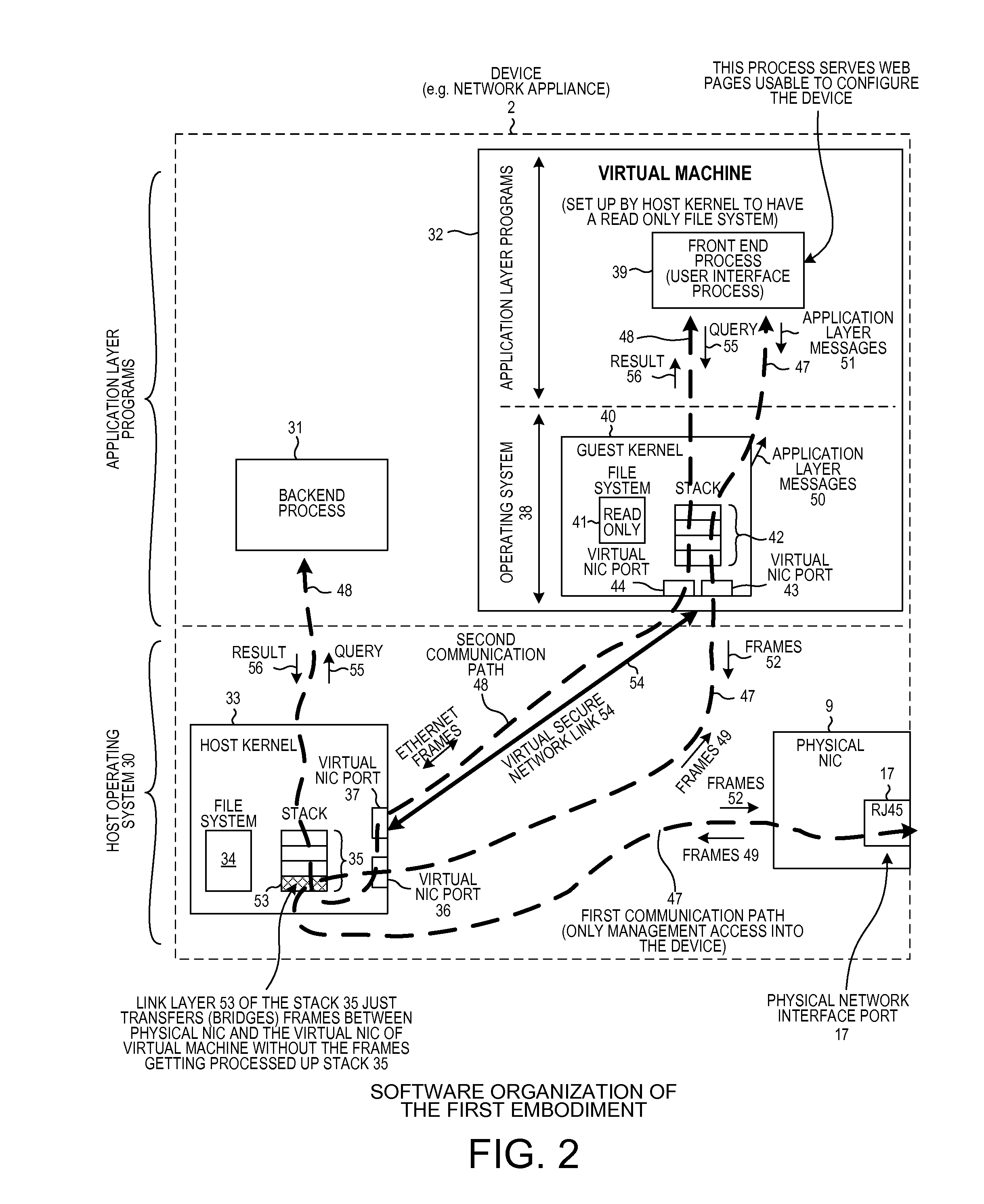

Compartmentalization of the user network interface to a device

ActiveUS20140201734A1Efficiently wipeGuaranteed uptimeHybrid transportSoftware simulation/interpretation/emulationPathPingNetwork link

A device has physical network interface port through which a user can monitor and configure the device. A backend process and a virtual machine (VM) execute on a host operating system (OS). A front end user interface process executes on the VM, and is therefore compartmentalized in the VM. There is no front end user interface executing on the host OS outside the VM. The only management access channel into the device is via a first communication path through the physical network interface port, to the VM, up the VM's stack, and to the front end process. If the backend process is to be instructed to take an action, then the front end process forwards an application layer instruction to the backend process via a second communication path. The instruction passes down the VM stack, across a virtual secure network link, up the host stack, and to the backend process.

Owner:NETRONOME SYST

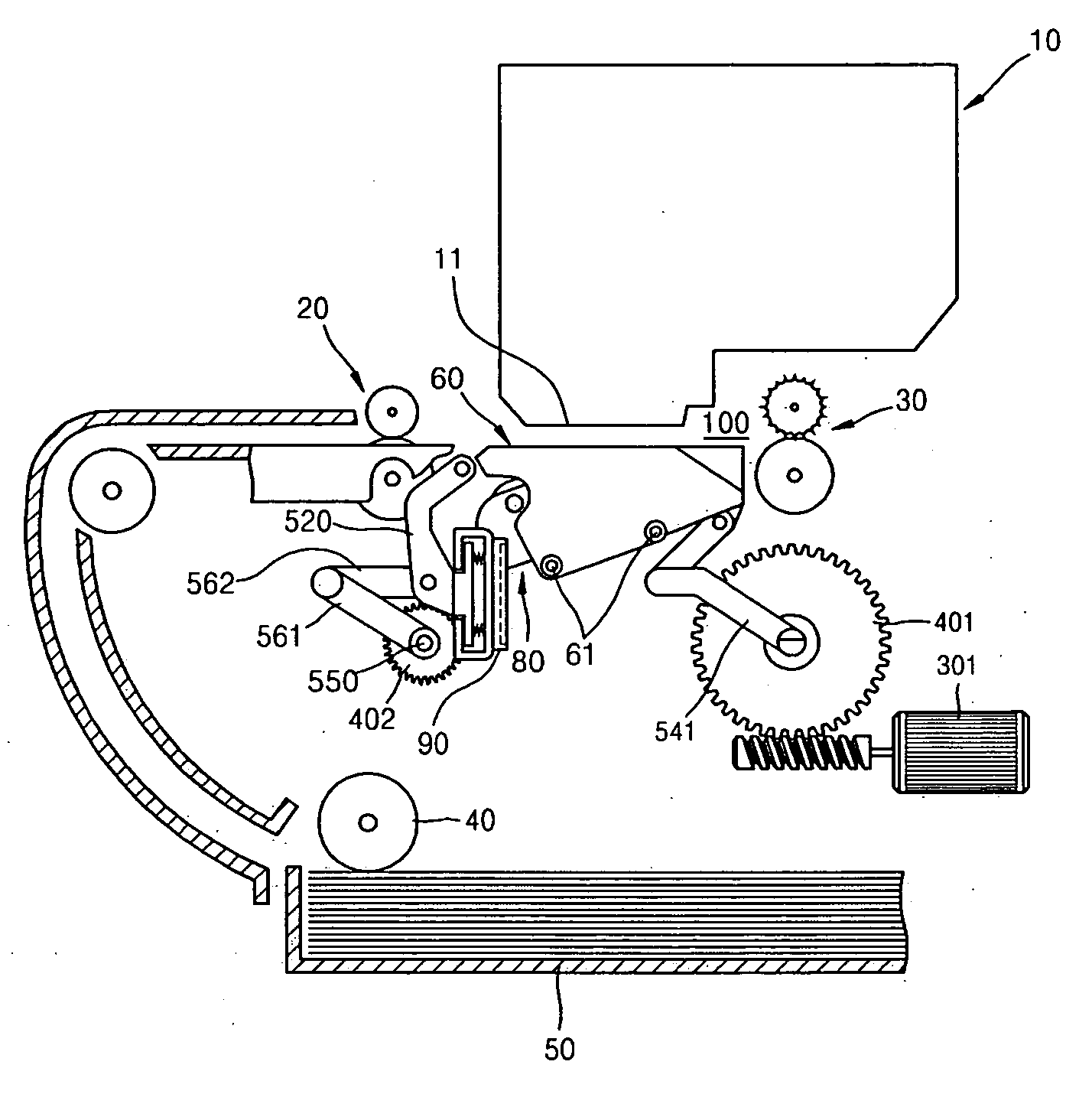

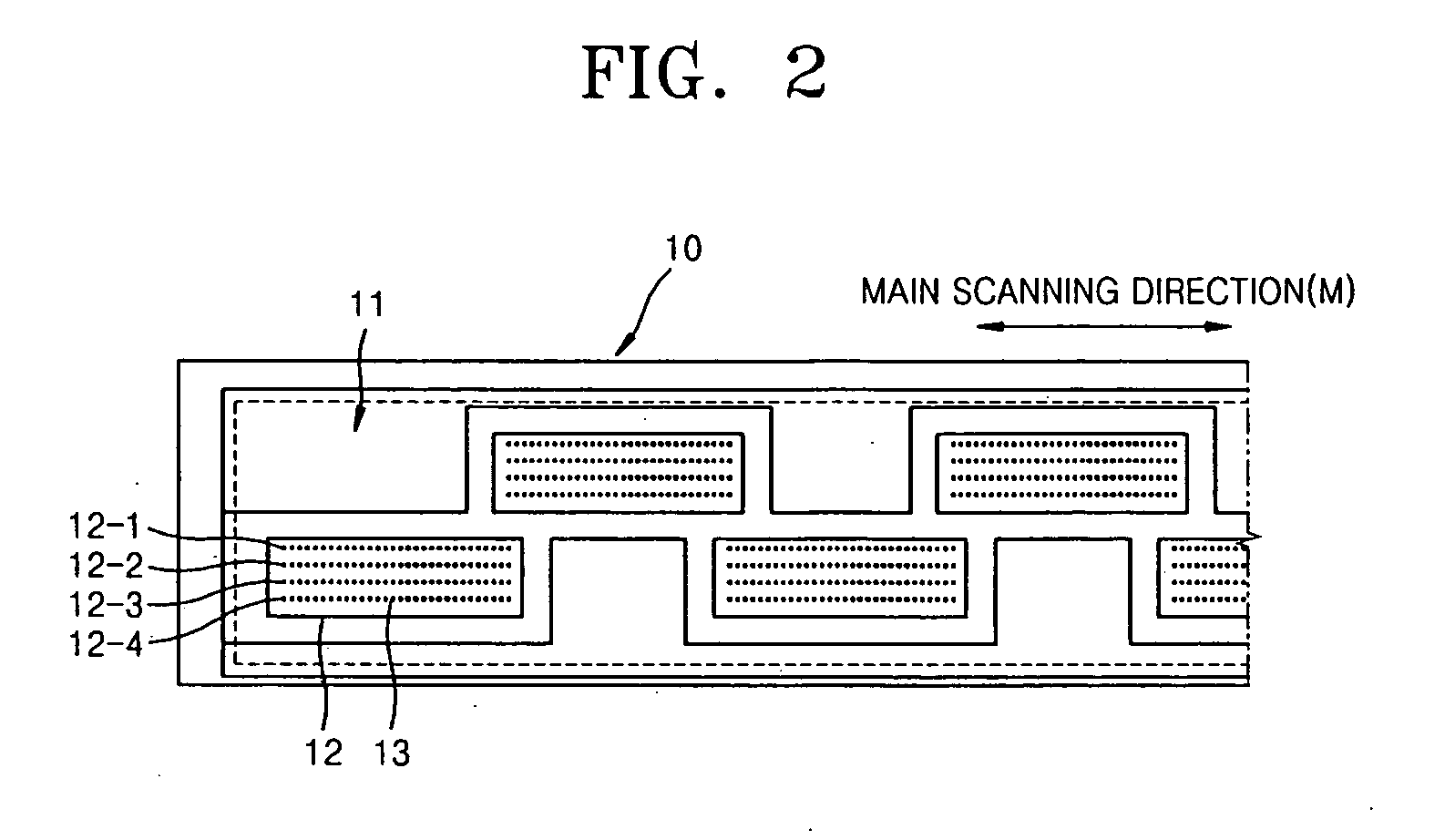

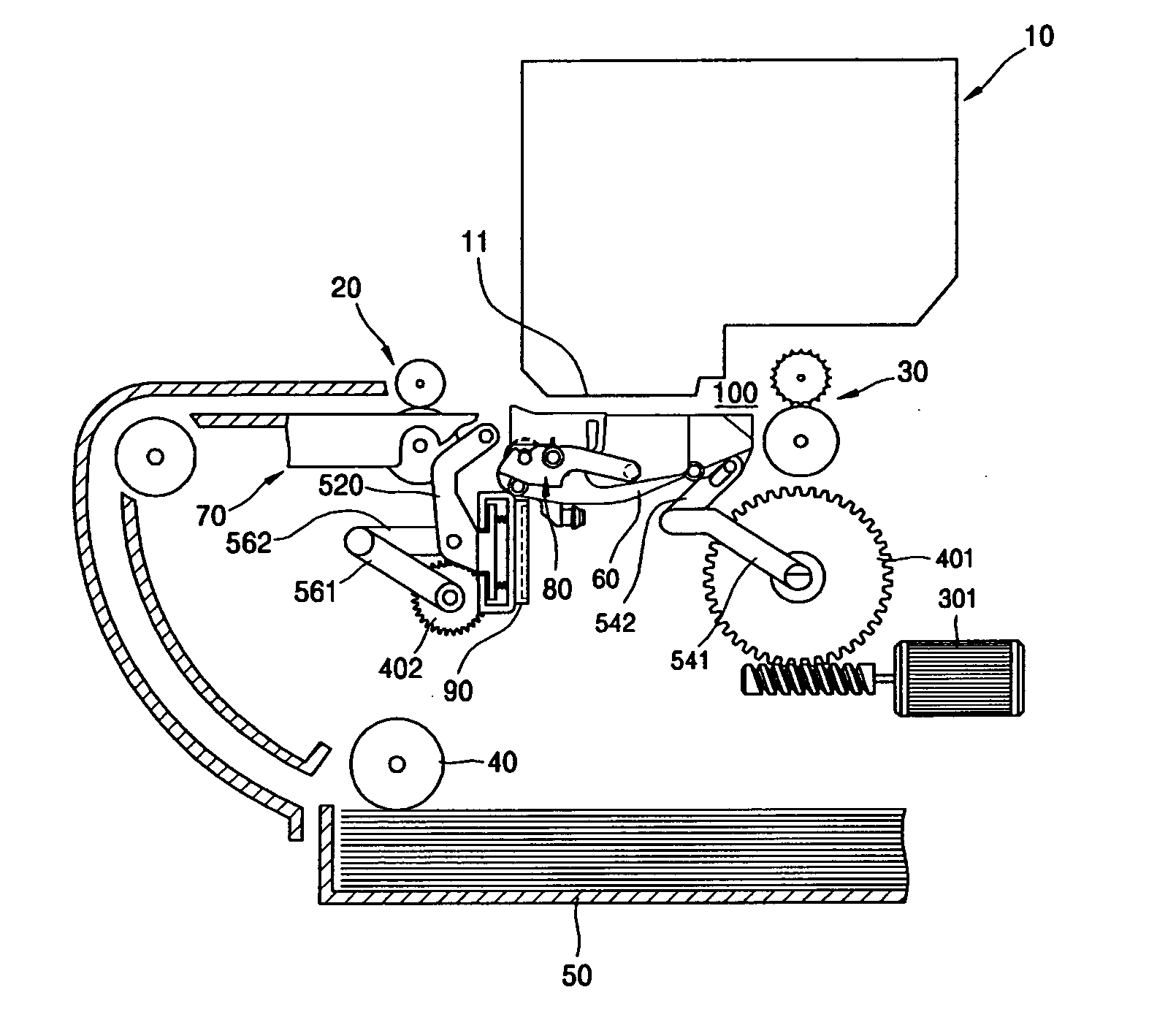

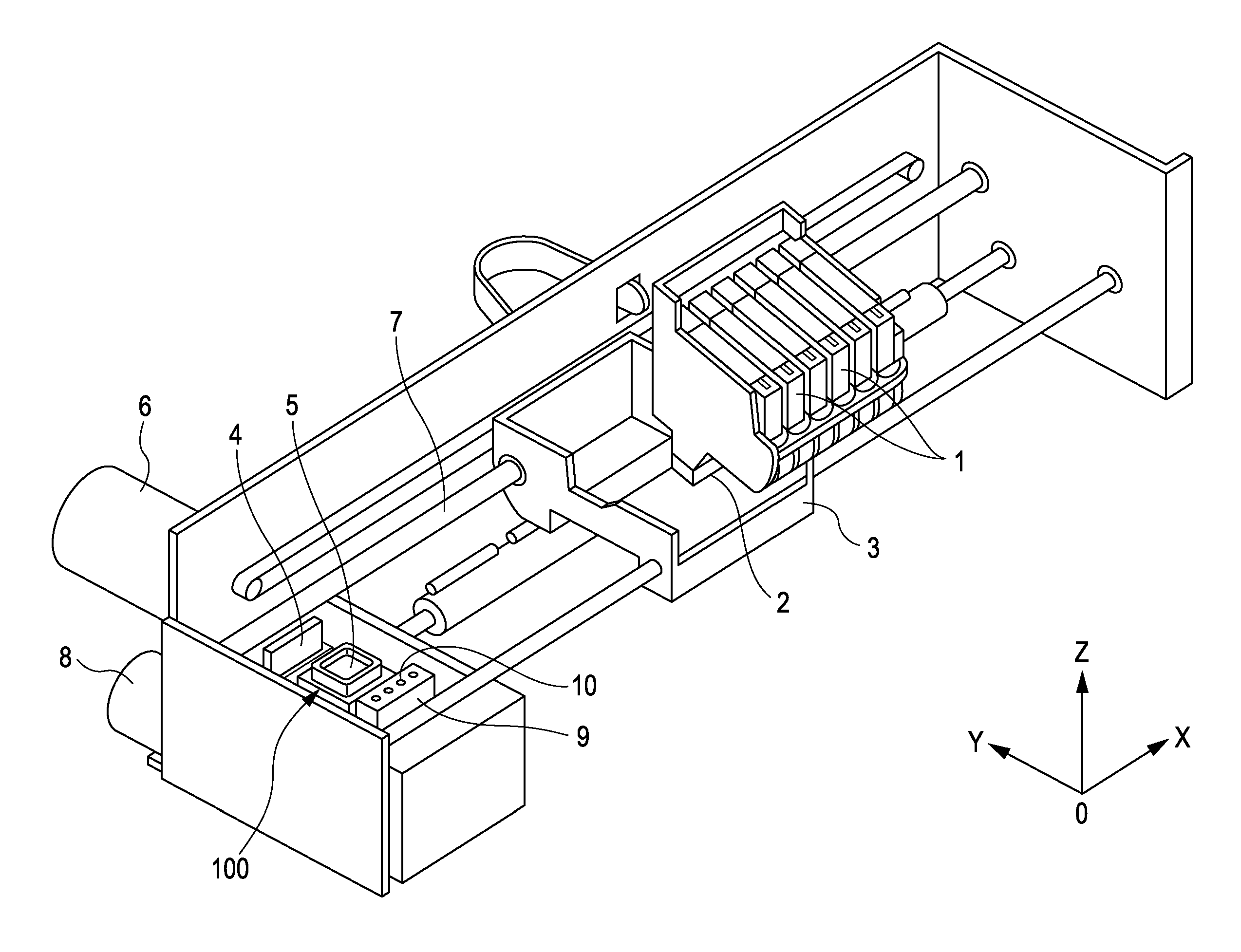

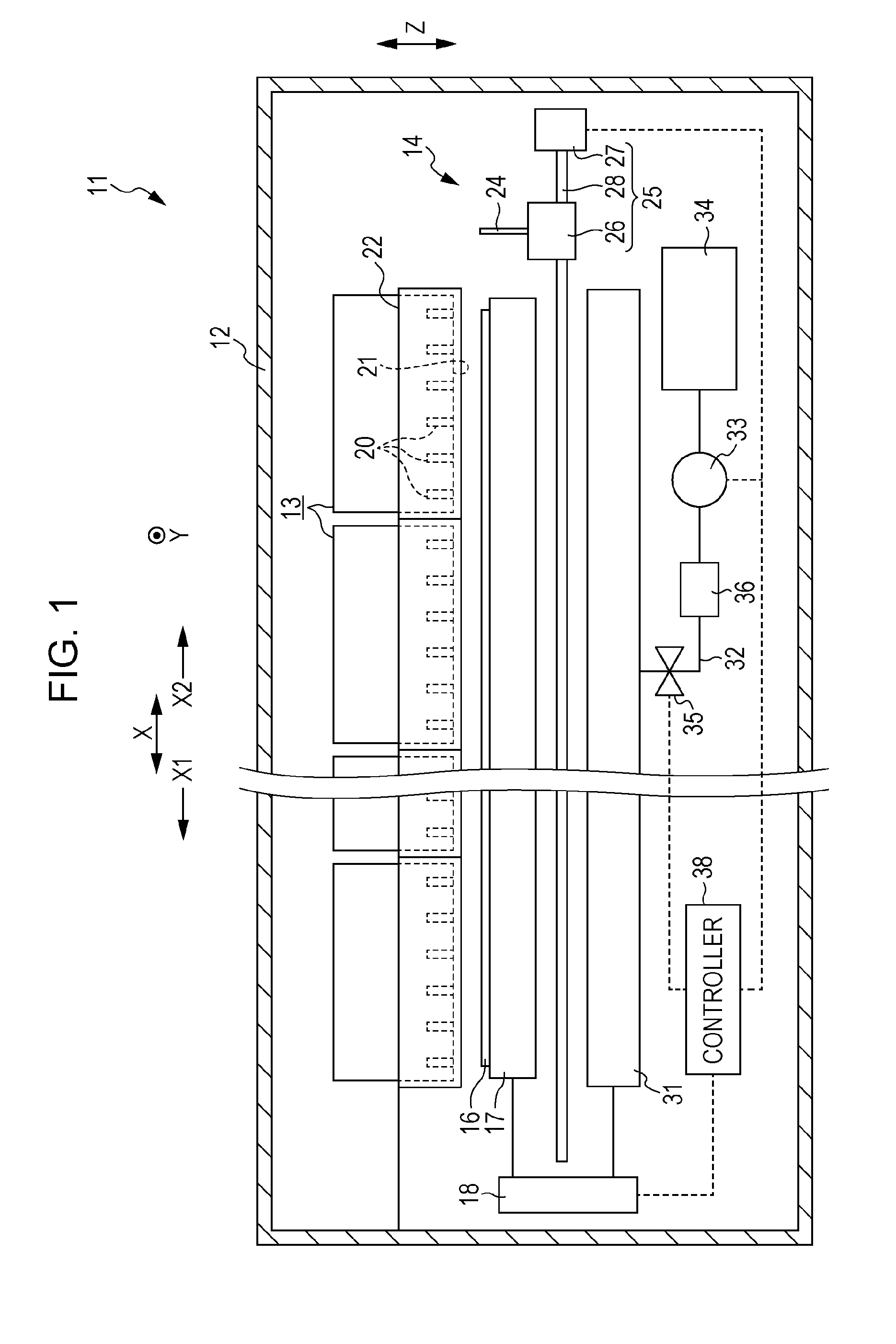

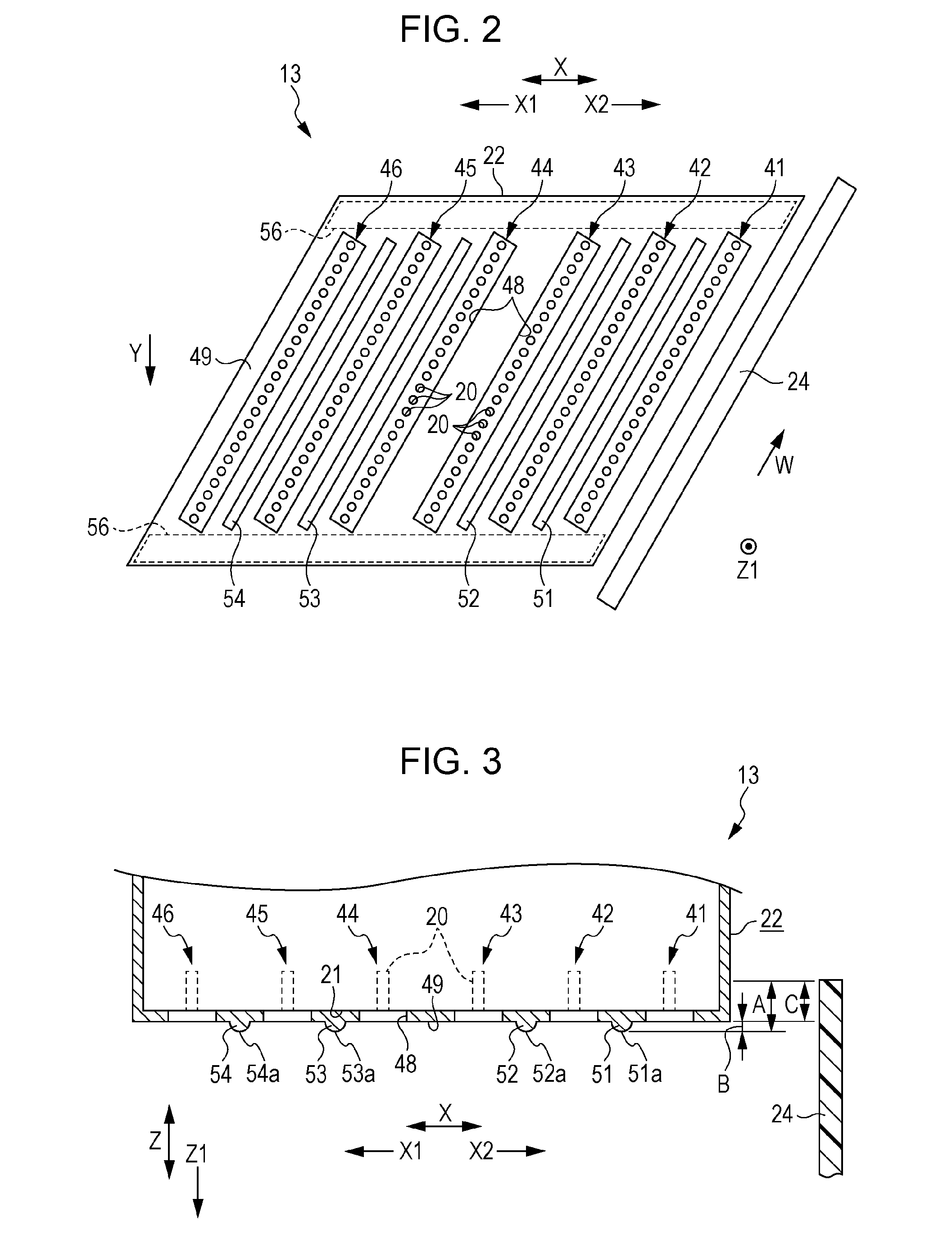

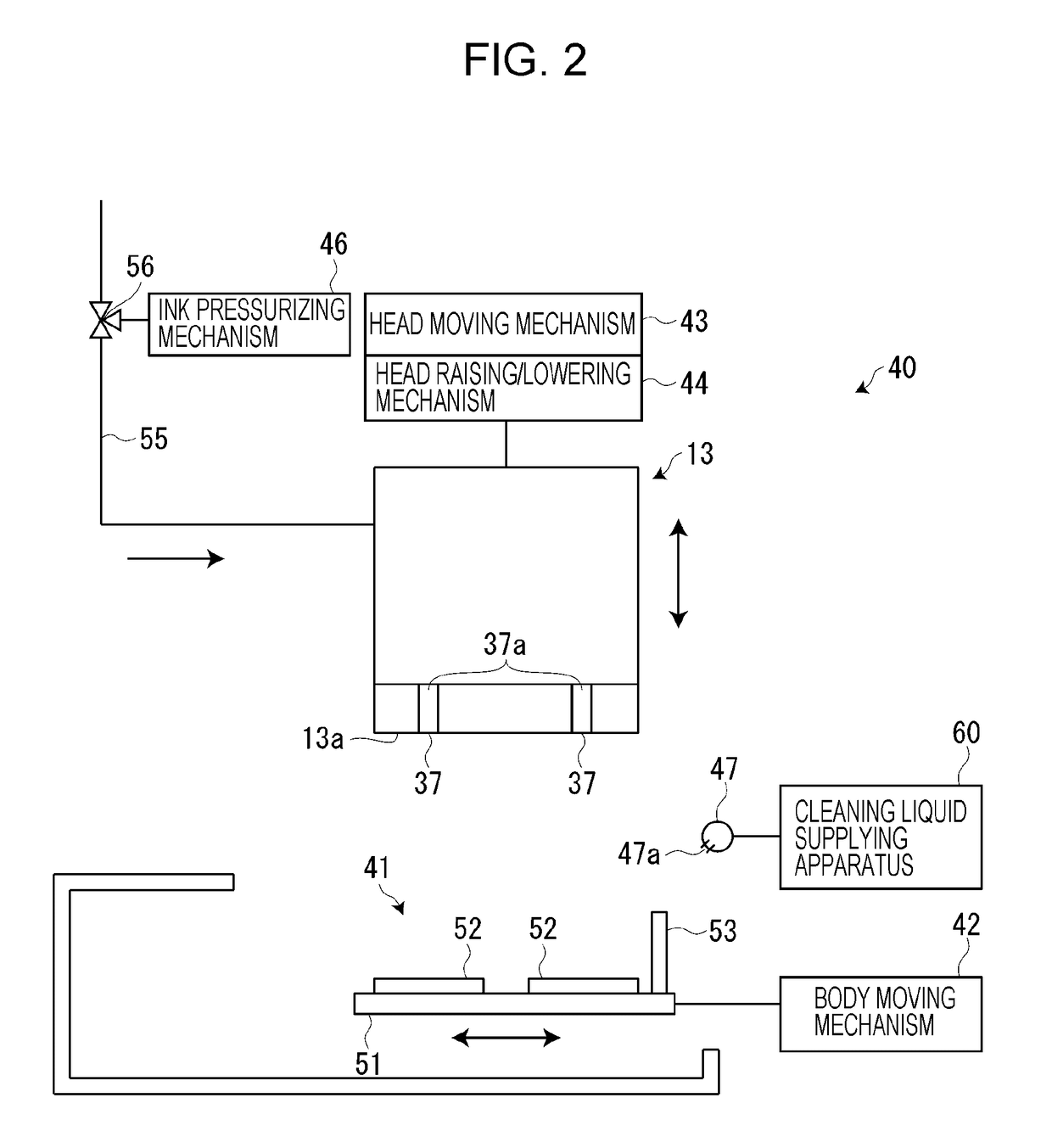

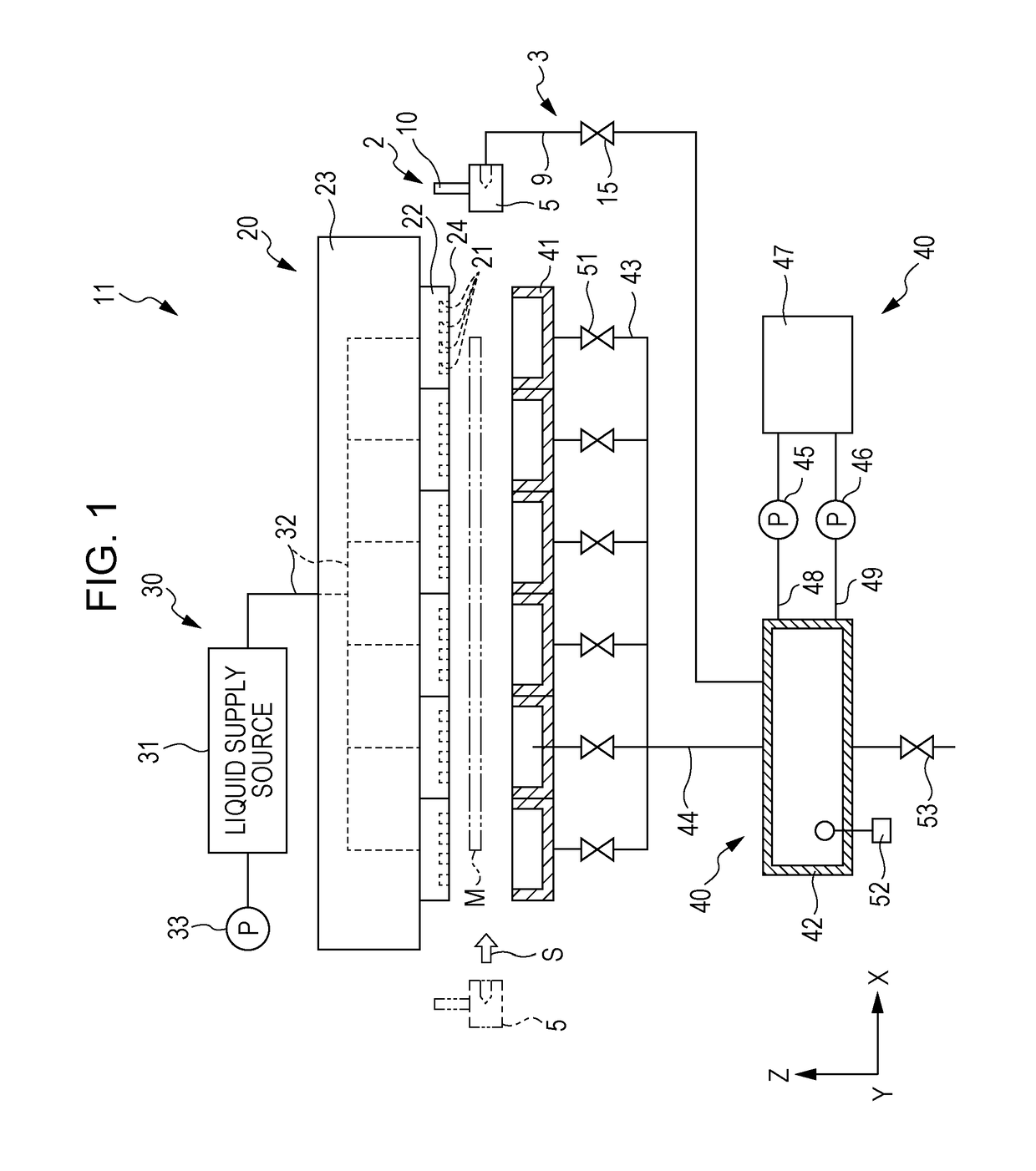

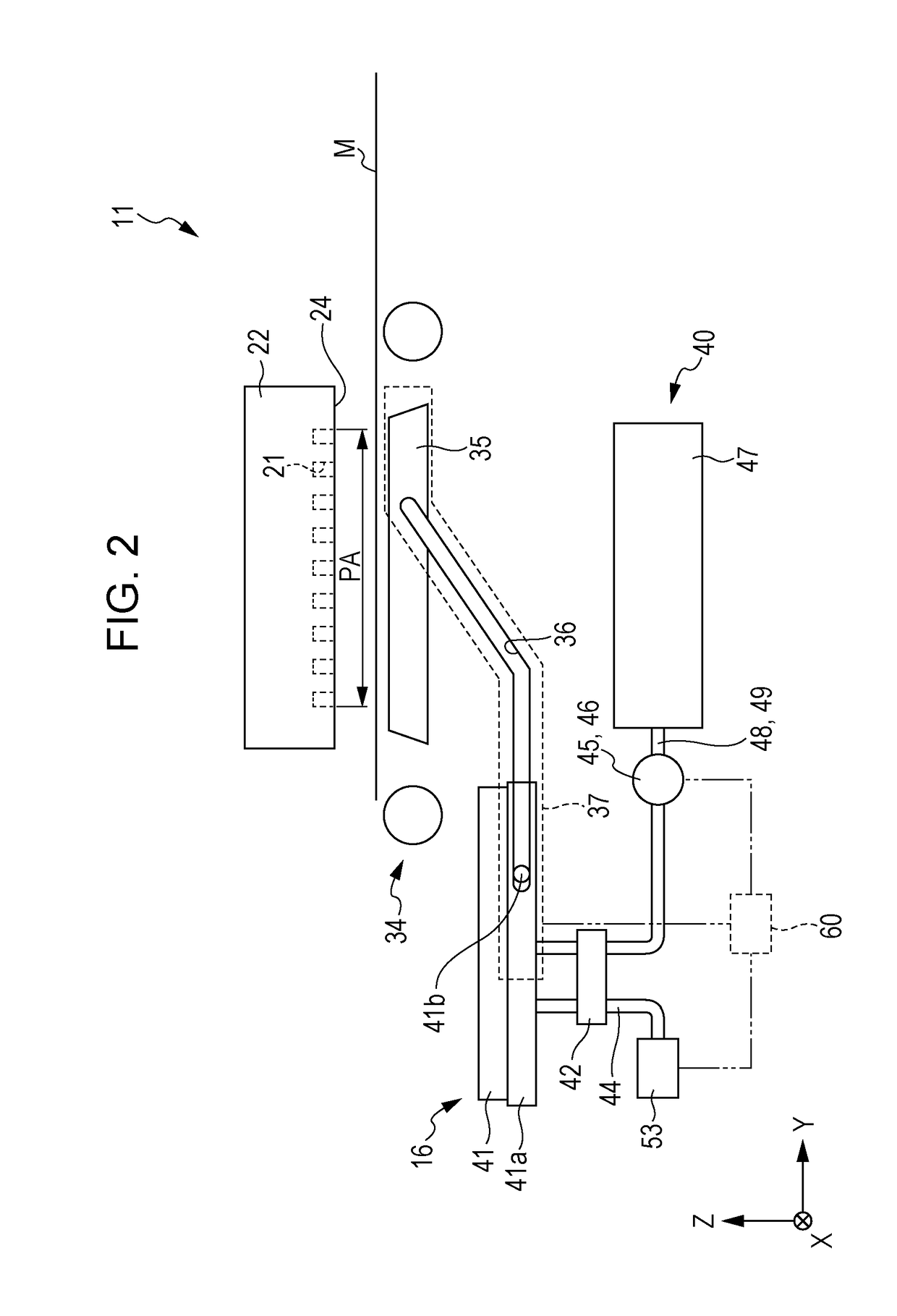

Ink-jet image forming apparatus to maintain a nozzle unit

An ink-jet image forming apparatus includes an ink-jet head having a nozzle unit having a length in a main scanning direction corresponding to a width of a printing medium, a platen to face the nozzle unit, to support a rear side of the printing medium, and to form a paper conveying path, and a wiping unit to clean the nozzle unit. The platen has a printing location in which the paper conveying path is formed, a maintenance location different from the printing location, and a replacement location in which the wiping unit is replaced.

Owner:SAMSUNG ELECTRONICS CO LTD

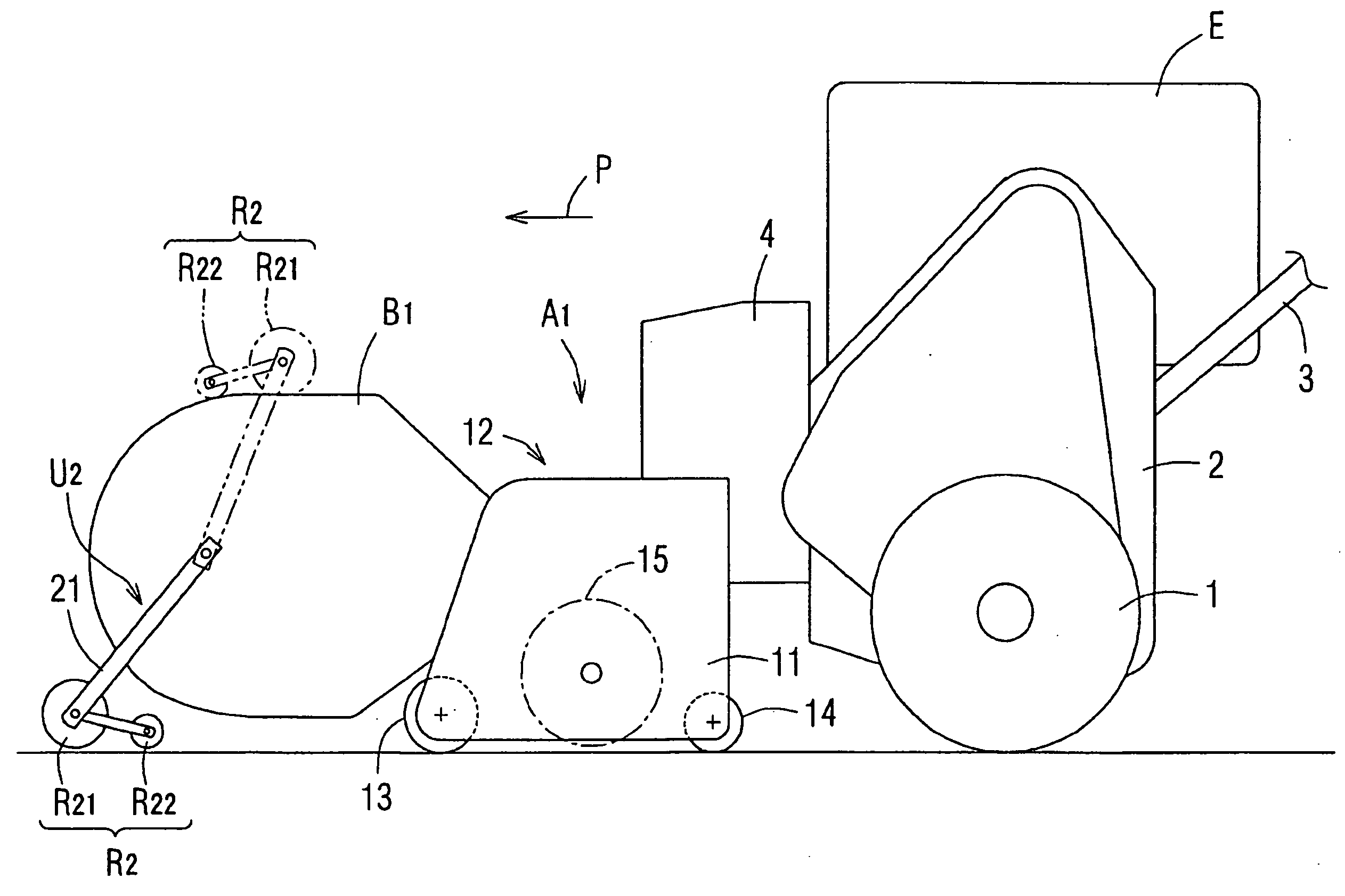

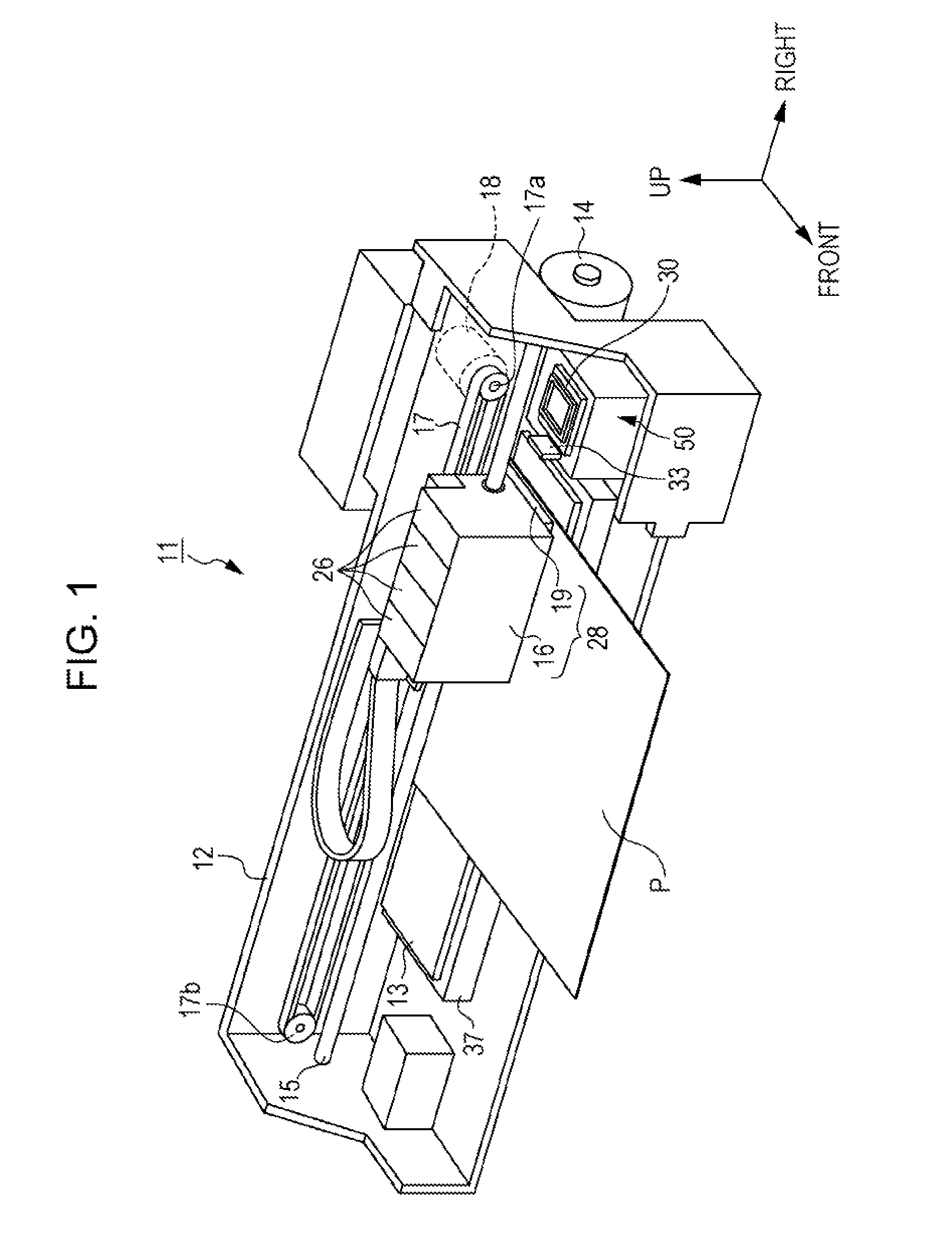

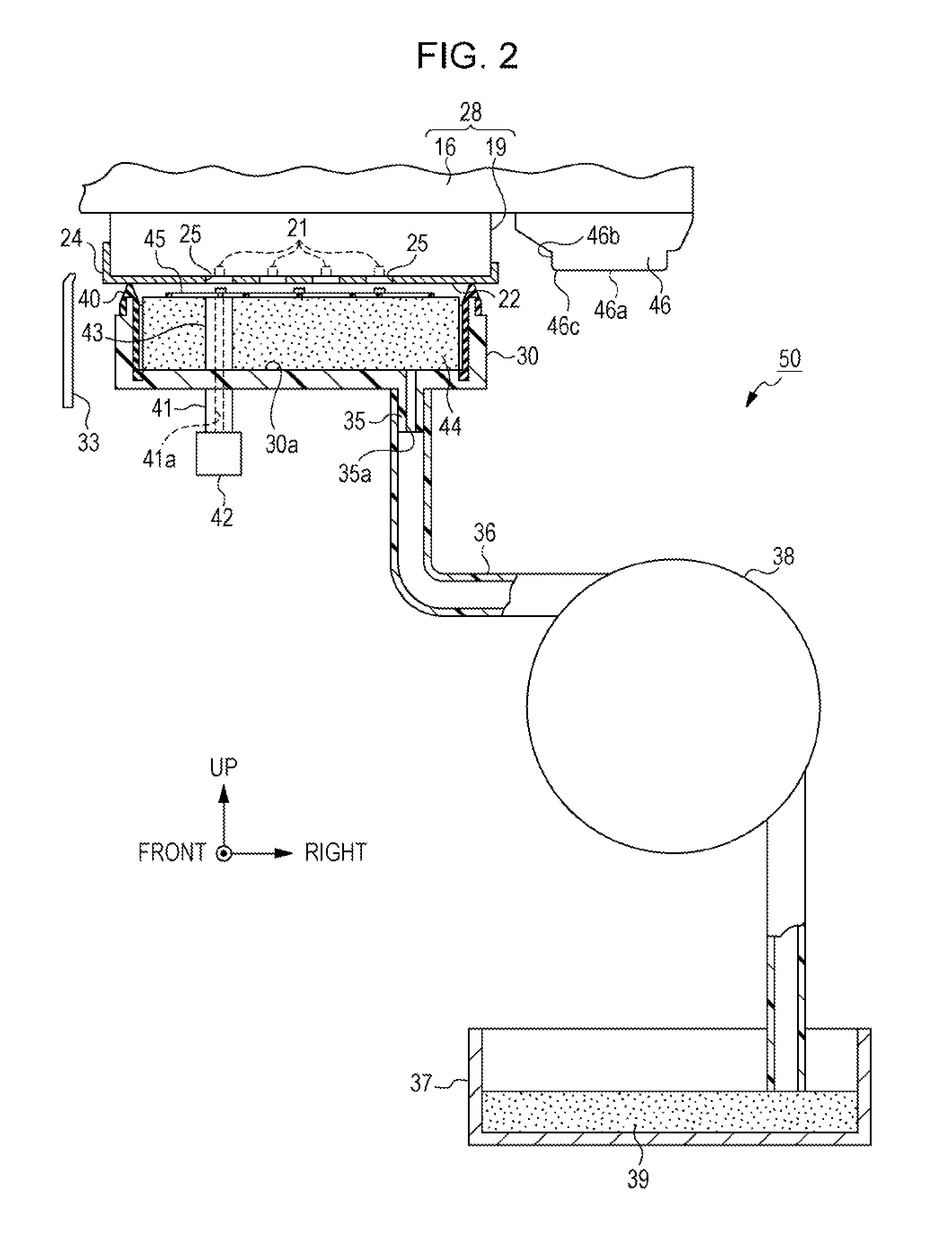

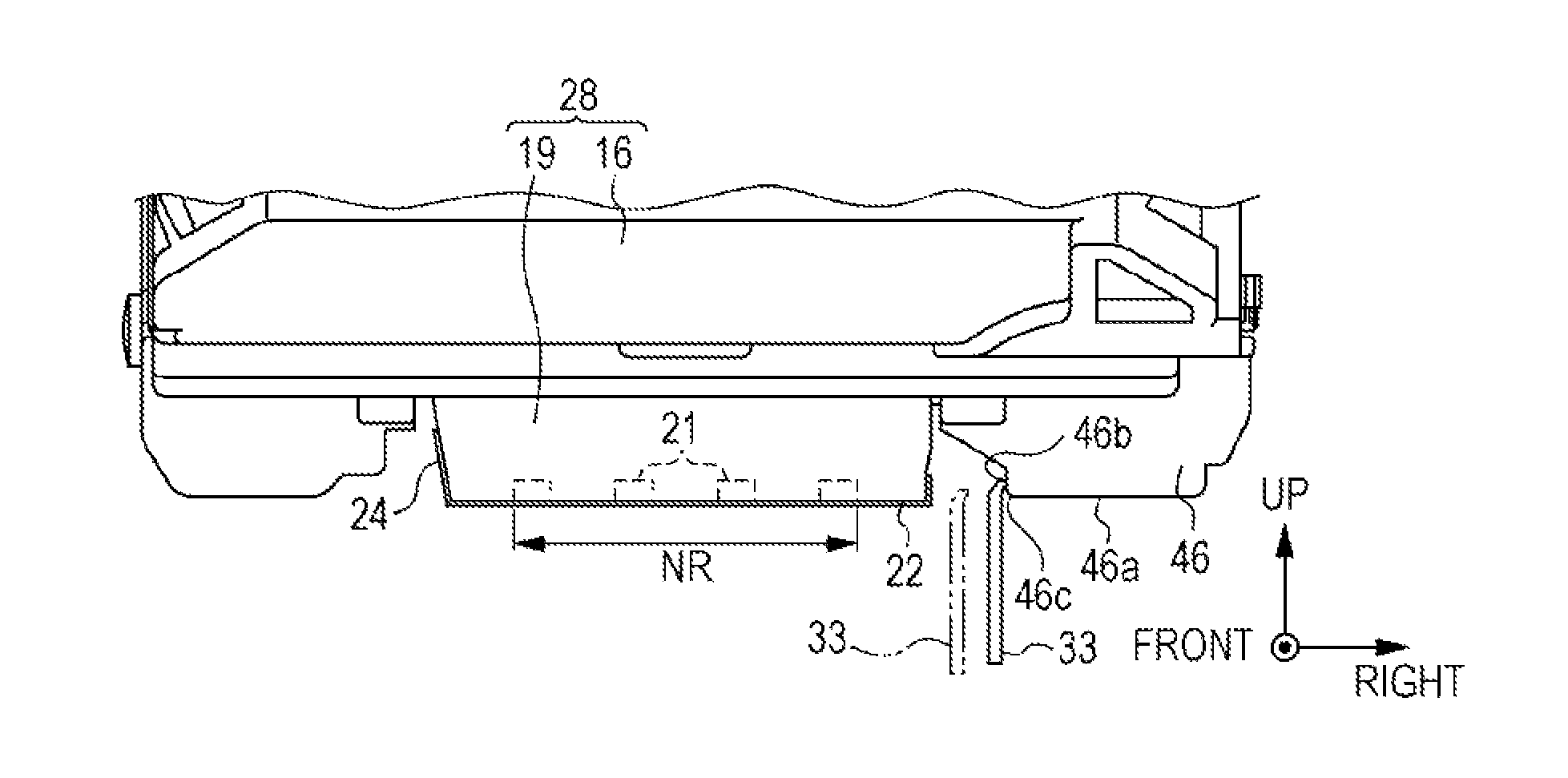

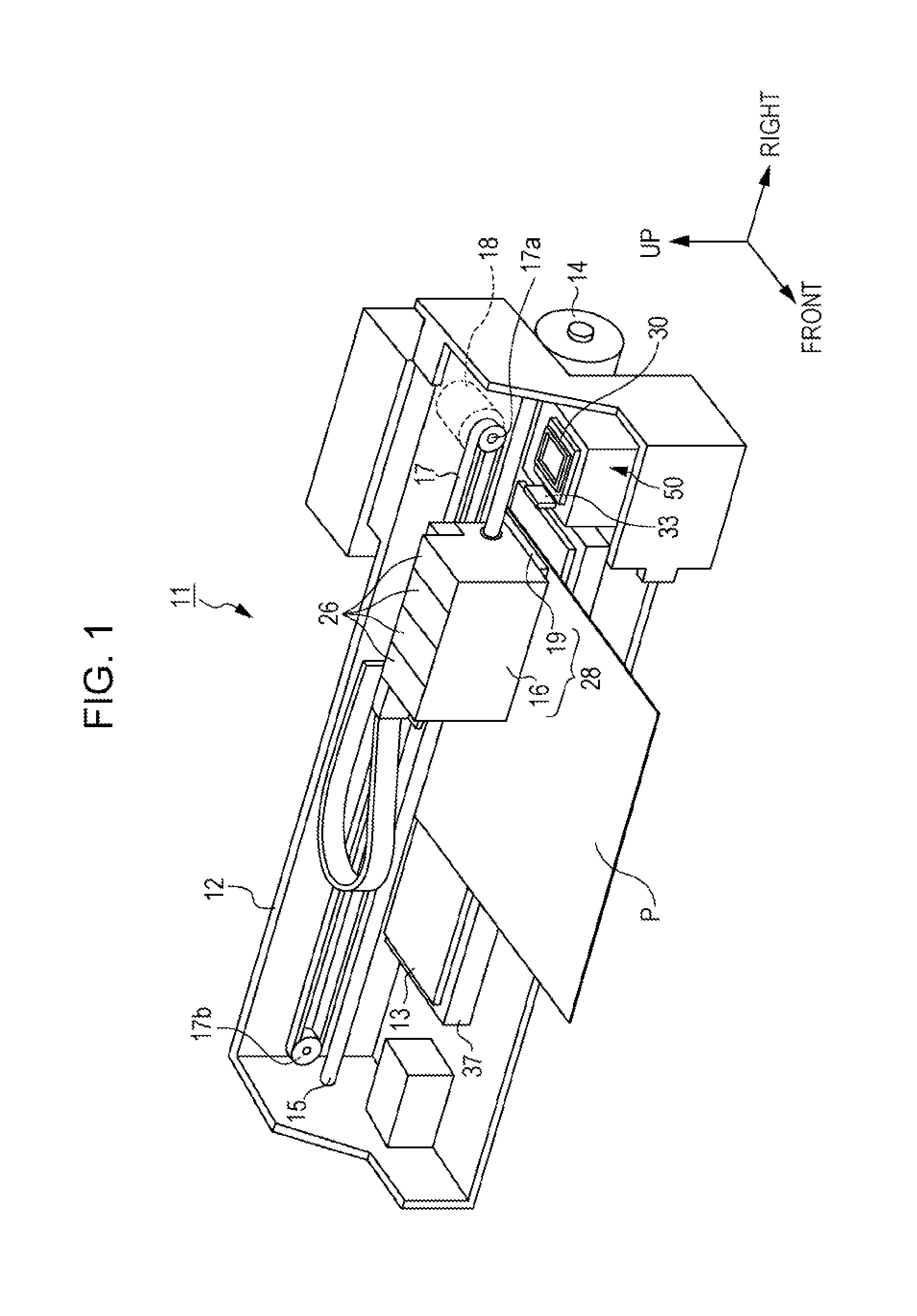

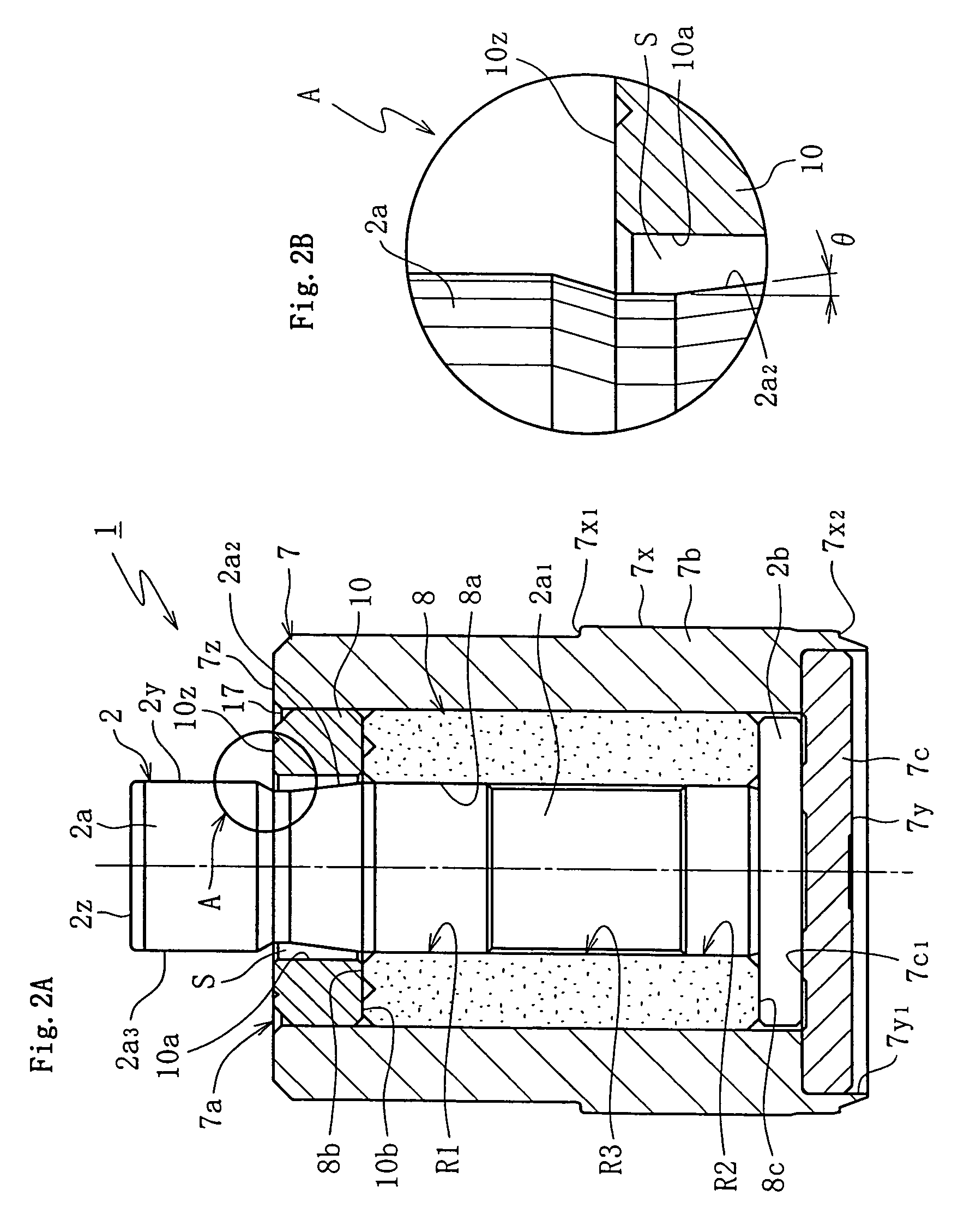

Lawn Mower and Droplet Wiping Roller Unit

A lawn mower comprising a reel cutter type lawn mowing unit (A1) for neatly mowing a lawn by wiping droplets adhered to the lawn without damaging the lawn to increase the mowing rate of the lawn. A pair of right and left arms (21) are rotatably supported on the front part of the housing (12) of the lawn mowing unit (A1), and a roller (R1) for wiping droplets is rotatably supported at the free end parts of the pair of arms (21). Accordingly, the roller (R1) for wiping droplets is disposed at the front of the lawn mowing unit (A1) when used, and when not in use, allowed to retreat to a retreated position at the upper part of the lawn mowing unit (A1) positioned on the diagonal rear upper side of a use position.

Owner:KYOEISHA

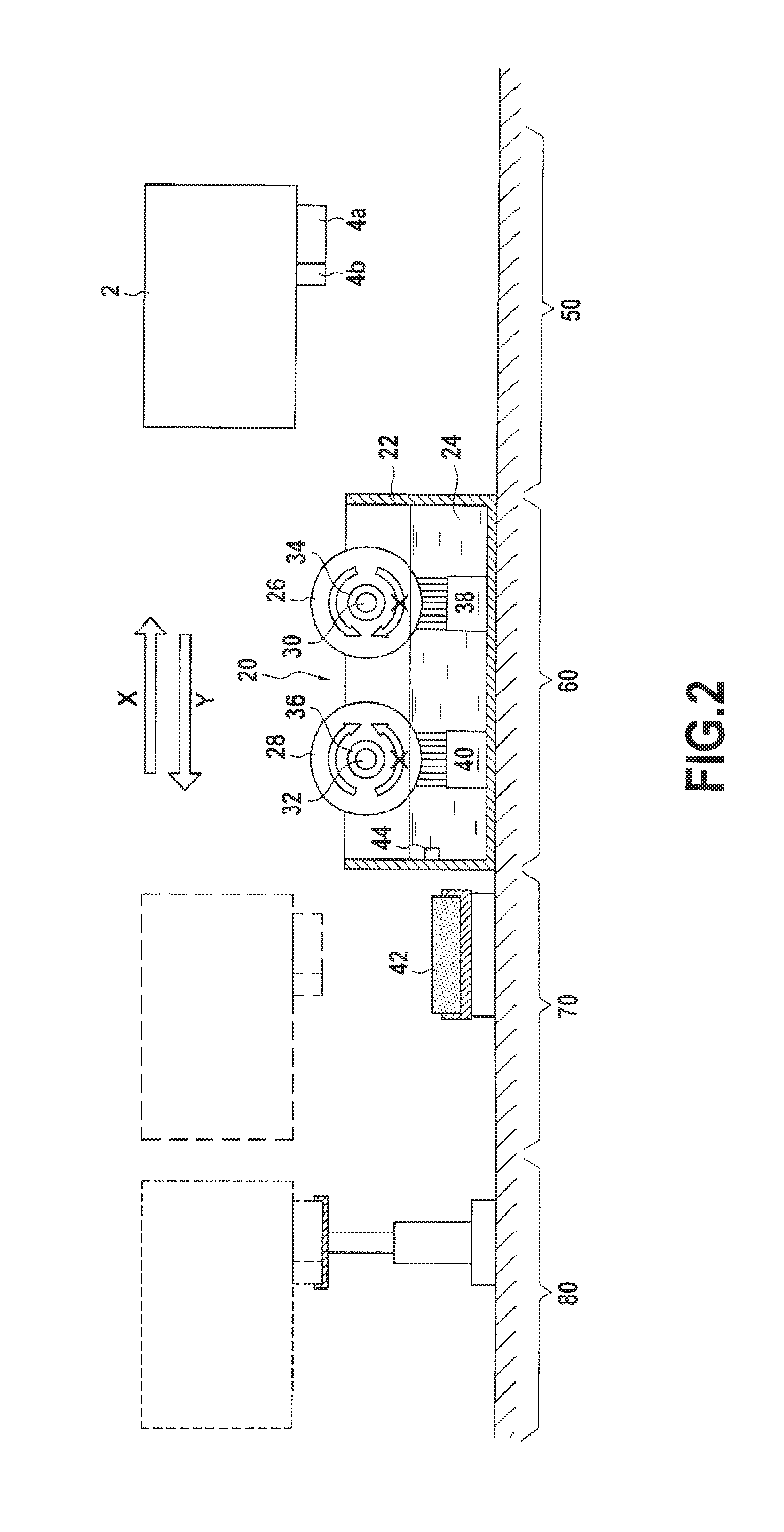

Wiping device for an ink jet franking machine

ActiveUS8752934B2Efficiently and periodically cleaningEasy to cleanFranking apparatusPrintingHead partsNozzle

A wiping device (20) for cleaning outer surfaces of at least one row of ejection nozzles in at least one print head (4a, 4b) of an ink jet printing module (2) of a franking machine when the module is moving above the wiping device in first and second directions (X, Y), comprising two wiping rollers (26, 28) located one behind the other in the first direction and adapted to rotate in opposite directions around respective fixed shafts (30, 32), the two wiping rollers being permanently dampened in contact with a cleaning fluid (24) contained inside a container (22); and the two wiping rollers are adapted via a one-way bearing (34, 36) to remain stationary alternatively, one during the moving of the module in the first direction and the other during the moving of the module in the second direction.

Owner:NEOPOST TECH SA

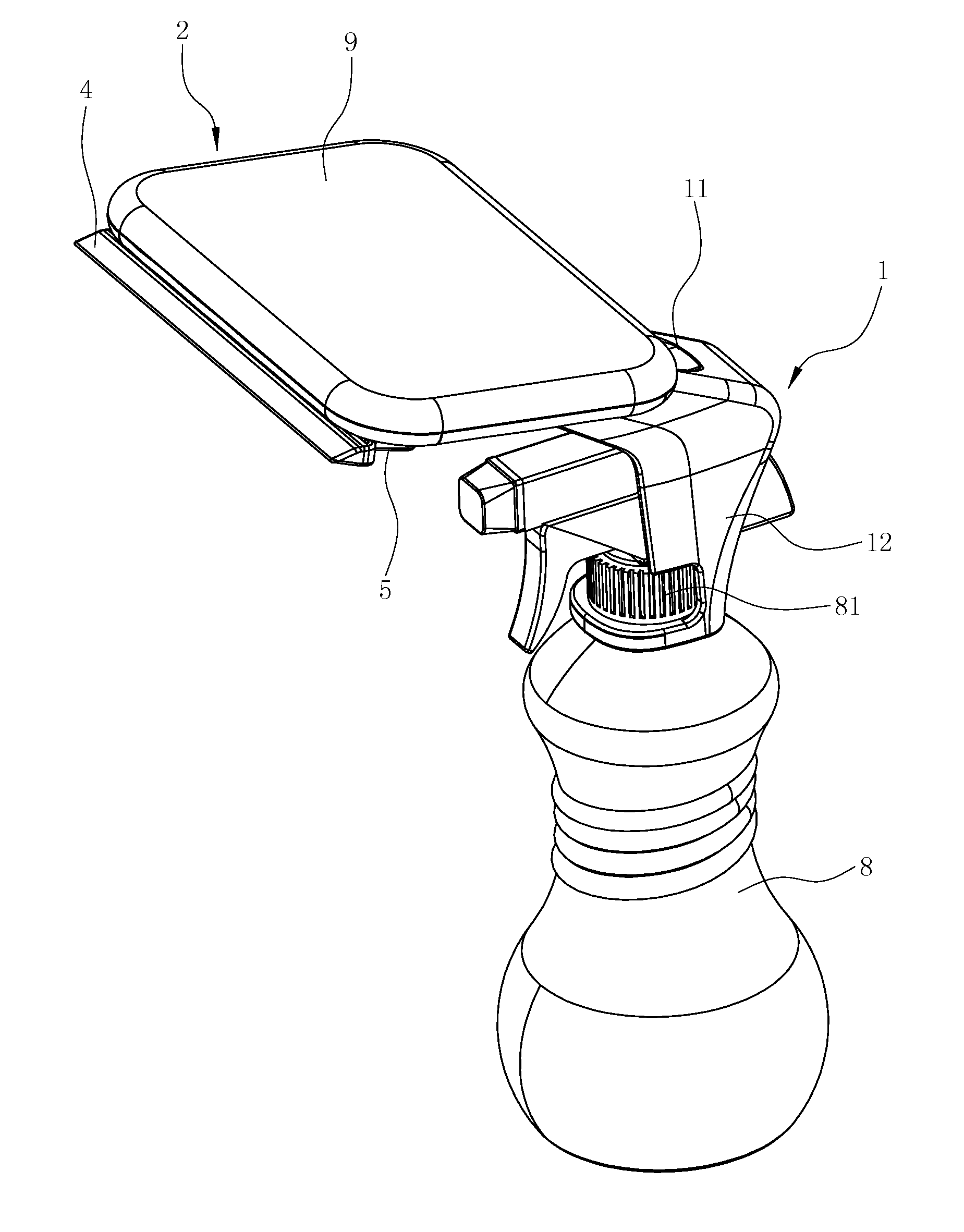

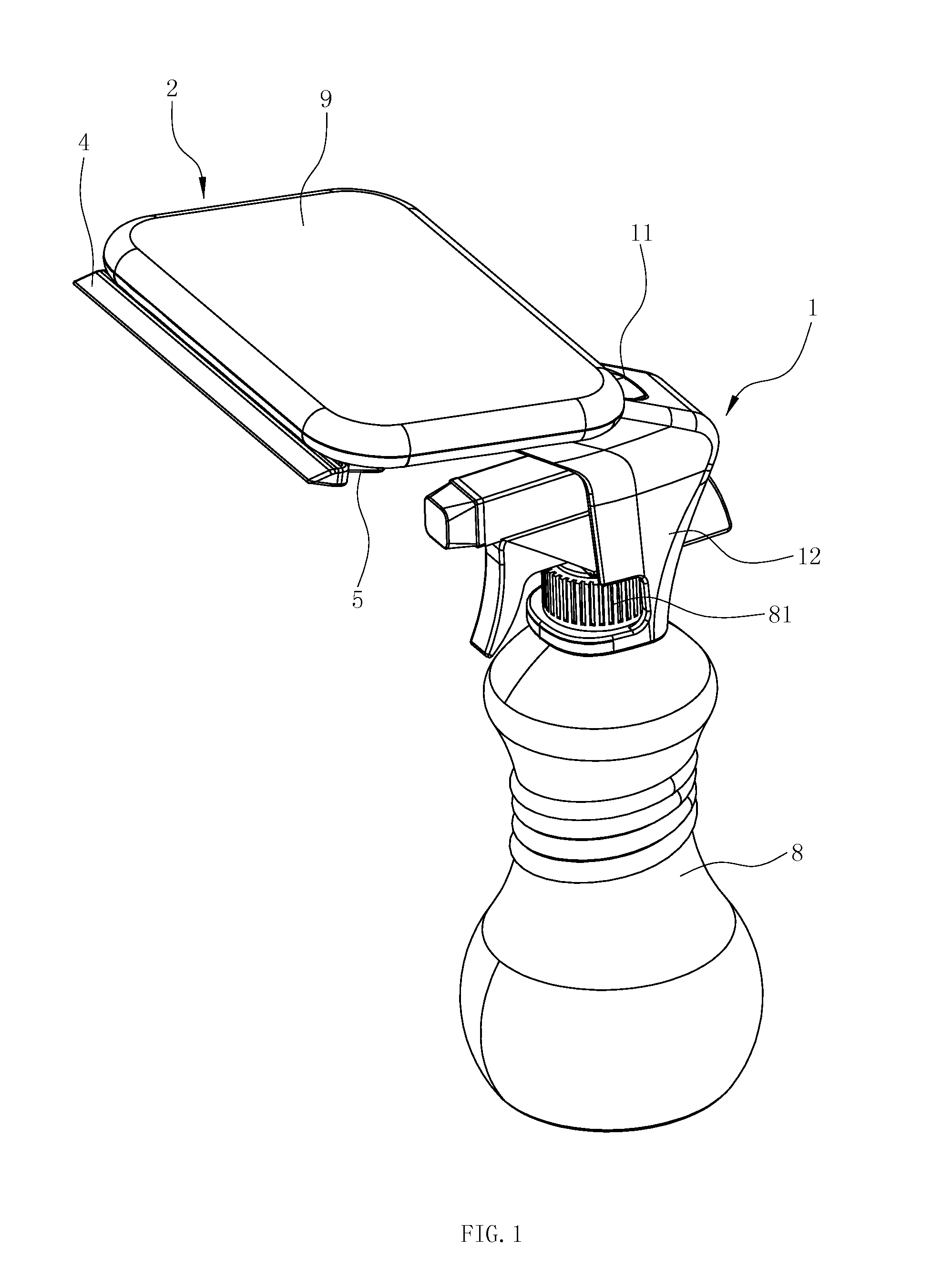

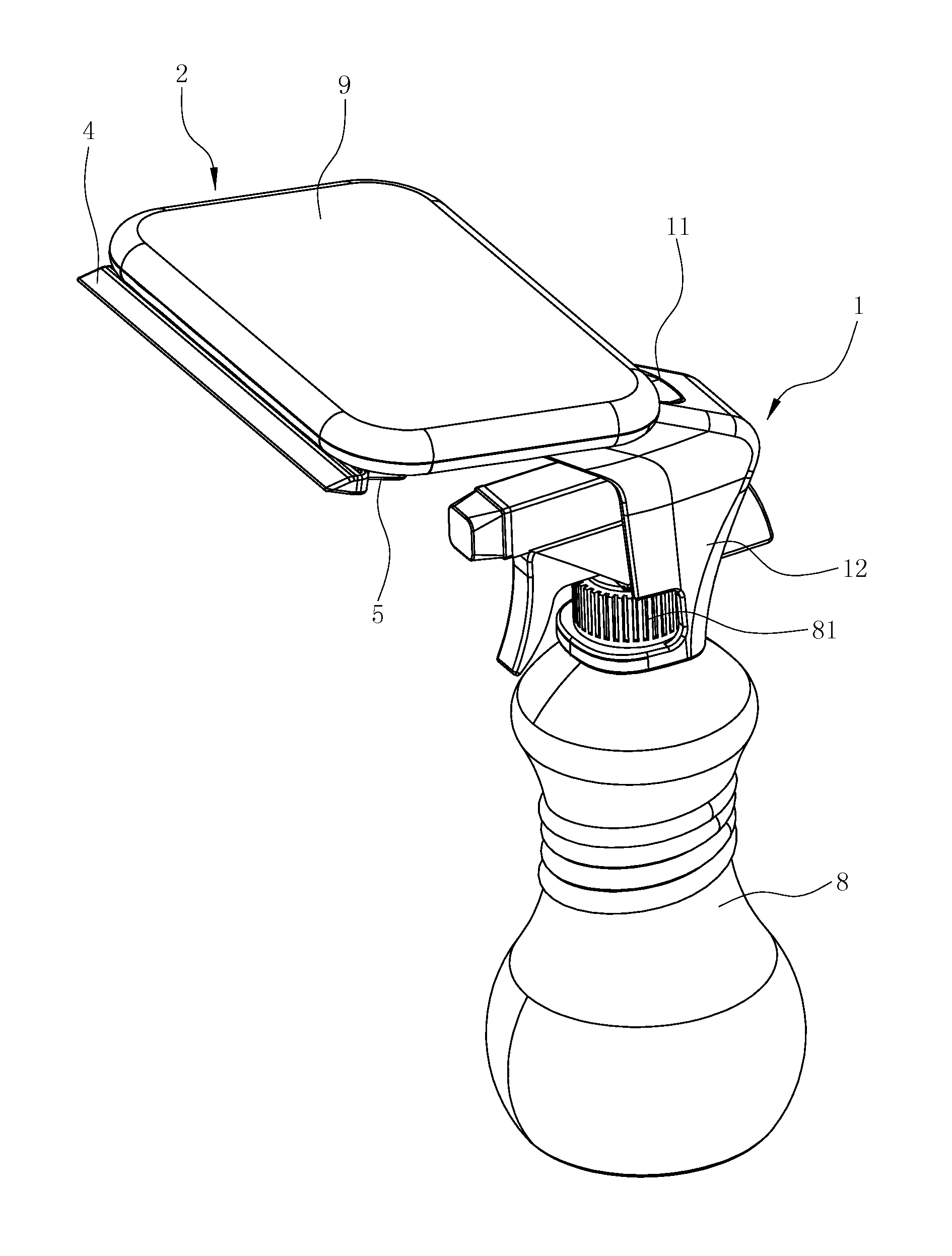

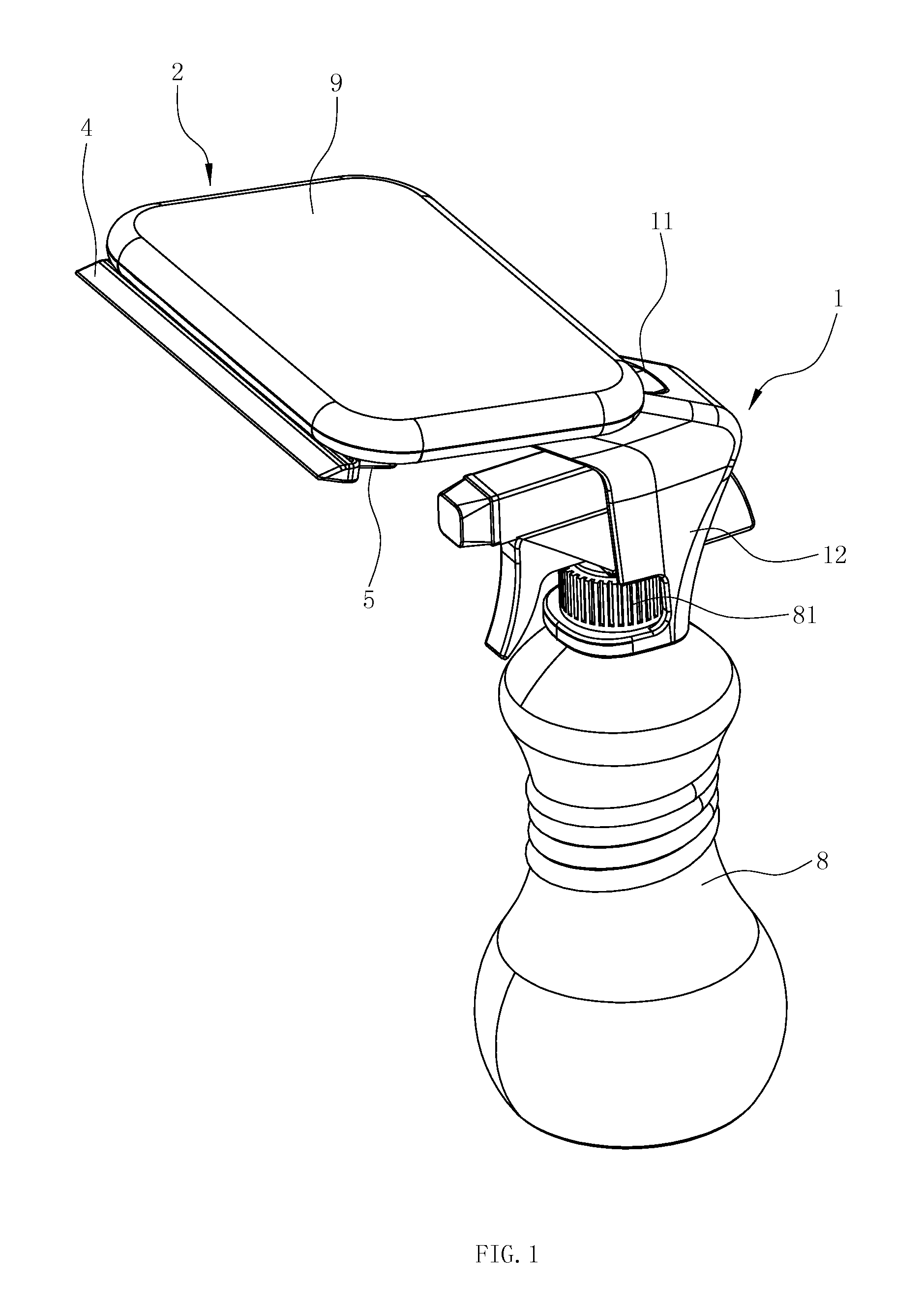

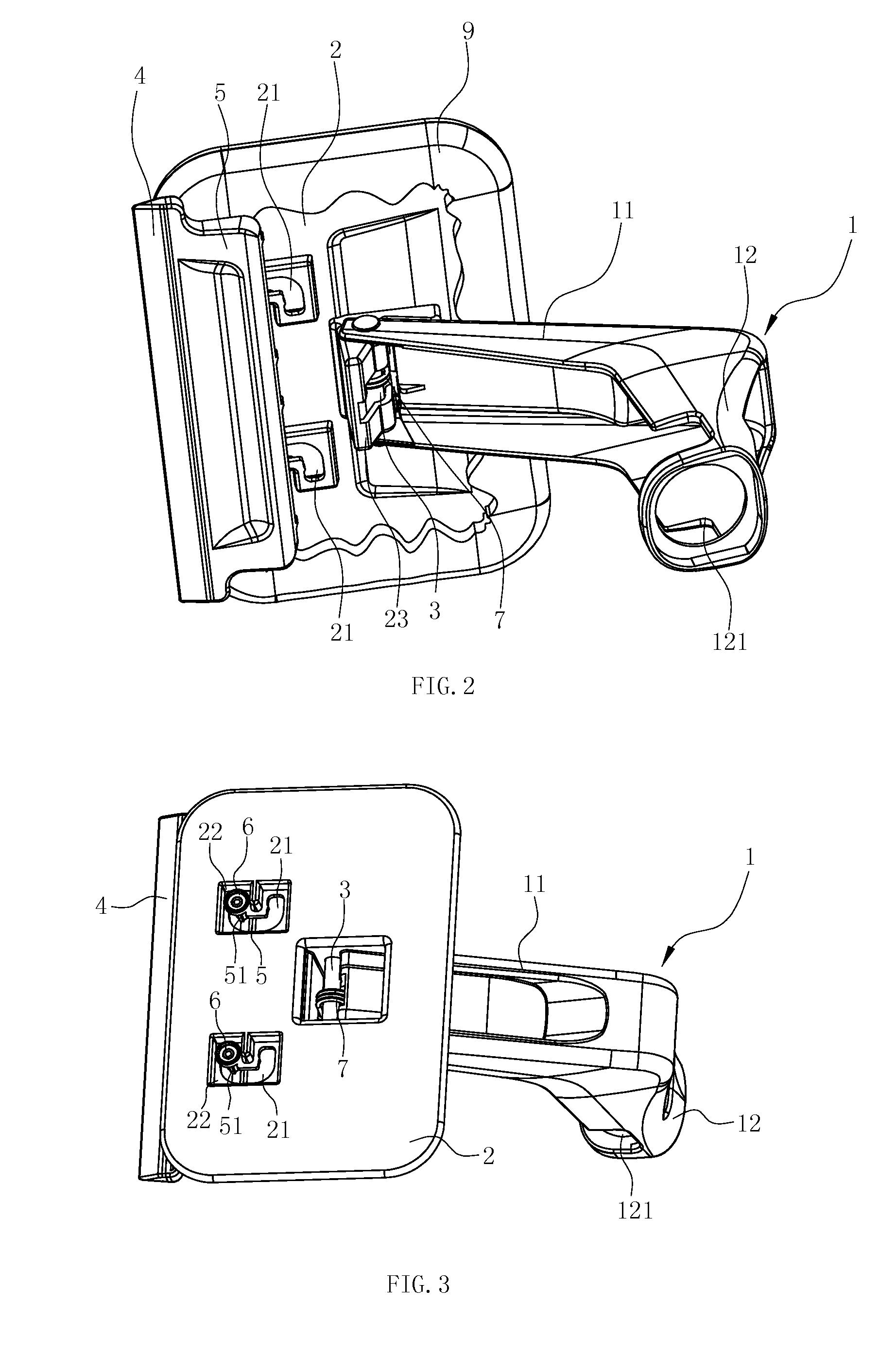

Glass wiper

ActiveUS20140366296A1Simple and reasonable structureEasy to operateCarpet cleanersFloor cleanersEngineering

Owner:NINGBO BEARI PLASTIC PROD & ELECTRIC APPLIANCE CO LTD

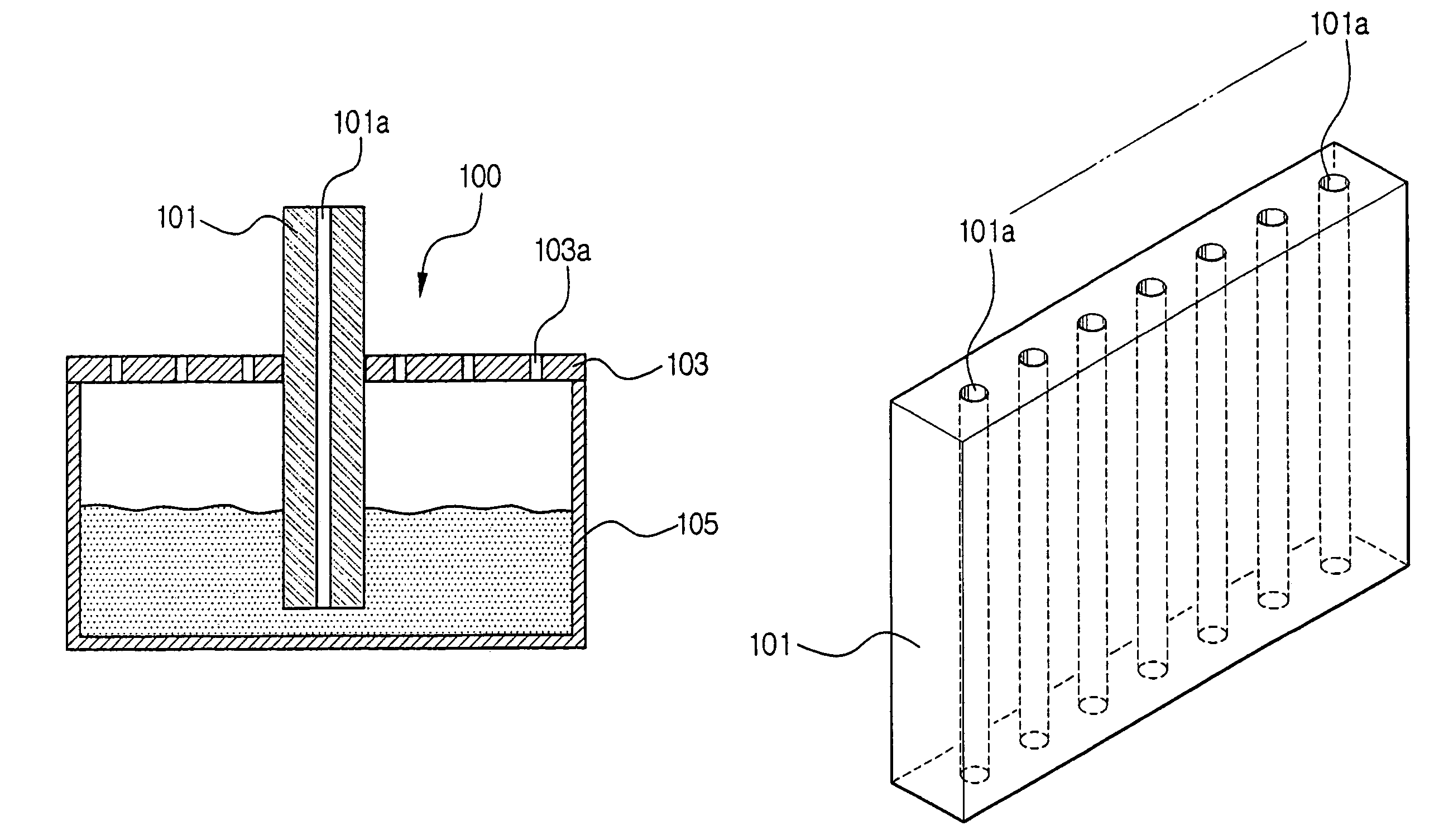

Wet-type wiping apparatus of inkjet printer and maintenance apparatus having the same

A wet-type wiping apparatus of an inkjet printer to clean a print head of the inkjet printer includes a moisture storing portion, a moisture suction portion disposed on an upper side of the moisture storing portion and having a plurality of moisture suction holes, and a wiper portion inserted in the moisture storing portion and having a plurality of capillary tubes vertically penetrating therein. The moisture suction portion includes one of calcium chloride, a silica gel, and a high molecular weight substance, which are highly absorbent. The moisture storing portion includes a foam for containing moisture therein.

Owner:S PRINTING SOLUTION CO LTD

Compartmentalization of the user network interface to a device

ActiveUS9331906B1Efficiently wipeGuaranteed uptimeMemory loss protectionError detection/correctionOperational systemNetwork link

A device has physical network interface port through which a user can monitor and configure the device. A backend process and a virtual machine (VM) execute on a host operating system (OS). A front end user interface process executes on the VM, and is therefore compartmentalized in the VM. There is no front end user interface executing on the host OS outside the VM. The only management access channel into the device is via a first communication path through the physical network interface port, to the VM, up the VM's stack, and to the front end process. If the backend process is to be instructed to take an action, then the front end process forwards an application layer instruction to the backend process via a second communication path. The instruction passes down the VM stack, across a virtual secure network link, up the host stack, and to the backend process.

Owner:NETRONOME SYST

Printhead nozzle face wiper with fibrous pad

ActiveUS7753478B2No longer clean the nozzle face effectivelyReduced service lifePrintingPrint mediaEngineering

A maintenance facility for an inkjet printer has a printhead with an array of nozzles defined in a nozzle face and media feed assembly for moving sheets of print media along a media feed path extending past the printhead in a media feed direction. The printhead maintenance facility has a wiper member having a fibrous pad for wiping the nozzle face and a maintenance drive for moving the wiper member over the printhead in a direction parallel to the media feed direction. During use, the maintenance drive moves the fibrous pad through the media feed path in order to contact the nozzle face.

Owner:MEMJET TECH LTD +1

Liquid ejecting apparatus and wiping method

A liquid ejecting apparatus includes a liquid ejecting unit which includes a nozzle forming surface having nozzle openings for ejecting liquid formed thereon, a wiper which is contactably disposed on the nozzle forming surface, a movement unit which is able to relatively move the liquid ejecting unit and the wiper, and a control unit which controls the movement units such that an interference amount of the wiper and the nozzle forming surface in a position of the wiper which comes in contact with the liquid ejecting unit, is smaller than an interference amount of the wiper and the nozzle forming surface when the wiper is relatively moved through a nozzle region which is a region including the nozzle openings of the nozzle forming surface in a direction along the nozzle forming surface.

Owner:SEIKO EPSON CORP

Wiping method for inkjet recording head

An inkjet recording apparatus to record an image by discharging ink includes a recording head, a processing-liquid transferring unit, a wiper, and a control unit. The recording head includes, at a discharge surface, a first discharge-port row configured to discharge a first ink and a second discharge-port row configured to discharge a second ink. The processing-liquid transferring unit provides processing liquid. The wiper wipes the discharge surface, wherein the wiper includes a first wiper segment positioned to wipe the first discharge-port row and a second wiper segment positioned to wipe the second discharge-port row. The control unit moves the wiper into and out of contact force engagement with the processing-liquid transferring unit, wherein the first wiper segment receives a quantity of processing liquid from the processing-liquid transferring unit that is greater than a quantity of processing liquid received by the second wiper segment from the processing-liquid transferring unit.

Owner:CANON KK

Wiper member for a container

ActiveUS8888392B2Efficiently wipeEliminating the reverse wiping conditionBrushesPackaging toiletriesEngineeringMechanical engineering

Owner:ZEN DESIGN SOLUTIONS

Wiping member, wiping method, and image forming apparatus

A wiping member to wipe a nozzle surface of a liquid discharging head includes a first layer configured to be brought into contact with the nozzle surface and one or more other layers, wherein the following relation is satisfied: t1<t2, where t1 represents the thickness of the first layer and t2 represents the thickness of the one or more other layers, wherein the porosity of the first layer is smaller than the porosity of at least one of the one or more other layers.

Owner:RICOH KK

Wiper member for a container

ActiveUS20120263515A1Efficiently wipeEliminating reverse wiping conditionBrushesPackaging toiletriesEngineeringMechanical engineering

Owner:ZEN DESIGN SOLUTIONS

Liquid ejecting apparatus and wiping method

A liquid ejecting apparatus includes a liquid ejecting unit which includes a nozzle forming surface having nozzle openings for ejecting liquid formed thereon, a wiper which is contactably disposed on the nozzle forming surface, a movement unit which is able to relatively move the liquid ejecting unit and the wiper, and a control unit which controls the movement units such that an interference amount of the wiper and the nozzle forming surface in a position of the wiper which comes in contact with the liquid ejecting unit, is smaller than an interference amount of the wiper and the nozzle forming surface when the wiper is relatively moved through a nozzle region which is a region including the nozzle openings of the nozzle forming surface in a direction along the nozzle forming surface.

Owner:SEIKO EPSON CORP

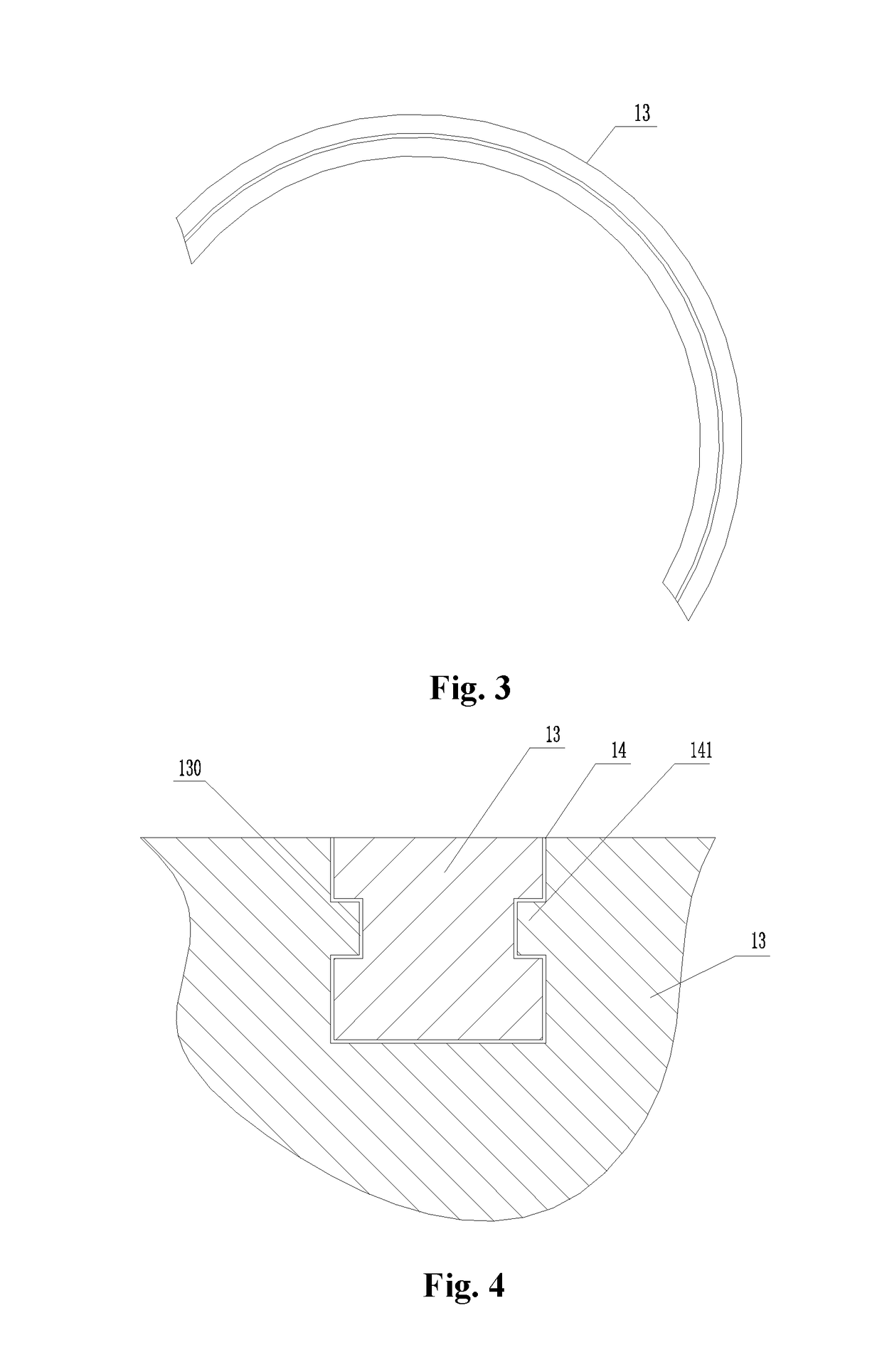

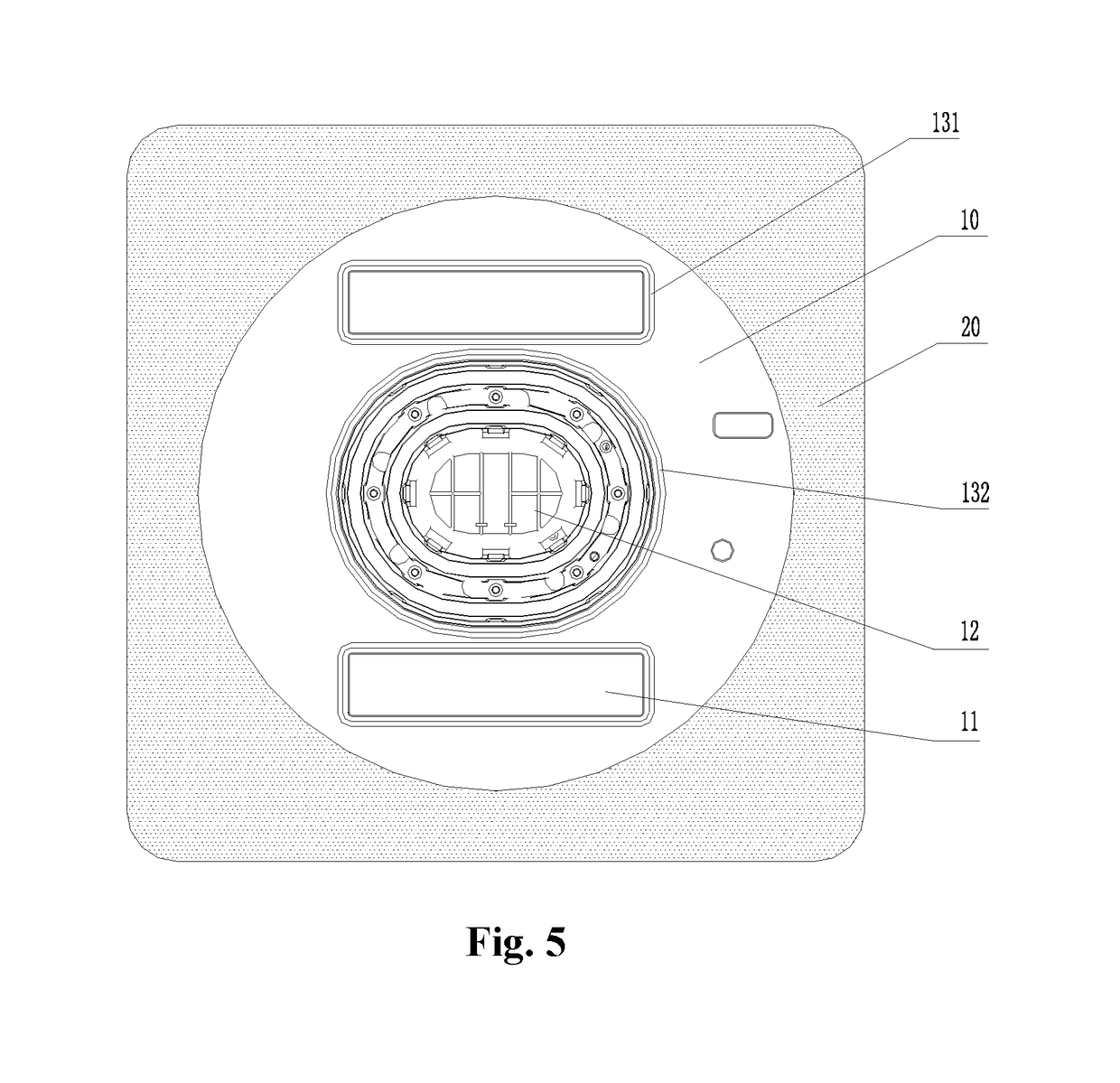

Window-cleaning robot provided with closed wiper

ActiveUS10213073B2Efficiently wipeEffectively preventing the robot from slippingCleaning equipmentWindow cleanersEngineeringRobot

A window-cleaning robot provided with a closed wiper (13), comprising a rotating base (10) and an outer frame (20); said rotating base (10) being rotatably disposed on the outer frame (20); the bottom of said outer frame (20) being provided with a cleaning unit (21); said rotating base (10) being provided with a travel unit (11) and a suction cup (12); the bottom surface of the rotating base (10) also being provided with a wiper (13); said wiper (13) being disposed on the bottom surface such that the wiper (13) surrounds the rotating base (10) in a closed shape; the travel unit (11) and / or the suction cup (12) being enclosed within said closed shape. The wiper (13) is entirely closed such that regardless of where the robot travels, 360° wiping can be accomplished, effectively preventing the travel unit (11) and the suction cup (12) from becoming wet, resulting in more effective wiping and effectively preventing slippage.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Liquid ejecting apparatus and wiping method thereof

There is provided a liquid ejecting apparatus including a liquid ejecting unit that has a nozzle row configured to have a plurality of nozzles lined up along a first direction, and a wiping portion that moves in a second direction intersecting the first direction such that the liquid ejecting unit is wiped, in which the liquid ejecting unit includes a plurality of nozzle rows configured to have space therebetween in the second direction, a convex portion placed between the nozzle rows in the second direction, and flat portions placed at both sides of the convex portion in the first direction, and the wiping portion wipes at a first relative travel speed to collect liquid attached to the liquid ejecting unit to the flat portion, and then wipes at a second relative travel speed faster than the first relative travel speed to move liquid attached to the flat portion.

Owner:SEIKO EPSON CORP

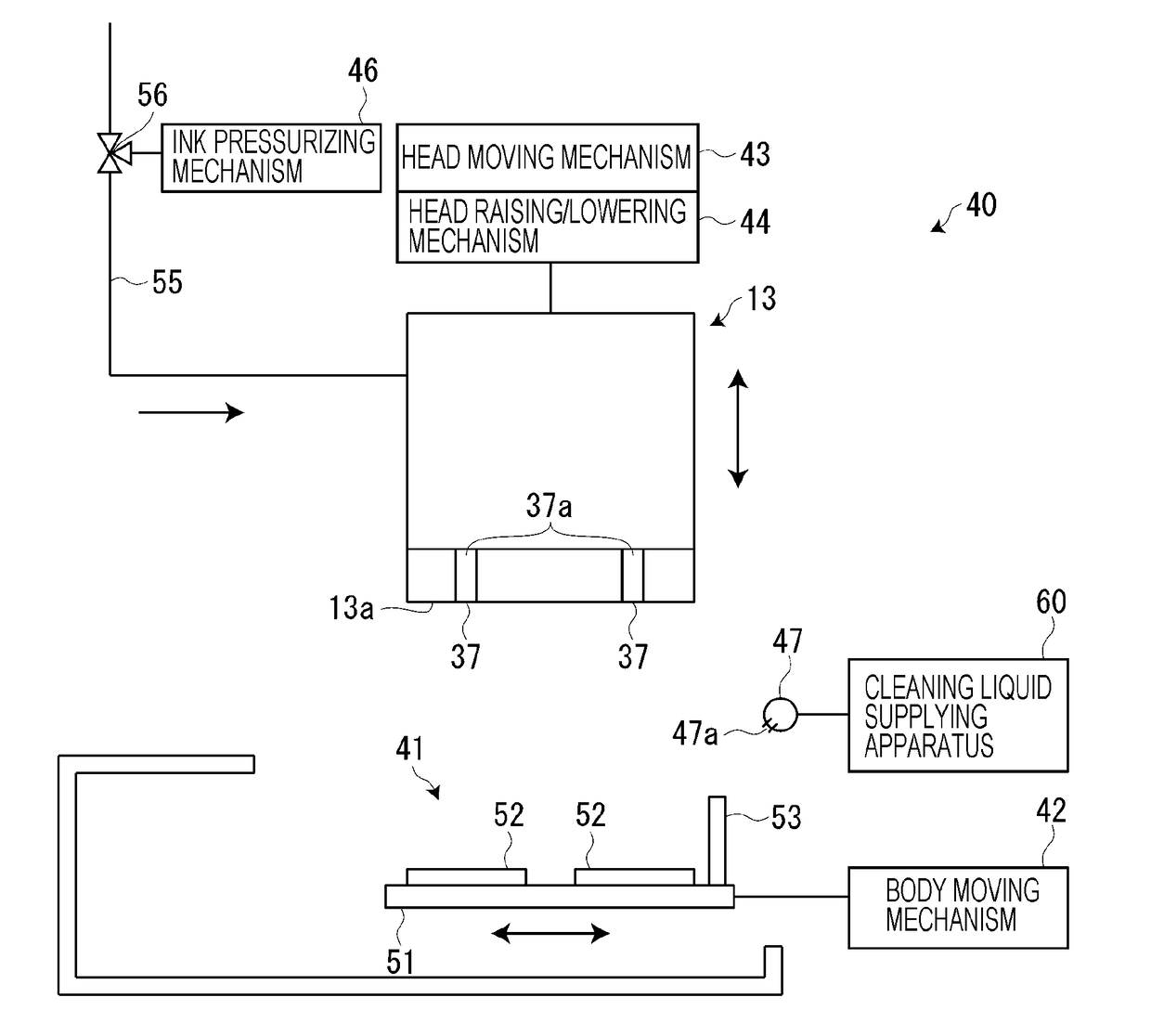

Cleaning liquid supplying apparatus and liquid droplet ejecting apparatus including the same

ActiveUS20170274660A1Nozzle surface can be efficientlyEfficiently wipePower drive mechanismsEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

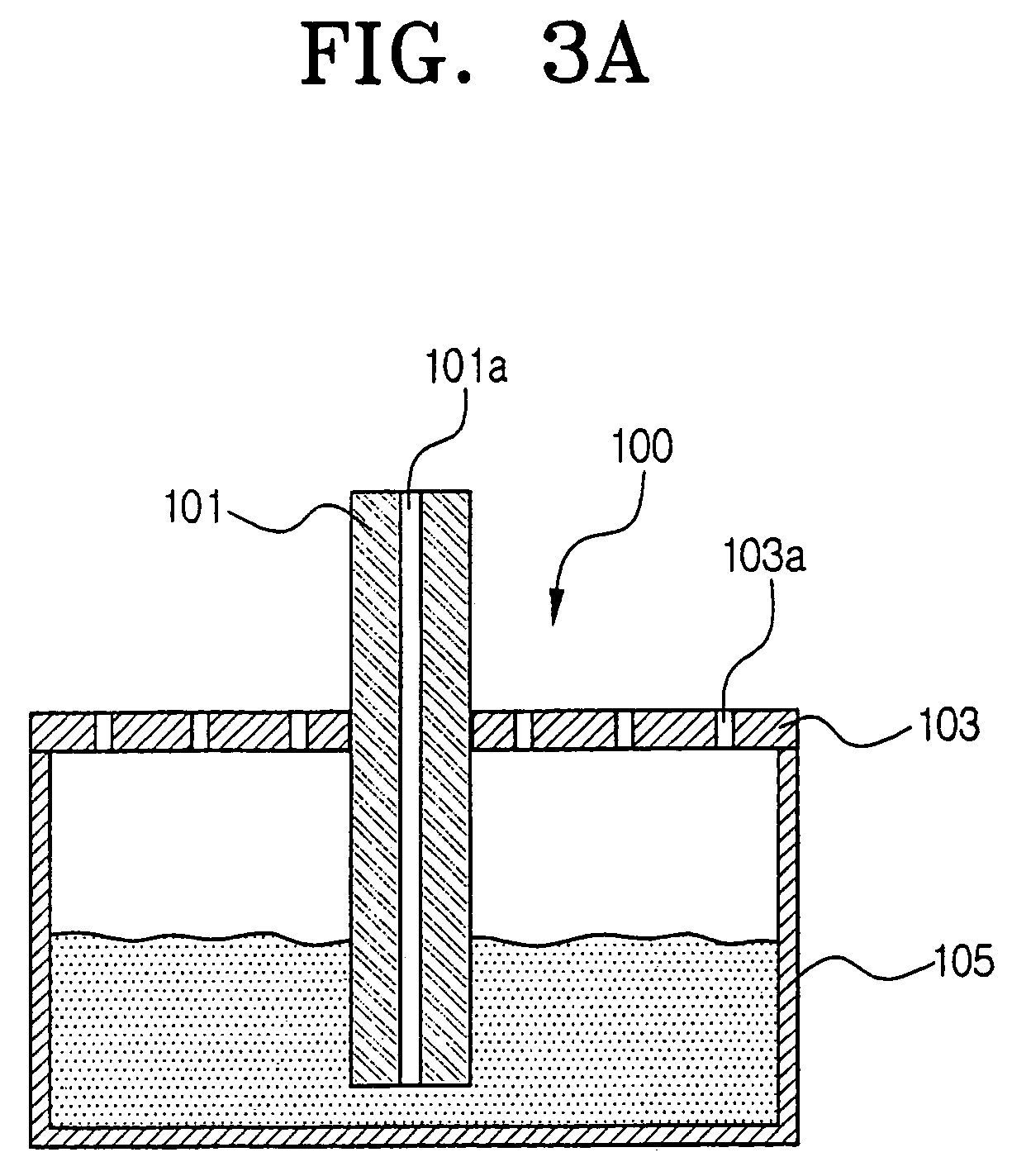

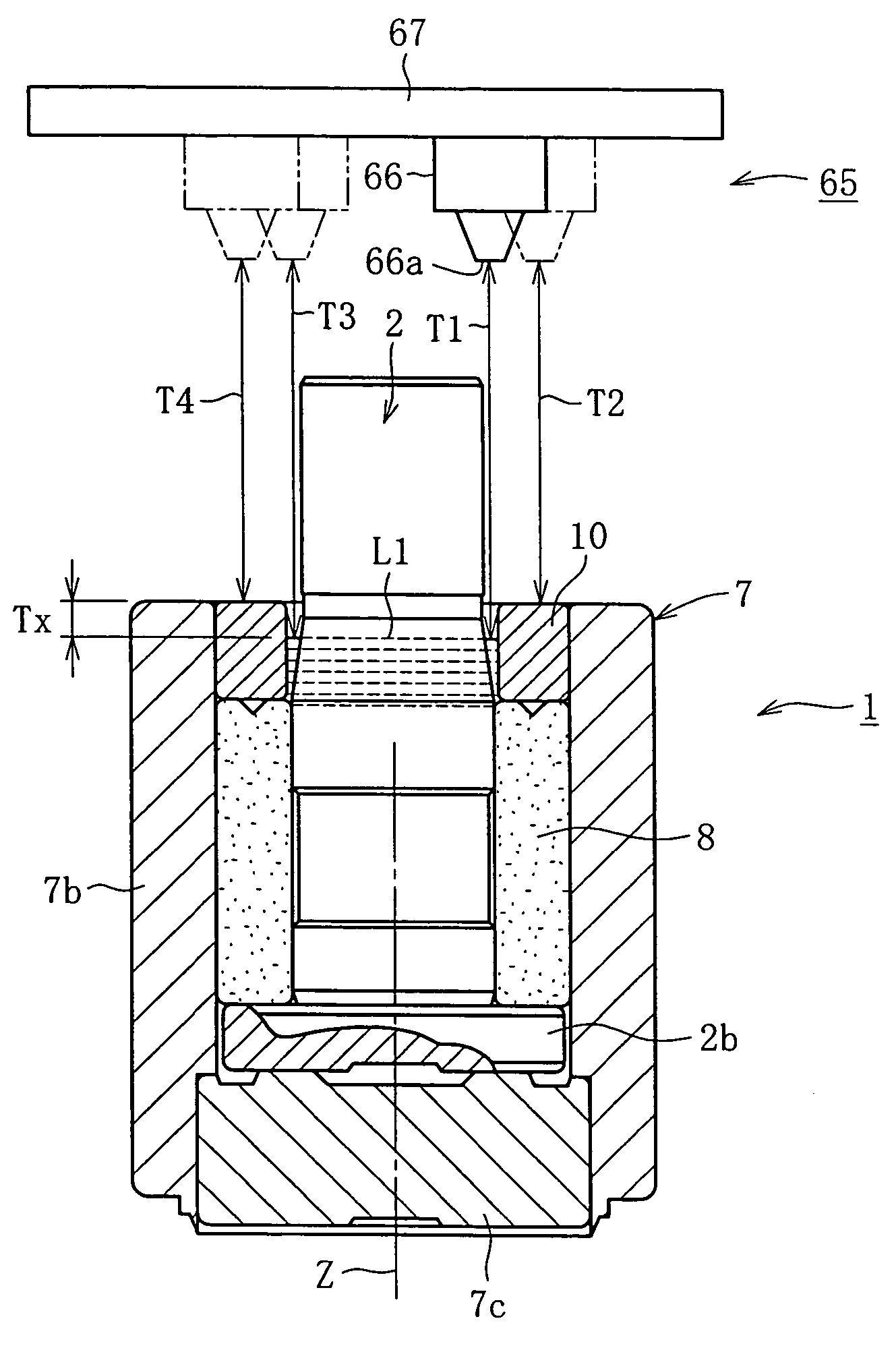

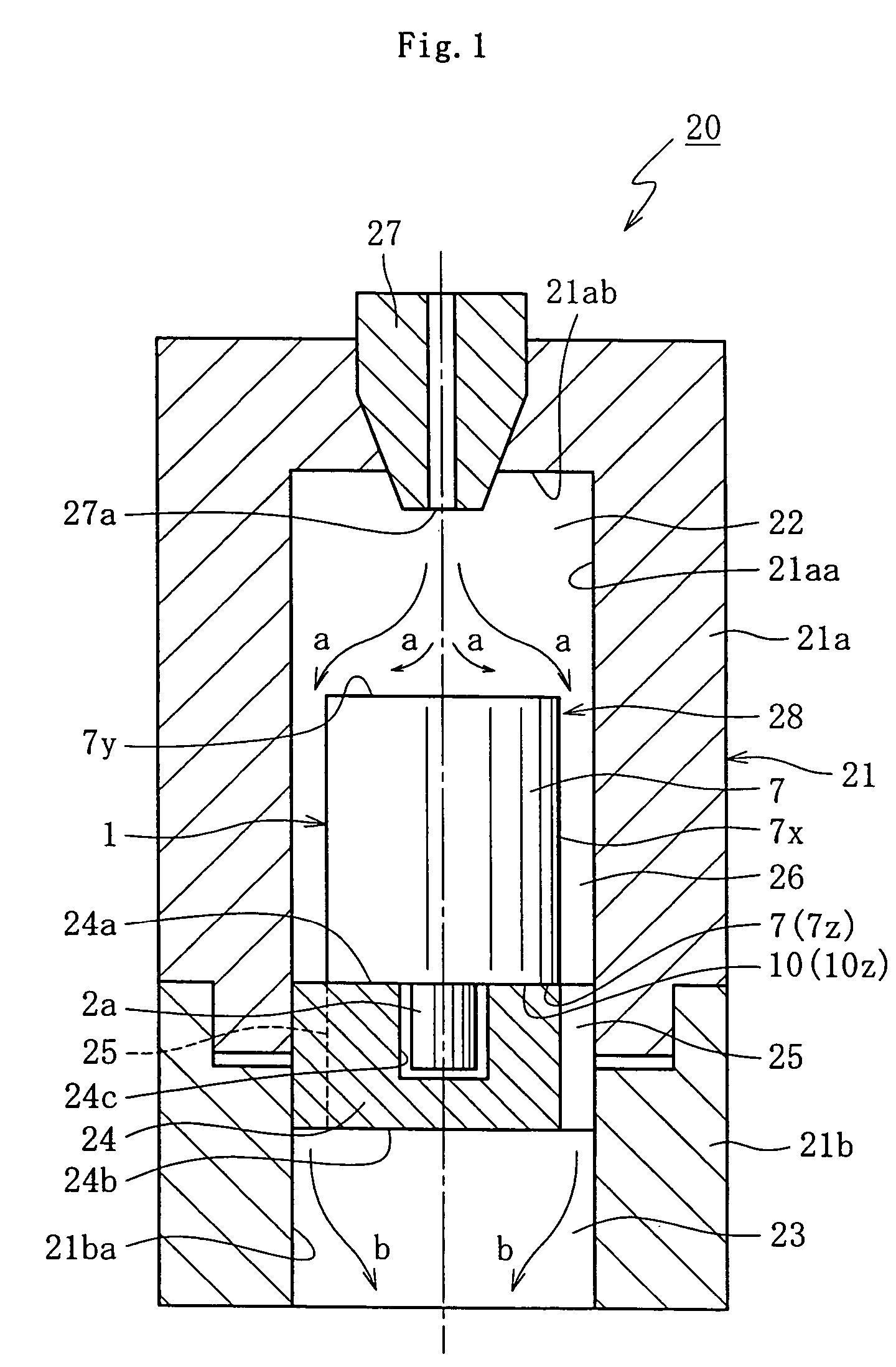

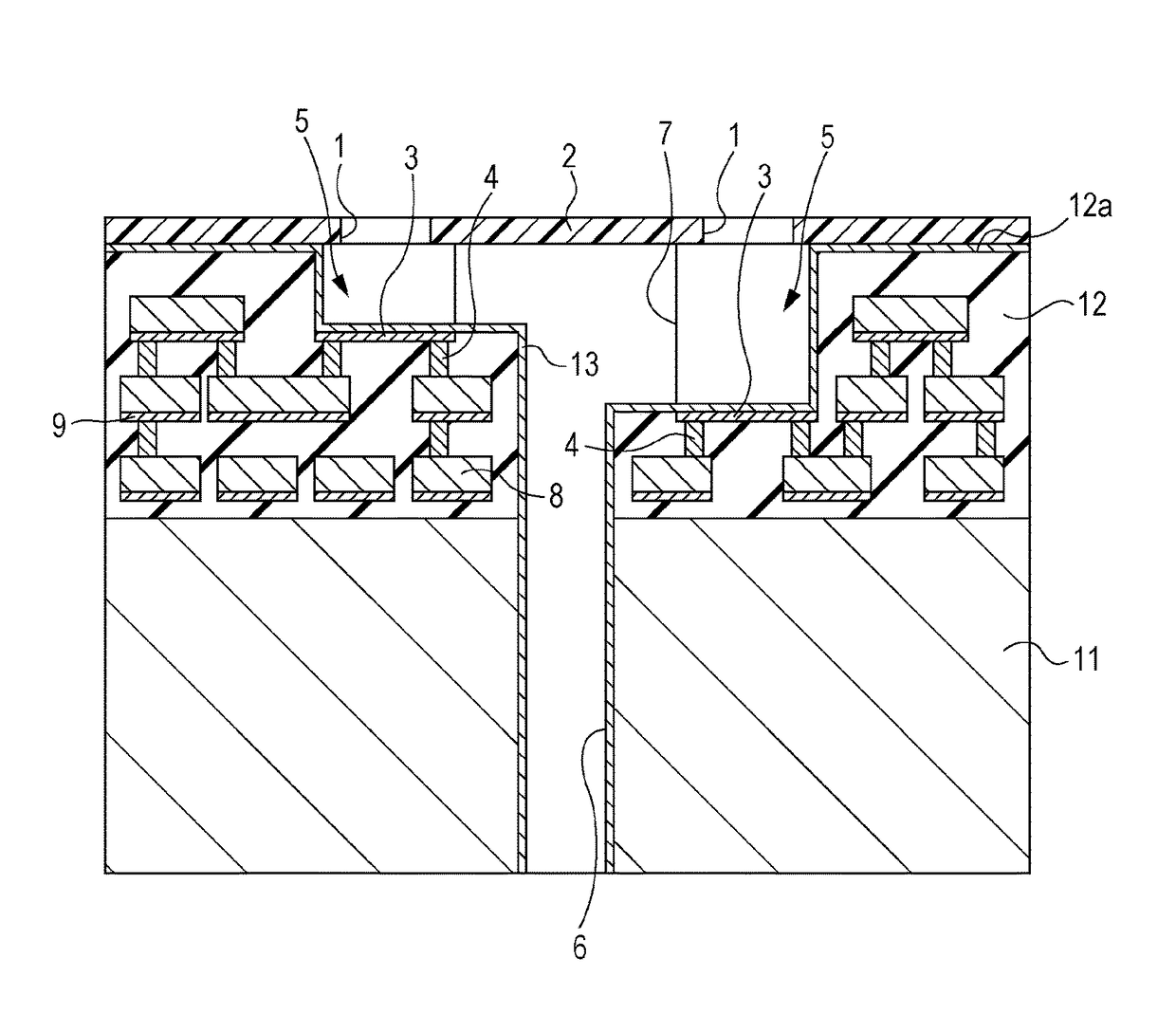

Method for manufacturing hydro dynamic bearing device

ActiveUS7600320B2Efficiently wipeBearing assemblyUsing optical meansMechanical engineeringDynamic pressure

A method for manufacturing a hydro dynamic bearing device is provided for the finishing treatment of lubricating oil after lubricating the hydro dynamic bearing device. The hydro dynamic bearing is constructed of an axial member housed in a housing, a radial bearing part for supporting the axial member in a non-contact manner in a radial direction by a hydro dynamic pressure action of the lubricating oil generated in a radial bearing clearance, and a sealing part arranged in an opening part of the housing, and the method has the step of measuring the oil-level height of the lubricating oil in the housing by a laser detector.

Owner:NTN CORP

Compartmentalization of the user network interface to a device

ActiveUS8918868B2Efficiently wipeGuaranteed uptimeResource allocationMemory loss protectionPathPingNetwork link

A device has physical network interface port through which a user can monitor and configure the device. A backend process and a virtual machine (VM) execute on a host operating system (OS). A front end user interface process executes on the VM, and is therefore compartmentalized in the VM. There is no front end user interface executing on the host OS outside the VM. The only management access channel into the device is via a first communication path through the physical network interface port, to the VM, up the VM's stack, and to the front end process. If the backend process is to be instructed to take an action, then the front end process forwards an application layer instruction to the backend process via a second communication path. The instruction passes down the VM stack, across a virtual secure network link, up the host stack, and to the backend process.

Owner:NETRONOME SYST

Liquid discharge head and method for manufacturing the same

A method for manufacturing a liquid discharge head that includes a discharge-port-forming member, which has discharge ports through which a liquid is discharged, and a pressure-chamber-forming member, which includes pressure chambers communicating with the discharge ports and each including a heating resistor formed in a bottom portion thereof and which has a surface joined to the discharge-port-forming member, includes preparing the pressure-chamber-forming member in which wiring layers each including a barrier metal as a base member are formed, forming the pressure chambers, whose depths from the surface are different from each other and which include the heating resistors each formed of one of the barrier metals, by recessing the pressure-chamber-forming member from the surface and removing at least two of the wiring layers, which are formed at different positions in a depth direction from the surface, to expose the corresponding barrier metals, and forming the discharge-port-forming member on the surface.

Owner:CANON KK

Liquid ejecting apparatus

InactiveUS20180194138A1Preventing an apparatus inner portion from being soiledDischarging liquid removedPrintingHead partsNozzle

A liquid ejecting apparatus includes a liquid ejecting head having a nozzle which ejects a liquid onto a medium, a wiping member that wipes the liquid which has adhered to a nozzle forming surface of the liquid ejecting head, a support member that supports the wiping member, moves the wiping member relative to the liquid ejecting head, and has a receiving portion receiving the liquid wiped by the wiping member, and a connection flow path that is capable of being connected to the support member, wherein the receiving portion and the connection flow path communicate with each other with movement of the support member.

Owner:SEIKO EPSON CORP

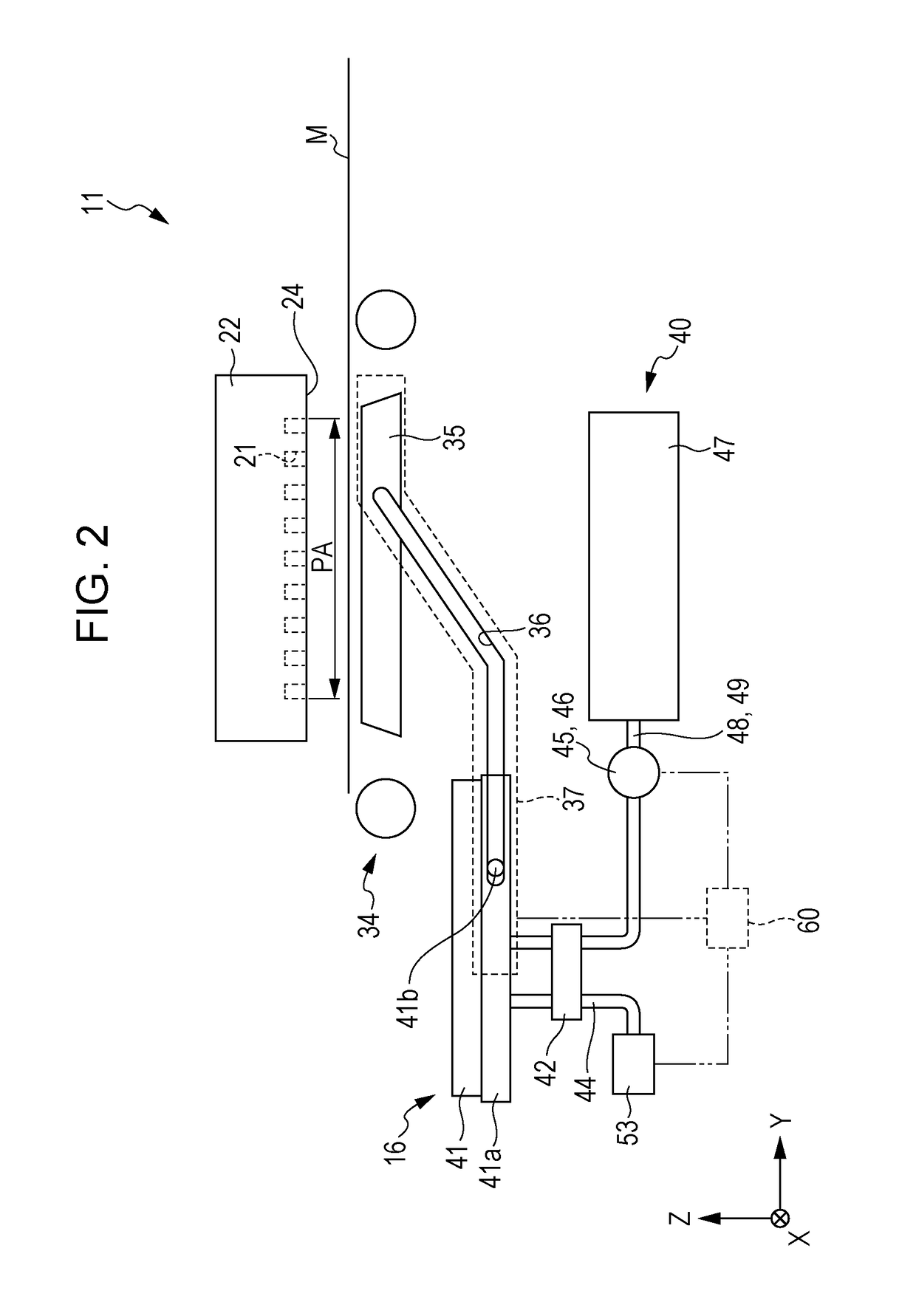

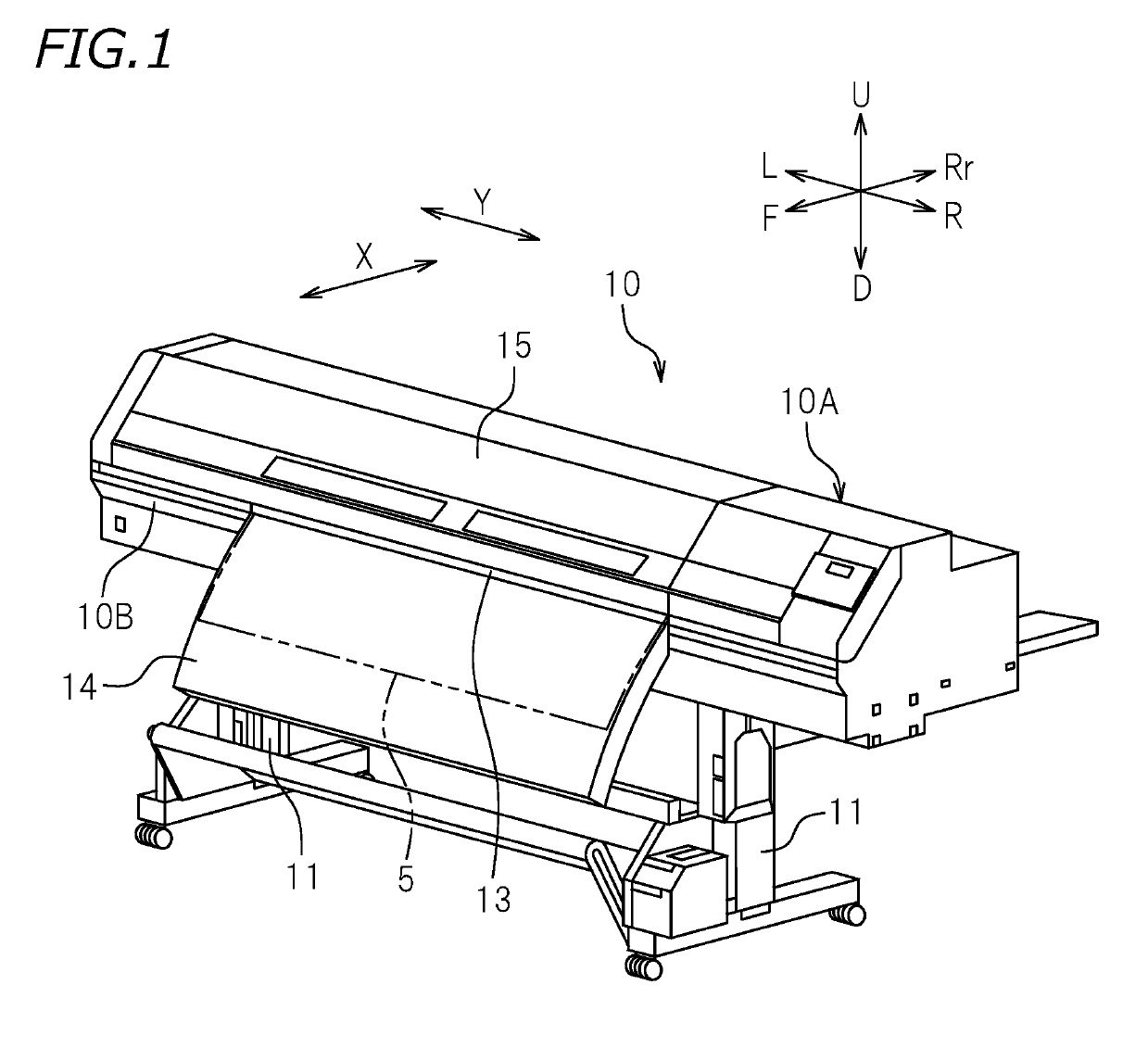

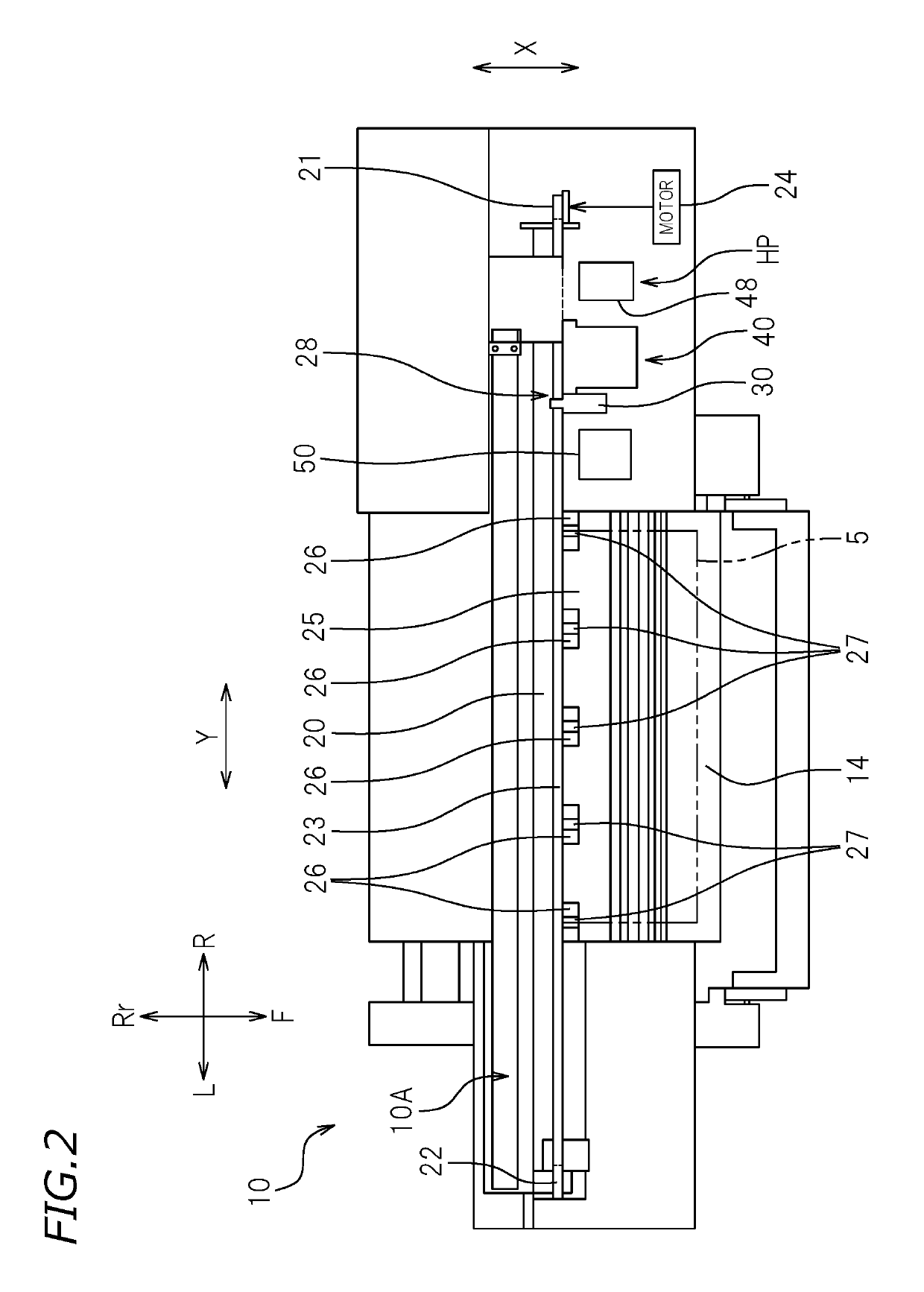

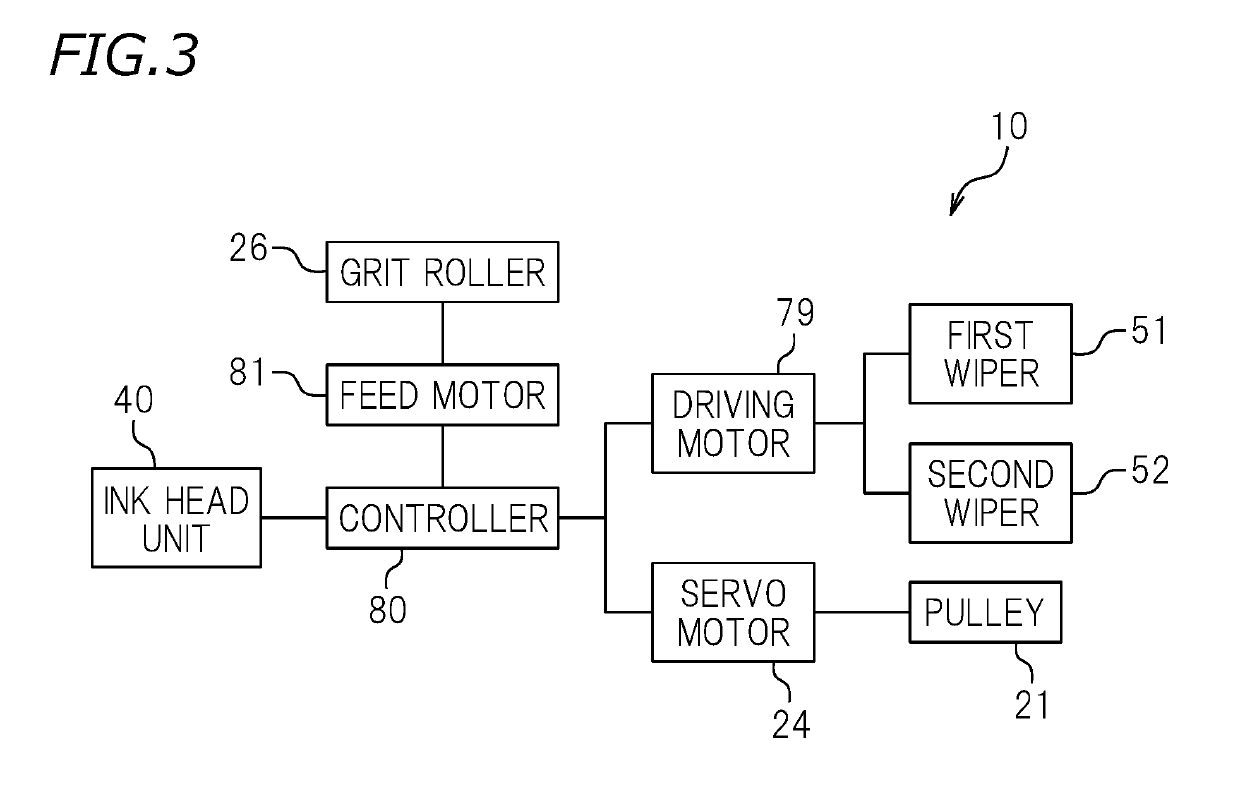

Ink jet printer

A printer includes a first ink head including first nozzles arranged in a sub-scanning direction and a first nozzle surface on which the first nozzles are disposed, a second ink head disposed at a side of the first ink head in a main scanning direction and including second nozzles arranged in the sub-scanning direction and disposed partially at a position identical to a position of a portion of the first nozzles in the sub-scanning direction and a second nozzle surface on which the second nozzles are disposed, a first wiper that wipes the first nozzle surface at a first wiping position, and a second wiper that wipes the second nozzle surface at a second wiping position.

Owner:ROLAND DG CORP

Glass wiper

ActiveUS9402514B2Easy to operateReasonable configuration designCarpet cleanersFloor cleanersEngineeringWindscreen wiper

Owner:NINGBO BEARI PLASTIC PROD & ELECTRIC APPLIANCE CO LTD

Liquid ejecting apparatus

InactiveUS20180194139A1Preventing an apparatus inner portion from being soiledDischarging liquid removedPrintingNozzle

A liquid ejecting apparatus includes a liquid ejecting head having a nozzle which ejects a liquid onto a medium, a wiping member that wipes the liquid which has adhered to a nozzle forming surface of the liquid ejecting head, a support member that supports the wiping member, moves the wiping member relative to the liquid ejecting head, and has a receiving portion receiving the liquid wiped by the wiping member, and a connection flow path that is capable of being connected to the support member, wherein the receiving portion and the connection flow path communicate with each other with movement of the support member.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com