Wiper member for a container for packaging and dispensing products

a technology for cosmetics or care products and wipers, which is applied in the direction of packaging foodstuffs, transportation and packaging, and packaged goods types. it can solve the problems of not stopping users from continuing, the applicator stem being prone to jump out of the container, and the wiper not being able to fit into narrow necked containers. , to achieve the effect of preventing the product from drying out and increasing the product li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

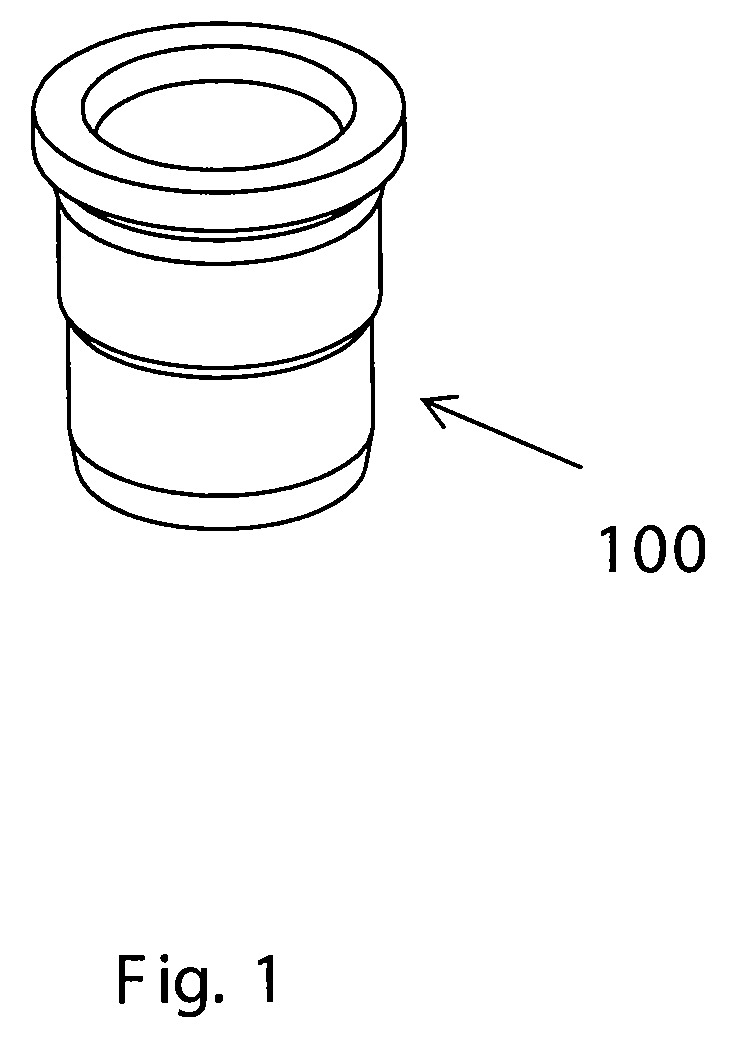

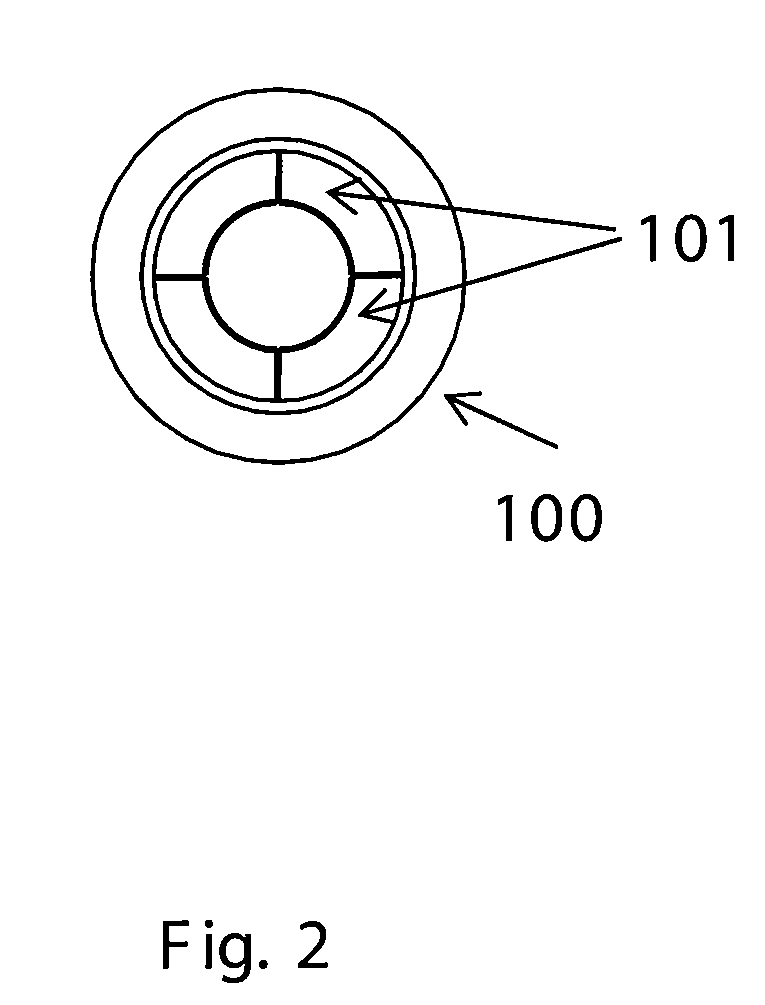

[0047]The wiper member of a container according to one embodiment of the present invention is shown in FIGS. 1 to 4.

[0048]FIG. 1 is one embodiment of the present invention showing the wiper member 100. As represented by FIGS. 2 and 3, there are present flange-like projections 101 on the inner diameter of the wiper member 100. FIG. 4 illustrates an align section view of the wiper member 100 wherein it is visible that the flange-like projections 101 are placed at varying heights inside the wiper. Further, there are more than one flange-like projections 101 present in the wiper member 100.

[0049]FIGS. 5 to 7 represent the wiper member 200 according to yet another embodiment of the invention. As can be seen from these figures, there are present two flange-like projections 201 and 202 inside the wiper member 200 and one of the projections 201 occupies a larger proportion than the other flange-like projection 202. Further, these projections are placed at varying heights inside the wiper. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com