Preparation method of waterborne hyperbranched polyurethane acrylate emulsion, UV curing coating and preparation method and application of UV curing coating

A polyurethane acrylate, curing coating technology, used in polyurea/polyurethane coatings, antifouling/underwater coatings, conductive coatings, etc., can solve the problems of adhesion and scratch resistance that cannot meet the requirements, and achieve broad market applications Value, toughness improvement, effect of lowering reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

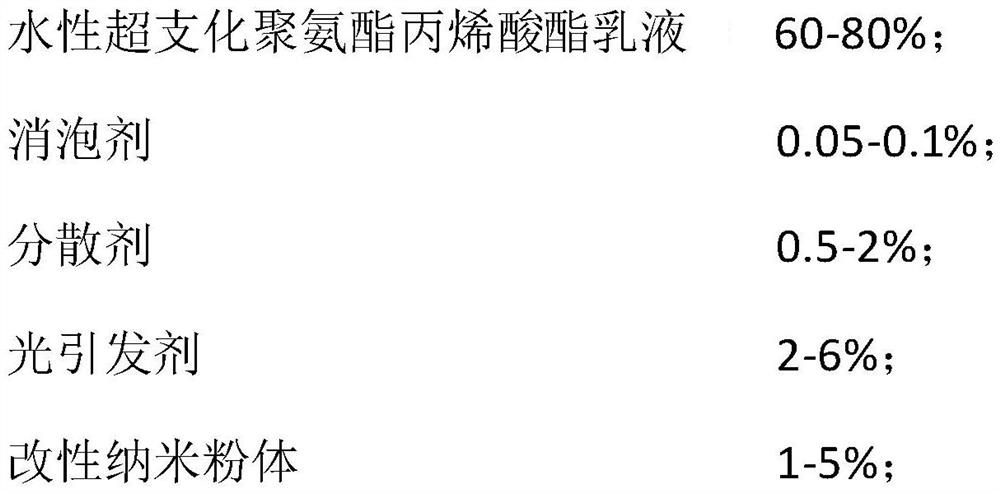

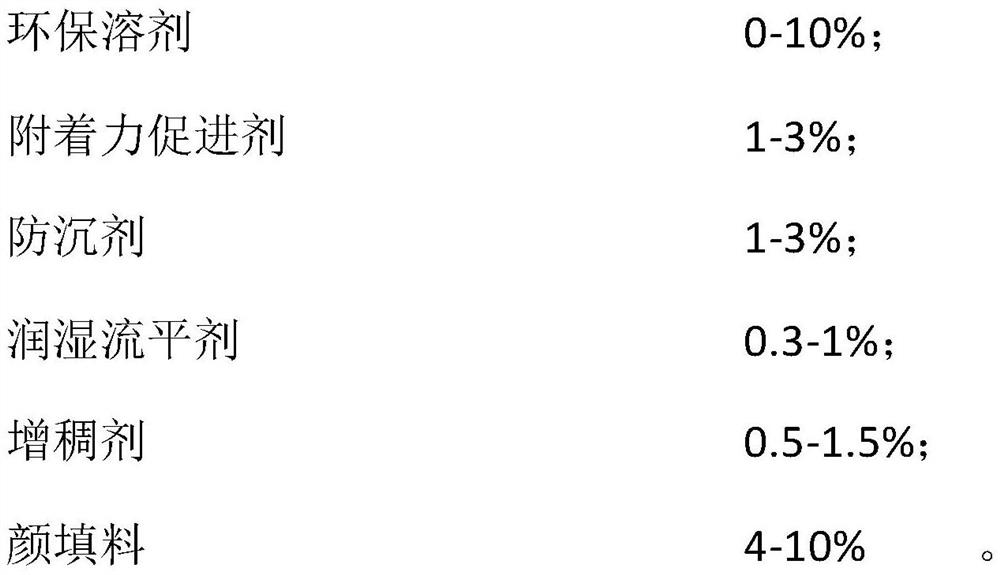

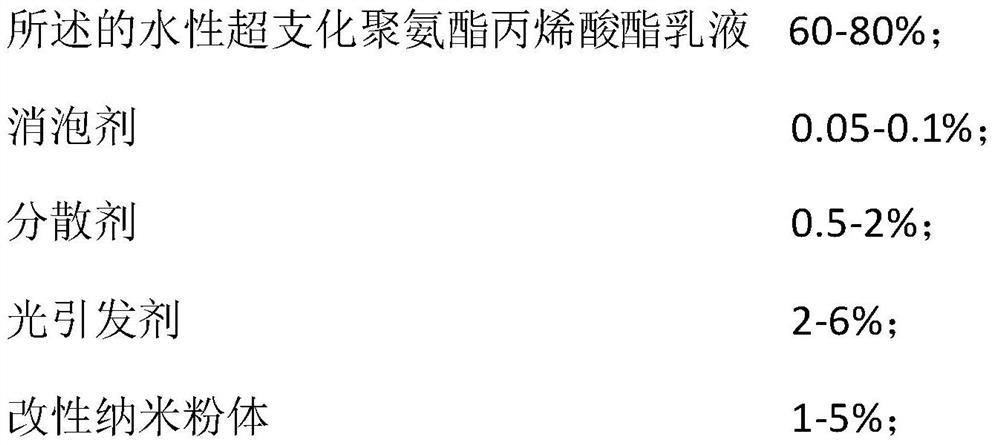

[0051] A kind of UV curable paint for polypropylene plastic packaging barrel, its raw material and weight ratio are:

[0052] Water-based hyperbranched polyurethane acrylate emulsion (UVWHPUA-1) 78.5%, defoamer TEGO 901W 0.05%, dispersant BYK190 1%, environmental solvent ester pure-12 6%, photoinitiator TPO 4%, modified nano-tin oxide Antimony 2%, adhesion promoter chlorinated polyethylene 1%, anti-settling agent attapulgite 2%, wetting and leveling agent TEGO4100 0.6%, thickener RM8W 0.8% and pigment and filler 4%.

[0053] A preparation method for a UV-cured coating for a polypropylene packaging drum, comprising the steps of:

[0054] (1) Preparation of modified nano-tin antimony oxide

[0055] Mix the silane coupling agent KH570, methanol and water at a mass ratio of 20:72:8 to hydrolyze the silane coupling agent KH570, adjust the pH value between 4-5 with glacial acetic acid, and hydrolyze for 30-60 minutes , to obtain the silane coupling agent KH570 hydrolyzate; add nan...

Embodiment 2

[0080] A kind of UV curable coating for polypropylene packaging drum, its raw material and weight ratio are:

[0081]Water-based hyperbranched polyurethane acrylate emulsion (UVWHPUA-2) 66.3%; defoamer TEGO901W 0.1%; dispersant BYK194N 1%; environmental solvent ester alcohol-12 10%; photoinitiator 651 6%; modified nano-silica 6%; adhesion promoter chlorinated polyethylene 3%; anti-settling agent montmorillonite 2%; wetting and leveling agent TEGO4100 0.6%; thickener OMG0620 1%; pigment and filler 4%.

[0082] A preparation method for a UV-cured coating for a polypropylene packaging drum, comprising the steps of:

[0083] (1) Preparation of modified nano silica

[0084] Add nano-silica to absolute ethanol, ultrasonically disperse for 20 minutes, and make a nano-silica dispersion liquid; then add titanate coupling agent 311w, adjust the pH of the system to 8-10, and then add liquid polyethylene glycol Alcohol propylene glycol, emulsified for 20 minutes, the pH of the emulsifie...

Embodiment 3

[0100] A kind of UV curable coating for polypropylene packaging drum, its raw material and weight ratio are:

[0101] Water-based hyperbranched polyurethane acrylate emulsion (UVWHPUA-3) 79.5%, defoamer TEGO901W 0.05%, dispersant TEGO747 2%, environmental solvent ester alcohol-12 1%, photoinitiator 184 3%, modified nano titanium dioxide 4% , Chlorinated polyethylene adhesion promoter 2%, anti-settling agent montmorillonite 2%, wetting and leveling agent TEGO4100 1%, thickener OMG0620 1.5%, coloring pigment 4%.

[0102] A preparation method for a UV-cured coating for a polypropylene packaging drum, comprising the steps of:

[0103] (1) Preparation of modified nano titanium dioxide

[0104] Mix the silane coupling agent KH550, methanol and water in a mass ratio of 20:72:8 to hydrolyze the silane coupling agent KH550, adjust the pH value with sodium hydroxide to control it between 9.0-10.0, and hydrolyze it at 30-60 minutes, to obtain the hydrolyzate of silane coupling agent KH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com