Flocked decorative steel plate and production process thereof

A technology of steel plate and flocking, applied in the field of decorative steel plate, can solve the problems of increased production cost and higher requirements for adhesives, and achieves the effect of saving materials and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

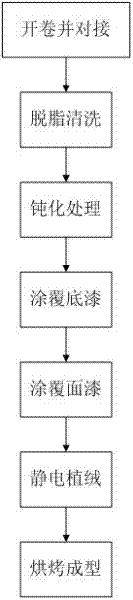

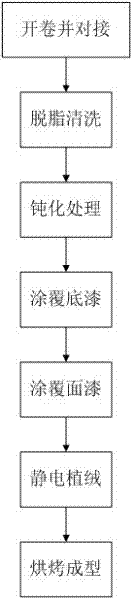

Method used

Image

Examples

Embodiment 1

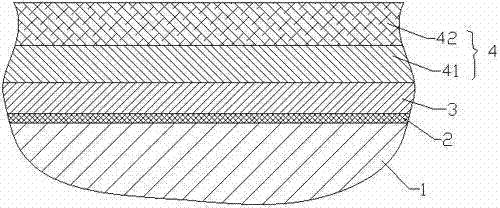

[0037] Embodiment 1: The base plate is made of hot-dip galvanized color-based steel plate: the base material is Q235, the thickness is 0.35 mm, the amount of galvanizing is 120 grams, and it has been pre-coated before color coating. Process: Uncoil the steel coil-shaped substrate on the uncoiler, and after uncoiling, first weld the substrates unrolled on the adjacent steel coils to obtain the substrate to be treated; introduce the substrate to be processed into a degreasing tank filled with a degreasing agent solution for degreasing, and Remove the oil stain attached to the surface of the substrate to be treated, control the amount of degreasing agent and the temperature of the degreasing agent solution, introduce the washing tank for washing after degreasing, and then dry to obtain the cleaned substrate after the surface is cleaned; use passivation solution to clean the substrate Passivation treatment, followed by hot air drying to obtain a substrate to be coated with a passiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com