Anti-corrosion material and preparation method thereof

A technology of anti-corrosion materials and raw materials, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as low curing content, poor substrate adhesion, and large environmental pollution, and achieve high curing content, good surface toughness, Good leveling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

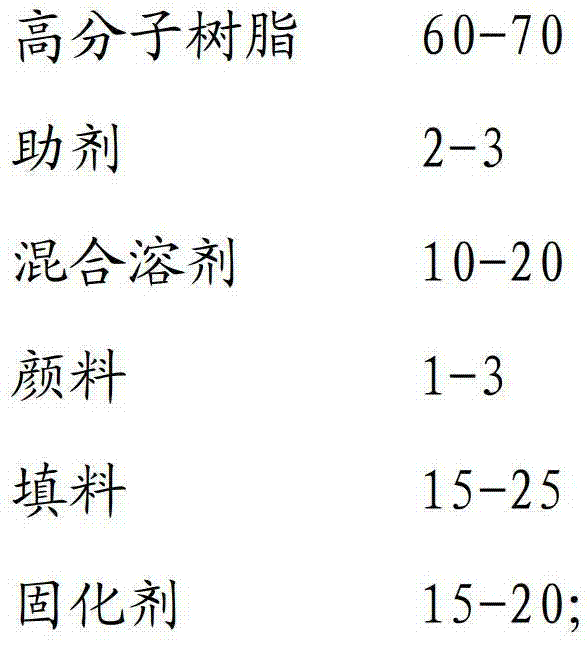

[0039] A kind of anticorrosion material of the present embodiment, comprises the raw material of following weight portion:

[0040]

[0041] The additives are castor oil, dibutyl phthalate, crosslinking agent CN-01 and petroleum microcrystalline wax in a weight ratio of 1:1:0.5:0.5.

[0042] The mixed solvent is ethanol, butanone and DBE with a weight ratio of 1:2:7.

[0043] The preparation method of above-mentioned anticorrosion material, comprises the steps:

[0044] ⑴ dissolve

[0045] Weigh the mixed solvent and polymer resin respectively, then add the polymer resin into the mixed solvent while stirring, after stirring for 2 hours, place it in a constant temperature box, control the temperature at 80°C±1°C, and wait until the polymer resin is completely dissolved Afterwards, lower the temperature to 40°C for later use.

[0046] ⑵ preparation

[0047] Weigh and add additives, pigments, and fillers respectively, add them to the mixture obtained in step (1) in sequenc...

Embodiment 2

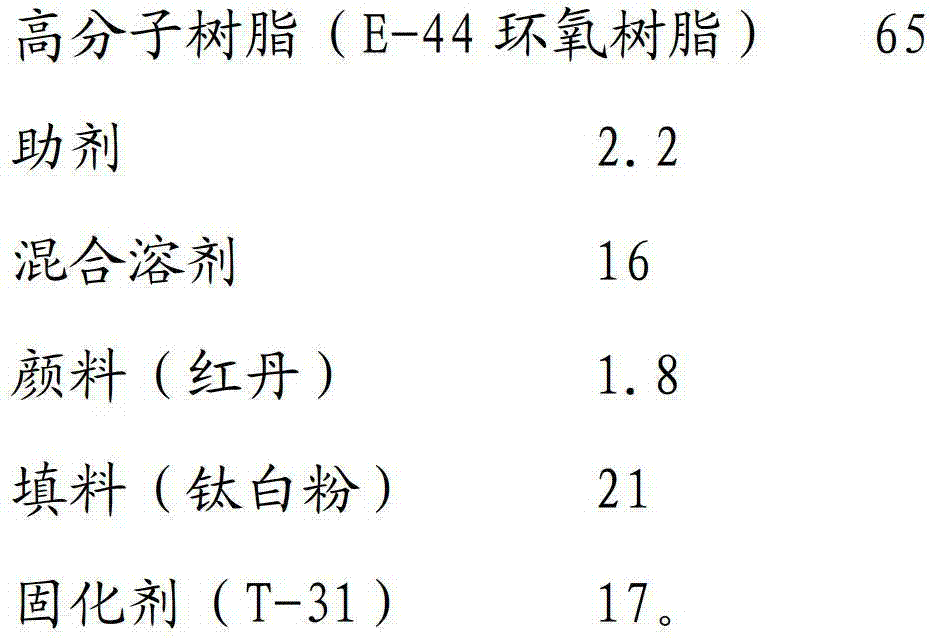

[0053] A kind of anticorrosion material of the present embodiment, comprises the raw material of following weight portion:

[0054]

[0055] The additives are castor oil, dibutyl phthalate, crosslinking agent CN-01 and petroleum microcrystalline wax in a weight ratio of 1:1:0.5:0.5.

[0056] The mixed solvent is ethanol, butanone and DBE with a weight ratio of 1:2:7.

[0057] The preparation method of above-mentioned anticorrosion material, comprises the steps:

[0058] ⑴ dissolve

[0059] Weigh the mixed solvent and polymer resin respectively, then add the polymer resin into the mixed solvent while stirring, after stirring for 2 hours, place it in a constant temperature box, control the temperature at 80°C±1°C, and wait until the polymer resin is completely dissolved Afterwards, lower the temperature to 40°C for later use.

[0060] ⑵ preparation

[0061] Weigh and add additives, pigments, and fillers respectively, add them to the mixture obtained in step (1) in sequenc...

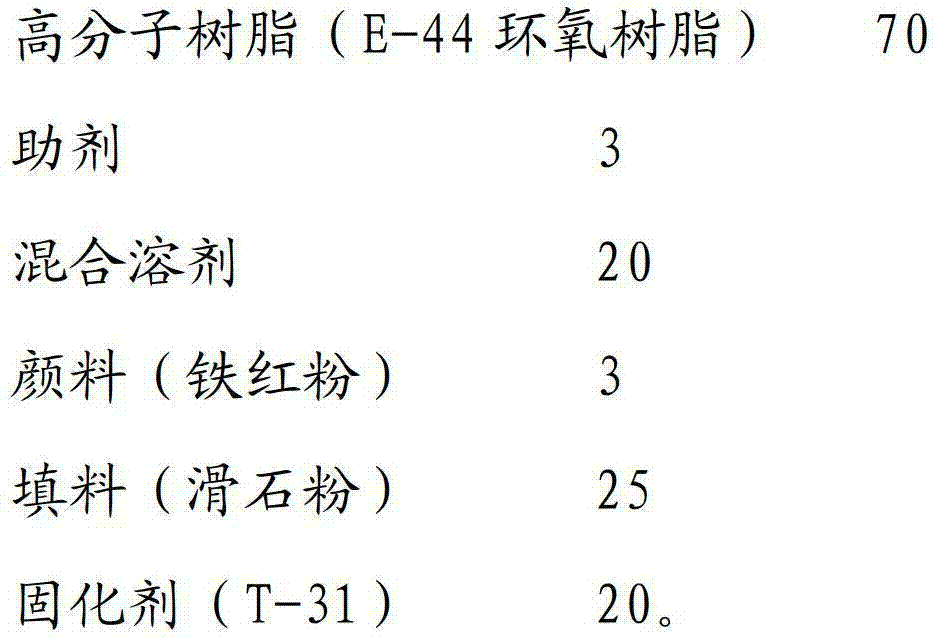

Embodiment 3

[0078] Embodiment 3 application performance test

[0079] 1. The influence of solvent on the performance of anti-corrosion materials:

[0080] DBE: Polarity 3.4 Xylene: Polarity 2.5

[0081] Table 1

[0082]

[0083] illustrate:

[0084] The polarity of DBE is greater than the polarity of xylene. Under the condition of the same amount of solvent used, the amount of DBE dissolved resin is greater than the amount of dissolved xylene, and the dissolution time of DBE is faster than that of xylene.

[0085] Table 2

[0086]

[0087] illustrate:

[0088] Adhesion level 0 is the best, the higher the level, the worse the adhesion performance.

[0089] 2. The performance test results of the anticorrosion materials obtained in Example 1-2 and Comparative Example 1-2 are shown in Table 3:

[0090] table 3

[0091]

[0092] Description: Examples 1 and 2 are better than Comparative Examples 1 and 2 in terms of solid content, adhesion, impact strength and chemical stability....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com