Nitrogen-doped carbon nanotube/rare earth metal ion-doped lithium iron phosphate composite cathode material and preparation method thereof

A technology of rare earth metal ions and lithium iron phosphate, which is applied in the field of lithium-ion batteries, can solve the problems of low ion mobility, affecting cycle capacity and battery rate charge and discharge performance, etc., to increase specific capacity, increase rate charge and discharge performance, and improve Hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

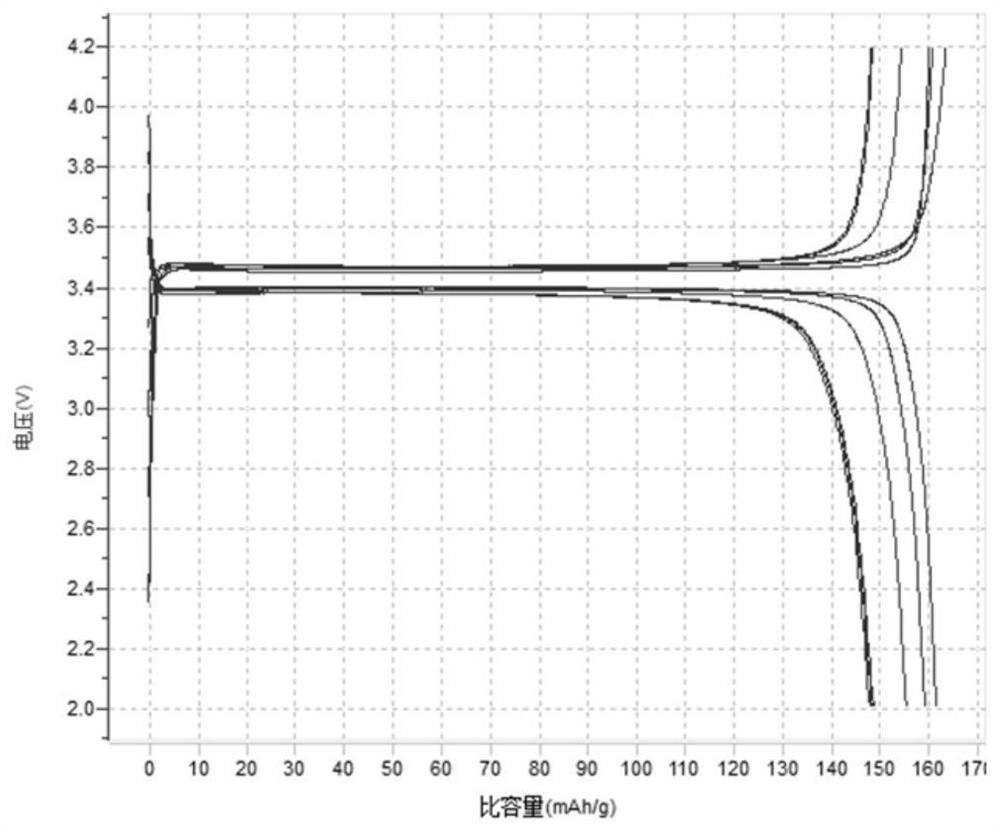

Embodiment 1

[0023] (1) Add 25ml of hydrazine hydrate with a solute mass fraction of 30% into 50ml of deionized water, then add 300mg of carbon nanotubes, heat and reflux at 60°C for 6h, wash and suction filter with deionized water, and freeze-dry the solid obtained by suction filtration to obtain Nitrogen-doped carbon nanotubes.

[0024] (2) Add 5.0g of lithium hydroxide, 30.0g of iron phosphate, 50.0g of oxalic acid, 5.0g of glucose, and 10.0g of deionized water into a three-necked flask, and then add 4.5g of cerium oxide to it. Heating to 90°C and keeping it for 5 hours, then cooling down to room temperature, vacuum distillation to 80°C, taking out and drying, then adding ethanol to the material and ball milling for 3 hours, after drying, put the material in N 2 Calcined at 400°C for 5 hours in a protected tubular muffle furnace, cooled to room temperature, taken out, then added ethanol and ball milled for 6 hours, after drying, the material was placed in N 2 Calcined at 700°C for 10 h...

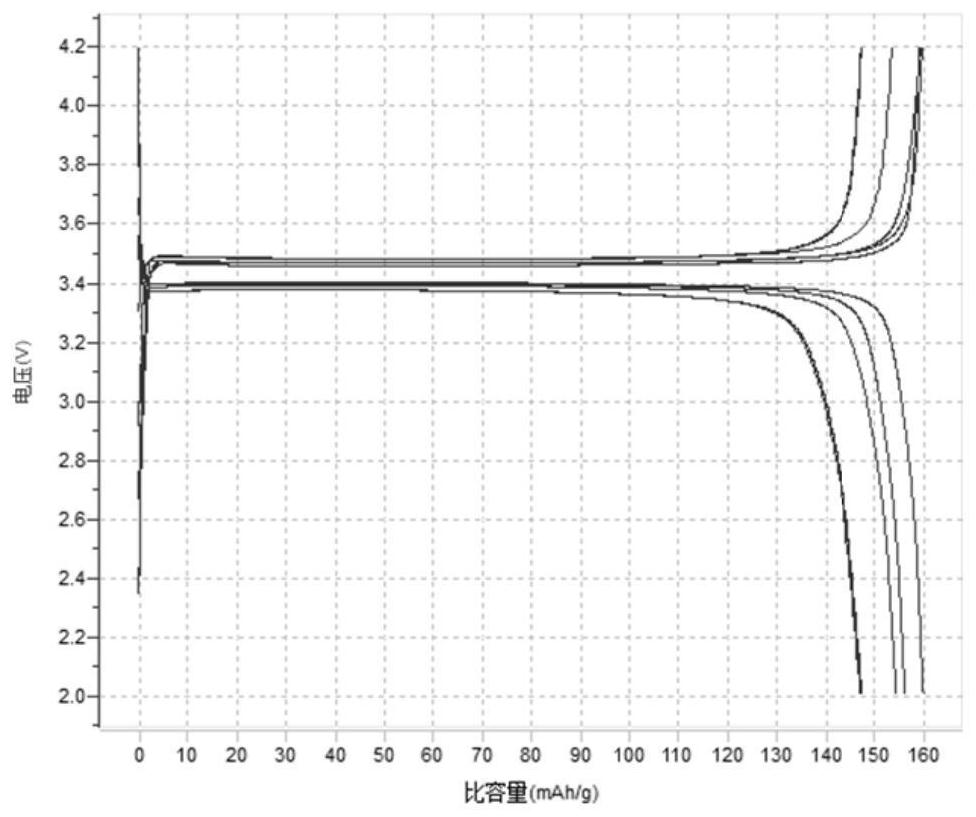

Embodiment 2

[0027] (1) Add 50ml of hydrazine hydrate with a solute mass fraction of 30% into 50ml of deionized water, then add 300mg of carbon nanotubes, heat and reflux at 60°C for 6h, wash and suction filter with deionized water, and freeze-dry the solid obtained by suction filtration to obtain Nitrogen-doped carbon nanotubes.

[0028] (2) Add 5.0g of lithium hydroxide, 25g of iron phosphate, 45g of oxalic acid, 3.0g of glucose, and 8g of deionized water into a three-necked flask, and then add 1.56g of Tm 2 o 3 Under rapid stirring, the water bath was heated to 90°C and kept for 5 hours, then lowered to room temperature, then vacuum distilled to 80°C, taken out and dried, then added ethanol to the material and ball milled for 3 hours, after drying, the material was placed in N 2 Calcined at 400°C for 5 hours in a protected tubular muffle furnace, cooled to room temperature, taken out, then added ethanol and ball milled for 6 hours, after drying, the material was placed in N 2 Calcine...

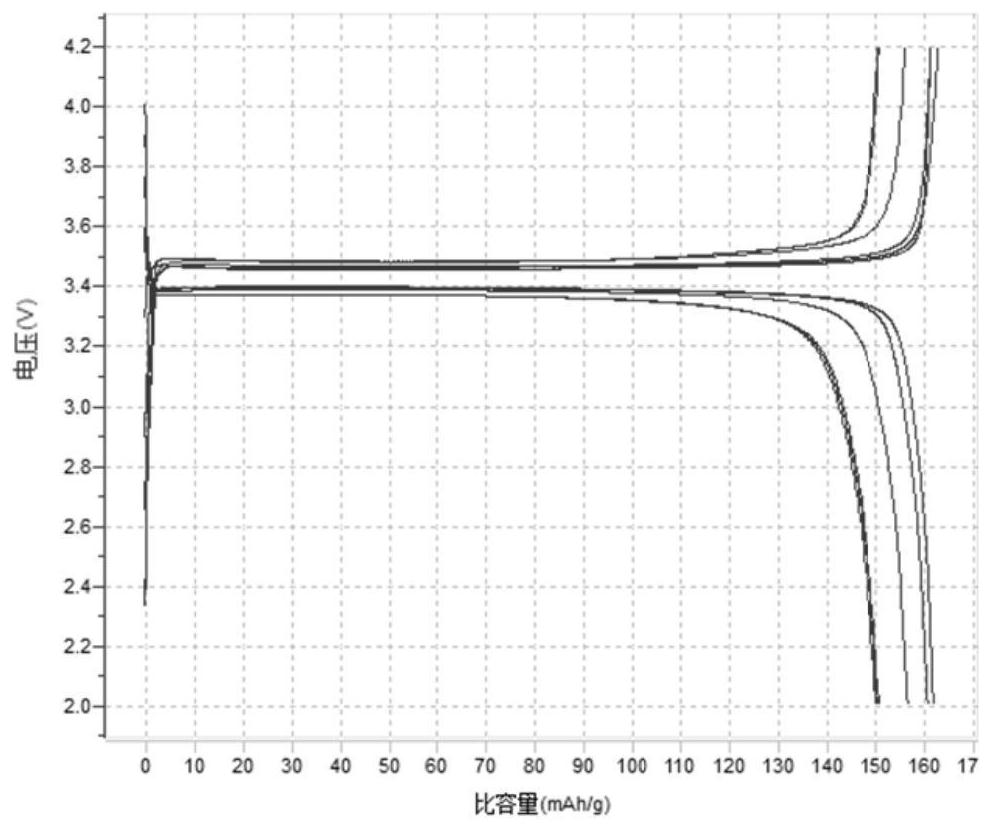

Embodiment 3

[0031] (1) Add 50ml of hydrazine hydrate with a solute mass fraction of 30% into 50ml of deionized water, then add 300mg of carbon nanotubes, heat and reflux at 60°C for 6h, wash and suction filter with deionized water, and freeze-dry the solid obtained by suction filtration to obtain Nitrogen-doped carbon nanotubes.

[0032] (2) Add 5.0g of lithium hydroxide, 30.0g of iron phosphate, 50.0g of oxalic acid, 5.0g of glucose, and 10.0g of deionized water into a three-necked flask, and then add 4.5g of cerium oxide to it. Heating to 90°C and keeping it for 5 hours, cooling down to room temperature, vacuum distillation to 80°C, taking out and drying, then adding ethanol to the material and ball milling for 3 hours, after drying, put the material in N 2 In a tubular muffle furnace under protection, calcined at 400°C for 5 hours, cooled to room temperature, took it out, then added ethanol and ball milled it for 6 hours, after drying, the material was placed in N2 Calcined at 700°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com