Magnesium-nickel-yttria hydrogen storage alloy thin belt and preparation method thereof

A hydrogen storage alloy and thin strip technology, which is applied in the field of magnesium-nickel-yttrium hydrogen storage alloy and its preparation, can solve the problems of high production cost, waste of magnesium resources, alloy composition change, etc., and achieve low equipment requirements and increase the area , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

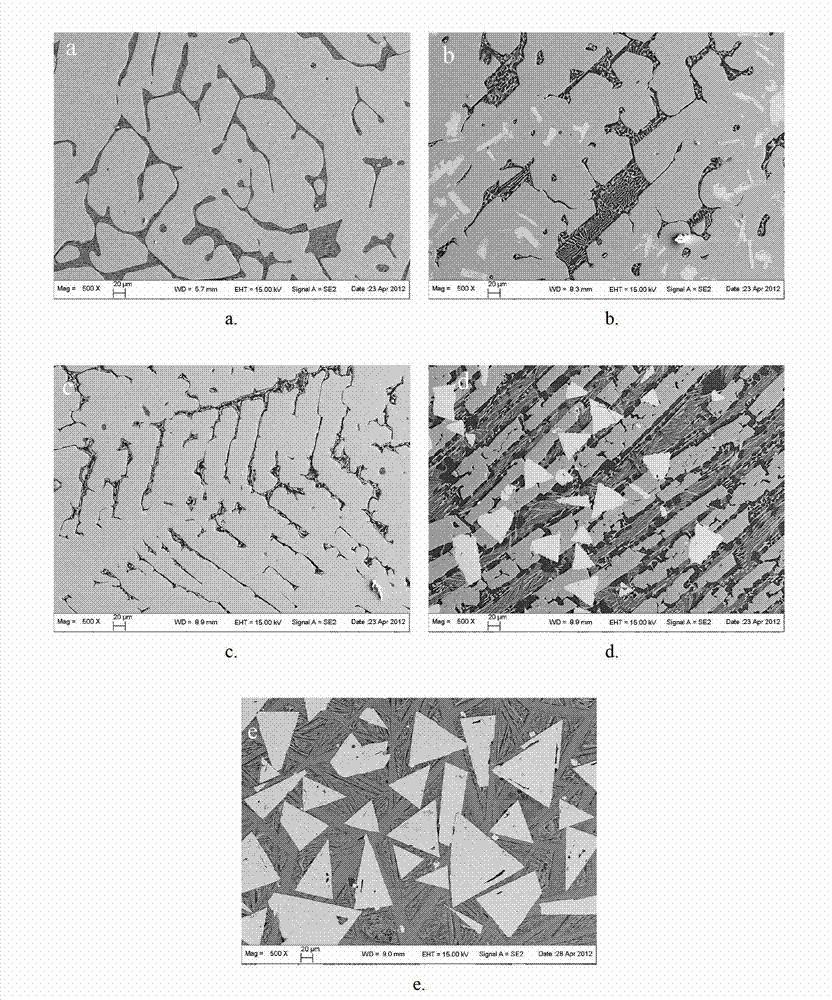

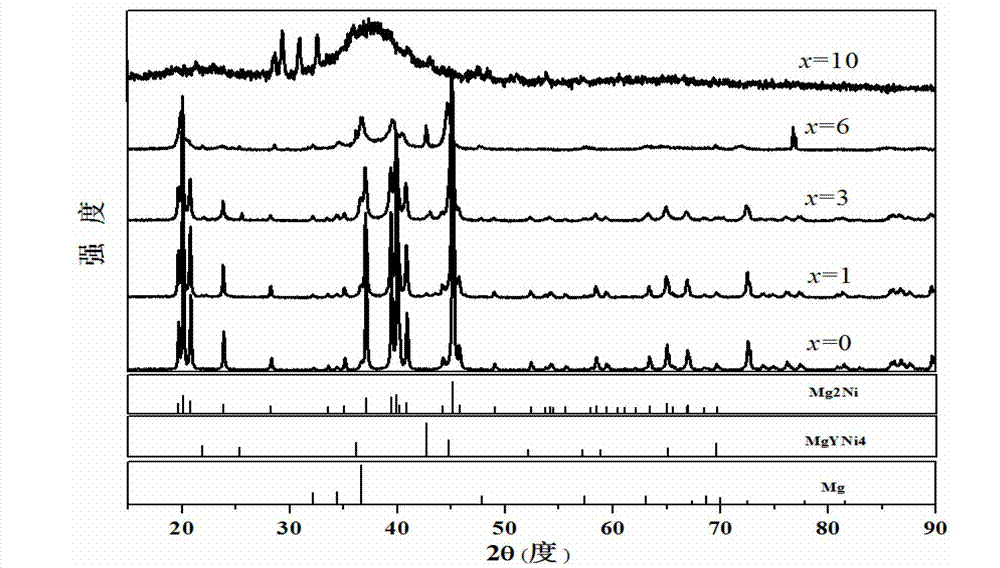

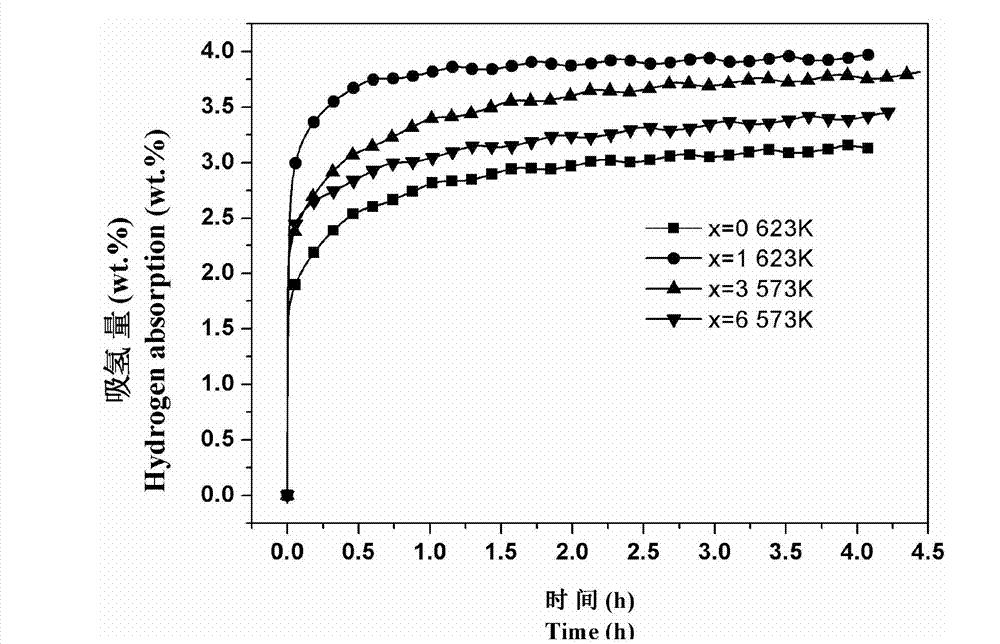

Embodiment 1

[0025] This embodiment is a magnesium-nickel hydrogen storage alloy strip, the raw materials of the magnesium-nickel hydrogen storage alloy strip include block magnesium with a purity of 99.8% and powdered nickel with a purity of 99.8%, according to the chemical formula Mg 67 Ni 33 The stoichiometric ratio is weighed, and the magnesium excess is 5wt.% as the burning loss. The stoichiometric specific weight is shown in Table 1. In this embodiment, 88.243 g of magnesium and 99.959 g of nickel powder are weighed.

[0026] Table 1 Alloy smelting ingredient list

[0027]

[0028]

[0029] Note: Mg excess 5wt.%, Y excess 2wt.%.

[0030] This embodiment also proposes a method for preparing a magnesium-nickel hydrogen storage alloy thin strip, the specific steps are:

[0031] Step 1, nickel powder is pre-pressed into blocks. Put the weighed nickel powder into a mold with an inner cavity diameter of 10mm, and place the mold in a tablet press. Pressurize the tablet machine t...

Embodiment 2

[0039] This embodiment is a magnesium-nickel-yttrium hydrogen storage alloy strip, the raw materials of the magnesium-nickel-yttrium hydrogen storage alloy strip include bulk magnesium with a purity of 99.8%, and magnesium-30 yttrium with a purity of 99.8%. The master alloy and powdered nickel with a purity of 99.8% are weighed according to the stoichiometric ratio of the chemical formula Mg67Ni32Y1, and the excess of magnesium is 5wt.% and the excess of yttrium is 2wt.% as the burning loss. The stoichiometric specific weight is shown in Table 1. In this embodiment, 76.673 g of magnesium, 15.470 g of magnesium-30 yttrium master alloy, and 96.116 g of nickel powder were weighed.

[0040] This embodiment also proposes a method for preparing a magnesium-nickel-yttrium hydrogen storage alloy strip, the specific steps are:

[0041] Step 1, nickel powder is pre-pressed into blocks. Put the weighed nickel powder into a mold with an inner cavity diameter of 10mm, and place the mold ...

Embodiment 3

[0049] This embodiment is a magnesium-nickel-yttrium hydrogen storage alloy strip, the raw materials of the magnesium-nickel-yttrium hydrogen storage alloy strip include bulk magnesium with a purity of 99.8%, and magnesium-30 yttrium with a purity of 99.8%. Master alloy and powdered nickel with a purity of 99.8%, according to the chemical formula Mg 67 Ni 30 Y 3 The stoichiometric ratio is weighed, and the excess of magnesium is 5wt.% and the excess of yttrium is 2wt.% as the amount of burning loss. The stoichiometric specific weight is shown in Table 1. In this embodiment, 54.107 g of magnesium, 45.640 g of magnesium-30 yttrium master alloy, and 88.619 g of nickel powder were weighed.

[0050] This embodiment also proposes a method for preparing a magnesium-nickel-yttrium hydrogen storage alloy strip, the specific steps are:

[0051] Step 1, nickel powder is pre-pressed into blocks. Put the weighed nickel powder into a mold with an inner cavity diameter of 10mm, and plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com