Preparation method of ultrahigh-capacity ternary lithium-rich manganese-based composite electrode material

A ternary lithium-rich manganese-based, composite electrode technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., to achieve the effects of improved transmission efficiency, good rate performance, and easy deintercalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

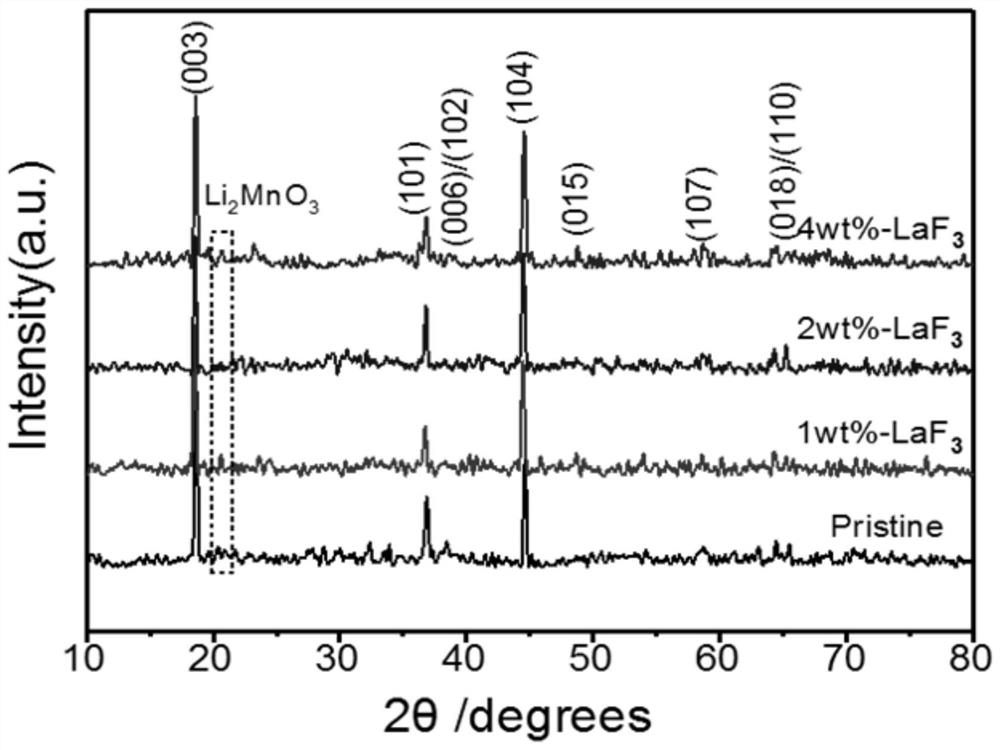

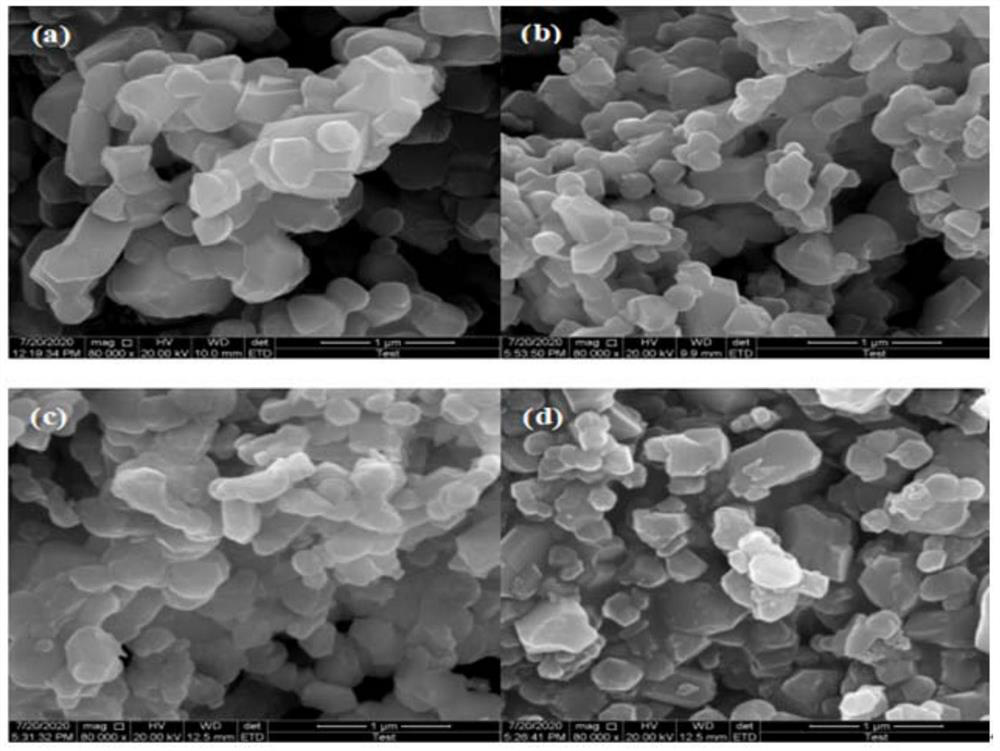

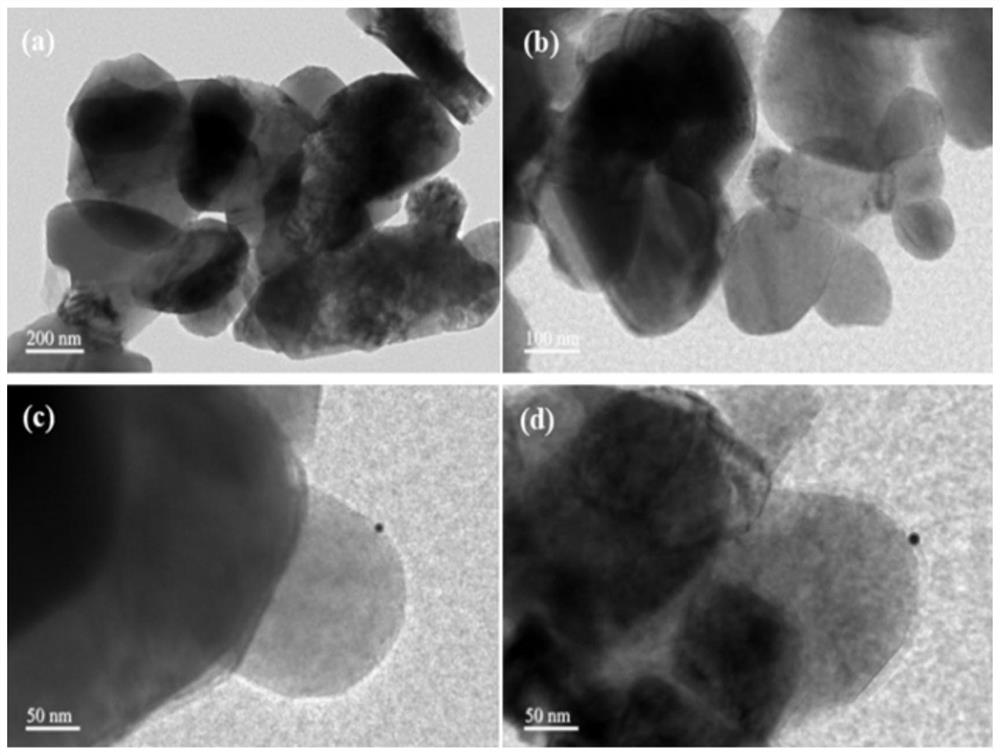

[0032] Li 1.2 mn 0.54 co 0.13 Ni 0.13 o 2 @LaF 3 The composite electrode material is prepared by the following steps:

[0033] (1) According to the stoichiometric ratio Li:Mn:Co:Ni=1.25:0.54:0.13:0.13, weigh 3.199g Li(CH 3 COO)·2H 2 O, 1.825g Mn(CH 3 COO) 2 4H 2 O, 0.730g Ni(CH 3 COO) 2 4H 2 O, 0.683g Co(CH 3 COO) 2 4H 2 O, dissolved in 11ml of deionized water, fully stirred to form a transparent uniform solution; according to the metal ion: citric acid molar ratio of 1:1, weigh 8.616g of citric acid, configure 2mol / L citric acid aqueous solution, and then follow the method of 1.5 drops / s Add the above-mentioned mixed metal salt solution dropwise at a speed of 100°C and continue stirring; then use ammonia water as a pH regulator to adjust the pH of the mixed solution to 8; place the above solution in a water bath at 85°C and heat and stir until a gray wet gel is formed; Dry the gray wet gel in a forced air drying oven at 120°C for 12 hours to obtain Li 1.2 mn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com