Lithium iron phosphate positive electrode material, preparation method thereof, and lithium ion battery

A lithium-ion battery, lithium iron phosphate technology, applied in the field of lithium-ion batteries, can solve problems such as low compaction density, and achieve the effects of improving electrical conductivity, material uniformity, and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

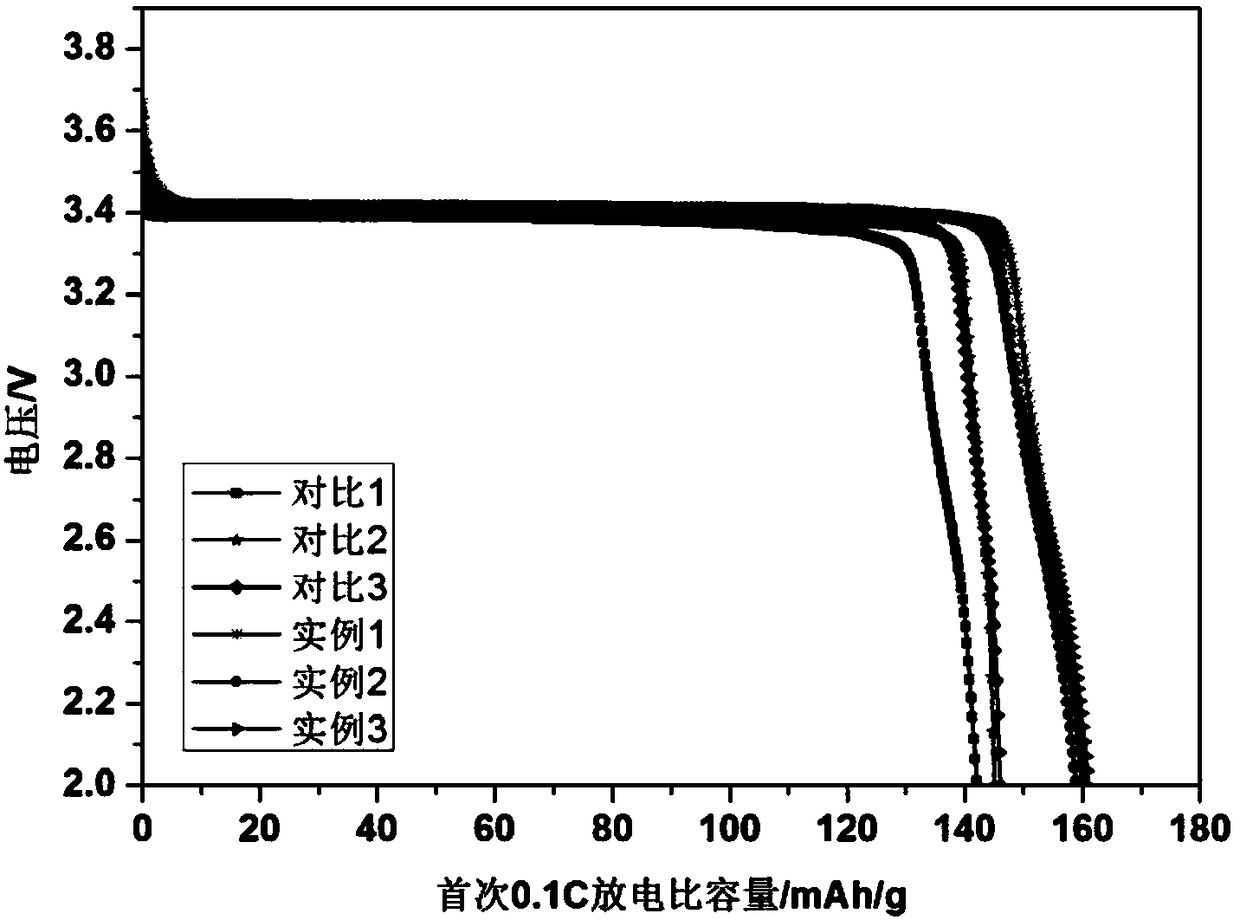

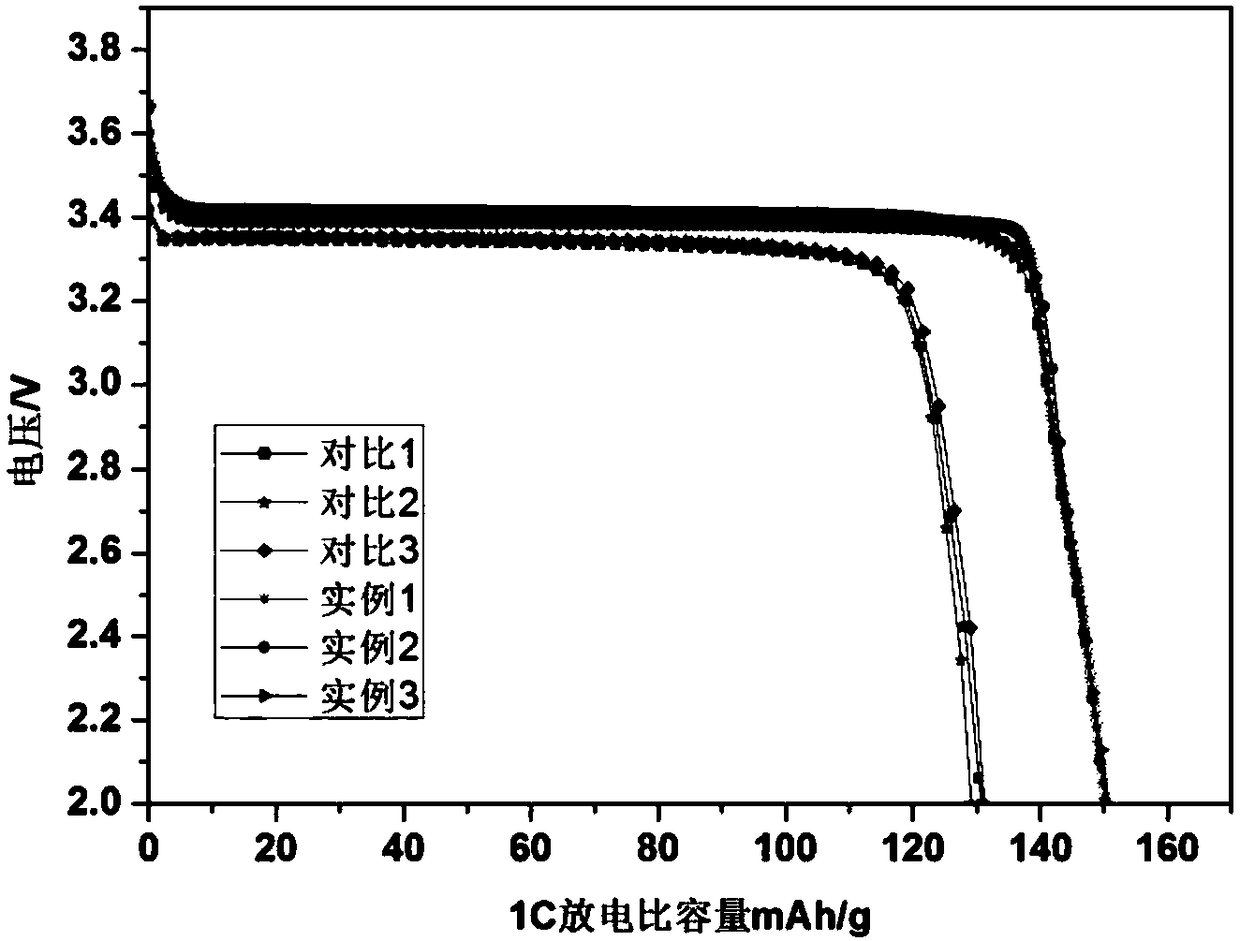

Embodiment 1

[0057] A preparation method of lithium iron phosphate cathode material, comprising the following steps:

[0058] (1) Get lithium carbonate 7.46g, ferric nitrate 81.2g, ammonium dihydrogen phosphate 23.24g, it is mixed homogeneously, obtains mixed material;

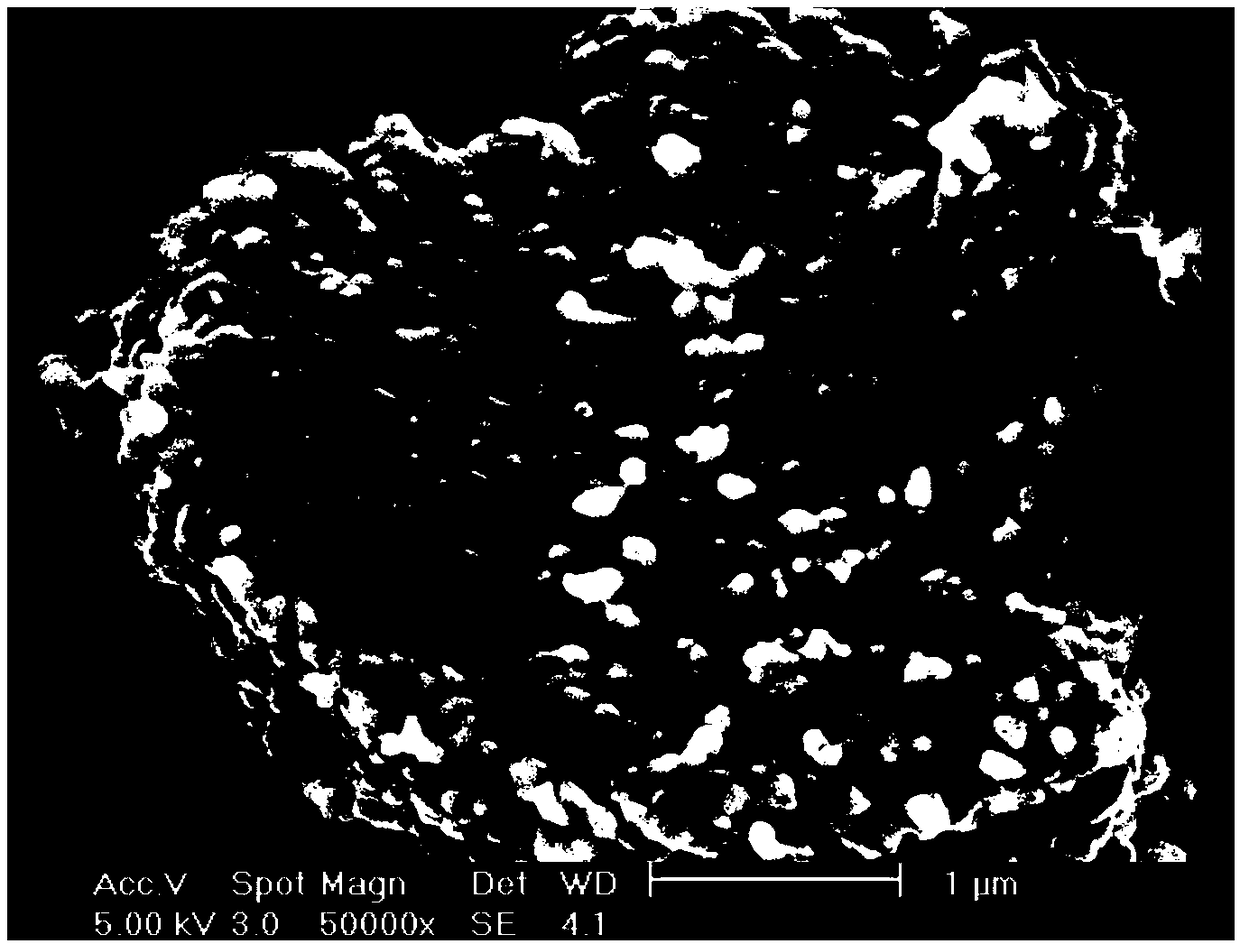

[0059] (2) The above-mentioned mixed material is subjected to ceramic grinding with a nano-ceramic grinding machine, wherein the ceramic grinding is ground for 4 hours by means of a plane counter-grinding method to obtain a powdery precursor with a particle size ≤ 40nm;

[0060] (3) Under a nitrogen atmosphere, the above-mentioned powdery precursor is sintered; wherein, the sintering is divided into the first sintering stage, the second sintering stage and the third sintering stage; the first sintering stage is 3 °C / min The heating rate was raised from room temperature to 180°C, and sintered for 3 hours; the second sintering stage was raised from 180°C to 380°C at a rate of 10°C / min, and sintered for 6 hours; the third sta...

Embodiment 2

[0065] A preparation method of lithium iron phosphate cathode material, comprising the following steps:

[0066] (1) Lithium dihydrogen phosphate (that is, phosphorus source and lithium source) and lithium acetate are mixed in a ratio of molar ratio Li:Fe:P=1:1:1 to obtain a mixed material;

[0067] (2) The above-mentioned mixed material is subjected to ceramic grinding with a nano-ceramic grinder, wherein the ceramic grinding is ground for 3 hours in a plane counter-grinding manner to obtain a powdery precursor with a particle size of less than 50 nm;

[0068] (3) Under a nitrogen atmosphere, the above-mentioned powdery precursor is sintered; wherein, the sintering is divided into the first sintering stage, the second sintering stage and the third sintering stage; the first sintering stage is 5 ° C / min The heating rate was raised from room temperature to 200°C, and sintered for 5 hours; the second sintering stage was raised from 200°C to 400°C at a rate of 20°C / min, and sin...

Embodiment 3

[0071] A preparation method of lithium iron phosphate cathode material, comprising the following steps:

[0072] (1) Ferric phosphate (i.e. iron source and phosphorus source) FePO 4 .2H 2 O and lithium hydroxide are mixed in a molar ratio Li:Fe:P=1:1:1 to obtain a mixed material;

[0073] (2) The above-mentioned mixed material is ground for 4 hours by using a nano-ceramic grinder, wherein the ceramic grinding is ground for 4 hours by means of plane grinding to obtain a powdery precursor with a particle size ≤ 35 nm;

[0074] (3) Under a nitrogen atmosphere, the above-mentioned powdery precursor is sintered; wherein, the sintering is divided into a first-stage sintering stage, a second sintering stage, and a third sintering stage; the first sintering stage is carried out at 10°C / min The heating rate was raised from room temperature to 220°C, and sintered for 6 hours; the second sintering stage was raised from 220°C to 420°C at a rate of 25°C / min, and sintered for 10 hours; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com