Method for producing high performance lithium ion battery anode material LiFePO4/C

A technology for lithium ion batteries and cathode materials, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of poor performance and high cost of lithium iron phosphate, improve uniformity and conductivity, and facilitate the reaction process. Control and prevent the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

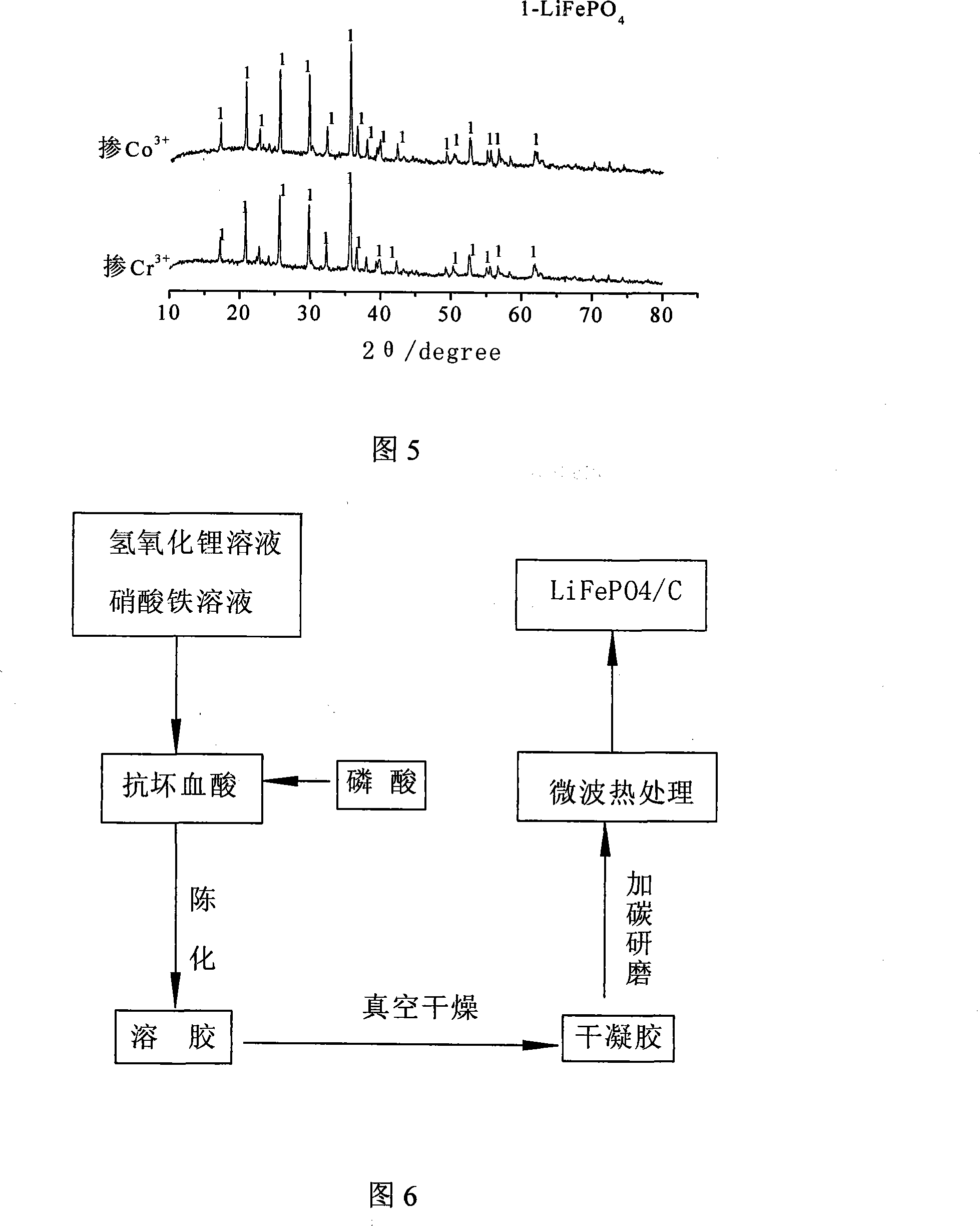

[0043] Example 1: LiFePO, the cathode material for lithium-ion batteries 4 Preparation method of / C

[0044] (1) LiOH·H 2 O, Fe(NO 3 ) 3 9H 2 O, H 3 PO 4 1. Ascorbic acid was weighed in a molar ratio of 1:1.2:1.0:0.6, and deionized water was added thereto to form a solution with a concentration of 1.0 mol / L. Fe(NO 3 ) 3 9H 2 O solution, LiOH·H 2 The O solution was added to the ascorbic acid solution, followed by H 3 PO 4 solution, fully stirred and mixed evenly, and aged for 13 hours;

[0045] (2) drying for 12 hours at a temperature of 70°C and a vacuum of less than 10 Pa to obtain a xerogel, and grinding the xerogel into a fine powder to obtain a precursor;

[0046] (3) Add 8.0% nano-carbon black to the precursor, grind it in a ball mill for 15 minutes, then place it in an alumina crucible, and microwave heat treatment at a temperature of 720 ° C for 20 minutes under the protection of an argon atmosphere to obtain LiFePO 4 / C.

Embodiment 2

[0047] Example 2: LiFePO 4 Preparation method of / C

[0048] (1) LiOH·H 2 O, Fe(NO 3 ) 3 9H 2 O, H 3 PO 4 1. Ascorbic acid is weighed according to the molar ratio of 1:1:1:0.5, and distilled water is added to form a solution, and the solution concentration is 1.5mol / L. Fe(NO 3 ) 3 9H 2 O solution, LiOH·H 2 The O solution was added to the ascorbic acid solution, followed by H 3 PO 4 solution, fully stirred and mixed evenly, aged for 12 hours;

[0049] (2) Under the protection of an argon atmosphere, the temperature is 70 ° C and dried for 10 hours to obtain a xerogel, which is ground into a fine powder to obtain a precursor;

[0050] (3) Add 5.0% nano-acetylene black to the precursor, grind it in a ball mill for 15 minutes, then place it in an alumina crucible, and microwave heat treatment at a temperature of 700 ° C for 15 minutes under the protection of an argon atmosphere to obtain LiFePO 4 / C.

Embodiment 3

[0051] Example three: LiFePO 4 Preparation method of / C

[0052] (1) LiOH·H 2 O, Fe(NO 3 ) 3 9H 2 O, H 3 PO 4 1. Ascorbic acid was weighed in a molar ratio of 1:1.2:1:0.3, and deionized water was added to form a solution, and the solution concentration was 3.0 mol / L. Fe(NO 3 ) 3 9H 2 O solution, LiOH·H 2 The O solution was added to the ascorbic acid solution, followed by H 3 PO 4 solution, fully stirred and mixed evenly, and aged for 10 hours;

[0053] (2) Under the conditions of vacuum degree of 7 Pa and temperature of 60°C, dry for 12 hours to obtain xerogel, and grind the xerogel into fine powder to obtain the precursor;

[0054] (3) Add 2.0% nano-graphite to the precursor, grind it in a ball mill for 12 minutes, then place it in an alumina crucible, and heat it with microwave at 650°C for 25 minutes under the protection of nitrogen atmosphere to obtain LiFePO 4 / C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com