A doped modified sodium vanadium phosphate positive electrode material and preparation method thereof

A technology of sodium vanadium fluorophosphate and positive electrode material, which is applied to battery electrodes, structural parts, electrical components, etc., can solve the problems of unfavorable industrialization and other production technologies, low charge-discharge specific capacity, and complicated process, and achieves a favorable transmission rate. , excellent rate performance, the effect of increasing the transportation channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of doped modified sodium vanadium fluorophosphate cathode material, comprising:

[0028] (1) Take 1.072g of citric acid, add NaF, NH 4 VO 3 , Ca(NO 3 ) 2 ·4H 2 O, NH 4 H 2 PO 4 And C 6 H 8 O 7 ·H 2 After the O is weighed according to the substance ratio of 3:1.95:0.05:2:1.6, it is added to 20 ml of deionized water at a speed of 400 r / min at 80 ○ C was stirred for 1 hour to obtain a uniformly dissolved and dispersed precursor solution.

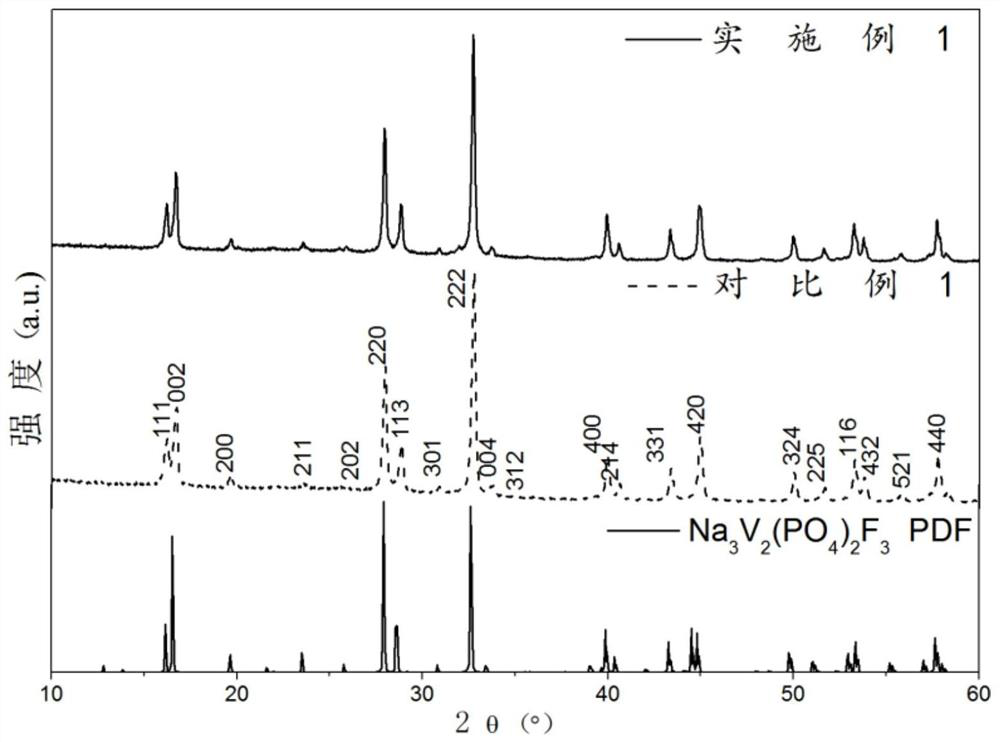

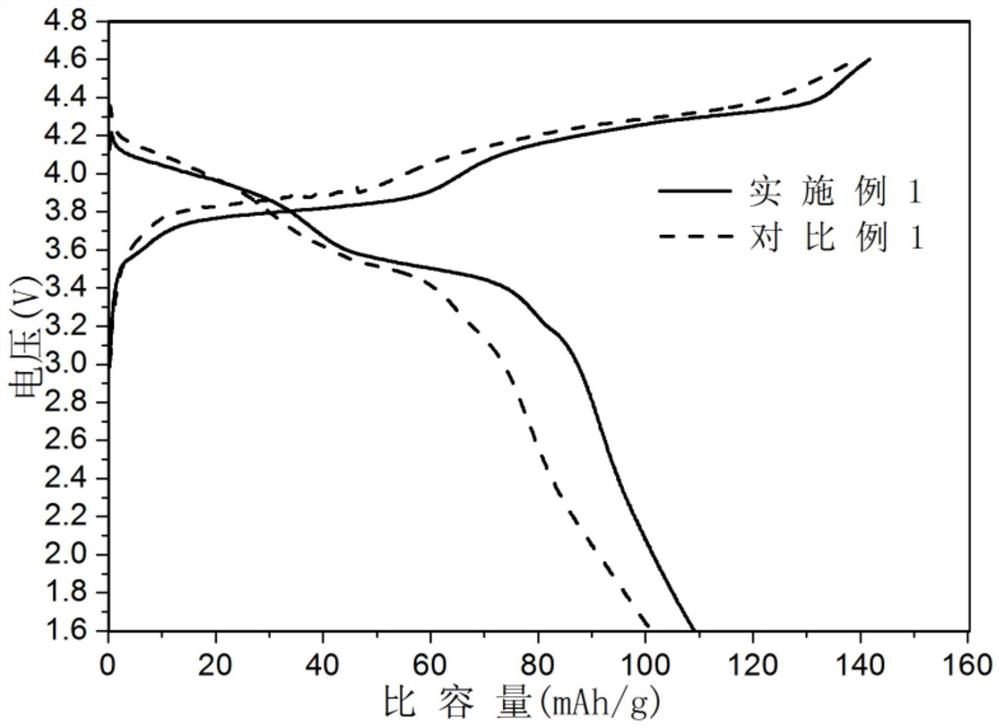

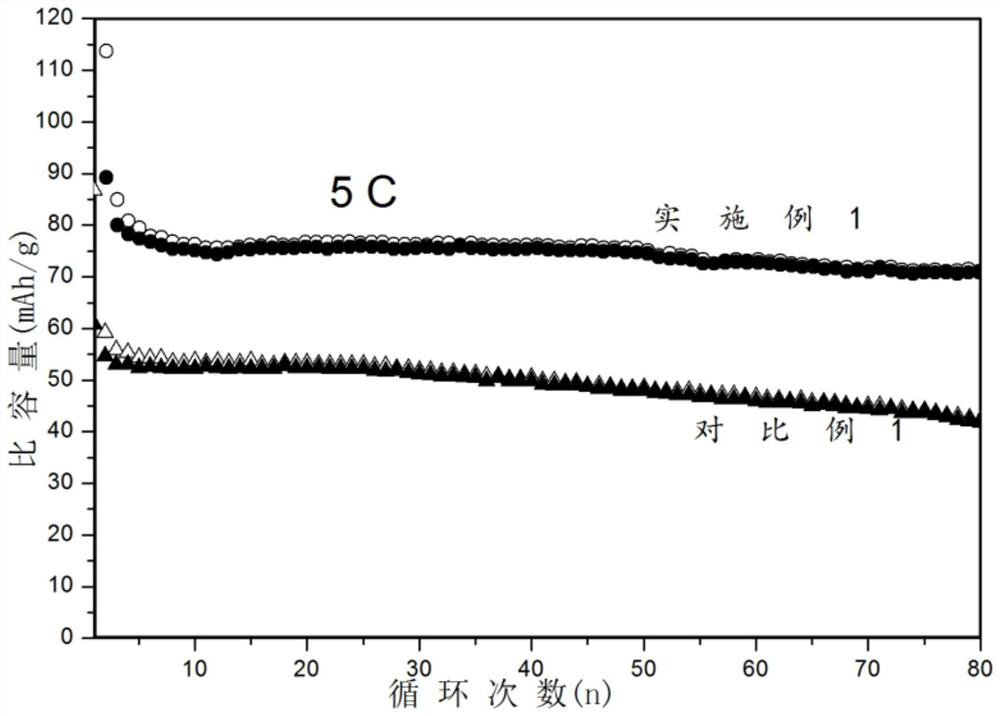

[0029] (2) Put the above precursor solution at 80 ○ C. After drying in a blast drying box for 18 hours, grind it in a mortar to obtain a precursor; ○ C heat preservation for 4 hours, 650 ○ C sintered for 8 hours to obtain the doped modified sodium vanadium fluorophosphate cathode material Na 3 V 1.95 Ca 0.05 (PO 4 ) 2 F 3 . The prepared calcium-doped sodium vanadium fluorophosphate was used as a sodium ion battery cathode material for electrochemical performance test, and the electrode ratio was sodium vanadium fluorophosp...

Embodiment 2

[0031] A preparation method of doped modified sodium vanadium fluorophosphate cathode material, comprising:

[0032] (1) Take 2 g of citric acid, add NaF, NH 4 VO 3 , Ca(OH) 2 , NH 4 H 2 PO 4 And C 6 H 8 O 7 ·H 2 After the O is weighed according to the substance ratio of 3:1.95:0.05:2:3, it is added to 15 ml of deionized water at a speed of 500 r / min at 60 ○ C was stirred for 6 hours to obtain a uniformly dissolved and dispersed precursor solution.

[0033] (2) Put the above precursor solution at 120 ○ C dry in a blast drying box for 6 hours, grind in a mortar to obtain a precursor; the above-mentioned precursor is heated under a nitrogen atmosphere at 300 ○ C heat preservation for 5 hours, 700 ○ C sintering for 6 hours to obtain the doped modified sodium vanadium fluorophosphate cathode material Na 3 V 1.9 Ca 0.1 (PO 4 ) 2 F 3 . The prepared calcium-doped sodium vanadium fluorophosphate was used as a sodium ion battery cathode material for electrochemical performance test, and the ...

Embodiment 3

[0035] A preparation method of doped modified sodium vanadium fluorophosphate cathode material, comprising:

[0036] (1) Take 1.072 g of citric acid, add NaF, NH 4 VO 3 , CaCO 3 , NH 4 H 2 PO 4 And C 6 H 8 O 7 ·H 2 After the O is weighed according to the substance ratio of 3:1.9:0.1:2:1.6, it is added to 40 ml of deionized water at a speed of 300 r / min at 100 ○ C was stirred for 0.2 hours to obtain a uniformly dissolved and dispersed precursor solution.

[0037] (2) Place the above-mentioned precursor solution in a blast drying oven at 80 ℃ for 18 hours, and grind in a mortar to obtain the precursor; the above-mentioned precursor solution is heated at 400°C under a high-purity argon atmosphere. ○ C heat treatment for 5 hours, 600 ○ C sintered for 8 hours to obtain the doped modified sodium vanadium fluorophosphate cathode material Na 3 V 1.8 Ca 0.2 (PO 4 ) 2 F 3 . The prepared calcium-doped sodium vanadium fluorophosphate was used as a sodium ion battery cathode material for electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com