Solid melt method for manufacturing lithium-intercalated layered multielement complex

A layered and solid solution technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of inability to accurately control the ratio of raw materials, inability to produce in batches, long synthesis process routes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

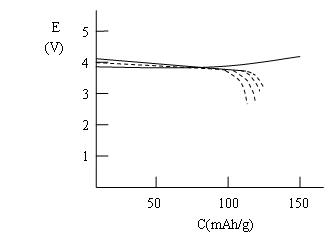

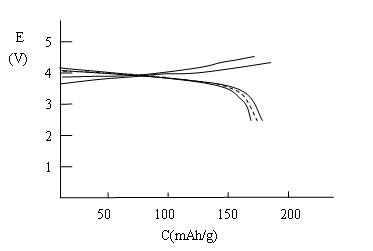

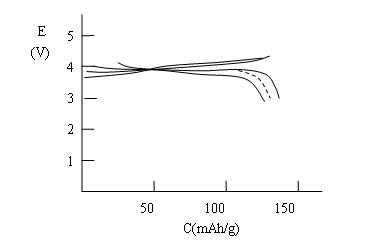

[0008] Solid solution method to produce lithium-intercalated layered multi-component composites (Ni, Co, Mn) Preparation: Cobalt, nickel, manganese and other element oxides are used as raw materials, mixed with battery-grade lithium carbonate in a certain proportion, calcined at high temperature, crushed, sieved After separate treatment, Li(Mn-Ni-Co)O2 ternary material powder was obtained. The particle size distribution of the product was analyzed with a laser particle size analyzer (LS230, Coulter, USA); the crystal phase structure of the product was analyzed with an X-ray diffractometer (D / max-rB, Rigaku Corporation, Japan); scanning electron microscopy (S- 3500N) to observe its microstructure.

[0009] Manganese and nickel sources are used as raw materials, respectively mixed with cobalt oxide (~5μm)) and battery grade lithium carbonate according to n(Li):n(Mn):n(Ni):n(Co) =1.10:1 / 3:1 / 3 : 1 / 3 mixed, calcined at 1000°C for 20 h to obtain the ternary system product LiMn 1 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com