Preparation method of lithium battery negative electrode material with litchi-shaped sodium tungstate/nitrogen-doped carbon composite structure

A nitrogen-doped carbon and composite structure technology, applied in battery electrodes, negative electrodes, structural parts, etc., can solve the problems of complex synthesis and treatment process, harsh reaction conditions, unfavorable green production, etc., and achieve the effect of excellent cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

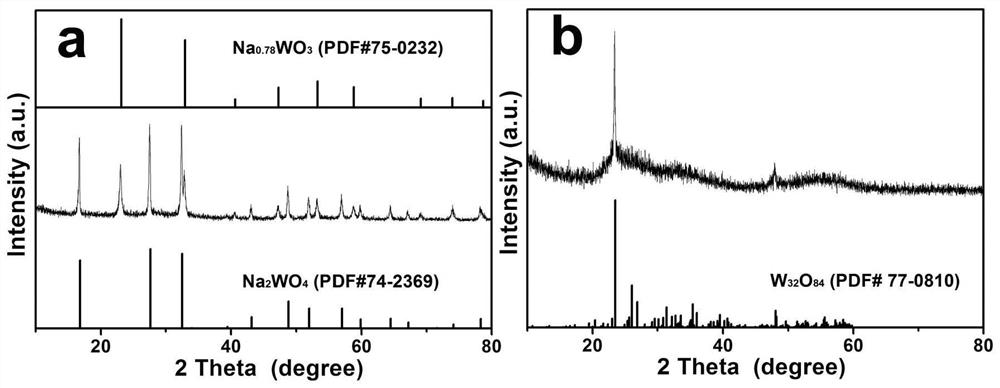

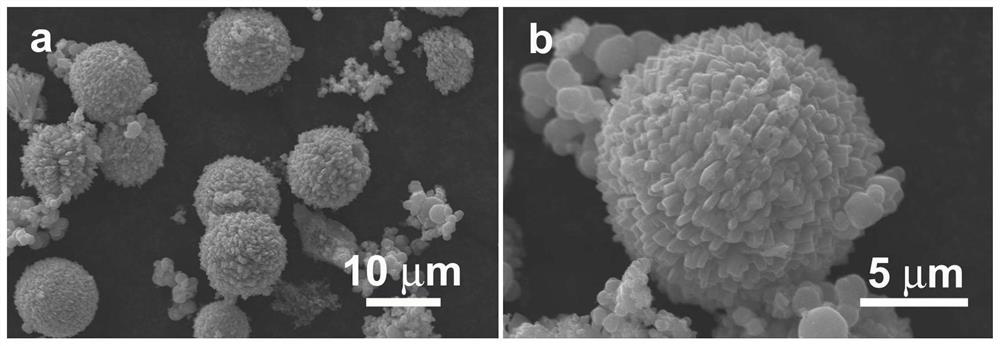

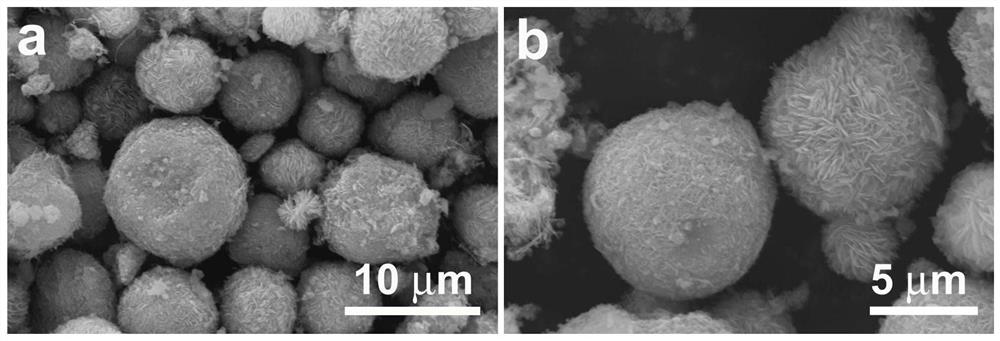

[0035] A preparation method of a litchi-shaped sodium tungstate / nitrogen-doped carbon composite structure lithium battery negative electrode material, comprising the following steps:

[0036] (1) Material preparation: take sodium carboxymethyl cellulose with an average molecular weight of 90,000 and dissolve it in 29mL of water, then add ammonium metatungstate for dissolution to obtain a dispersion containing tungstate and CMC; take dopamine and dissolve it in In ionized water, a dopamine solution is formed;

[0037] (2) Hydrothermal reaction: Take the dopamine solution and add it to the dispersion containing ammonium metatungstate and CMC. At this time, the concentration of sodium carboxymethylcellulose in the solution is 15g / L, and the concentration of ammonium metatungstate is 30mmol / L , the concentration of dopamine is 30mmol / L, and the mixed reaction solution is prepared. After stirring evenly, it is placed in an oven for hydrothermal reaction at 180°C for 6 hours. After ...

Embodiment 2-6

[0047] Example 2-6 On the basis of Example 1, the influence of different hydrothermal reaction conditions on the electrochemical performance of the lithium battery negative electrode material of litchi-shaped micron sodium tungstate / nitrogen-doped carbon composite structure was studied (using the same method as in Example 1). 1 same test method), the results are as follows:

[0048]

[0049]

[0050] It can be seen from the above table: when the hydrothermal reaction temperature is insufficient, it is difficult to form lychee-like micron-sized sodium tungstate, thereby reducing the electrochemical performance; and when the hydrothermal reaction temperature is too high, although the electrochemical performance will be improved decreased, but the impact is not significant, but considering the energy consumption problem, it is not appropriate to choose an excessively high reaction temperature.

Embodiment 7-11

[0052] Examples 7-11 On the basis of Example 1, the influence of different calcination conditions on the electrochemical performance of the lithium battery negative electrode material of litchi-shaped micron sodium tungstate / nitrogen-doped carbon composite structure (using the same method as in Example 1) test method), the results are as follows:

[0053]

[0054] It can be seen from the above table that when the calcination temperature is lower than 300 °C, the crystallinity of the crystal may decrease due to insufficient temperature, which will affect the morphology of the composite structure and reduce the electrochemical performance; and when the temperature is too high, it may lead to composite The local collapse of the structure occurs, which seriously degrades the electrochemical performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com