A lithium-rich cathode material with molybdenum/fluorine co-doping and spinel in-situ coating and its preparation method

A lithium-rich positive electrode material and lithium-rich material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of poor structural stability and low lithium ion diffusion rate, achieve good consistency, and the preparation process is simple and easy to control , the effect of promoting diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

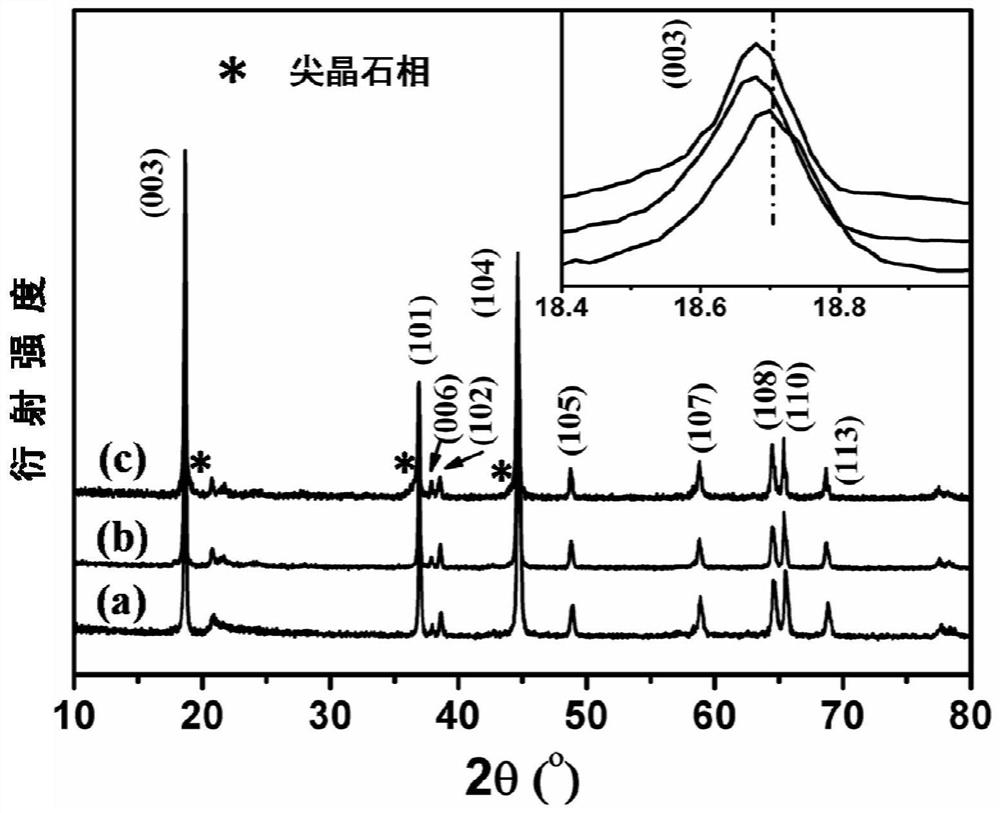

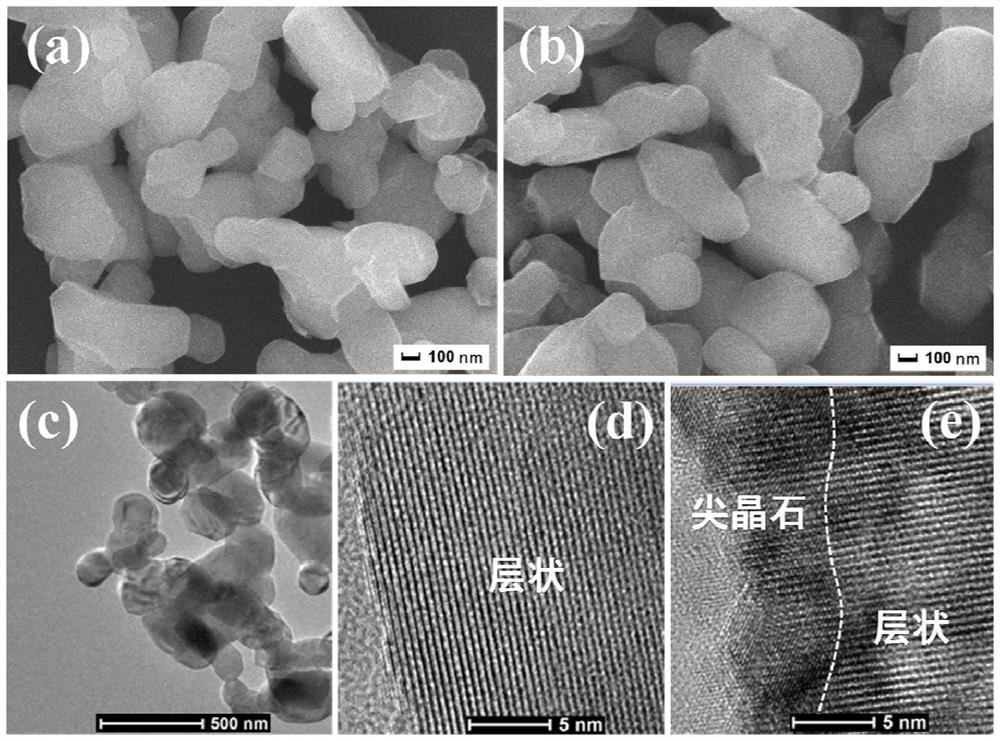

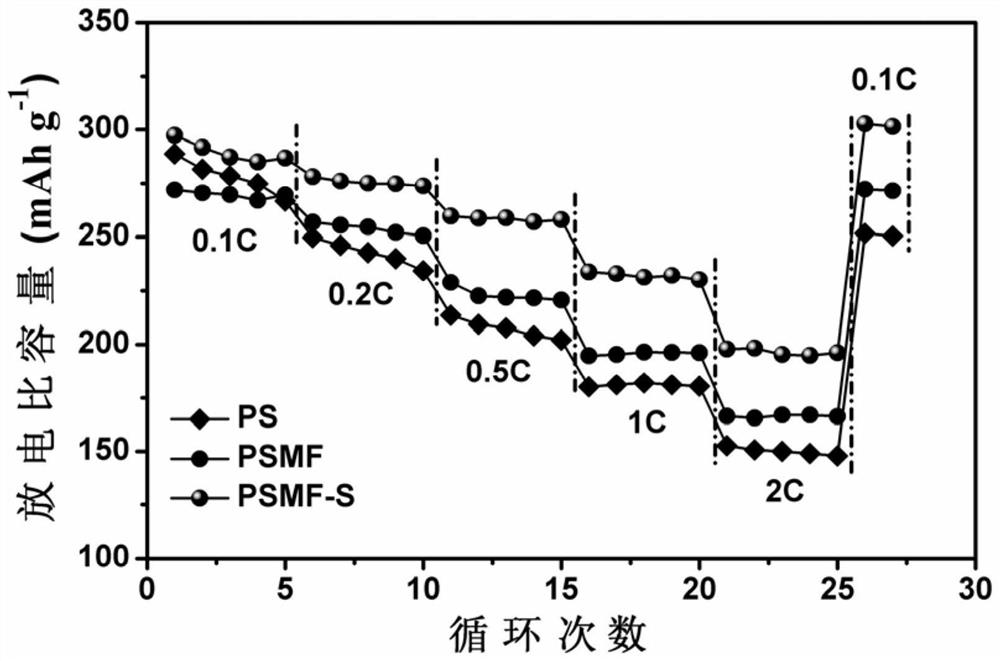

[0046] Synergistic doping of Mo and F ions and in-situ coating modification of spinel applied to lithium-rich manganese-based ternary cathode material Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 , prepared by the following steps:

[0047] (1) Prepare agar solution with a concentration of 30mg / mL, add lithium, nickel, cobalt and manganese nitrate, add ammonium heptamolybdate and lithium fluoride, wherein Mo 6+ and F - The moles are respectively 5.0% and 4.0% of the total moles of heavy metal ions. Add citric acid as a complexing agent to make a mixed solution, stir at 80 °C for 1 h, wait for it to cool to form a gel, prepare the precursor powder by freeze-drying, and sinter the precursor powder at 950 °C for 10 h to obtain Mo and F Lithium-rich cathode material modified by ion synergistic doping, the chemical formula is Li 1.168 mn 0.54 Ni 0.09 co 0.13 Mo 0.04 o 1.968 f 0.032 , as a nucleosome;

[0048] (2) preparation concentration is the tartaric acid solution of 5mg / mL;...

Embodiment 2

[0056] Example 2: Mo and F ion synergistic doping and spinel in-situ coating modification applied to lithium-rich manganese-based cathode material Li 1.2 mn 0.6 Ni 0.2 o 2

[0057] (1) prepare the agar solution that concentration is 20mg / mL, add the nitrate of lithium, nickel and manganese, add ammonium heptamolybdate and lithium fluoride, wherein, Mo 6+ and F - The moles are respectively 6.0% and 1.5% of the total moles of heavy metal ions. Add citric acid as a complexing agent to make a mixed solution, stir at 80 °C for 1 h, wait for it to cool to form a gel, prepare the precursor powder by freeze-drying, and sinter the precursor powder at 950 °C for 10 h to obtain Mo and F Lithium-rich cathode material modified by ion synergistic doping, the chemical formula is Li 1.188 mn 0.6 Ni 0.152 Mo 0.048 o 1.988 f 0.012 , as a nucleosome;

[0058] (2) preparation concentration is the tartaric acid solution of 3mg / mL;

[0059] (3) Take 1 g of nucleosome material powder an...

Embodiment 3

[0062] Example 3: Mo and F ion synergistic doping and spinel in-situ coating modification applied to lithium-rich manganese-based cathode material Li 1.2 mn 0.6 Ni 0.2 o 2

[0063] (1) prepare the agar solution that concentration is 50mg / mL, add the nitrate of lithium, nickel and manganese, add ammonium heptamolybdate and lithium fluoride, wherein, Mo 6+ and F - The moles are respectively 4.0% and 1.0% of the total moles of heavy metal ions. Add citric acid as a complexing agent to make a mixed solution, stir at 80 °C for 1 h, wait for it to cool to form a gel, prepare the precursor powder by freeze-drying, and sinter the precursor powder at 950 °C for 10 h to obtain Mo and F Lithium-rich cathode material modified by ion synergistic doping, the chemical formula is Li 1.19 mn 0.6 Ni 0.168 Mo 0.032 o 1.99 f 0.01 as nucleosomes;

[0064] (2) preparing a cysteine solution with a concentration of 1 mg / mL;

[0065] (3) Take 1 g of nucleosome material powder and add it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com