Functionalized graphene and its preparation method and its flame-retardant crosslinked polyurethane rigid foam

A technology of rigid foam and graphene, which is applied in the field of rigid polyurethane foam, can solve the problems of decreased dimensional stability and foam strength, and achieve the effects of increasing dimensional stability, increasing cross-linking degree, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

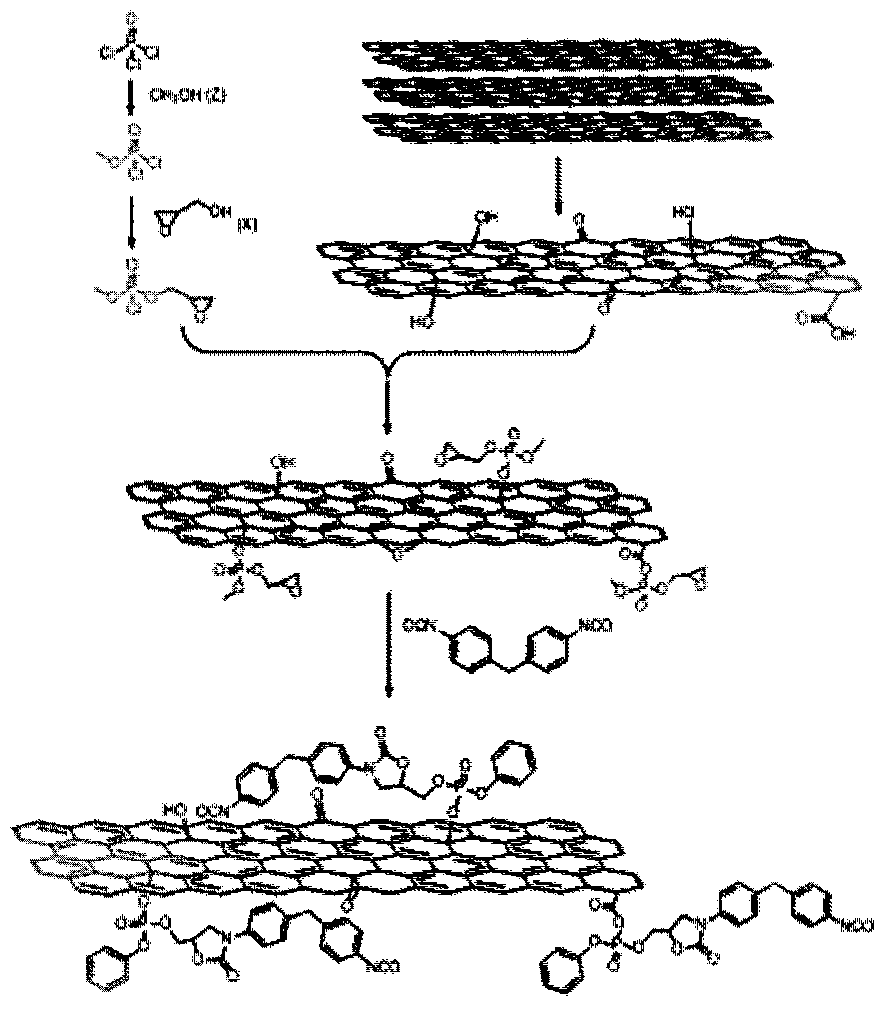

Method used

Image

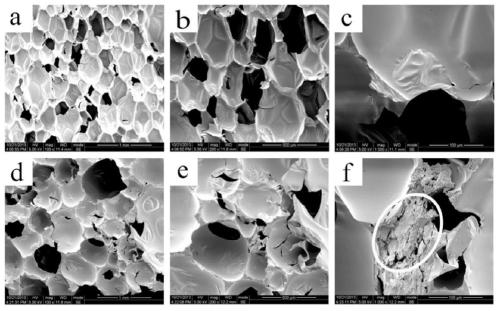

Examples

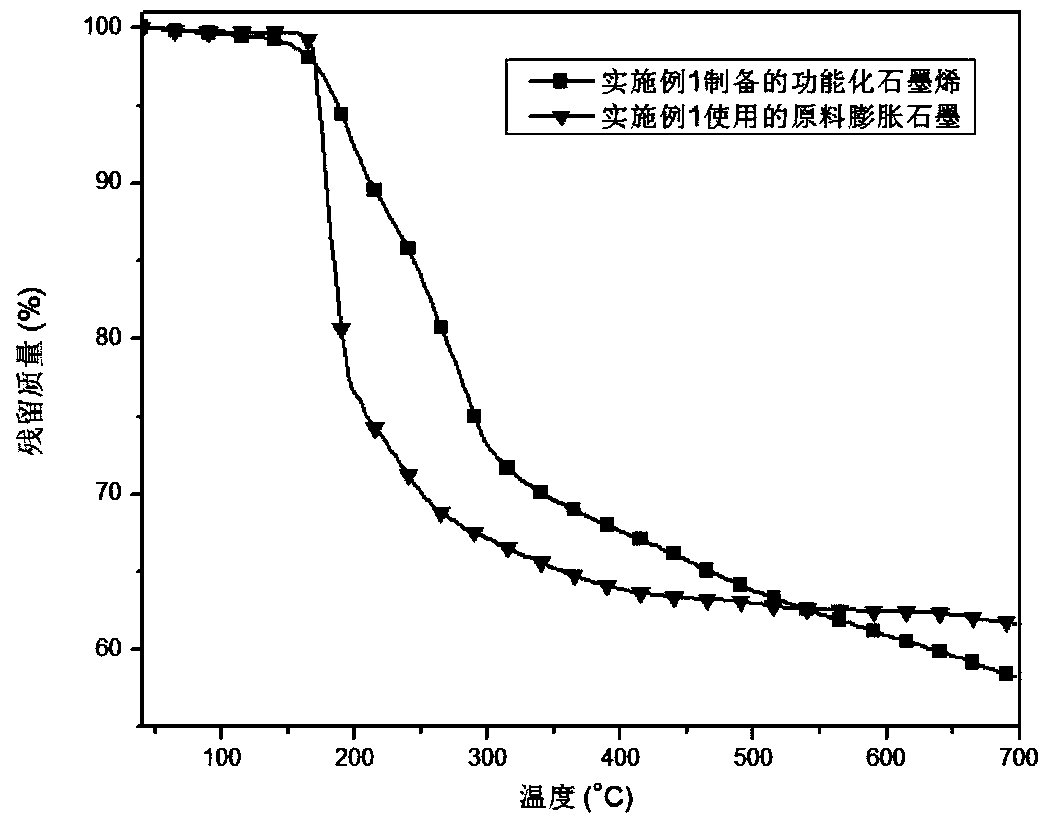

Embodiment 1

[0044] (1) Hummer method to prepare graphene

[0045] Put 10g of expanded graphite, 5g of nitric acid and 230ml of sulfuric acid into a three-necked flask, slowly add 30g of potassium permanganate under mechanical stirring in an ice bath, keep the temperature not exceeding 9°C, remove the water bath, react at 35°C for 4 hours, and dissolve the reactant in 460ml of water Slowly dilute, the temperature rises to about 98°C and keeps for 1h. After continuing to dilute with 1400ml of water, treat the reactant with 3% hydrogen peroxide until bright yellow, filter with suction, wash, reduce with 50ml of hydrazine hydrate, filter with suction, wash and dry.

[0046] (2) Preparation of grafts

[0047]

[0048] Put 30.6g of phosphorus oxychloride in a three-necked flask, and slowly drop in 6.4g of methanol within 30 minutes. The temperature was raised slowly to 50°C, and the chloroform was distilled off after 4 hours of reaction. The temperature was raised until the solution boile...

Embodiment 2

[0059] (1) Hummer method to prepare graphene

[0060]Put 10g of expanded graphite, 5g of nitric acid and 230ml of sulfuric acid into a three-necked flask, slowly add 30g of potassium permanganate under mechanical stirring in an ice bath, keep the temperature not exceeding 9°C, remove the water bath, react at 35°C for 4 hours, and dissolve the reactant in 460ml of water Slowly dilute, the temperature rises to about 98°C and keeps for 1h. After continuing to dilute with 1400ml of water, treat the reactant with 3% hydrogen peroxide until bright yellow, filter with suction, wash, reduce with 50ml of hydrazine hydrate, filter with suction, wash and dry.

[0061] (2) Preparation of grafts

[0062]

[0063] Put 19.4g of phenylphosphoryl dichloride in a three-necked flask, dilute and dissolve 7.4g of glycidyl alcohol with 150ml of acetone under ice bath, and then slowly add it dropwise within 2h. After the dropwise addition, slowly raise the temperature and reflux for 3h.

[0064...

Embodiment 3

[0070] (1) Hummer method to prepare graphene

[0071] Put 10g of expanded graphite, 5g of nitric acid and 230ml of sulfuric acid into a three-necked flask, slowly add 30g of potassium permanganate under mechanical stirring in an ice bath, keep the temperature not exceeding 9°C, remove the water bath, react at 35°C for 4 hours, and dissolve the reactant in 460ml of water Slowly dilute, the temperature rises to about 98°C and keeps for 1h. After continuing to dilute with 1400ml of water, treat the reactant with 3% hydrogen peroxide until bright yellow, filter with suction, wash, reduce with 50ml of hydrazine hydrate, filter with suction, wash and dry.

[0072] (2) Preparation of grafts

[0073]

[0074] Put 25.0g of pyrophosphate chloride in a three-necked flask, dilute and dissolve 7.4g of glycidol with 150ml of acetone, and then slowly add it dropwise in 2 hours under an ice-water bath. After the dropwise addition, slowly raise the temperature and reflux for 5 hours.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com