Patents

Literature

93results about How to "Will not negatively affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromatic bituminous cement improving workability

InactiveCN101205371AReduce construction temperatureEasy constructionBuilding insulationsPetroleum resinRoad surface

The invention discloses a colorful asphalt binder. The component of the colorful asphalt binder of the invention calculated by weight percentage comprises 20-65 per cent of petroleum resin, 30-79 per cent of lubricant refined extract oil and 1-5 per cent of polyethylene wax. By pulling a little of polyethylene wax into conventional colorful asphalt binder, temperature of mixing, spreading and rolling of asphalt mixture can be greatly reduced and negative influence on final colorful asphalt pavement is not caused, which allows an easy construction. As the same time, the reduction of construction temperature and odor emitted by the binder are decreased, which are in favor of environment protection. As the same time, addition of SEBS, SIS and SBR allows the colorful asphalt binder to be provided with better high-temperature stability.

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

Preparation method for amphoteric hydroxypropyl guar gum derivative

The invention discloses a preparation method for an amphoteric hydroxypropyl guar gum derivative. The preparation method is characterized by comprising the following steps: (1) performing esterification reaction on hydroxypropyl guar gum and toluene sulfochloride to obtain hydroxypropyl guar gum tosylate; (2) employing an amination reagent to perform nucleophilic substitution on hydroxypropyl guar gum tosylate, removing tosylate group, so as to obtain an amino guar gum derivative; and (3) reacting the amino guar gum derivative under the catalysis of an acid, so as to obtain an amphoteric polymer containing both amino and carboxyl. The preparation method is a new method for preparing the amphoteric guar gum derivative in the field, and the method is simple and practicable, and the reactions are easy to control.

Owner:昆山京昆油田化学科技有限公司

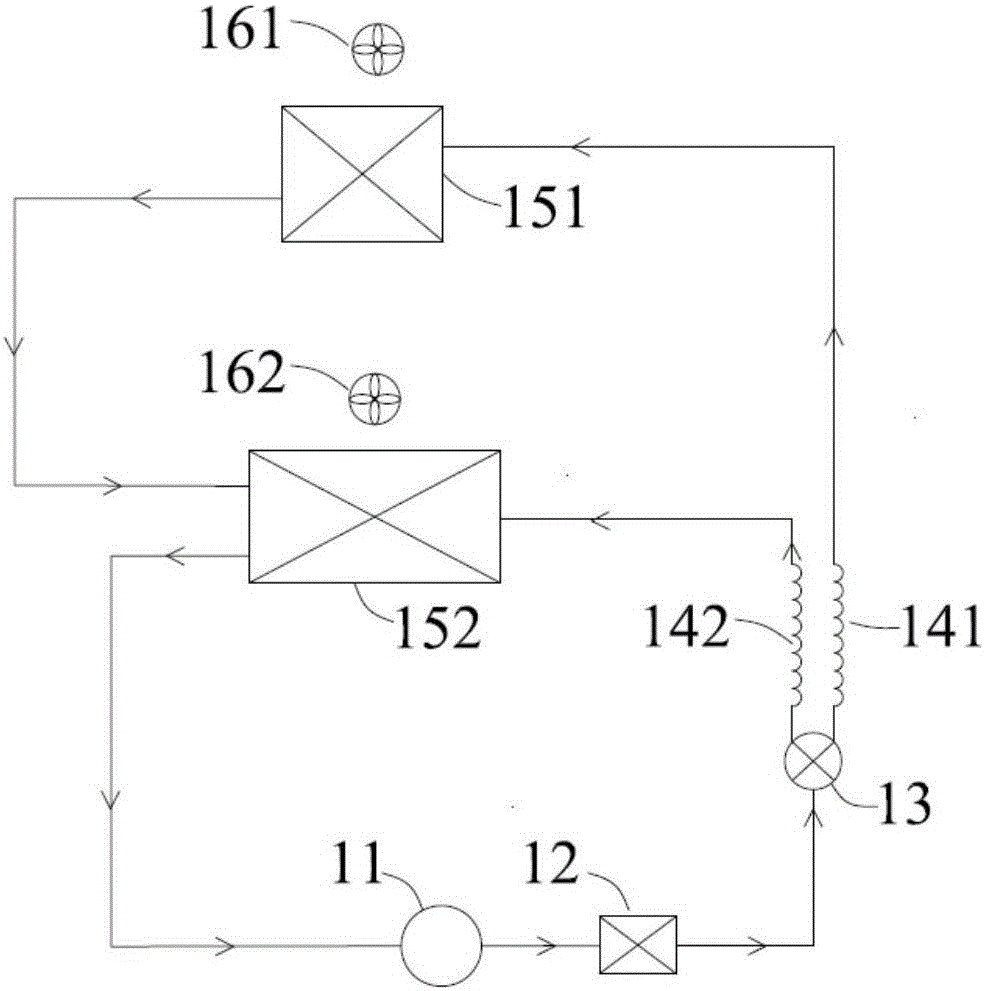

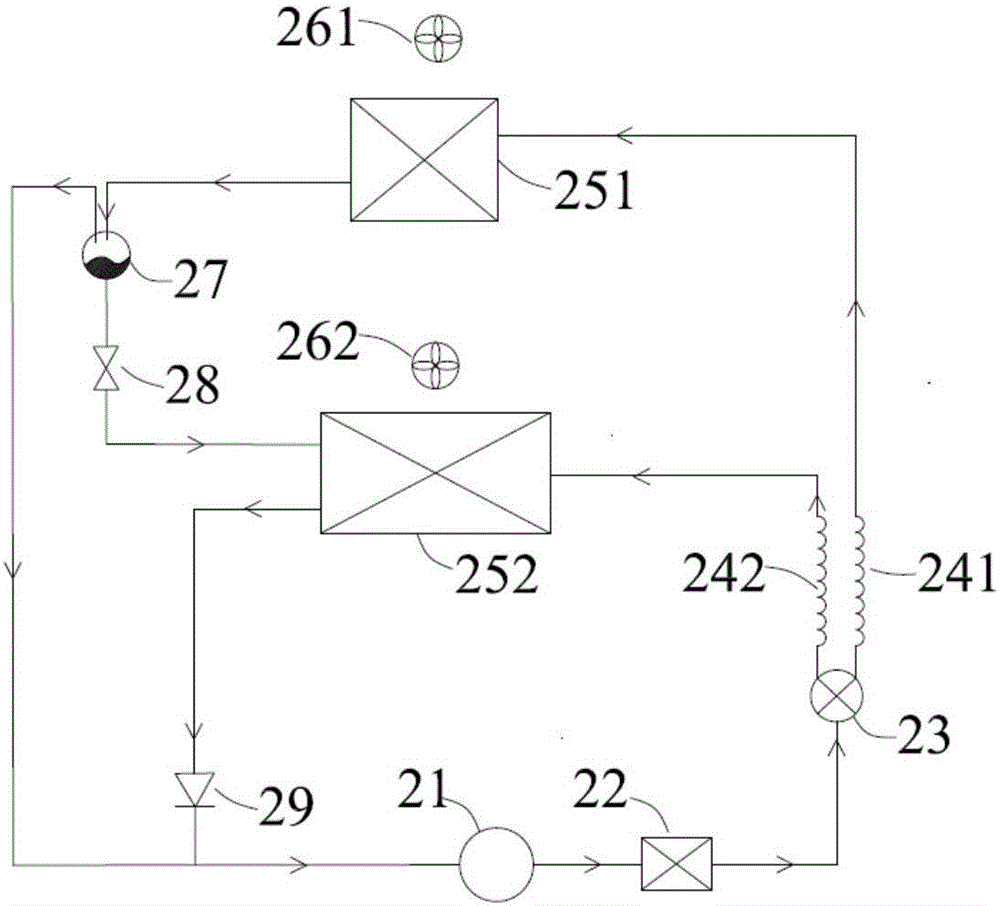

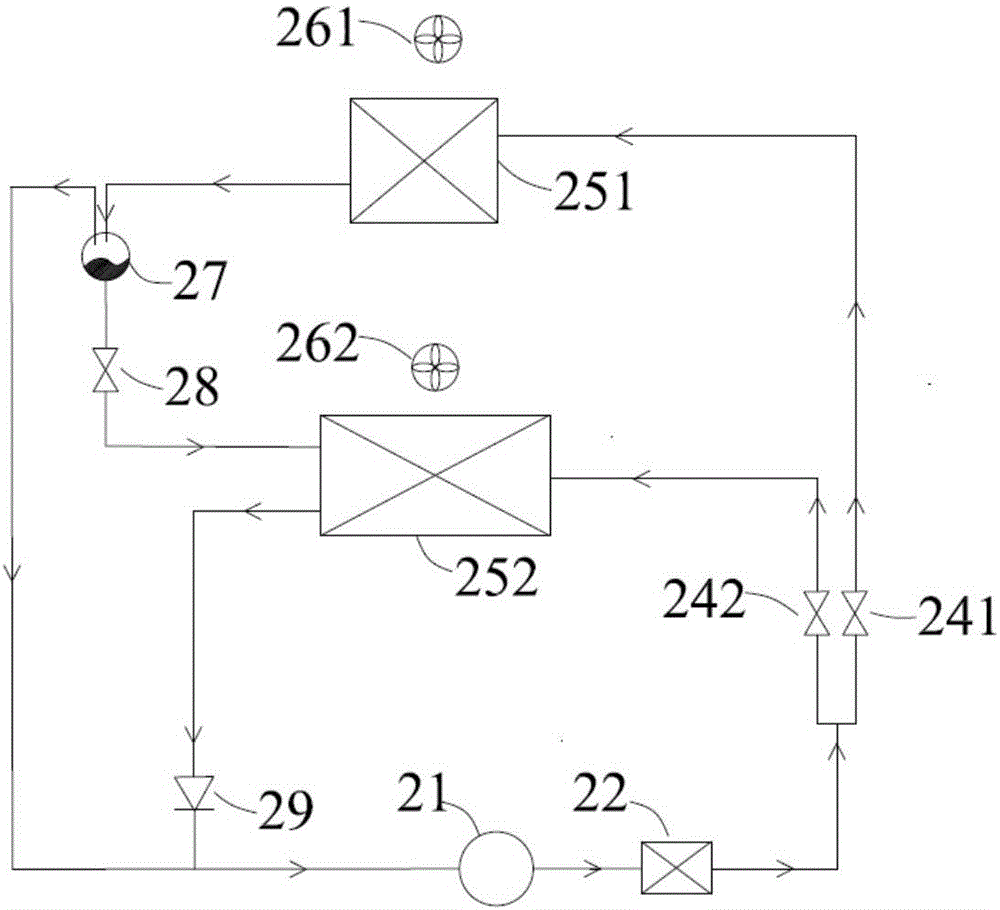

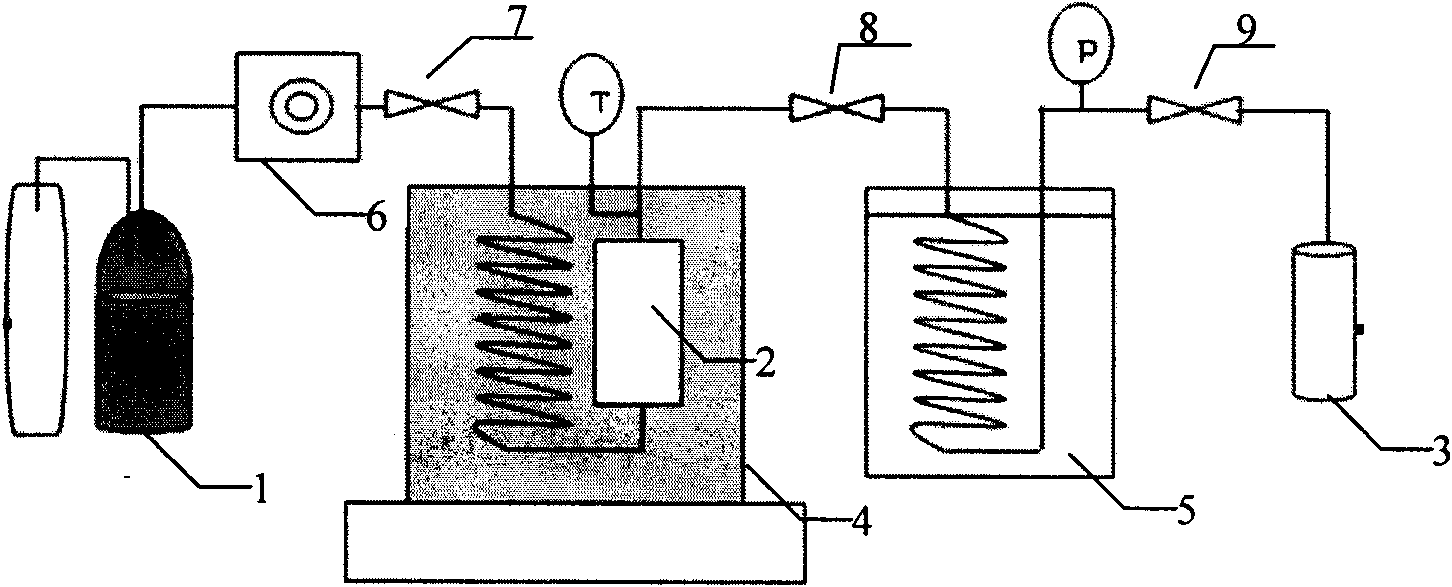

Series-parallel connection dual-evaporator refrigeration system, refrigerator provided with such system and control method

InactiveCN106766526AWon't interfereReduce the temperatureMechanical apparatusDomestic refrigeratorsFreezing chamberEngineering

The invention discloses a series-parallel connection dual-evaporator refrigeration system which comprises a freezing refrigeration component and a cold storage refrigeration component, wherein the cold storage refrigeration component is internally provided with a vapor-liquid separator and a first electronic expansion valve, in the refrigeration process of a refrigerator, if a refrigerant needs to pass through a cold storage evaporator and a freezing evaporator simultaneously, the refrigerant enters the freezing evaporator after processed by the vapor-liquid separator and the first electronic expansion valve, and the refrigerant, after processed, can reach relatively low evaporating temperature in the freezing evaporator to make the refrigeration system able to maintain relatively low temperature inside the freezing chamber while realizing the process of internal refrigeration in the cold storage chamber simultaneously, without generating a negative effect on the interior of the freezing chamber.

Owner:HAIER SMART HOME CO LTD

Catalyst system for synthesis of diphenyl carbonate by ester exchange reaction

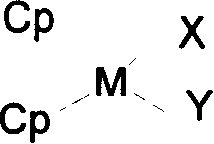

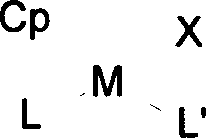

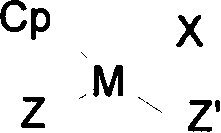

ActiveCN1698960AHigh activityEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMetalDicyclopentadiene

This invention relates to a catalyst system used for synthesizing diphenyl carbonate in the ester exchange reaction. Said catalyst system comprises primary cyclopentadienyl compound of IVB family metal, and it can be dicyclopentadiene compound, or single cyclopentadienyl compound, or their homologue. The catalyst has high selective and active, making the selective reach to 98%; besides, the catalyst system can be exist stably in air; the catalyst is homogeneous phase in reaction condition, and can be recovered, so it can be widely used in producing diphenyl carbonate.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

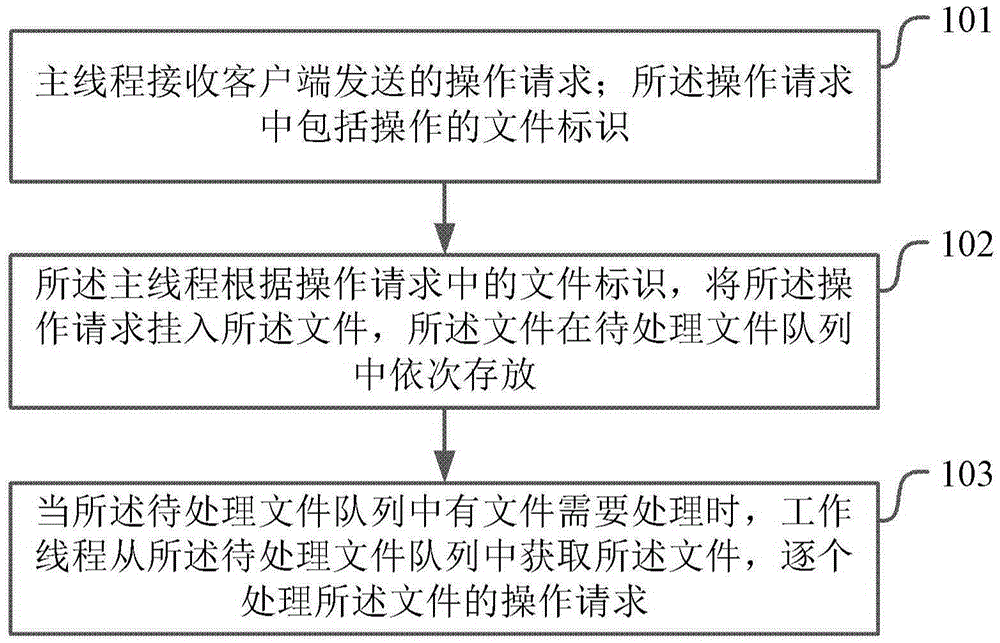

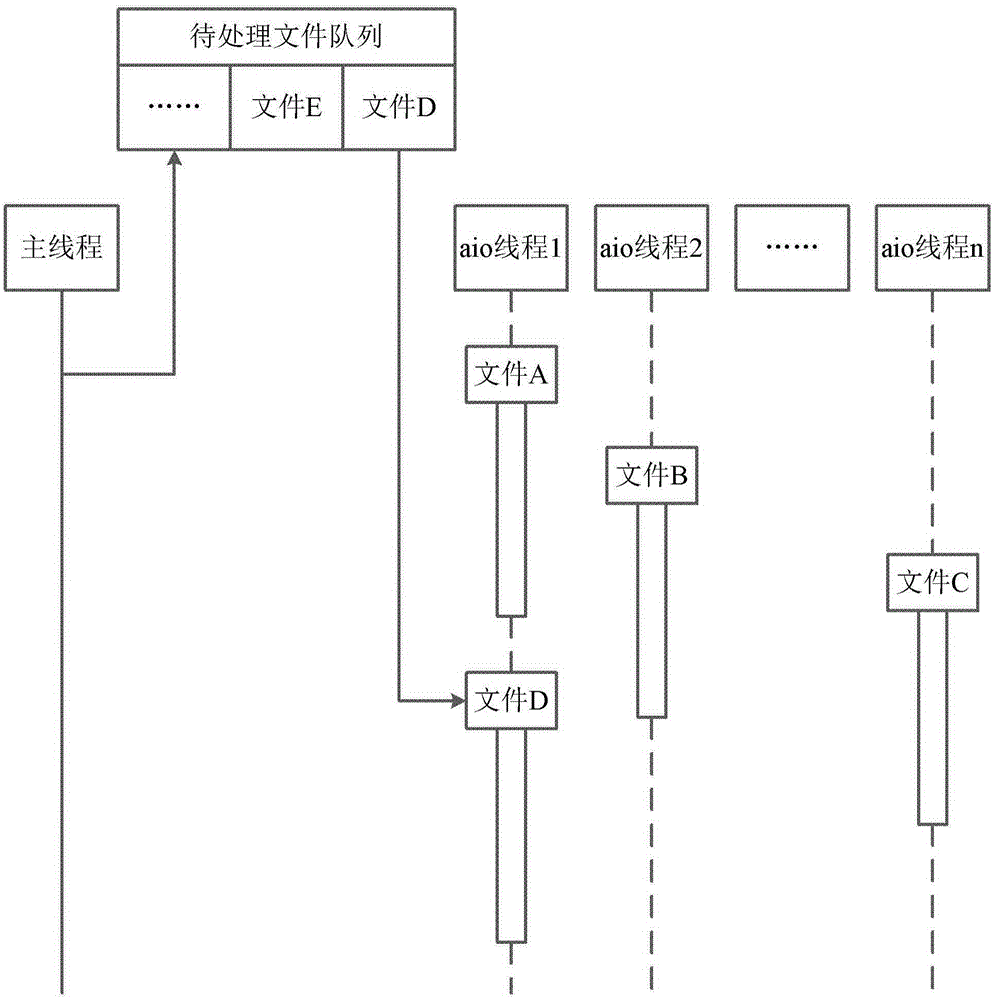

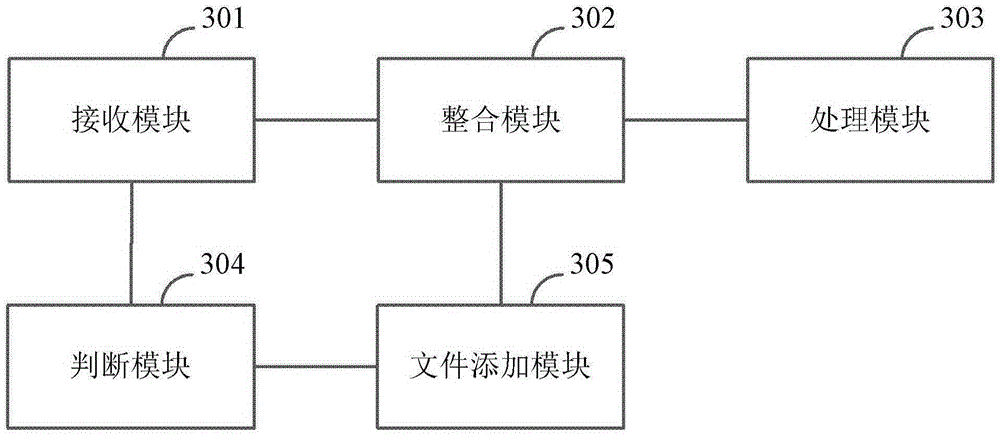

File processing method and device

InactiveCN105353987AWill not negatively affectOperation request balancingInput/output to record carriersSerializationLow delay

The invention provides a file processing method and device. The file processing method comprises the steps of receiving an operation request sent from a client by a main thread, wherein the operation request comprises operated file IDs; carrying the operation request into the files based on the file IDs in the operation request by the main thread and storing the files in a to-be-processed file queue in sequence; and when files in the to-be-processed file queue need to be processed, obtaining the files from the to-be-processed file queue by a working thread and processing operation requests of the files one by one. As the main thread in the embodiment integrates the operation requests, and operation requests for the same file are integrated together, a race condition of writing operation is excluded through a processing serialization mode for the same files; as pre-reading and magnetic disk bandwidth can be fully utilized, no obvious negative influence to a universal scene can be generated, a performance demand on a high-concurrency and low-delay scene also can be satisfied, and operation requests in the high-concurrency scene can be balanced efficiently.

Owner:SUGON INFORMATION IND

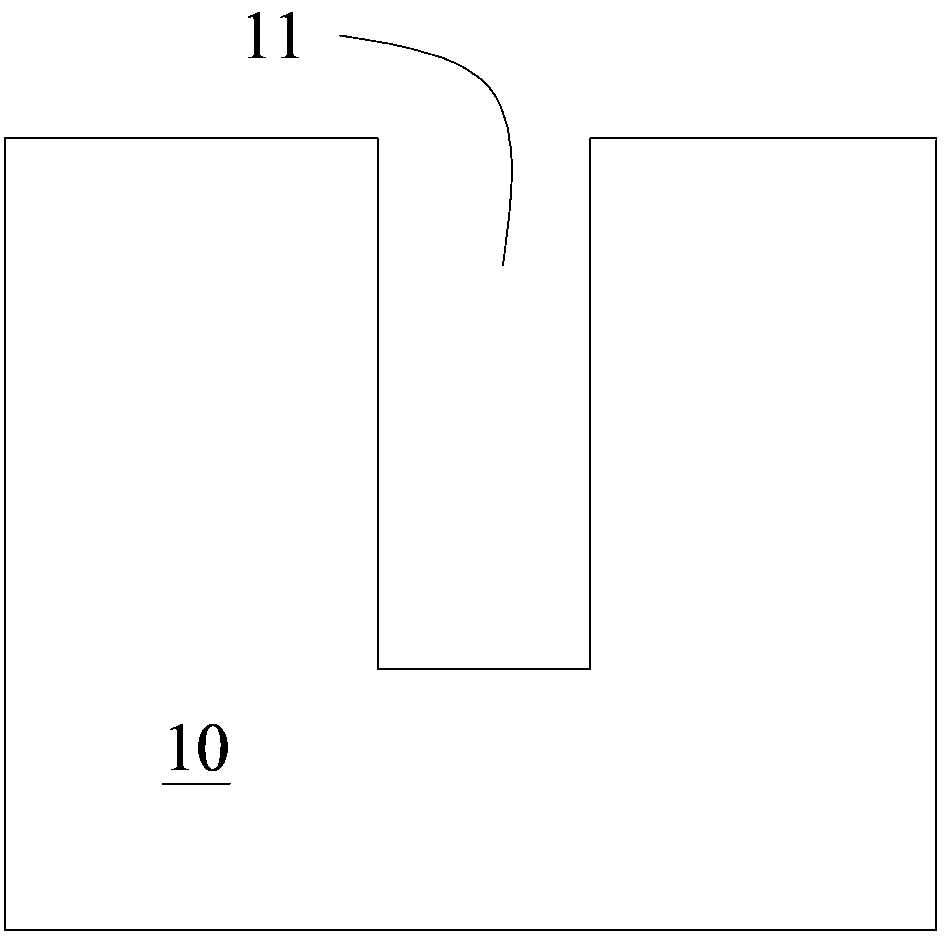

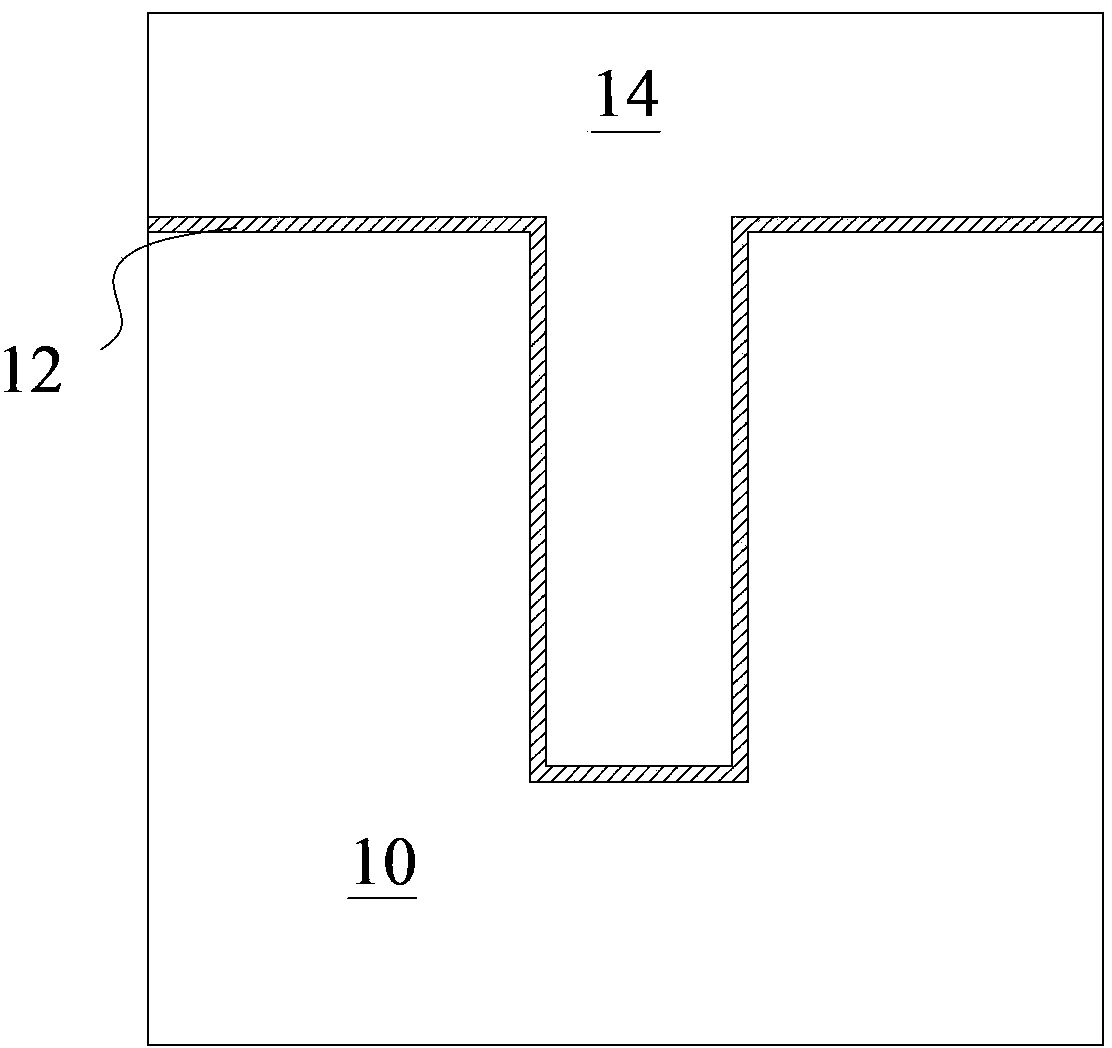

Conductive plug and TSV forming method

InactiveCN104143527AReduce forceAvoid situations where stress cannot be relievedSemiconductor/solid-state device manufacturingThermal expansionVolume deformation

The invention provides a conductive plug and TSV forming method. The conductive plug forming method includes the steps that a blind hole is formed in a semiconductor substrate, after metal layers are formed in the blind hole and formed on the semiconductor substrate, the metal layer, of the part of the full thickness, on the semiconductor substrate is removed first, and the substrate is heated by adopting the annealing technology, so that refinement, regrowth and homogenization of crystalline grains in the metal layers are achieved, and the internal structure of the metal layers is optimized. After the metal layer, of the part of the full thickness, on the semiconductor substrate is removed, while stress generated by deformation of the metal layers in the annealing process can be effectively reduced, stress generated by volume deformation, based on heat-expansion and cold-contraction, of the semiconductor substrate and structures on all the layers on the semiconductor substrate is fully released, acting force between the substrate and the structures on all the layers is reduced, and cracks on the connection faces between the semiconductor substrate and the structures on all the layers in the semiconductor substrate are avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

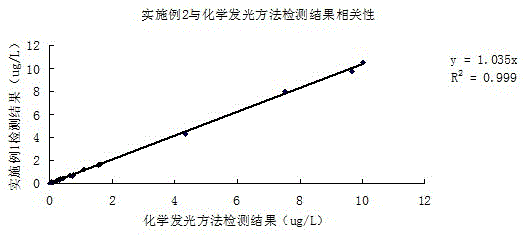

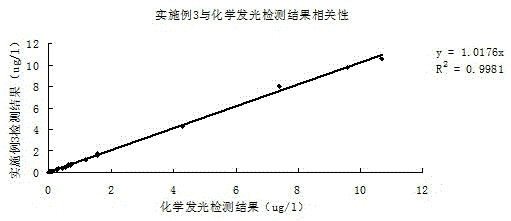

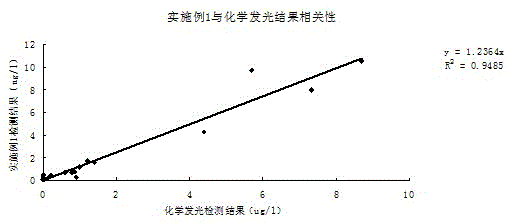

Troponin I detection reagent with high sensitivity through latex enhanced turbidimetric Immunoassay

InactiveCN105628930AImprove buffering effectGuaranteed cushioning effectDisease diagnosisBiological testingImmunonephelometric AssaysLatex particle

The invention relates to the technical field of troponin I detection, in particular to a troponin I detection reagent with high sensitivity through latex enhanced turbidimetric Immunoassay. The reagent comprises the following main components: a buffer solution, zinc chloride, Thesit, EMULGEN-A90, and a nitriloriacetic acid (NTA) preservative; a reagent R2 comprises the following main components: a buffer solution, triton-308, bovine serum albumin (BSA), a preservative, TnI antibody-coated latex particles and the like. The three surfactants, namely Thesit, EMULGEN-A90 and triton-308 are added, and the latex particles with appropriate particle sizes are selected, so that the reaction sensitivity is greatly improved, and the reagent is simple in product configuration, low in cost and very suitable for clinical expansion in large scale.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

Method for removing lignin from biomass by using alkaline electrolyzed functional water

InactiveCN101962449AWill not negatively affectHigh removal ratePaper material treatmentPre treatmentHemicellulose

The invention discloses a method for removing lignin from a biomass raw material. The method comprises the step of placing the biomass raw material into alkaline electrolyzed functional water to perform a continuous hydrolysis reaction so as to remove the lignin, one of the three components in the biomass raw material, to obtain cellulose and hemicellulose so as to contribute to the later enzymolysis and fermentation. The alkaline electrolyzed functional water is applied to a biomass pretreatment technique; and compared with the method using the traditional media such as aqueous alkali and the like, the method for removing the lignin from the biomass raw material by using the alkaline electrolyzed functional water has the advantages of: (1) simple preparation, no toxicity, no harm and low price; (2) basically no negative influence on environments, no wastes, no waste liquid and green production process; and (3) no negative influences, such as corrosion, damage and the like, on stainless steel pretreatment equipment. By the method of the invention, the removing rate of the lignin from the biomass raw material is up to 90 percent.

Owner:CHINA AGRI UNIV

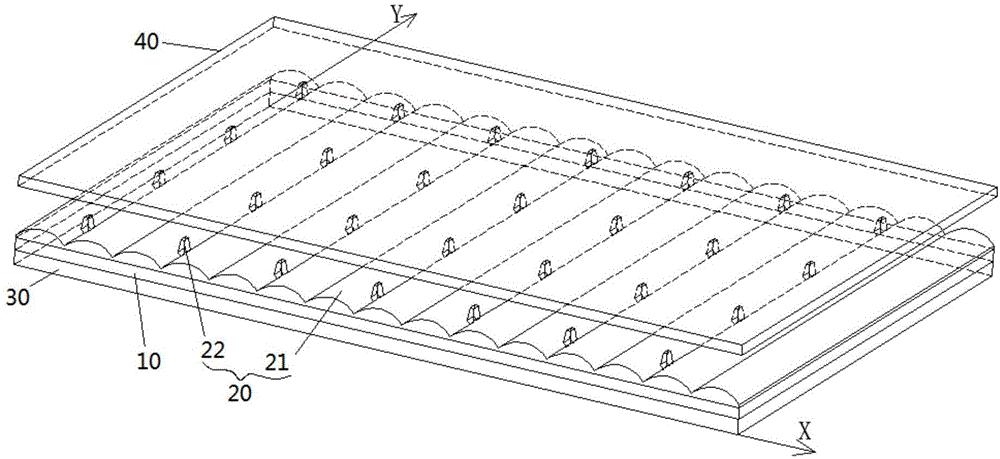

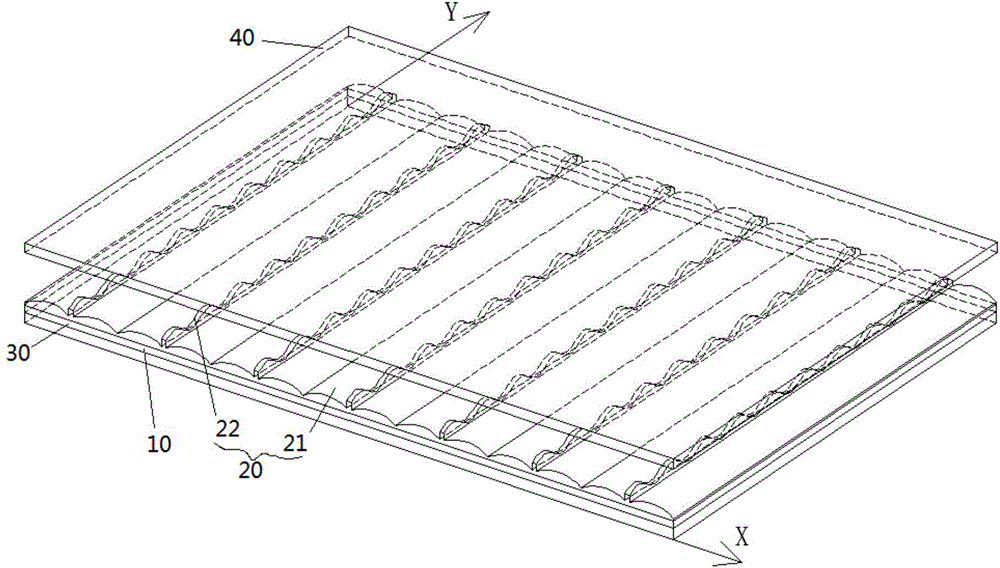

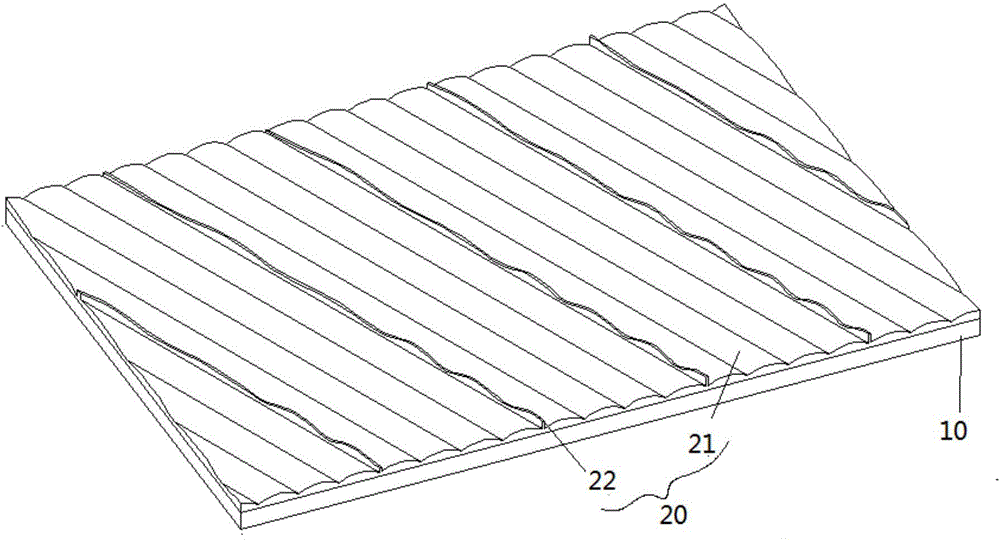

3D film and display device

The invention provides a 3D film and a display device. The 3D film comprises a substrate layer and a microstructure layer, wherein the microstructure layer is arranged on the substrate layer and comprises a plurality of cylindrical lens structures and a plurality of support structures, the plurality of cylindrical lens structures are arranged in a first direction, the support structures are arranged between every two adjacent cylindrical lens structures, and the support structures are higher than the cylindrical lens structures. The support structures are higher than the cylindrical lens structures, so that a sufficient safe distance can be reserved between a display screen and a touch screen which are arranged on two sides of the 3D film, and the display device can be prevented from generating a newton ring when the 3D film is integrated to the display device; meanwhile, the 3D film can keep the original 3D display function and cannot have the negative influence on the display device; the display device has the characteristics of lightness and thinness.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

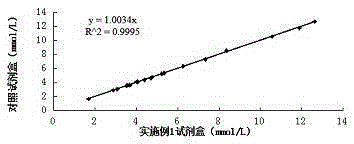

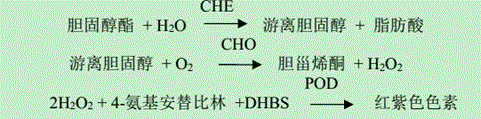

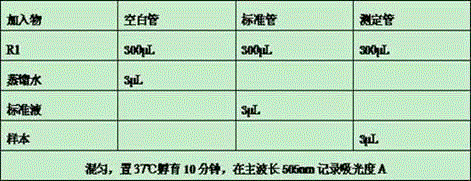

Total cholesterol detection reagent with high accuracy and disturbance resisting capacity

ActiveCN105385751AWill not negatively affectGuaranteed cushioning effectMicrobiological testing/measurementCholesterolActive agent

The invention provides a total cholesterol detection reagent with high accuracy and disturbance resisting capacity and relates to the technical field of total cholesterol detection. A biological buffer CAPS (3-(hexanaphthene amino)-1-propanesulfonic acid) is used in the reagent R, and therefore the buffering ability is ensured; a surfactant octadecy trimethyl ammonium bromide and a surfactant EMULGEN-707 are added into the reagent R, the emulsification effect of the reagent is improved well, and the accuracy and specificity of the reagent are improved; stabilizers such as trehalose and mannitol are added into the reagent R, and the stability of the reagent can be improved effectively; hydroxy ethidene diphosphonic acid is added into the reagent R, heavy metal ions can be effectively chelated, and the accuracy of the reagent can be improved; chemical-resistant succinoxidase and bilrubin oxidase are added into the reagent, disturbance of ascorbic acid and bilirubin can be effectively removed, and the reagent is simple in preparation, low in price and very suitable for large-area clinical popularization.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

Cysteine reinforcement method for rotten silk cultural relics

InactiveCN102433738AImprove breaking strengthHigh elongation at breakAnimal fibresBreaking strengthAqueous solution

The invention relates to a cysteine reinforcement method for rotten silk cultural relics, which is characterized by comprising the following steps: A), preparing L-cysteine aqueous solution with the mass percentage concentration being 2.5 percent; and B), adopting a spraying method to spray the cysteine aqueous solution onto surfaces of the rotten silk cultural relics until the rotten silk cultural relics are uniformly wetted by the cysteine aqueous solution and water drops down, and naturally drying the rotten silk cultural relics, thereby reinforcing the rotten silk cultural relics. Compared with the prior art, the method has the advantages that: 1) the operation is convenient; 2) other chemical additives are not needed except cysteine, the breaking strength and breaking elongation of weak silk can be significantly improved after reinforcement, and no negative impact can be produced on the cultural relics.

Owner:ZHEJIANG SCI-TECH UNIV

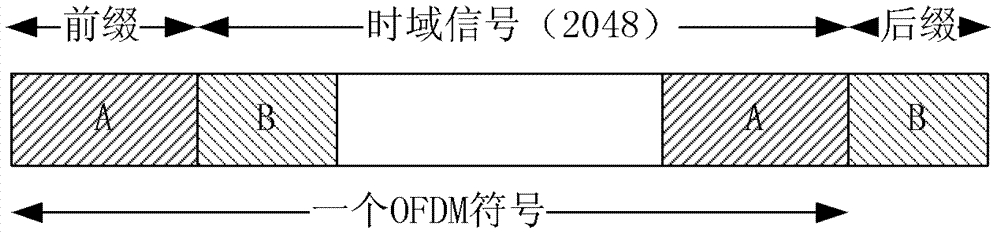

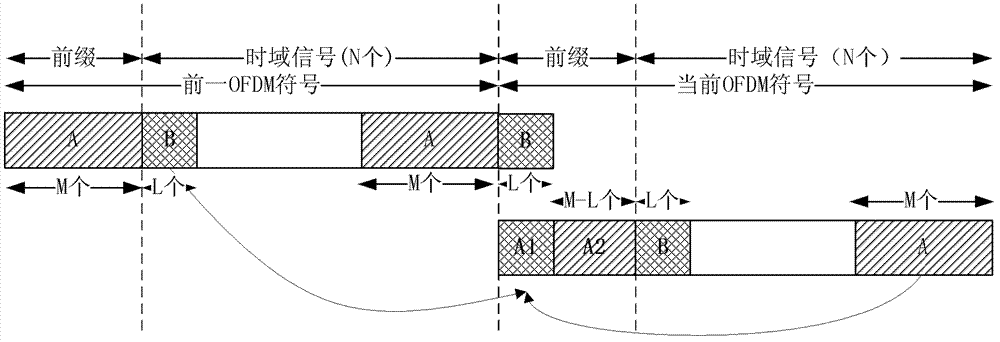

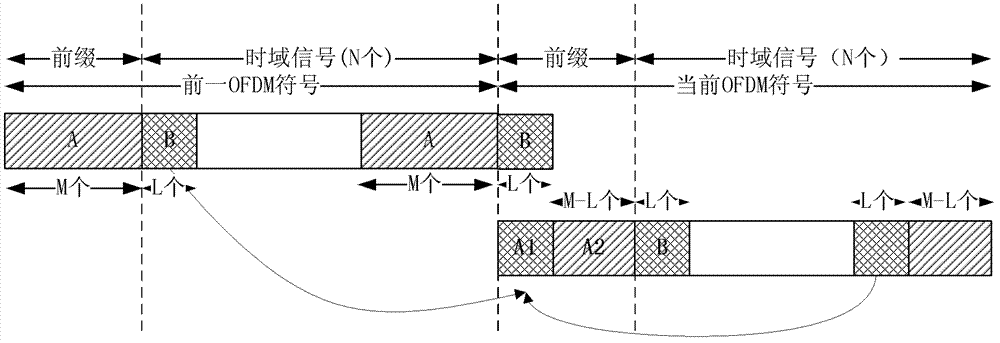

Method and device for reducing frequency spectrum leakage

ActiveCN102957653AWill not negatively affectReduce Spectral LeakageMulti-frequency code systemsTime domainFrequency spectrum

The invention discloses a method and a device for reducing frequency spectrum leakage. The method includes constructing L substitute sample points according to the previous L time-domain sample points in time-domain sample points of the previous OFDM (orthogonal frequency division multiplexing) symbol in current OFDM symbols and after M time-domain sample points of the time-domain sample points of the current OFDM symbols, combining the L substitute sample points with the after M-1 time-domain sample points in the M time-domain sample points to form M new sample points, and taking the M new sample points as cyclic prefix of the current OFDM symbols. On the basis of characteristics of transmitted baseband signals, signal structure of the cyclic prefix is modified, so that the ACLR (adjacent channel leakage rate) of the modified baseband signals is increased by at least 15dB, and frequency spectrum leakage is decreased. The modification of the signal structure accords with LTE (telecommunication) standards and is compatible with air-interface signals completely, and causes no adverse affection to receivers.

Owner:ZTE CORP

Chromatic bituminous cement and preparation method thereof

InactiveCN101205373AReduce construction temperatureEasy constructionBuilding insulationsPetroleum resinRoad surface

The invention discloses a colorful asphalt binder. The component of the colorful asphalt binder of the invention calculated by weight percentage comprises that: 20 per cent-65 per cent of petroleum resin, 30 per cent -79 per cent of lubricant refined extract oil and 1 per cent -5 per cent of polyethylene wax. By pulling a little of polyethylene wax into conventional colorful asphalt binder, temperature of mixing, spreading and rolling of asphalt mixture can be greatly reduced and negative influence on final colorful asphalt pavement is not caused. As the polyethylene wax is added, a reasonably low construction temperature can be obtained, which allows an easy construction. At the same time, the lowering of construction temperature decreases correspondingly the odor emitted by the asphalt binder, which is in favor of environmental protection. Simultaneously, the adding of SBR allows the colorful asphalt binder to be provided with a better high-temperature stability.

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

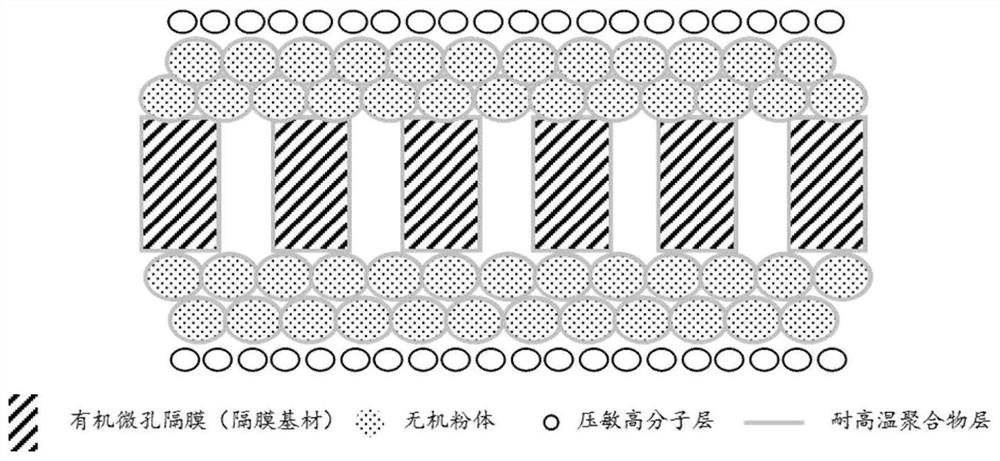

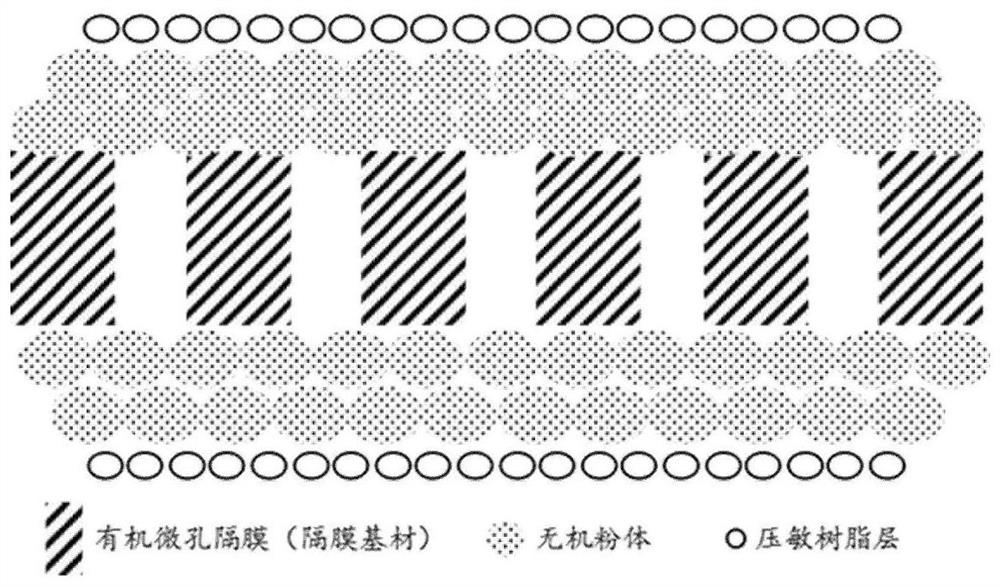

Pressure-sensitive polymer modified diaphragm as well as preparation method and application thereof

ActiveCN113224466AImprove adhesionSolve problems affecting battery cycle performanceSecondary cellsCell component detailsElastomerPolymer science

The invention discloses a pressure-sensitive polymer composite diaphragm as well as a preparation method and application thereof. A pressure-sensitive polymer layer is formed on the surface of a base material of the pressure-sensitive polymer composite diaphragm by coating, spraying or electrospinning a solution of a pressure-sensitive polymer material; the thickness of the pressure-sensitive polymer layer is 0.5 nm to 1 [mu] m; the pressure-sensitive polymer material comprises an elastomer type pressure-sensitive polymer and a resin type pressure-sensitive polymer; the elastomer pressure-sensitive polymer material comprises natural rubber and synthetic rubber; and the resin type pressure-sensitive polymer material comprises polyurethane, polyhalogenated olefin and derivatives thereof, organic silicon resin, fluororesin and polyacrylate. The problem that battery circulation is affected by residual gas due to poor adhesion between the diaphragm of the battery and the positive and negative electrodes is solved, so that the battery circulation performance is improved, and the battery circulation life is prolonged. The pressure-sensitive polymer of the diaphragm provided by the invention is suitable for compounding an existing diaphragm, and is very suitable for application scenarios requiring high safety characteristic and high energy storage performance.

Owner:XIAMEN UNIV

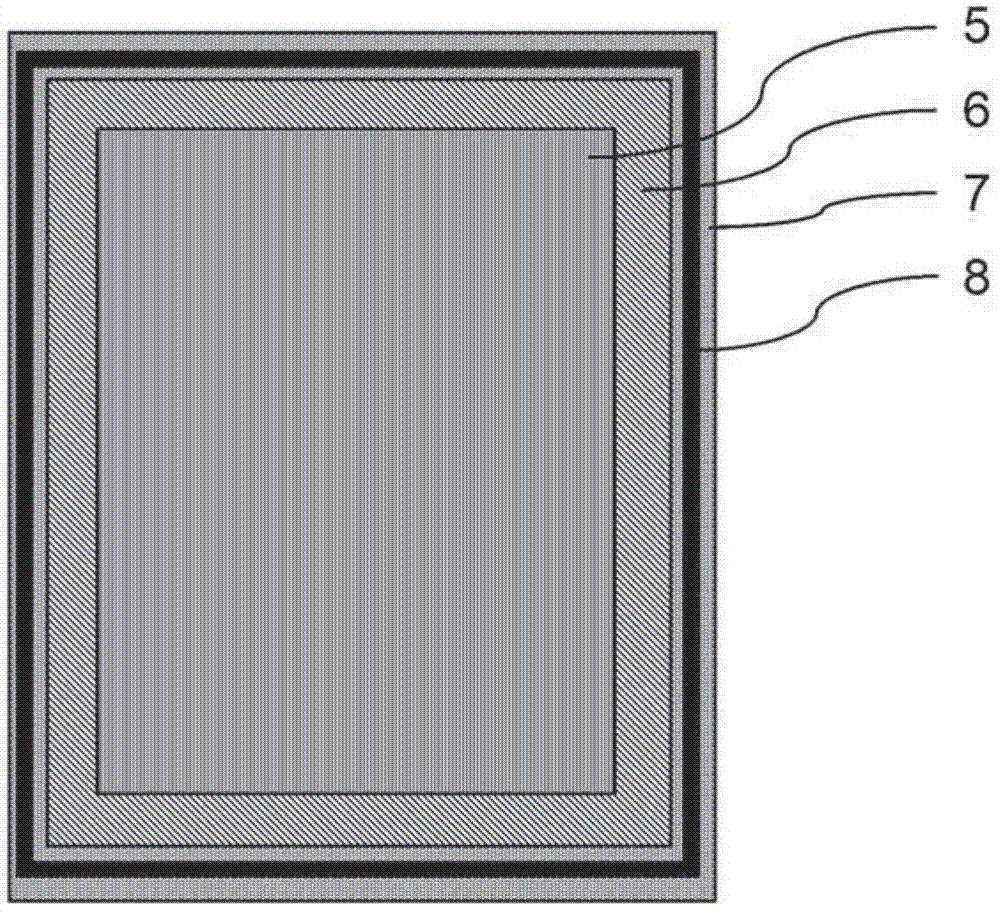

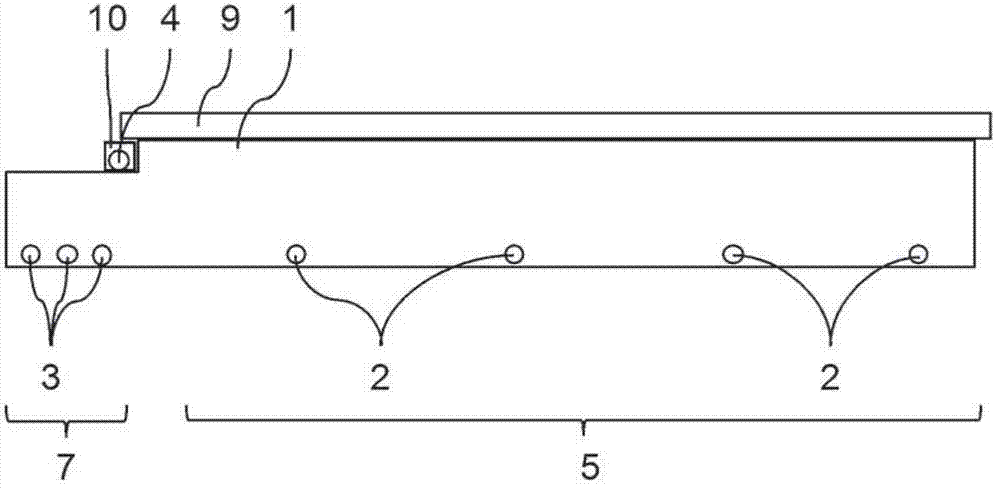

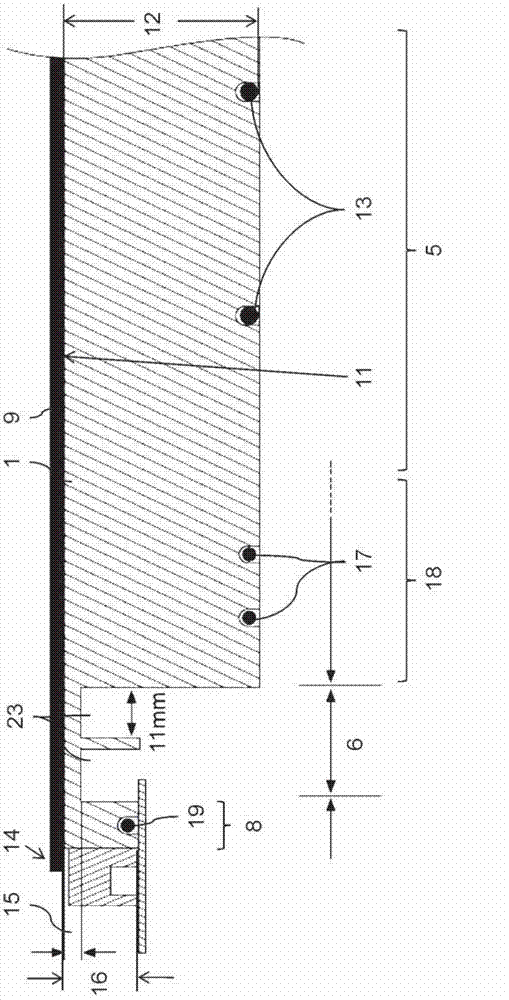

Substrate heating device

InactiveCN103081084AUniform thicknessUniform temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesSusceptorGas phase

The invention relates to a susceptor for supporting a substrate (9) within a vacuum process chamber, comprising a flat surface (11) for placing the substrate (9) thereon such that the substrate (9) is in thermally conductive contact with the surface (11), whereby the susceptor (1) comprises at least three adjacent zones (5, 6, 8), an outer zone (8), a middle zone (6) and an inner zone (5), the zones (5, 6, 8) arranged concentrically around each other and extending along the surface (11), the outer zone (8) completely surrounds the middle zone (6) and the middle zone (6) completely surrounds the inner zone (5), the inner zone (5) comprises at least one inner heating element (13) affecting the inner zone (5), the outer zone (8) comprises at least one outer heating element (19) affecting the outer zone (8), the middle zone (6) exhibits a maximal thickness (15); that is smaller than the minimal thickness (12) of the inner zone (5) and smaller than the minimal thickness (16) of the outer zone (8), each thickness (12, 15, 16) extending perpendicular to the surface (11). Thus, the invention allows for providing a smooth temperature profile over the complete surface (11) area resulting in a highly uniform substrate (9) temperature and thus in an improved thickness (12, 15, 16) uniformity of a coating to be provided e.g. in a chemical vapour deposition process.

Owner:东电电子太阳能股份公司

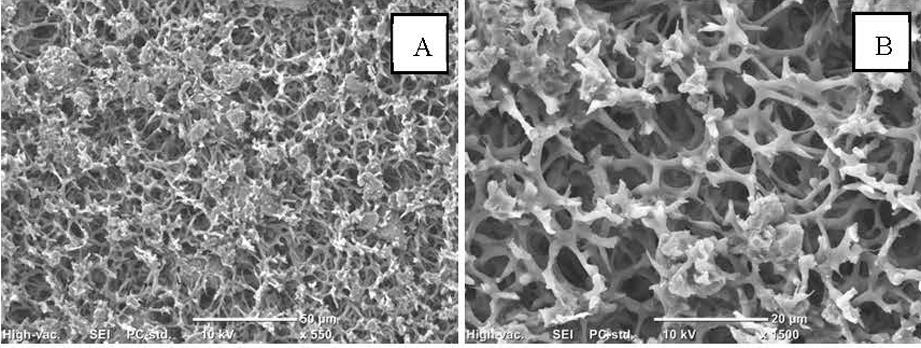

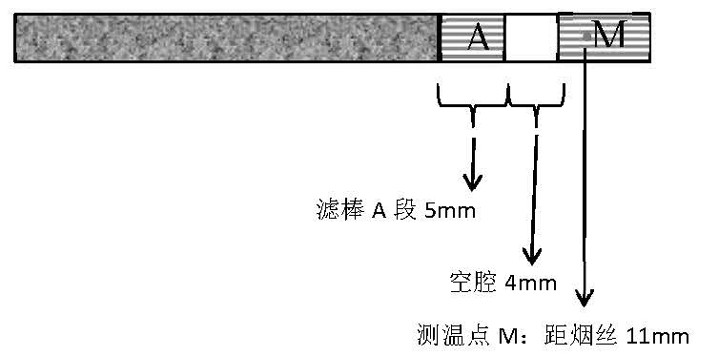

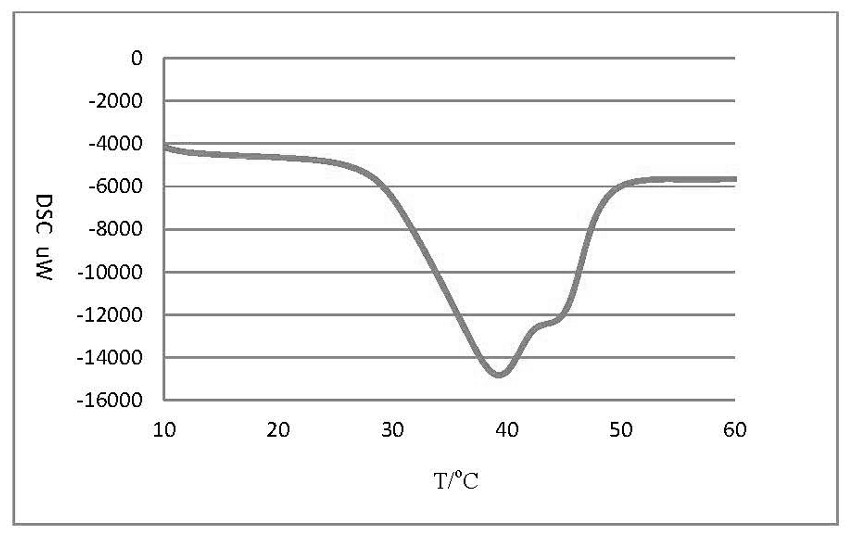

Composite phase change material for reducing cigarette smoke temperature and preparation method and application thereof

ActiveCN111944493ASolve the leakImprove securityTobacco smoke filtersHeat-exchange elementsCellulosePolymer science

The invention relates to the technical field of cigarette material manufacturing, in particular to a composite phase change material for reducing cigarette smoke temperature and a preparation method and application thereof. The phase change material is prepared from the following components in percentage by mass: 42% of PEG1000, 14% of PEG1500 and 44% of ethyl cellulose. According to the invention, with PEG 1000 and PEG 1500 used as phase change energy storage materials and ethyl cellulose used as a carrier, the PEG is uniformly dispersed in ethyl cellulose through a physical blending method,so that the problem of liquid leakage after phase change of a traditional solid-liquid phase change material is effectively solved; besides, the PEG and ethyl cellulose used for preparing the composite phase change material are biomedical polymer materials, so that the composite phase-change material is high in safety, low in price and free of peculiar smell, and does not have negative effects oncigarette senses; finally, the ethyl cellulose is used as a carrier, so that a porous material with a fluffy structure can be formed, the heat-conducting property is improved, and a heat-conducting material does not need to be additionally added. The preparation method of the phase-change material is simple and easy to implement.

Owner:GANSU TOBACCO IND

On-line detection device and method for shield machine tool and cutterhead wear based on optical fiber sensing

ActiveCN105973896BReduce volumeAvoid EMI designOptically investigating flaws/contaminationTunnelsGratingBeam splitting

The invention provides a shield tunneling machine cutter and cutter head wearing online detection device based on optical fiber sensing. The device comprises a fiber bragg grating position sensor group installed in a deep hole of a device to be detected, a beam splitting system used for transmitting light to each fiber bragg grating position sensor, a demodulating system used for demodulating light returned from each fiber bragg grating position sensor into electric signals, and a control system used for controlling on and off of the beam splitting system, analyzing the electric signals demodulated by the demodulating system, and judging whether any one or more of a cutter, a wearing detection cutter and a cutter head are worn and wearing positions, and the optical fiber end of each fiber bragg grating position sensor is located at the wearing limit position of the device to be detected. By the adoption of the device, the anti-electromagnetic interference design of the sensors is avoided, and no negative affect is caused to the normal working state of the shield tunneling machine cutter and cutter head.

Owner:WUHAN UNIV OF TECH

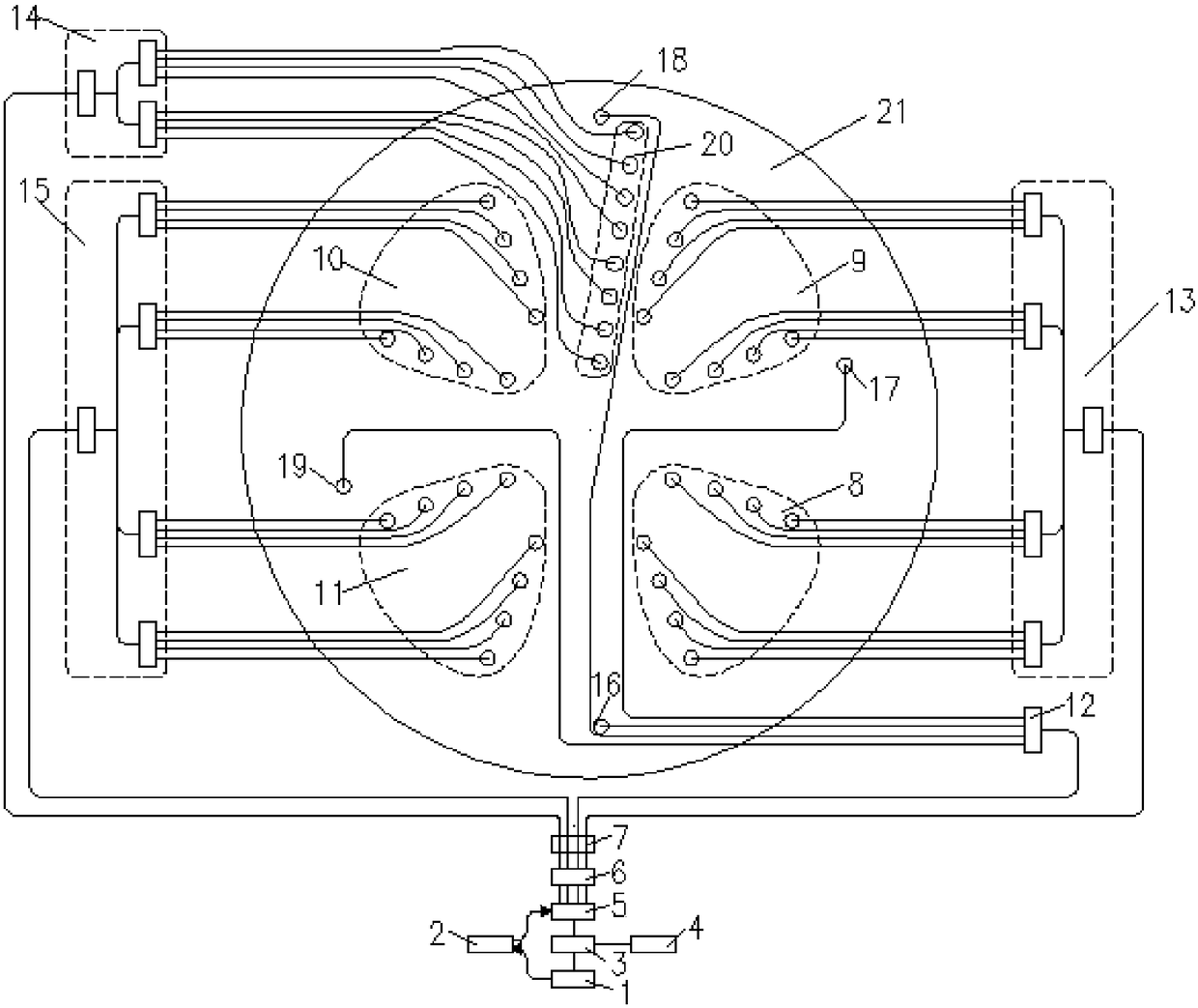

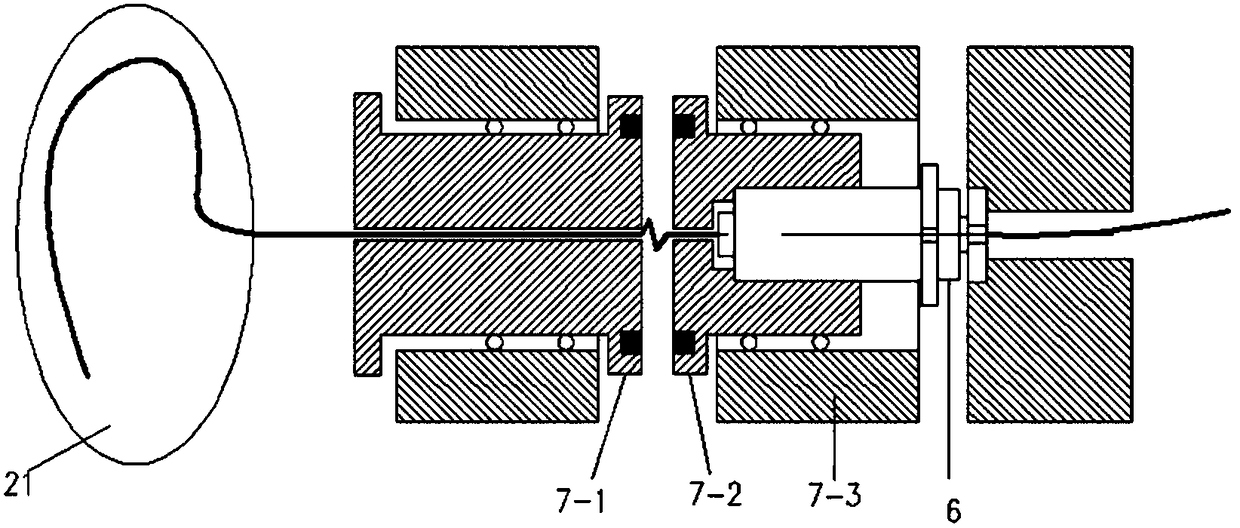

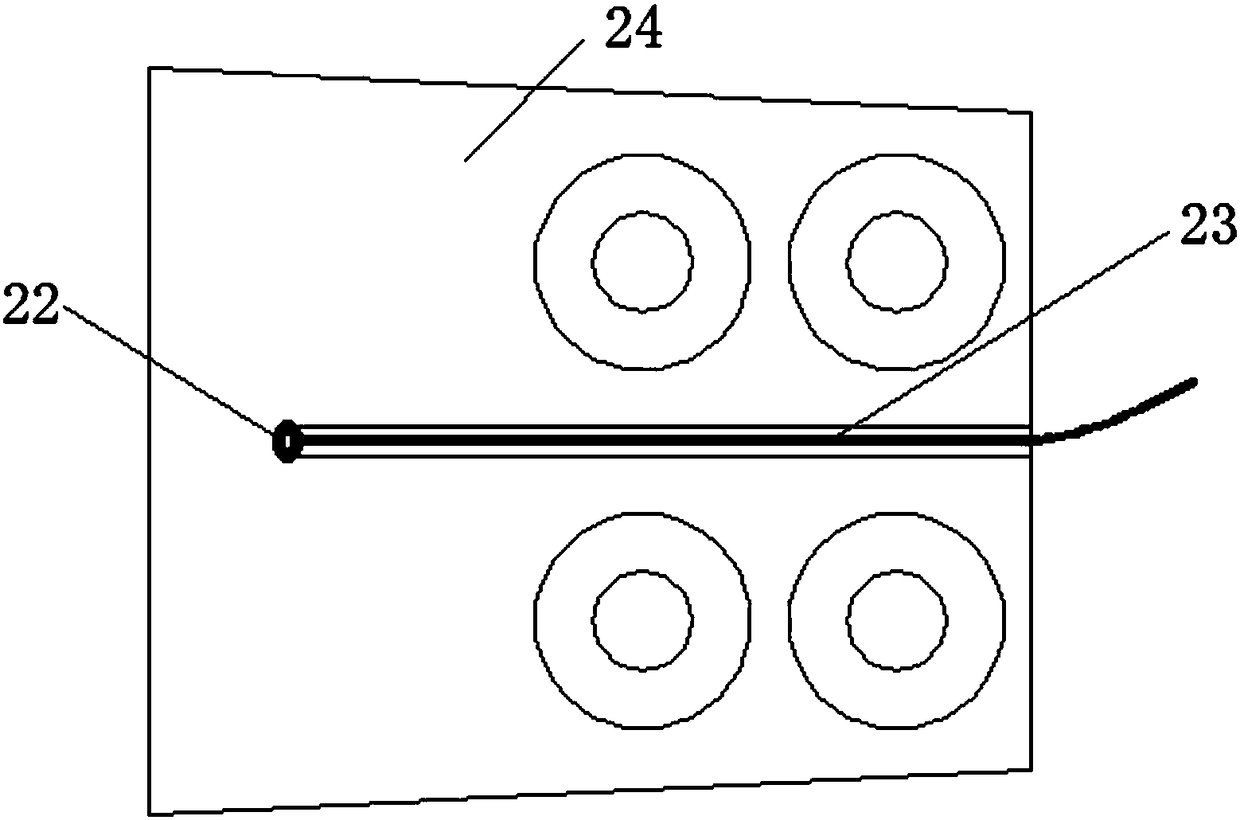

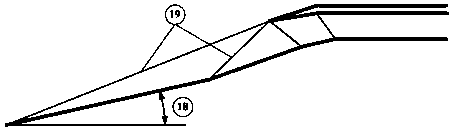

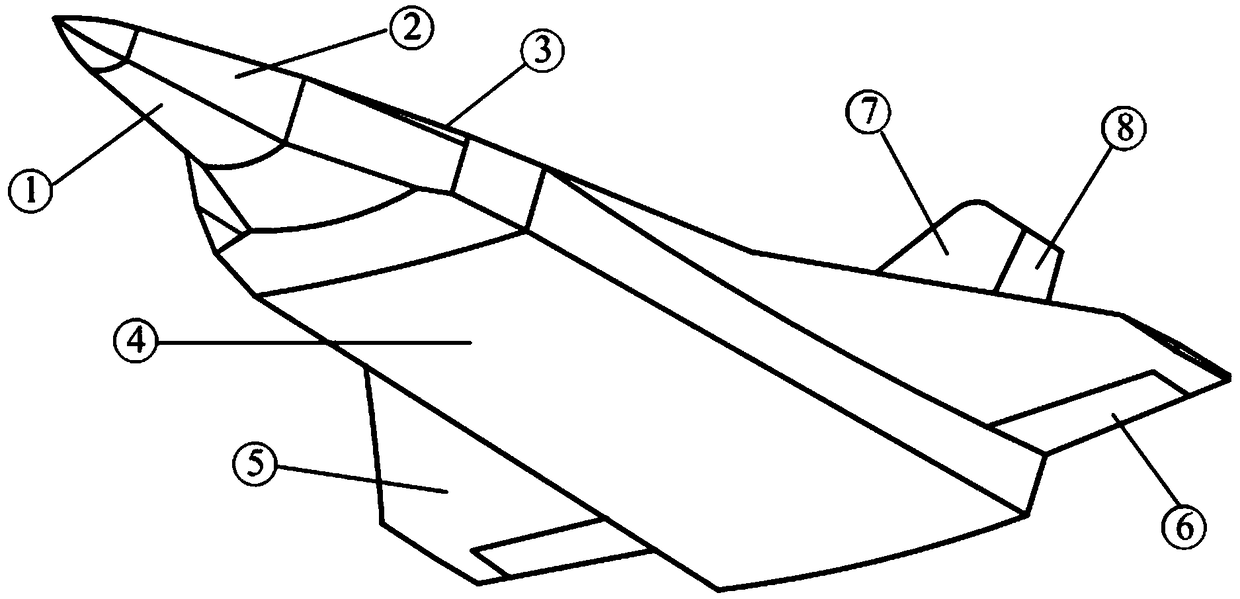

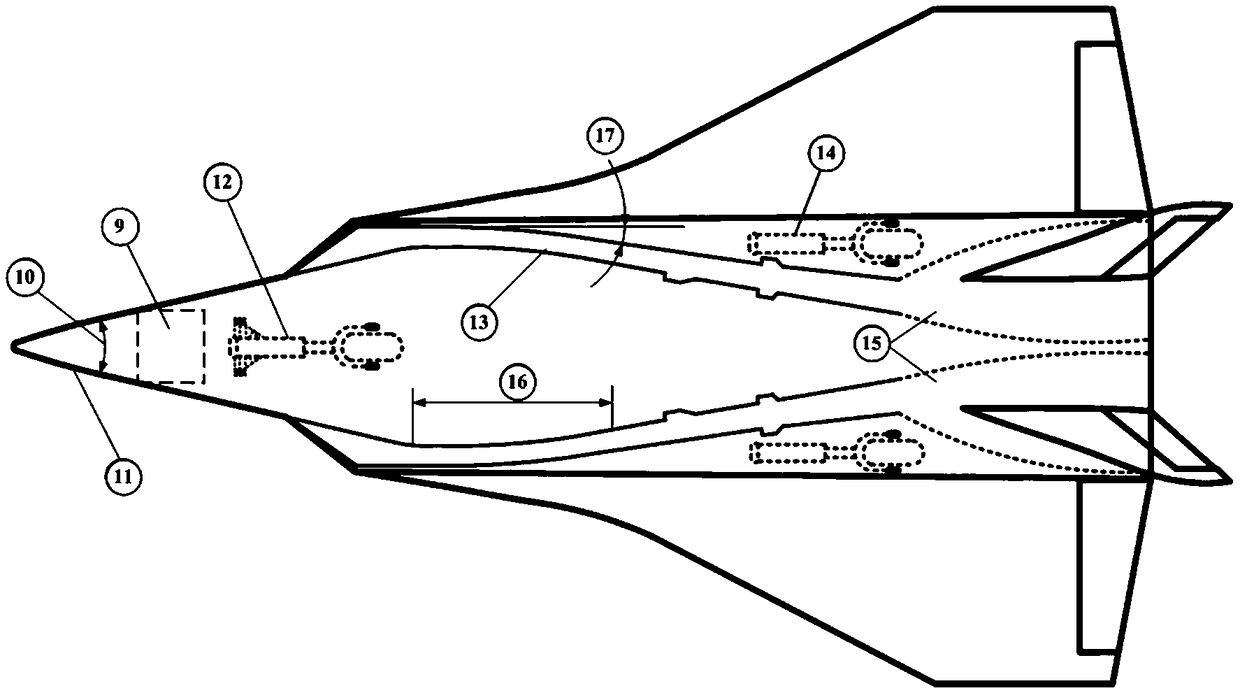

Aerodynamic layout of high-speed aircraft with airframe double-side gas intake

InactiveCN109367795AImprove the lift-to-drag ratioImproved heading stabilityPower plant arrangements/mountingWingsFlight vehicleShock wave

The invention provides an aerodynamic layout structure of a high-speed aircraft. A precursor (1), namely, the head of the aircraft, is designed to be an axisymmetric corpus vertebrae. Gas inlets (2) are arranged on two sides of the precursor (1). The installation included angle (19) is selected to be 150-180 degrees. Binary compression gas inlets are adopted as the gas inlets (2). A binary gas inlet profile is designed by using an oblique shock wave theoretical relation according to the principle of "sealing a compression shock wave system (18)". A radar of the aerodynamic layout structure isgood in wave transmission performance and sufficient in installation space, and the lift-to-drag ratio of the aircraft is improved.

Owner:BEIJING AEROSPACE TECH INST

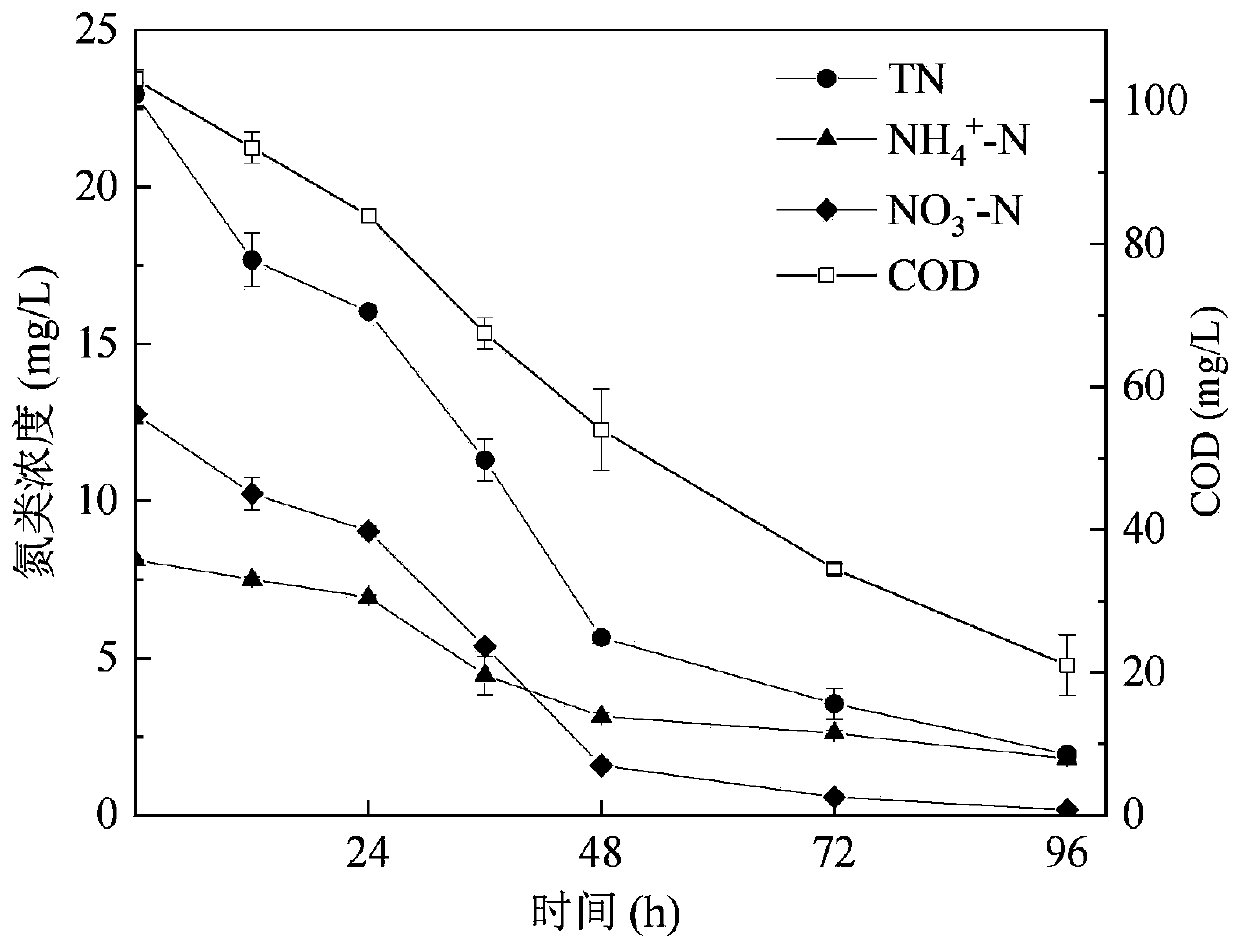

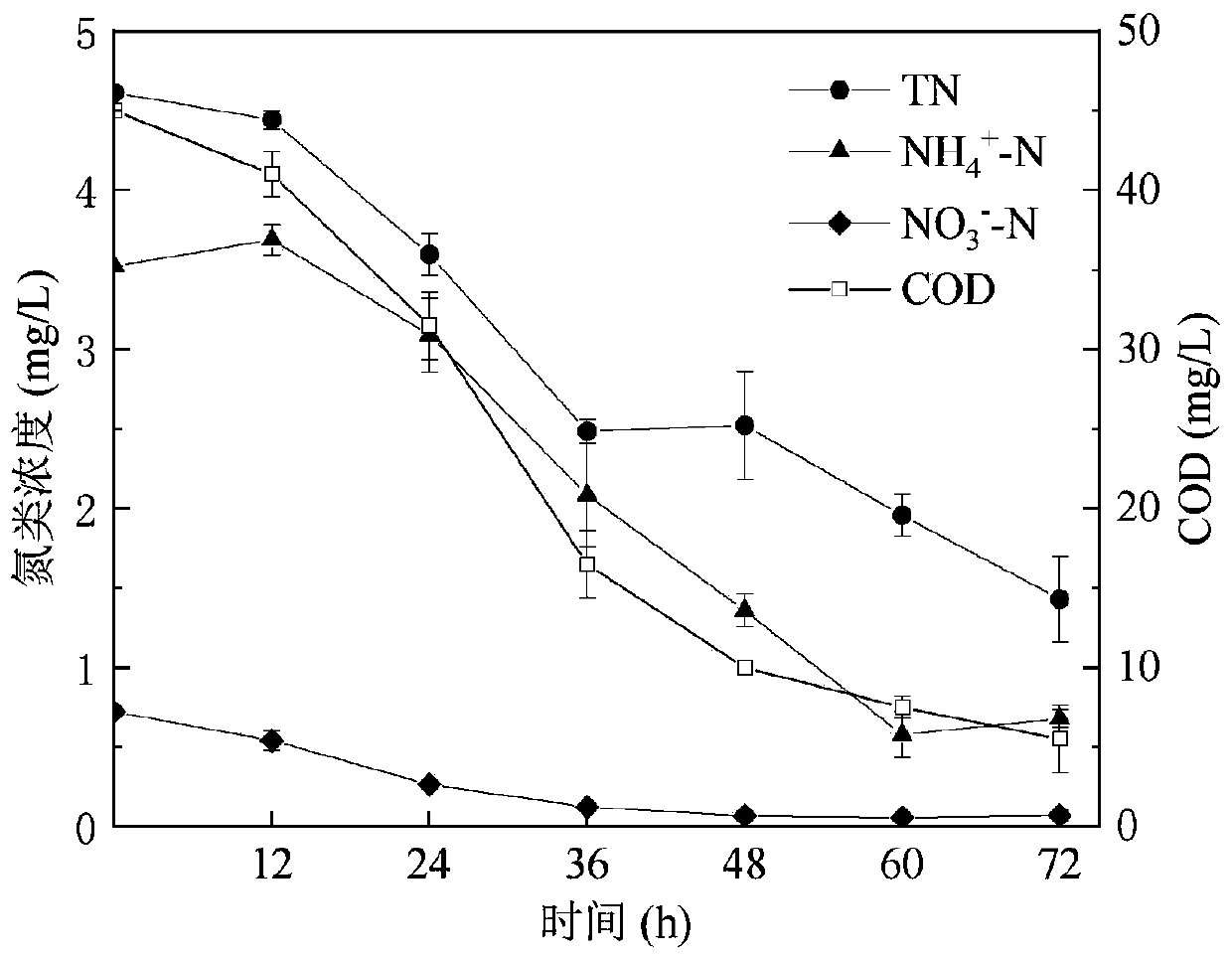

Preparation method of immobilized slow-release microorganisms for in-situ remediation of water body

InactiveCN111039415AEfficient degradationLong-term effective purificationWater treatment compoundsWater contaminantsMolecular sieveMicroorganism

The invention belongs to the technical field of water treatment, and particularly relates to a preparation method of immobilized slow-release microorganisms for in-situ remediation of a water body. The preparation method comprises the following steps: soaking molecular sieve particles in a denitrification functional bacteria solution to absorb a large amount of denitrification functional bacteriato prepare immobilized microorganism inner cores, and coating the surfaces of the inner cores with chitosan to prepare the chitosan coated immobilized slow-release microorganisms. Compared with the prior art, the immobilized slow-release microorganism particles prepared by the preparation method have relatively high stability, can stably purify a water body for a long time, prolong the service lifetime of the immobilized slow-release microorganisms and avoid secondary pollution of the water body.

Owner:TIANJIN UNIV

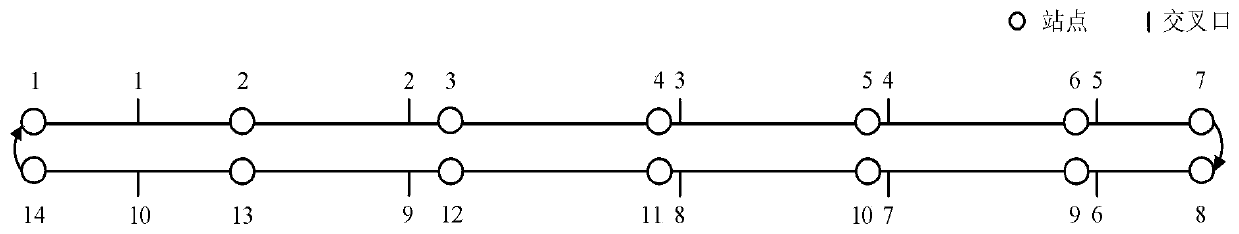

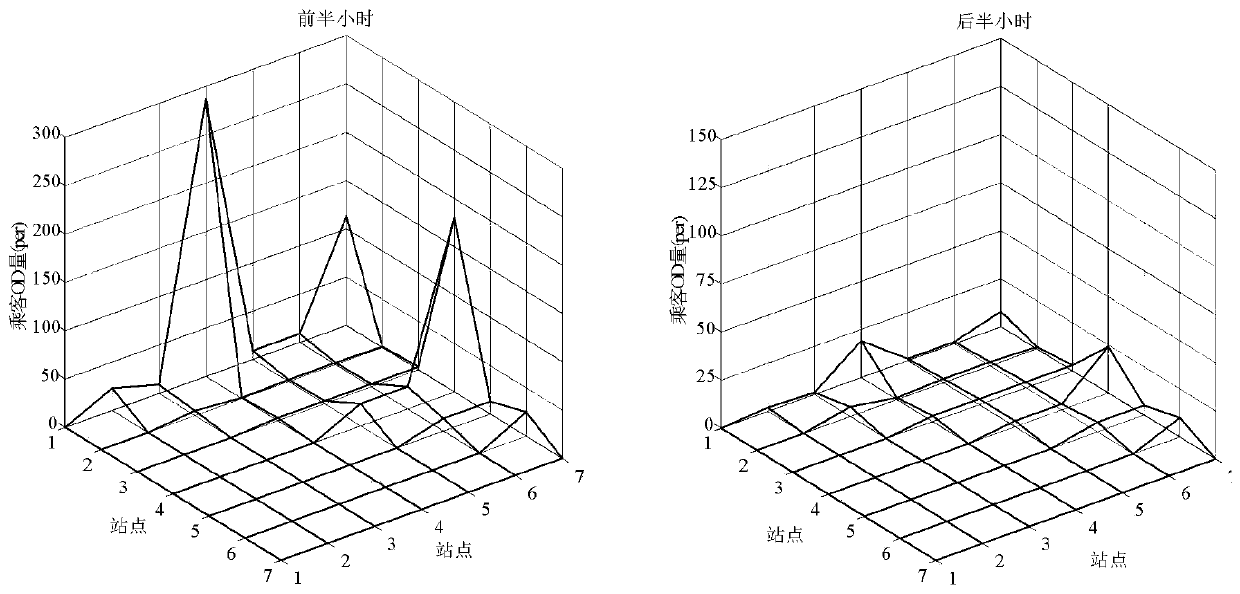

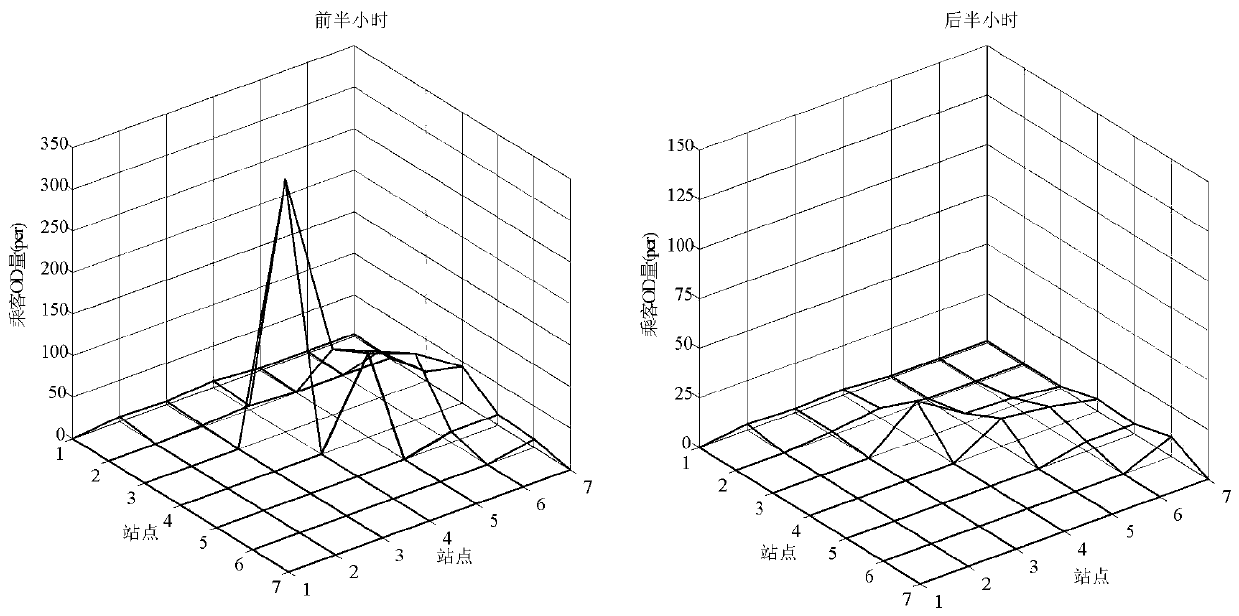

Bus multi-mode scheduling and along-the-line intersection signal timing collaborative optimization method

ActiveCN111429731AEasy to operateImprove operational efficiencyControlling traffic signalsBus rapid transitBus

The invention provides a bus multi-mode scheduling and along-the-line intersection signal timing collaborative optimization method. The method is realized by solving an optimization model, synchronously optimizing rapid bus operation mode selection, departure time of each shift and along-the-line intersection signal timing; the optimization model is expressed by a nonlinear programming model; theminimum total travel time of passengers is taken as an optimization target, various constraint conditions are considered in a combined mode, and the constraint conditions comprise intersection signalcontrol constraints, intersection saturation constraints, passenger waiting constraints and optimization parameter value ranges; according to the invention, aiming at the target uniformity of bus rapid transit scheduling and signal control, three operation mode selections (whole-journey bus, large-station bus and inter-regional bus), departure moments of all shifts and along-line intersection signal timing are integrated into one optimization model for collaborative optimization, so that the operation efficiency of bus rapid transit is improved, and the bus multi-mode scheduling and along-the-line intersection signal timing collaborative optimization method is provided.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

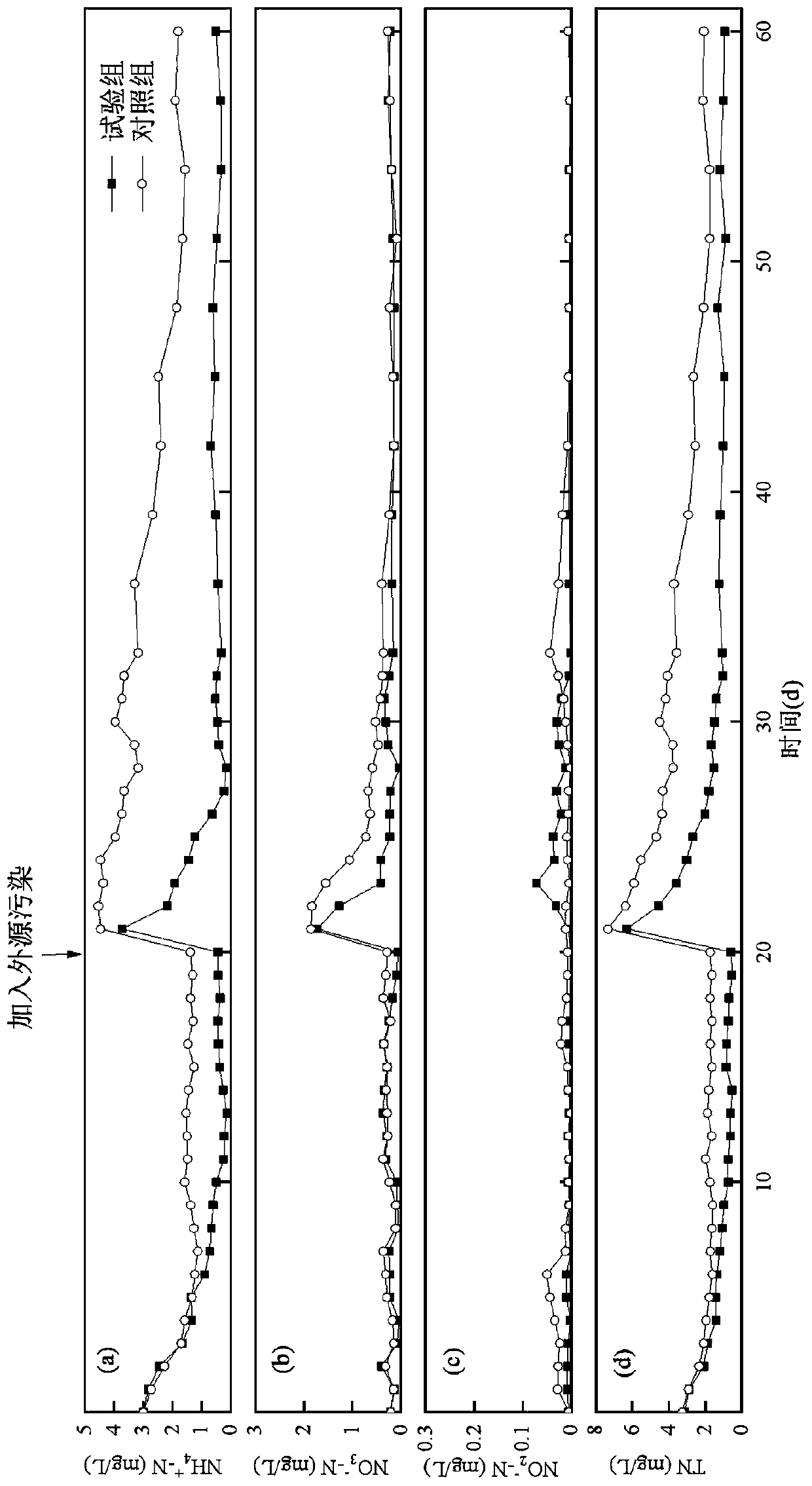

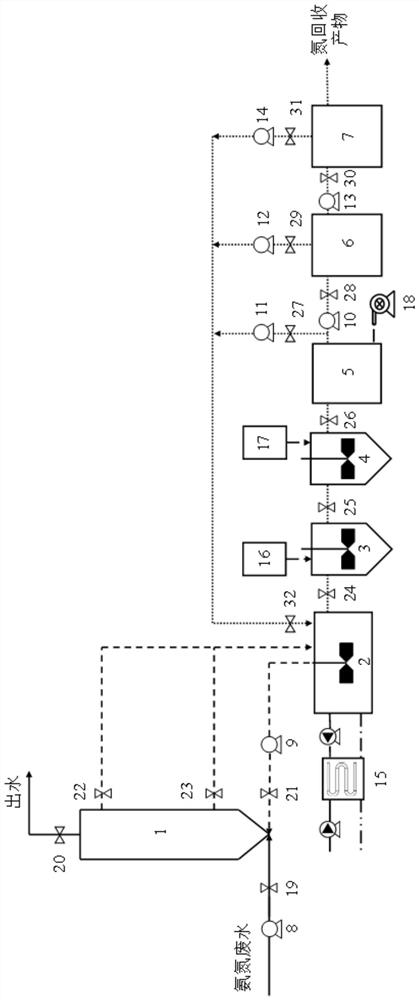

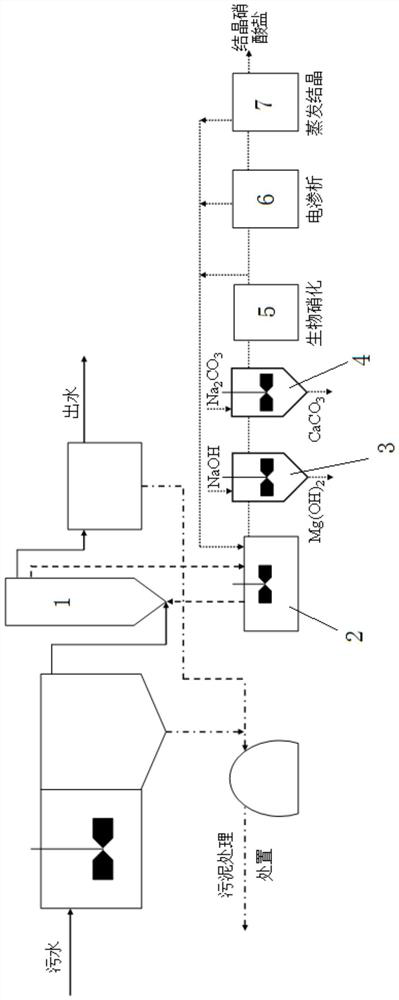

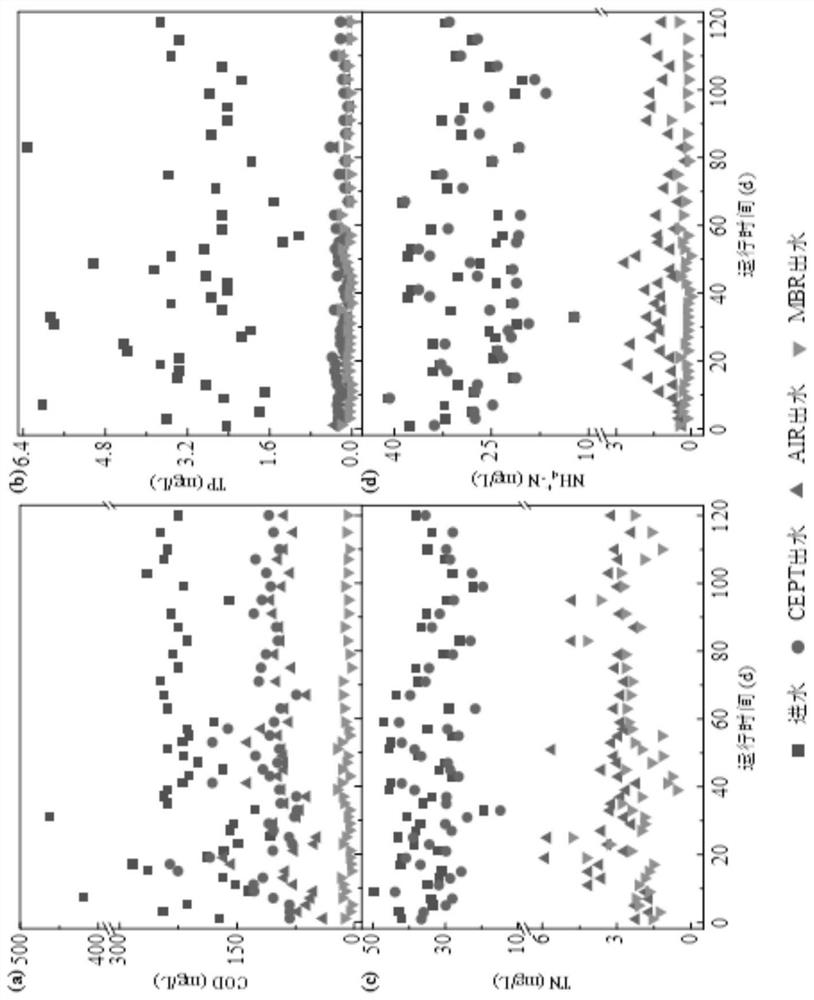

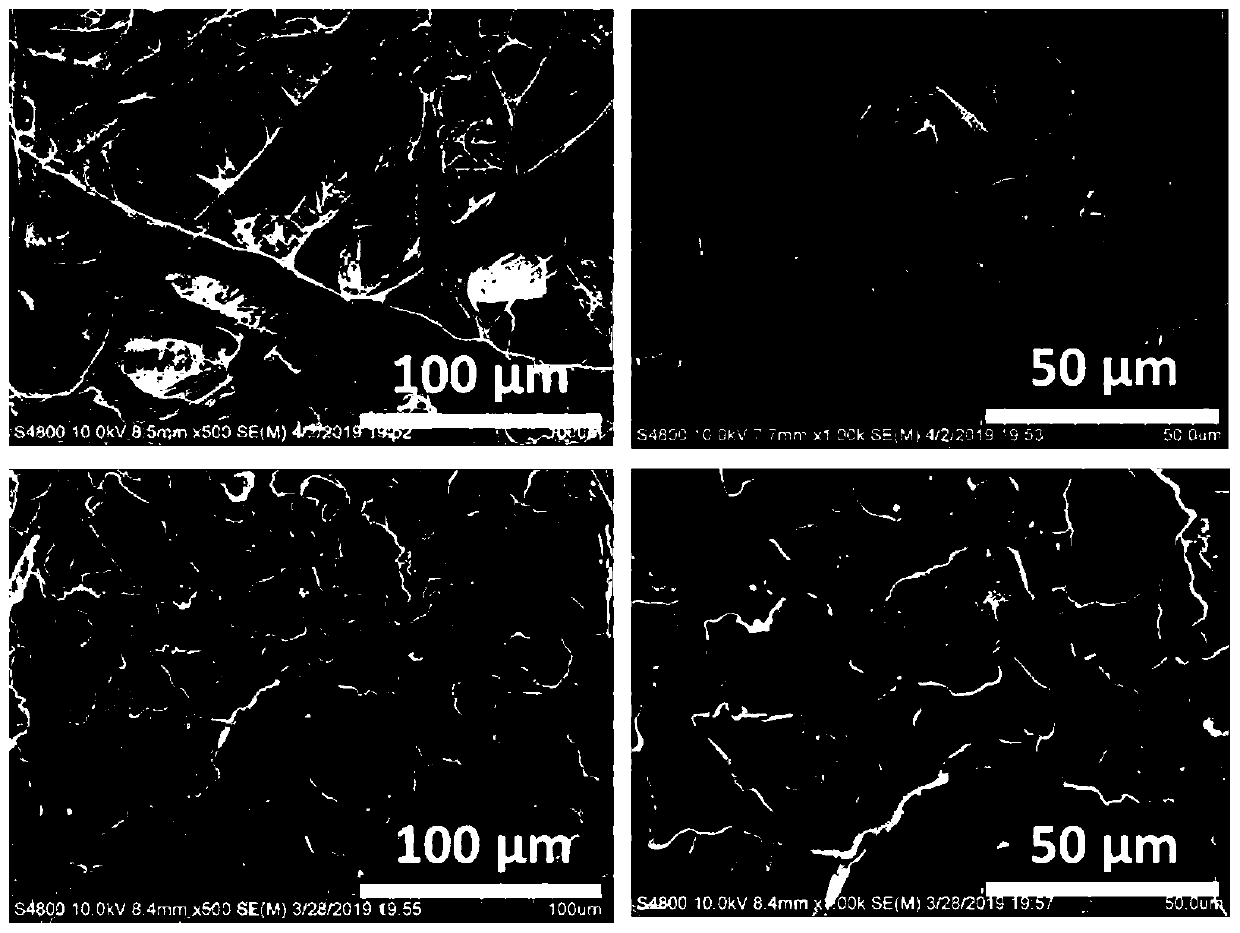

Efficient nitrogen recovery device and process for sewage

PendingCN112093980ASmall footprintReduce concentrationSpecific water treatment objectivesWater contaminantsLiquid storage tankIon exchange

The invention relates to an efficient nitrogen recovery device and process for sewage. The device comprises an ammonia nitrogen ion exchange unit connected into a mainstream sewage treatment pipe, anda regenerated liquid storage tank connected with the ammonia nitrogen ion exchange unit through a regenerated liquid circulating pipe to form circulation, The regenerated liquid storage tank is alsosequentially connected with a magnesium removal sedimentation tank, a calcium removal sedimentation tank, a biological nitrification reactor, an electrodialysis module and an evaporation concentrationmodule, and the biological nitrification reactor is also connected with the regenerated liquid storage tank in a returning manner. Compared with the prior art, the process has the advantages that theregenerated liquid with high NH4 < + >- N concentration is subjected to nitrogen recovery, so that synchronous nitrogen emission reduction and nitrogen recovery of mainstream ammonia nitrogen ion exchange-regeneration enrichment-biological nitrification-electrodialysis concentration-evaporation crystallization are realized.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

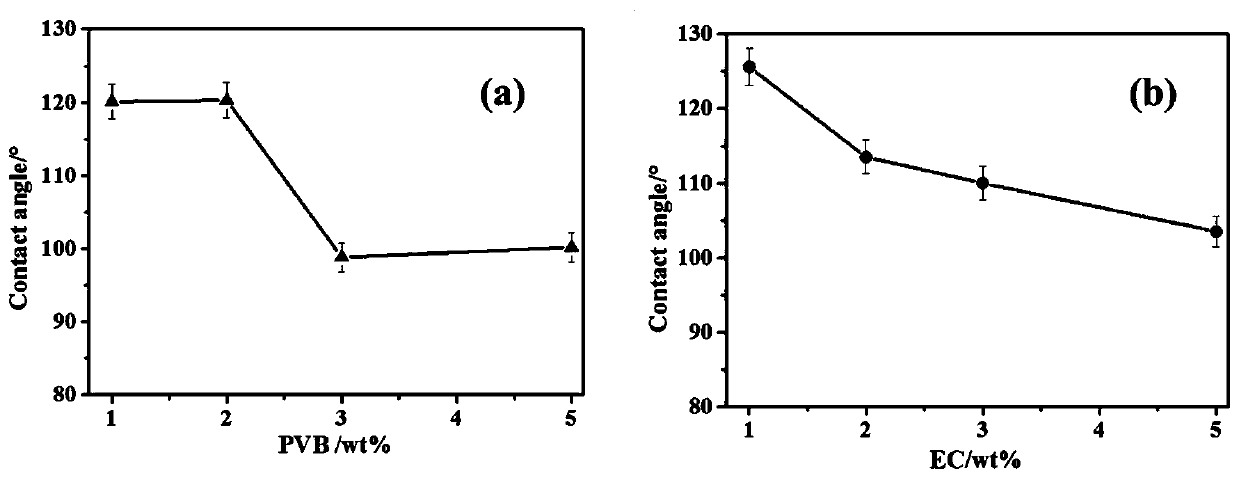

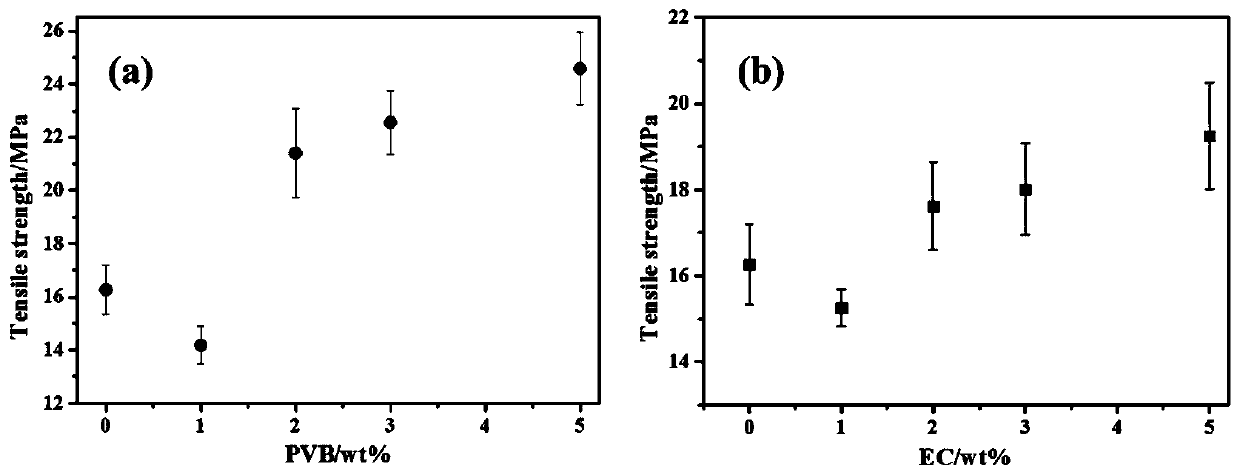

Hydrophobic slurry, and preparation method and application thereof

ActiveCN110670408AThoroughly mix and disperseEasy to manufactureWater-repelling agents additionCoatingsPolymer sciencePolyvinyl alcohol

The invention relates to the technical field of high polymer materials, and particularly discloses hydrophobic slurry, and a preparation method and an application thereof. The hydrophobic slurry comprises hydrophobic cellulose and a hydrophobic polymer used as a film-forming agent; the hydrophobic cellulose is cellulose with the surface coated with a fluorine-containing polymer; the fluorine-containing polymer is one or more of polytetrafluoroethylene, polyvinylidene fluoride, a fluorinated ethylene propylene copolymer and an ethylene-chlorotrifluoroethylene copolymer; and the hydrophobic polymer is one or more of polyvinyl butyral, ethyl cellulose, polycaprolactone and polylactic acid. The hydrophobic slurry has the advantages of simple components, simplicity in preparation, no chemical modification, and realization of excellent hydrophobic property of a hydrophilic material. The invention also provides a preparation method of the hydrophobic slurry. The method is simple, and is beneficial to industrial production. The invention also provides a hydrophobic paper. The hydrophobic paper comprises the hydrophobic slurry, is simple to prepare, and has good hydrophobic and mechanical properties.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

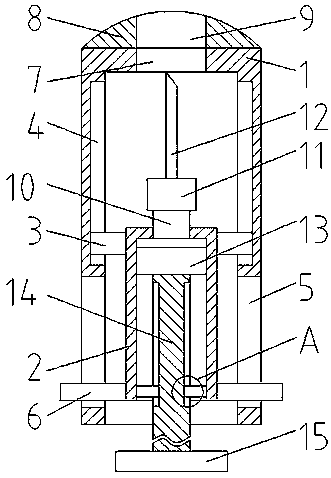

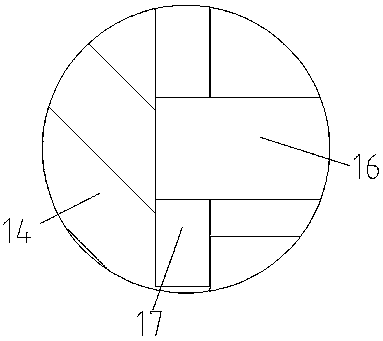

Needle device for pediatric surgical department

InactiveCN109011024AReduce difficultyImprove stabilityInfusion syringesInfusion needlesSurgical departmentAdverse effect

The invention discloses a needle device for a pediatric surgical department. The needle device comprises an outer sleeve. The outer sleeve is provided therein with an injection tube. The tops of the two sides of the injection tube are fixedly connected with first sliding rods. The tops of both sides of the inner wall of the outer sleeve are provided with first sliding slots. The inner wall of eachfirst slot is slidably connected to the end of the corresponding first sliding rod away from the injection tube. The device solves the problem that an existing needle device for the pediatric surgical department does not have a hidden syringe needle by the cooperative use of the outer sleeve, the first sliding rods, the first sliding slots, a through slot, a lever, through holes, a silicone blockand a pinhole, can hide the needle, avoids the resistant reaction of a child to the needle in use, reduces the difficulty for a medical worker to inject drugs into the child, does not have a certainnegative psychological effect on the child, contributes to the use and development of medical institutions, and it is worth promoting.

Owner:李健

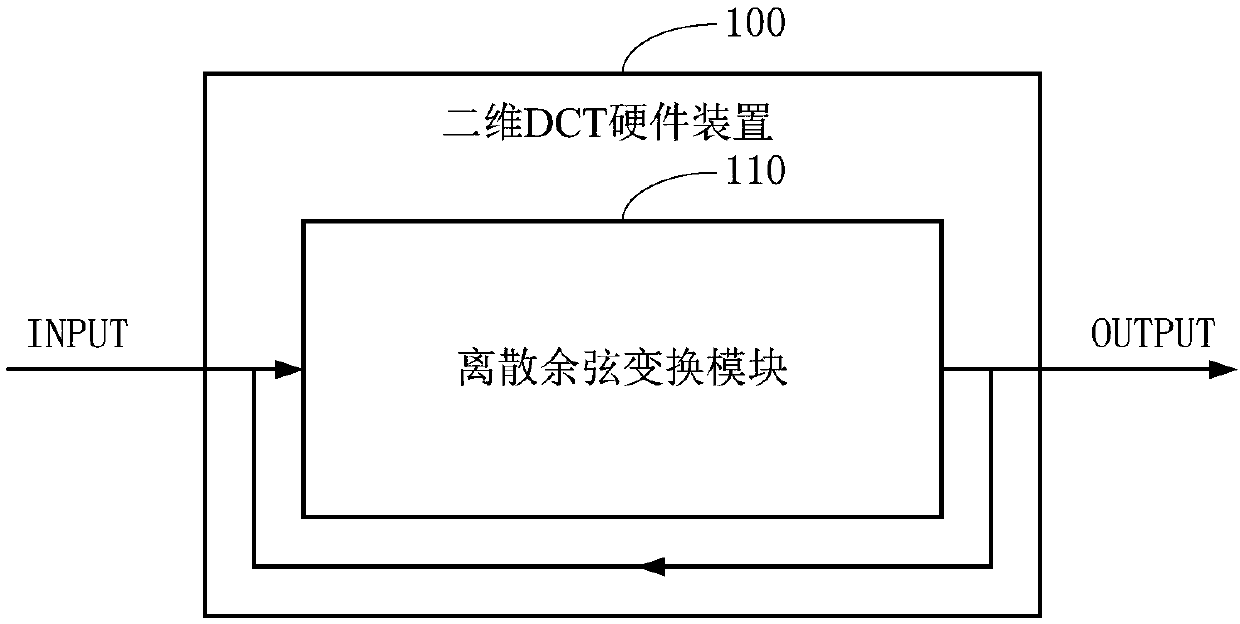

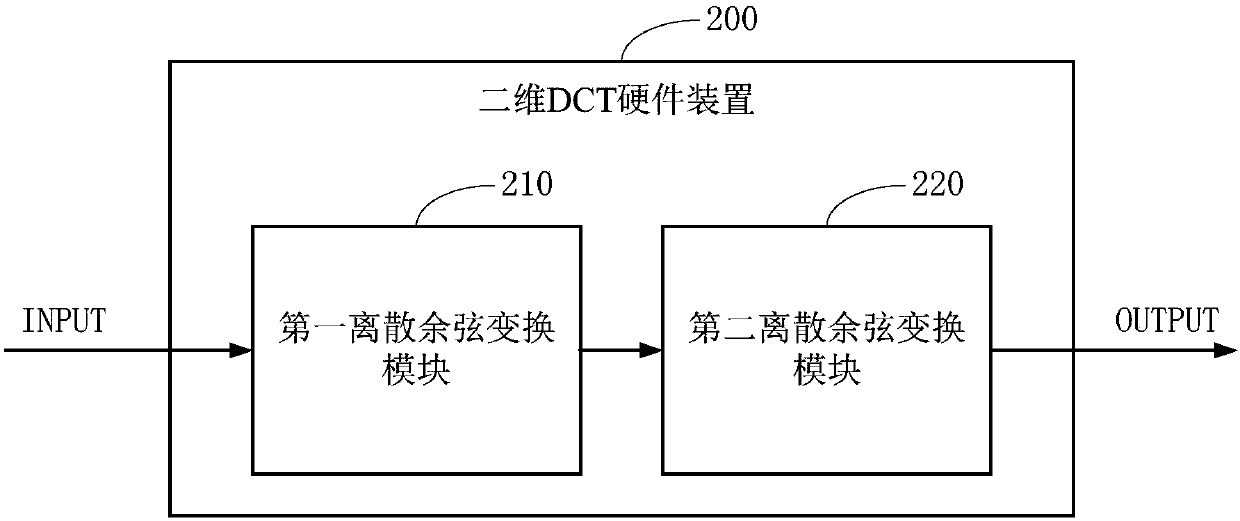

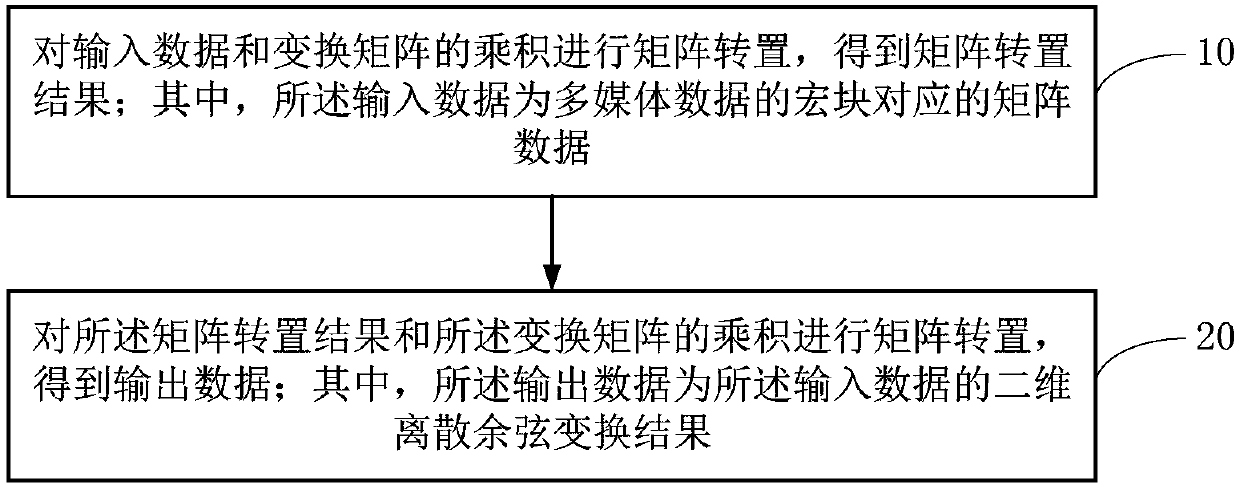

Two-dimensional DCT (Discrete Cosine Transform) hardware implementation method and device

InactiveCN108040257ARealize hardware processingEasy hardware processingDigital video signal modificationData compressionDiscrete cosine transform

The invention is applicable to the technical field of multimedia data compression, and provides a two-dimensional DCT (Discrete Cosine Transform) hardware implementation method and device. The deviceis a two-dimensional DCT hardware device comprising one or two DCT modules; when the two-dimensional DCT hardware device comprises one DCT module, by the DCT module, a product of input data and a transform matrix is subjected to matrix transposition, and then a product of a matrix transposition result and the transform matrix is subjected to matrix transposition so as to obtain a two-dimensional DCT result of the input data; and when the two-dimensional DCT hardware device comprises two DCT modules, by a first DCT module, the product of the input data and the transform matrix is subjected to matrix transposition, and then by a second DCT module, the product of the matrix transposition result and the transform matrix is subjected to matrix transposition so as to obtain the two-dimensional DCT result of the input data. The two-dimensional DCT hardware implementation method and device can implement hardware processing of two-dimensional DCT, is simple in structure and easy to implement and cannot generate negative effects on a main frequency of a system.

Owner:VALUEHD CORP

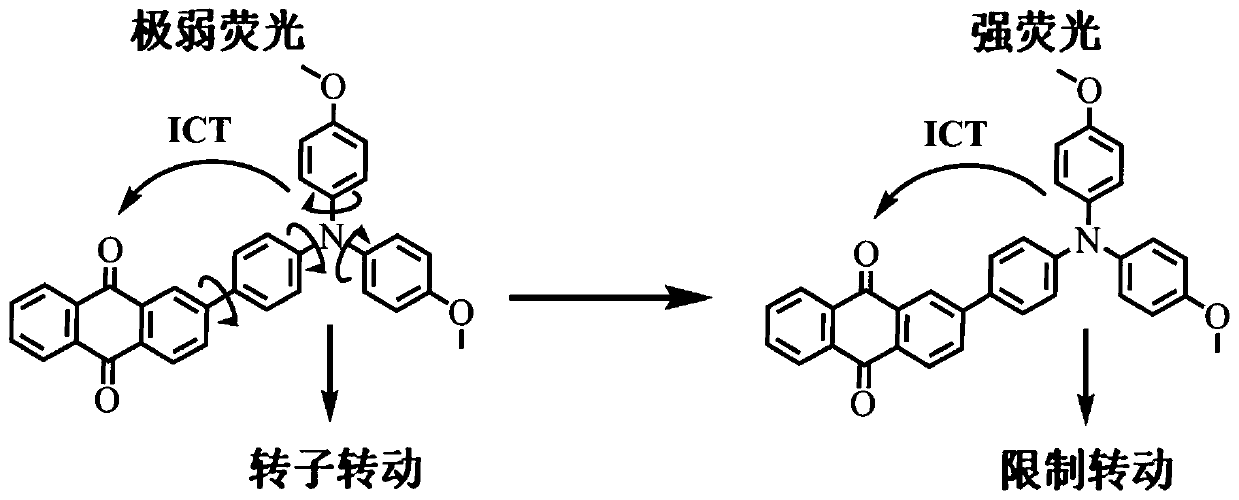

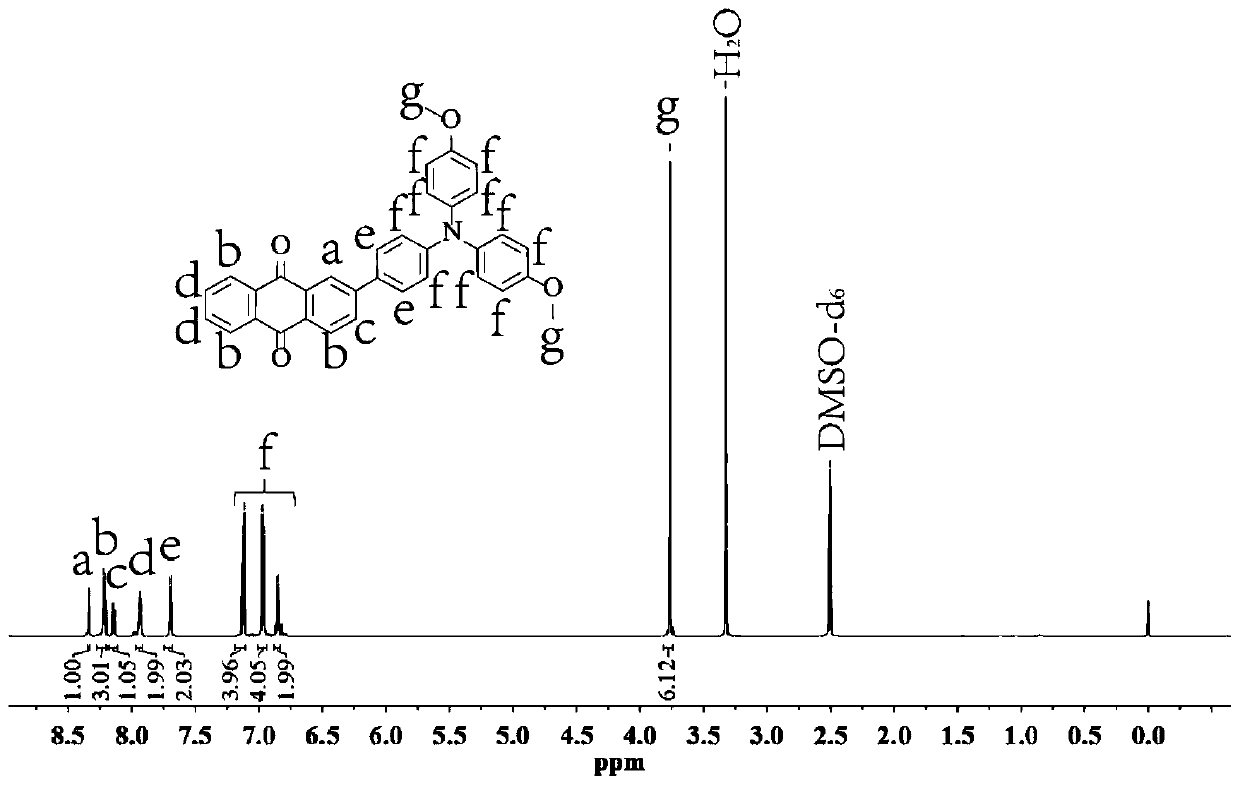

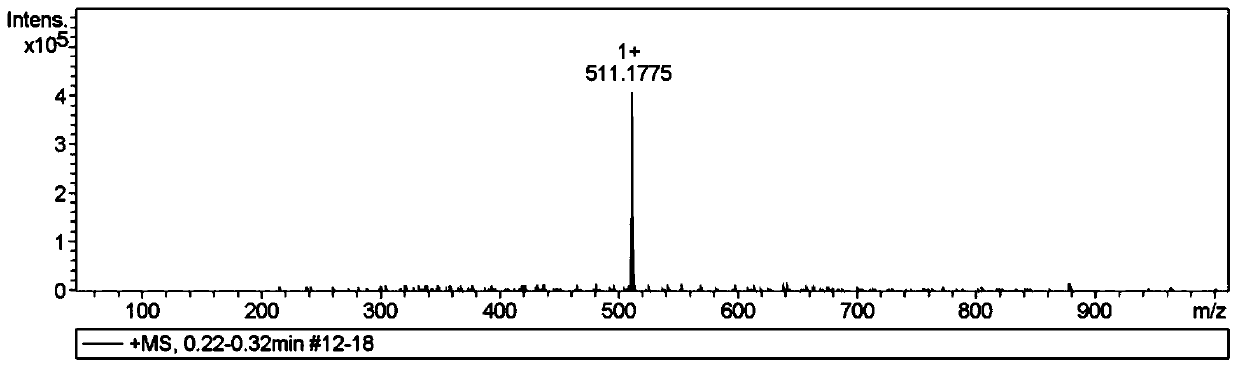

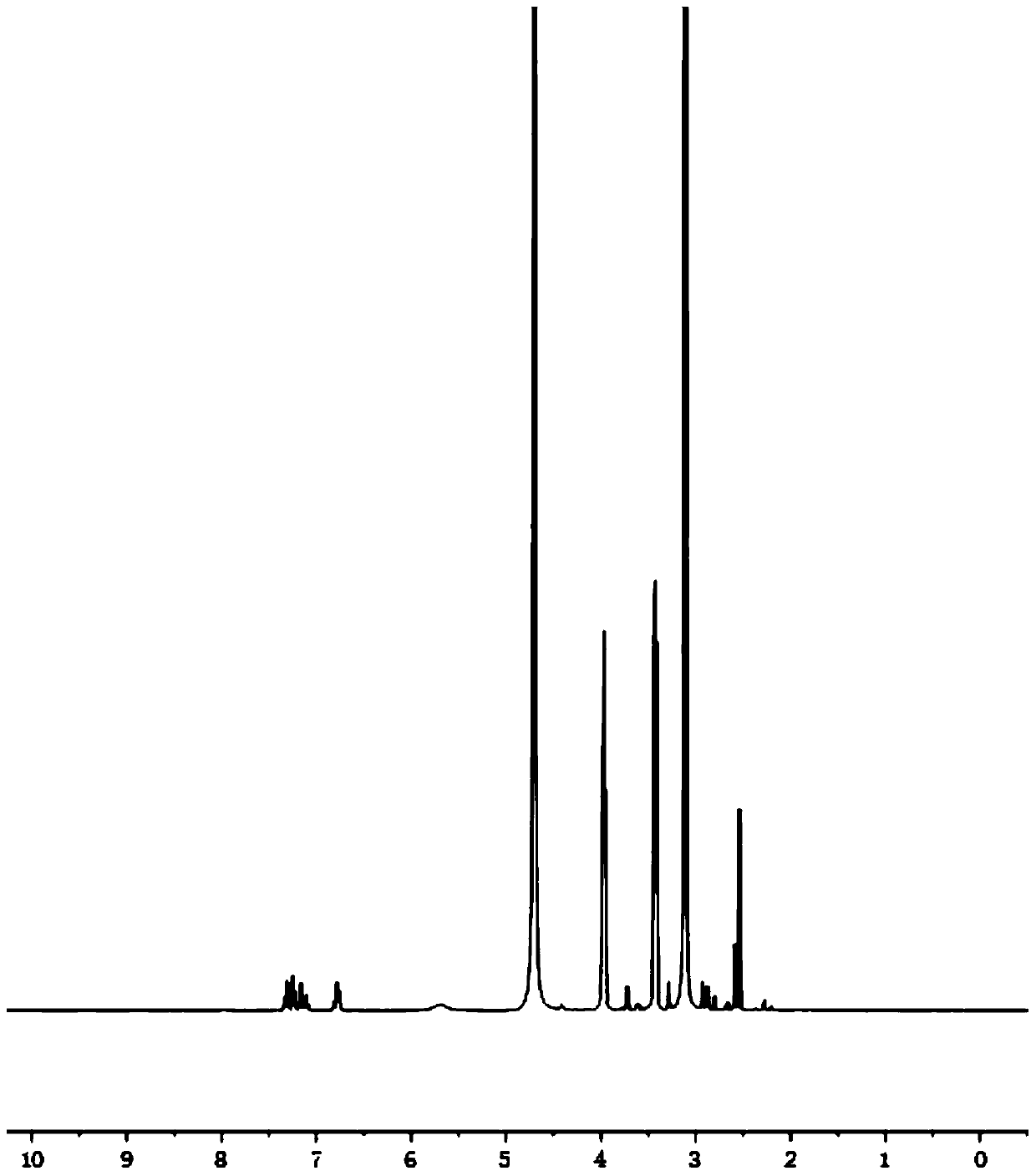

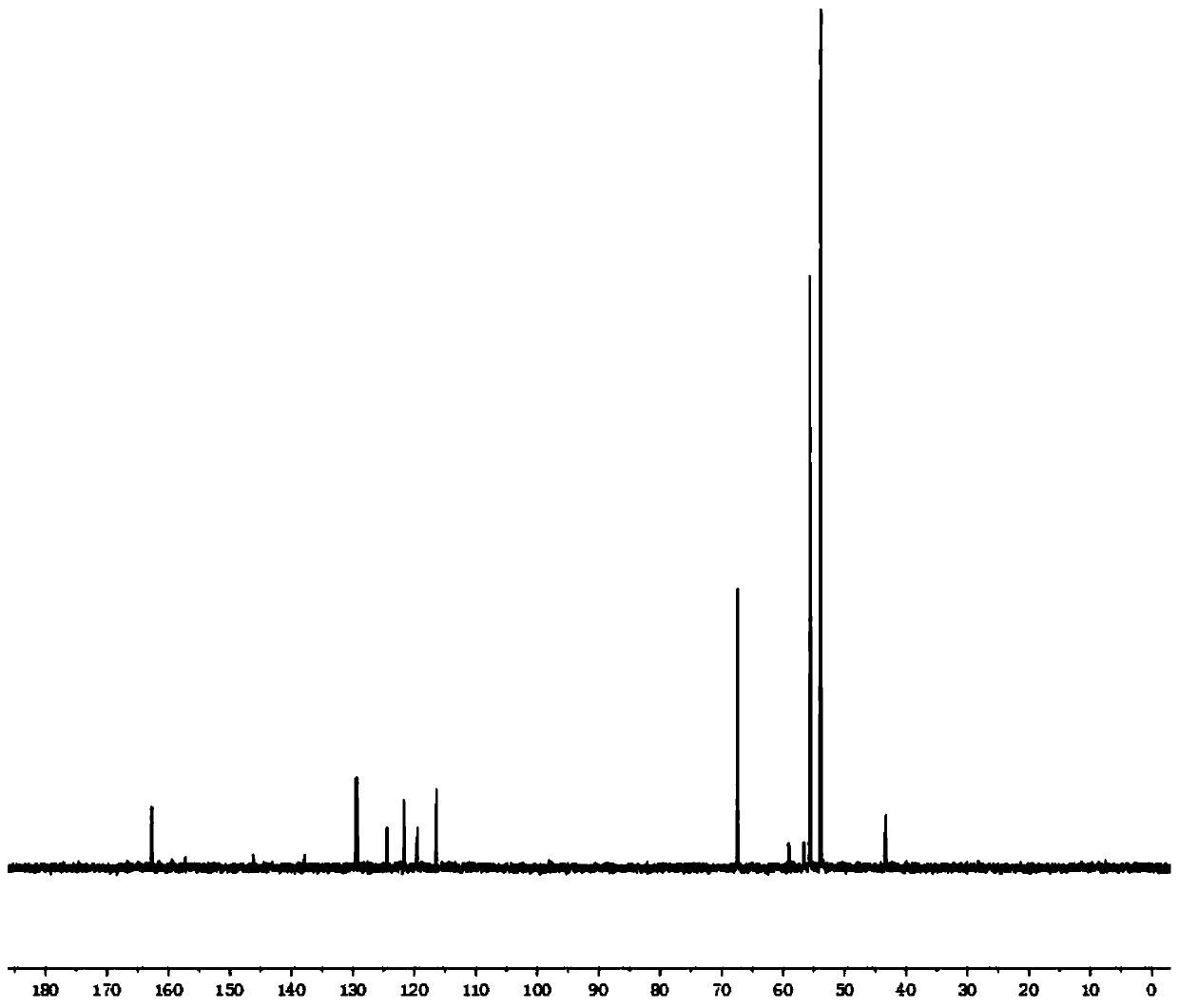

Fluorescent compound for detecting viscosity of oil displacement of tertiary oil recovery, and preparation method and application of fluorescent compound

ActiveCN110272350AHigh recognizabilityGood detection and analysis effectOrganic chemistryOrganic compound preparationSolventAggregation-induced emission

The invention relates to the technical field of photochemical detection and analysis, and discloses a fluorescent compound for detecting viscosity of oil displacement of tertiary oil recovery, and a preparation method and application of the fluorescent compound. The fluorescent probe is 2-(4-bis(4-methoxyphenyl)amino)phenyl)anthracene-9,10-dione (TPAMD). The probe compound disclosed by the invention is composed of groups with an aggregation-induced emission characteristic and anthraquinone groups with an electron-withdrawing effect, and thus has an aggregation-induced emission characteristic and an intramolecular charge transfer characteristic simultaneously. The probe is easy to prepare, is high in yield, has good viscosity responsiveness, and has relatively good linear response. The probe can be used in complex solvent environments, has good resistance to solvent perturbation, can be used to achieve detection of viscosity of chemical displacement agents in the oil production field, and the method has an analysis and detection potential for various viscosity-sensitive fields such as chemistry, food, environment and the like.

Owner:SOUTH CHINA UNIV OF TECH

Chromatic bituminous binder and preparation method thereof

InactiveCN101205370AReduce construction temperatureEasy constructionBuilding insulationsWaxPolypropylene

The invention discloses a colorful asphalt binder. The component of the colorful asphalt binder of the invention calculated by weight percentage comprises 20-65 per cent of petroleum resin, 30-79 per cent of lubricant refined extract oil and 1-5 per cent of polypropylene wax. By pulling a little of polypropylene wax into conventional colorful asphalt binder, temperature of mixing, spreading and rolling of asphalt mixture can be greatly reduced and negative influence on final colorful asphalt pavement is not caused, which allows an easy construction. As the same time, the reduction of construction temperature and odor emitted by the binder is decreased, which are in favor of environment protection. As the same time, addition of SBR allows the colorful asphalt binder to be provided with better high-temperature stability.

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

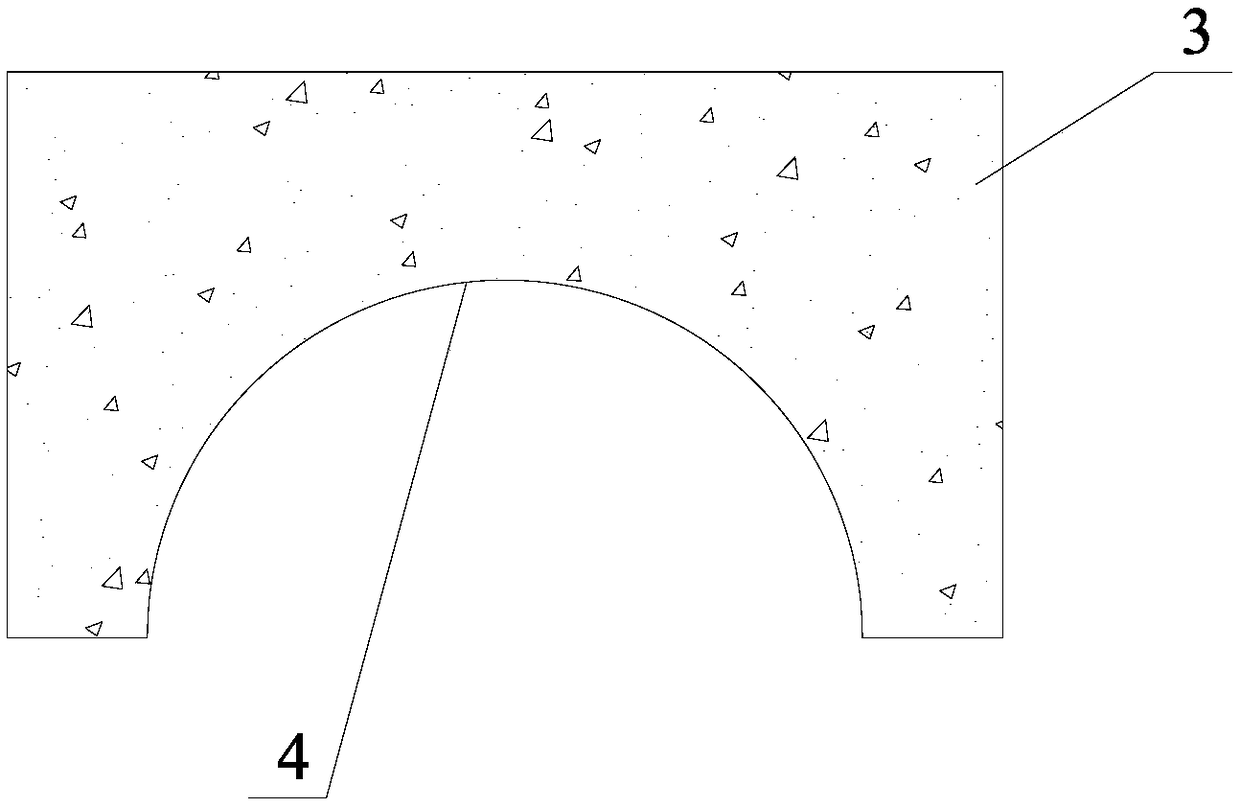

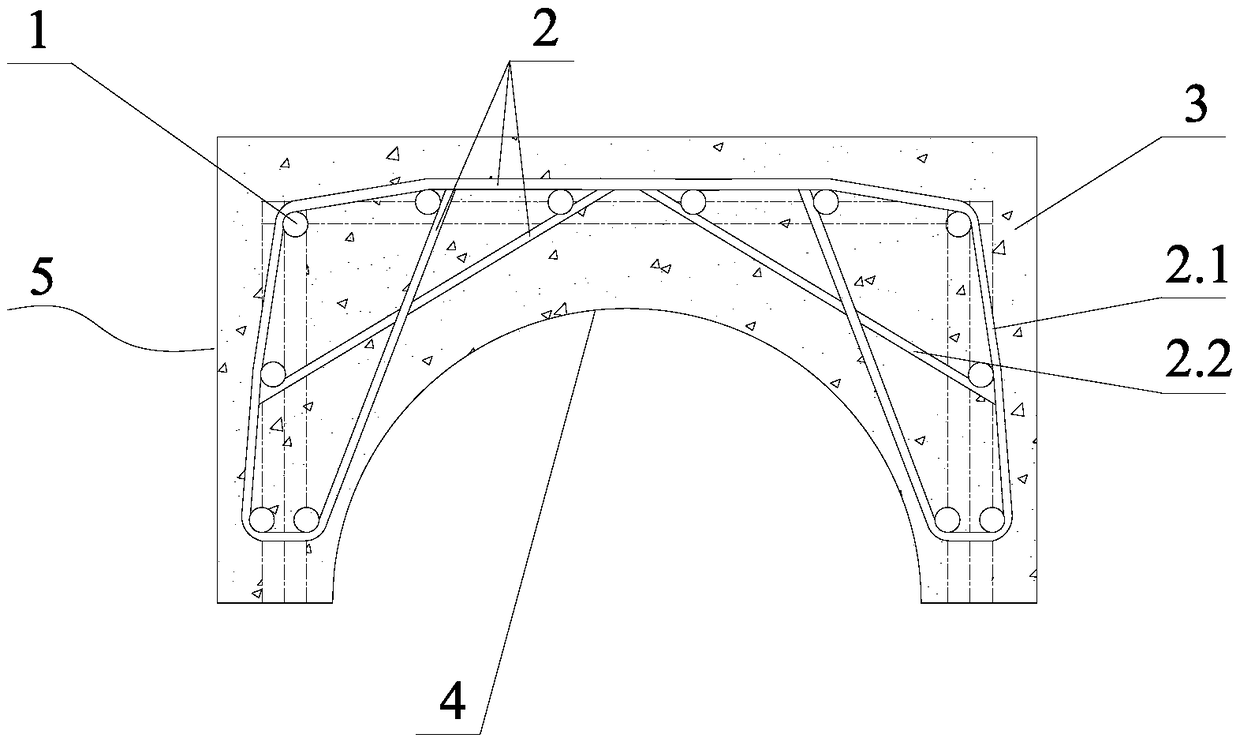

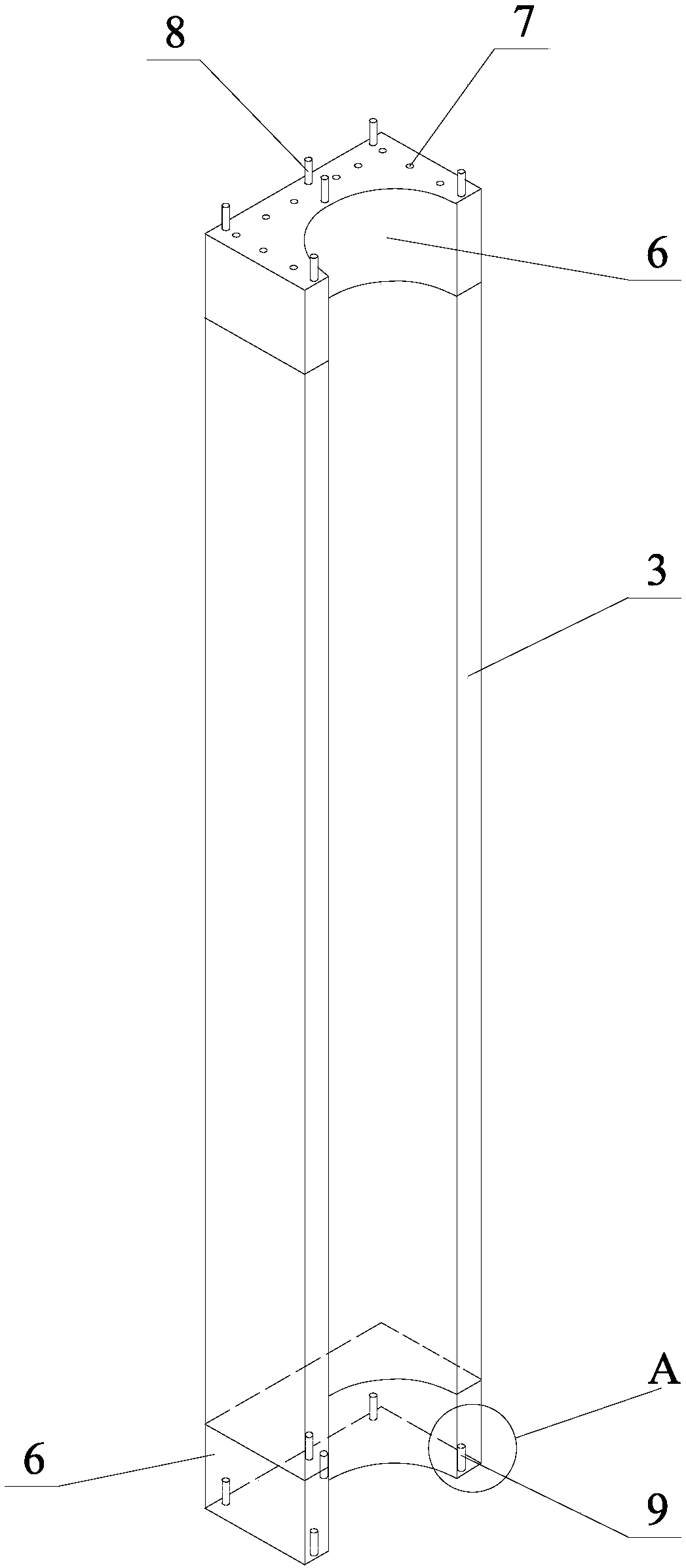

Supporting and protecting pile and composed supporting and protecting row pile

The invention discloses a supporting and protecting pile and a composed supporting and protecting row pile. The supporting and protecting pile comprises a precast concrete pile body with a reinforcingsteel bar cage composed of multiple vertical prestressed reinforcing steel bars and multiple transverse stirrups, and the cross section of the pile body is in a first rectangular shape with a first semicircular groove in one side. The supporting and protecting pile further comprises metal end plates at the two ends. Multiple through holes allowing the multiple vertical prestressed reinforcing steel bars to penetrate are formed in the metal end plates. Multiple guide insertion connection columns are arranged on one end plate, insertion connection blind holes which are in one-to-one correspondence with the multiple guide insertion connection columns are formed in the other end plate, horn mouth clamp rings with the large upper portions and the small lower portions are arranged in the holes,and each horn mouth clamp ring is composed of multiple metal elastic pieces. The long side of the supporting and protecting pile is close to the contact face of the foundation pit inner side around afoundation pit and the supporting and protecting pile and forms a ceaseless connection line extending in the length direction. The supporting and protecting pile and the composed supporting and protecting row pile have a small earth squeezing effect, are good in compactness, are large in contact area of the contact face of the foundation pit inner side around the foundation pit and the supportingand protecting pile, and are high in bending resistance.

Owner:浙江华展工程研究设计院有限公司

Novel pre-dispersion master batch and preparing method thereof

The invention discloses a novel pre-dispersion master batch and a preparing method thereof.The novel pre-dispersion master batch comprises carriers and rubber chemicals.The carriers include macromolecular polymerization wax, coumarone and lubricant EBS.The preparing method for the formula comprises the following steps that the raw materials in the carriers are mixed evenly according to a ratio; the rubber chemicals are added into the carriers and mixed evenly to obtain a mixture; the mixture is extruded out and granulated after being cooled, and the novel pre-dispersion master batch is obtained.The novel pre-dispersion master batch can be directly extruded out to be cut into granules without rubber mixing, energy consumption is low, and the yield is high; the obtained product has considerable hardness, does not absorb moisture and is beneficial to storage after being conveyed through a refrigeration house and subjected to cold-cutting.In addition, the novel pre-dispersion master batch has extensive universality and applicability, and the carriers can be suitable for the machining process of any rubber products and can not react with the rubber products.

Owner:彭均

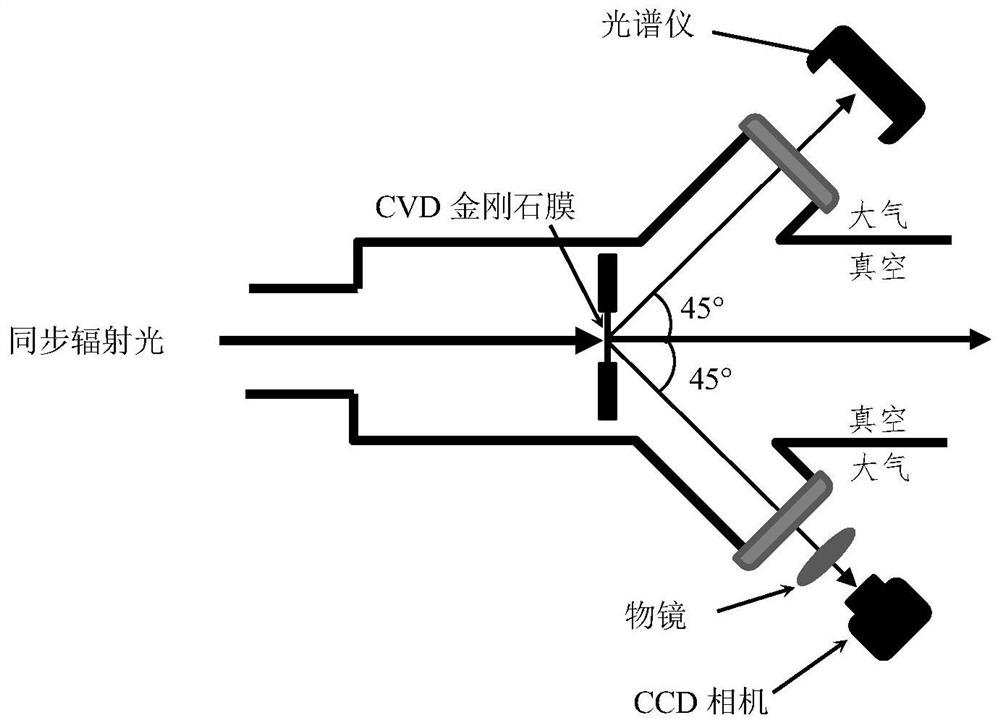

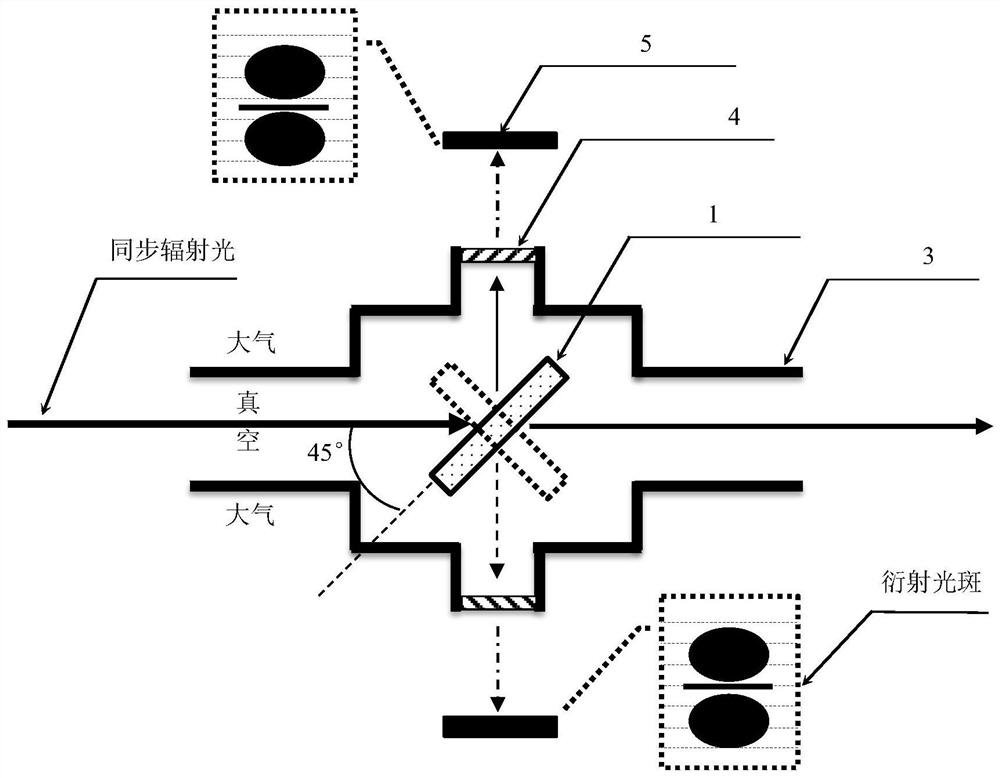

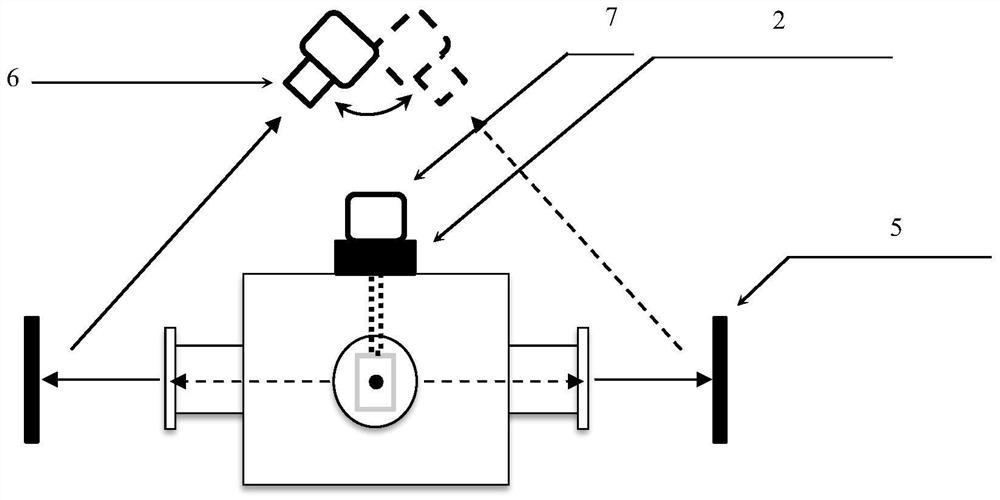

Detector and method for detecting beam position by using synchrotron radiation polarization

ActiveCN111982278AImprove permeabilityTrue vertical positionPhotometry using electric radiation detectorsFluorescenceBeryllium window

The invention discloses a detector and method for detecting a beam position by using synchrotron radiation polarization, wherein the detector comprises a vacuum cavity (3), and two beryllium windows (4) are parallel to a synchrotron radiation light beam and are symmetrically disposed on the vacuum cavity (3). A magnetic fluid transmission mechanism (2) is connected with the vacuum cavity (3); theatmospheric end of the magnetic fluid transmission mechanism (2) is connected with a motor (7); the vacuum end of the magnetic fluid transmission mechanism (2) is connected with a clamping mechanism of a graphite single crystal wafer (1) in the vacuum cavity (3) and is used for adjusting and positioning the graphite single crystal wafer (1) to enable the graphite single crystal wafer (1) and the synchrotron radiation light beam to form a 45-degree angle or a -45-degree angle, the diffraction intensity of a linear sigma polarization component of the synchrotron radiation light beam is zero, thediffraction intensity of a pi polarization component is not zero, and the pi polarization component diffracts and is emitted to a corresponding fluorescent screen (5). A visible light sensor (6) is used for observing and recording a light-emitting image on the fluorescent screen (5).

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI +1

Method for degrading and recovering polyester polyurethane

InactiveCN110105620ADegradation rate does not affectWon't happenOrganic compound preparationPlastic recyclingPolyesterRecovery method

The invention belongs to the field of recycling of organic polymer materials, and especially relates to a method for degrading and recovering polyester polyurethane. The waste polyester polyurethane is degraded in an alcohol solution by using urea as a catalyst, and obtained degradation products are separated and purified to obtain a small molecule alcohol and an amine. The method avoids pollutionof burying and burning to soil, water and air, avoids the defect that only chemicals with low added values can be obtained by physical crushing, and also avoids the harms of toxic gases generated byheat treatment. A degradation system used in the method is especially green, environmentally friendly, economical and saving.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com