Composite phase change material for reducing cigarette smoke temperature and preparation method and application thereof

A technology of composite phase change material and cigarette smoke, which is applied in the field of cigarette material manufacturing, can solve the problems of reducing the thermal conductivity of the phase change material, complicated preparation method of the composite phase change material, affecting the cooling performance, etc. Low cost and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 (weight part)

[0033] S1. Add 7.5 parts of PEG1000 and 2.5 parts of PEG1500 to 150 parts of ethanol, and stir at 600 rpm for 30 minutes at room temperature to prepare a certain concentration of PEG ethanol solution.

[0034] S2. Add 8 parts of ethyl cellulose to 150 parts of ethanol, ultrasonically dissolve it for 30 minutes, stir at 600 rpm for 20 minutes at 50°C, let it stand, and lower the temperature of the solution to room temperature to prepare an ethanol solution of ethyl cellulose with a certain concentration .

[0035] S3. Mix the solution obtained in step (1) and step (2), stir evenly, and let it dry naturally.

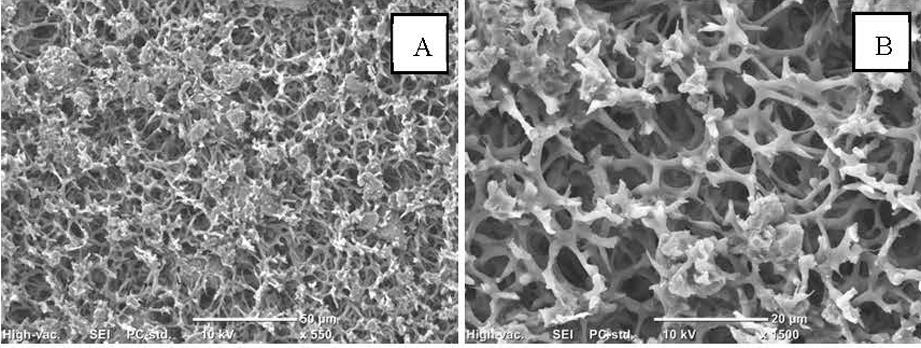

[0036] S4. After pulverizing the composite material obtained in step (3), collect 20-35 mesh samples to obtain a composite phase change material for reducing the temperature of mainstream cigarette smoke.

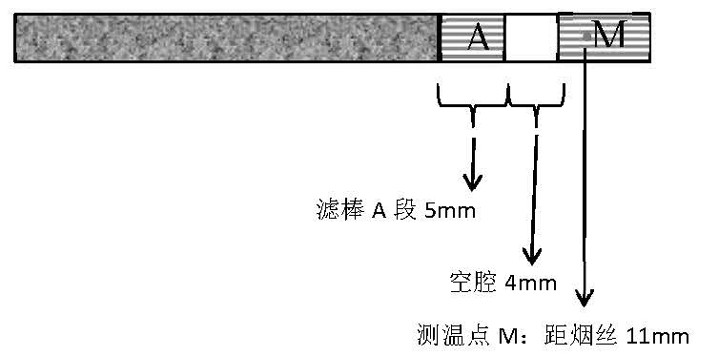

[0037] The present invention further provides a method for using the composite phase change material for reducing the mainstream s...

Embodiment 2

[0046] Embodiment 2 (weight part):

[0047] S1. Add 15 parts of PEG1000 and 5 parts of PEG1500 into 200 parts of ethanol, and stir at 600 rpm for 30 minutes at room temperature to prepare a certain concentration of PEG ethanol solution.

[0048]S2. Add 16 parts of ethyl cellulose to 250 parts of ethanol, ultrasonically dissolve it for 30 minutes, stir at 600 rpm for 20 minutes at 50°C, let it stand, and lower the temperature of the solution to room temperature to prepare an ethanol solution of ethyl cellulose with a certain concentration .

[0049] S3. Mix the solution obtained in step (1) and step (2), stir evenly, and let it dry naturally.

[0050] S4. After pulverizing the composite material obtained in step (3), collect 20-35 mesh samples to obtain a composite phase change material for reducing the temperature of mainstream cigarette smoke.

Embodiment 3

[0051] Embodiment 3 (weight part):

[0052] S1. Add 7.5 parts of PEG1000 and 2.5 parts of PEG1500 into 150 parts of ethanol, and stir at 400 rpm for 30 minutes at room temperature to prepare a certain concentration of PEG ethanol solution.

[0053] S2. Add 8 parts of ethyl cellulose to 150 parts of ethanol, ultrasonically dissolve it for 30 minutes, stir at 600 rpm for 10 minutes at 50°C, let it stand, and lower the solution temperature to room temperature to prepare a certain concentration of ethyl cellulose ethanol solution .

[0054] S3. Mix the solution obtained in step (1) and step (2), stir evenly, and let it dry naturally.

[0055] S4. After pulverizing the composite material obtained in step (3), collect 20-35 mesh samples to obtain a composite phase change material for reducing the temperature of mainstream cigarette smoke.

PUM

| Property | Measurement | Unit |

|---|---|---|

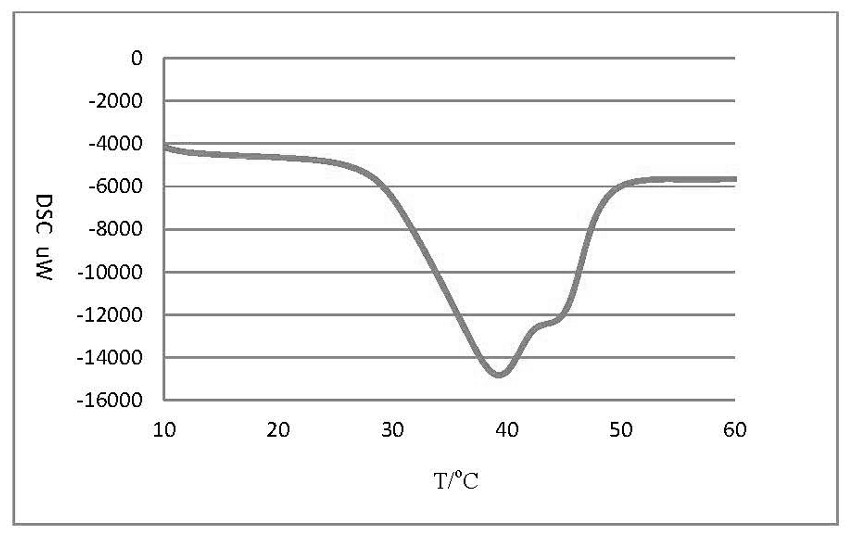

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com