On-line detection device and method for shield machine tool and cutterhead wear based on optical fiber sensing

A shield machine cutting tool and optical fiber sensing technology, which is applied in the direction of optical testing for flaws/defects, earthwork drilling, instruments, etc. Application of cutter head wear detection and other issues to achieve the effect of avoiding electromagnetic interference design, reducing transmission capacity limit, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

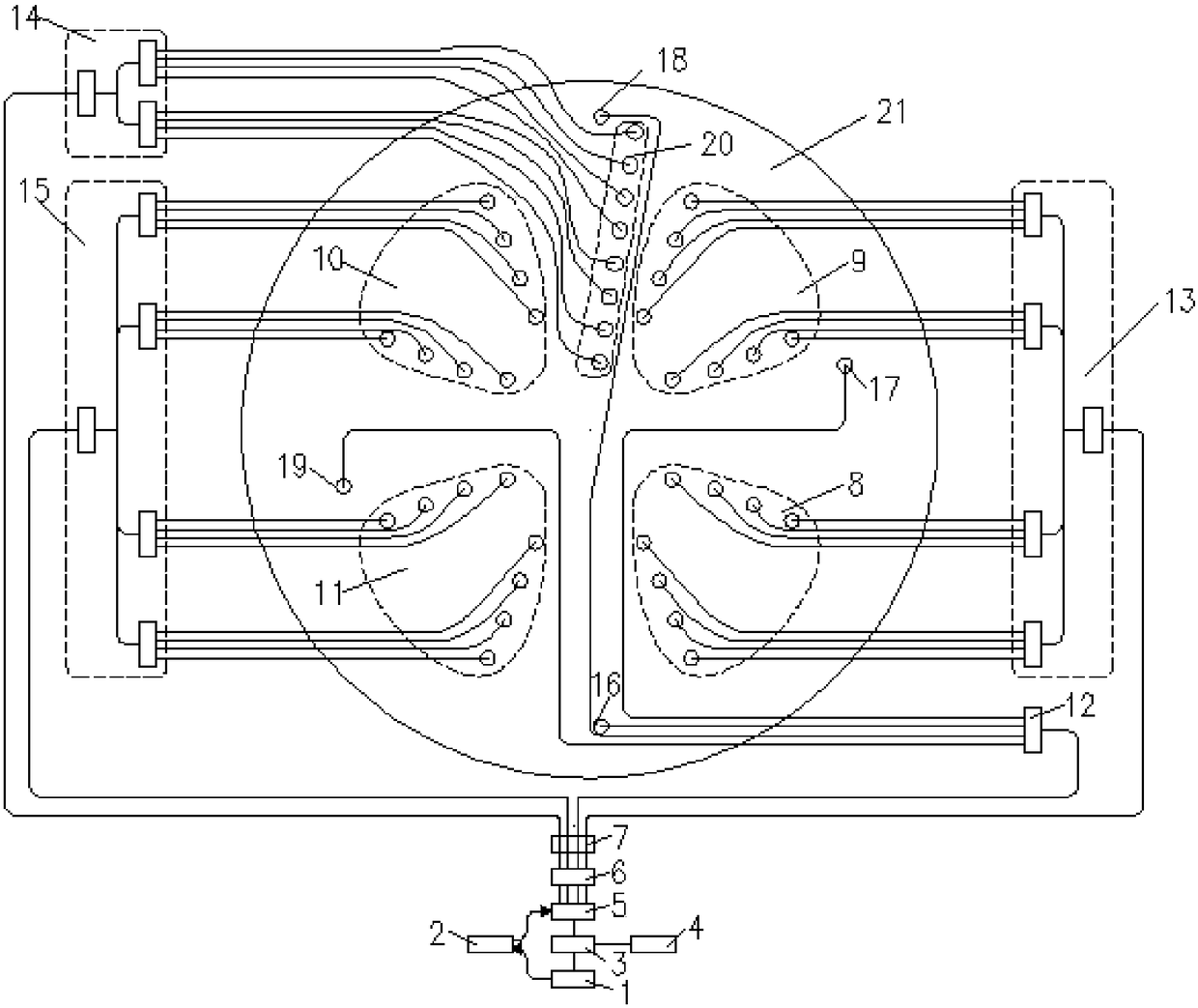

[0032] The invention provides an on-line detection device for shield machine tool and cutterhead wear based on optical fiber sensing, such as Figure 1 to Figure 4 shown, including:

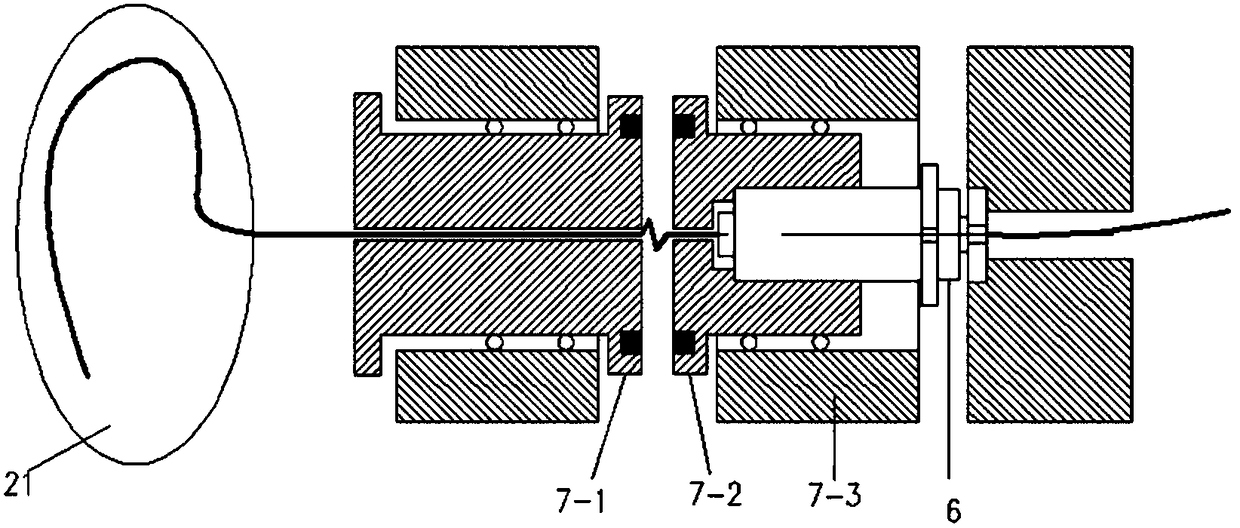

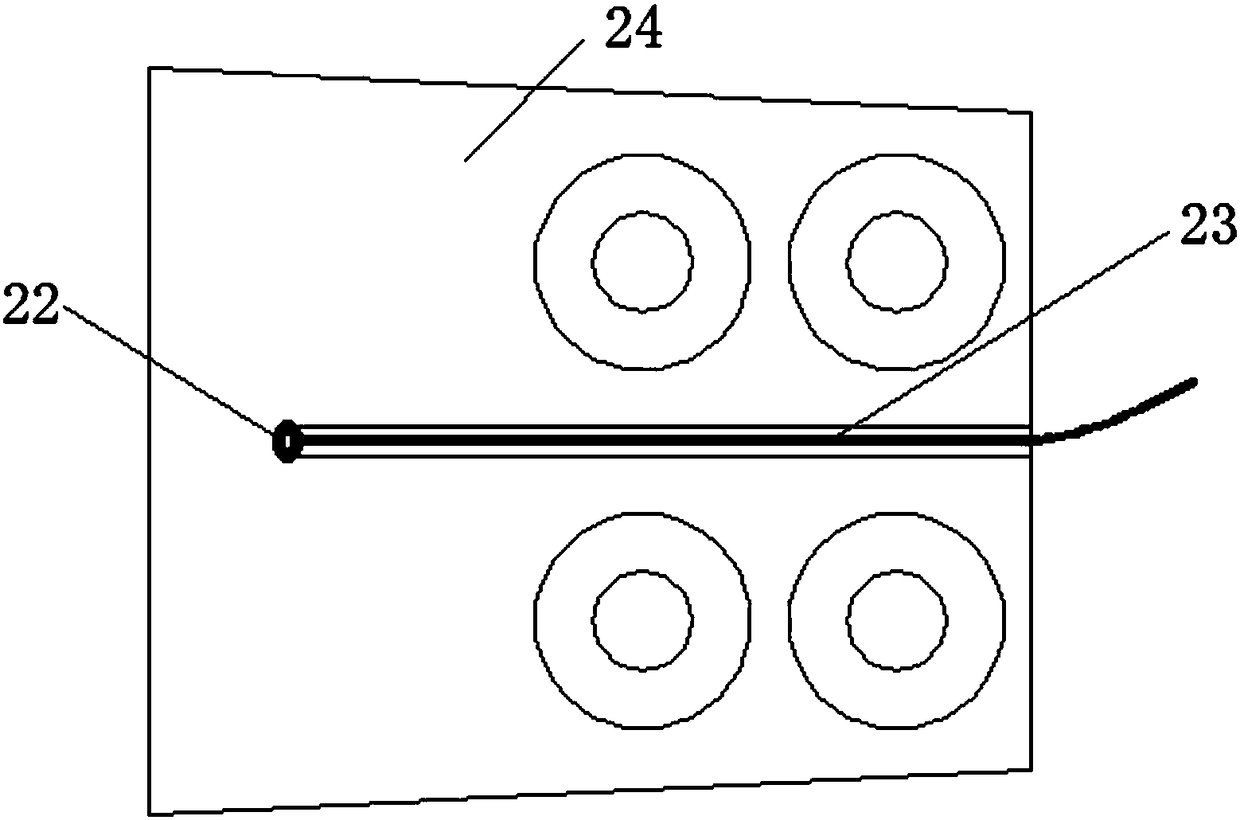

[0033] A fiber grating position sensor group consisting of several fiber grating position sensors 23 with the same structure, each fiber grating position sensor 23 includes a grating on an optical fiber, and each fiber grating position sensor 23 is installed in the deep hole of the device to be detected , and the fiber end of the fiber grating position sensor 23 is located at the wear limit position 22 of the device to be detected; the device to be detected includes a cutting tool 23 to be detected, a wear detection tool 25 and a cutter seat of the cutter head 21;

[0034] The light splitting system is used to transmit light to each fiber grating position sensor 23 resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com