Hydrophobic slurry, and preparation method and application thereof

A hydrophobic and slurry technology, used in paper coatings, water repellent addition, no pigment coating, etc., can solve the problems of non-biodegradable resin, many chemicals, aggravating environmental pollution, etc., which is conducive to large-scale popularization and application, The effect of alleviating white pollution and high hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides a kind of hydrophobic slurry, which is specifically prepared by the following steps:

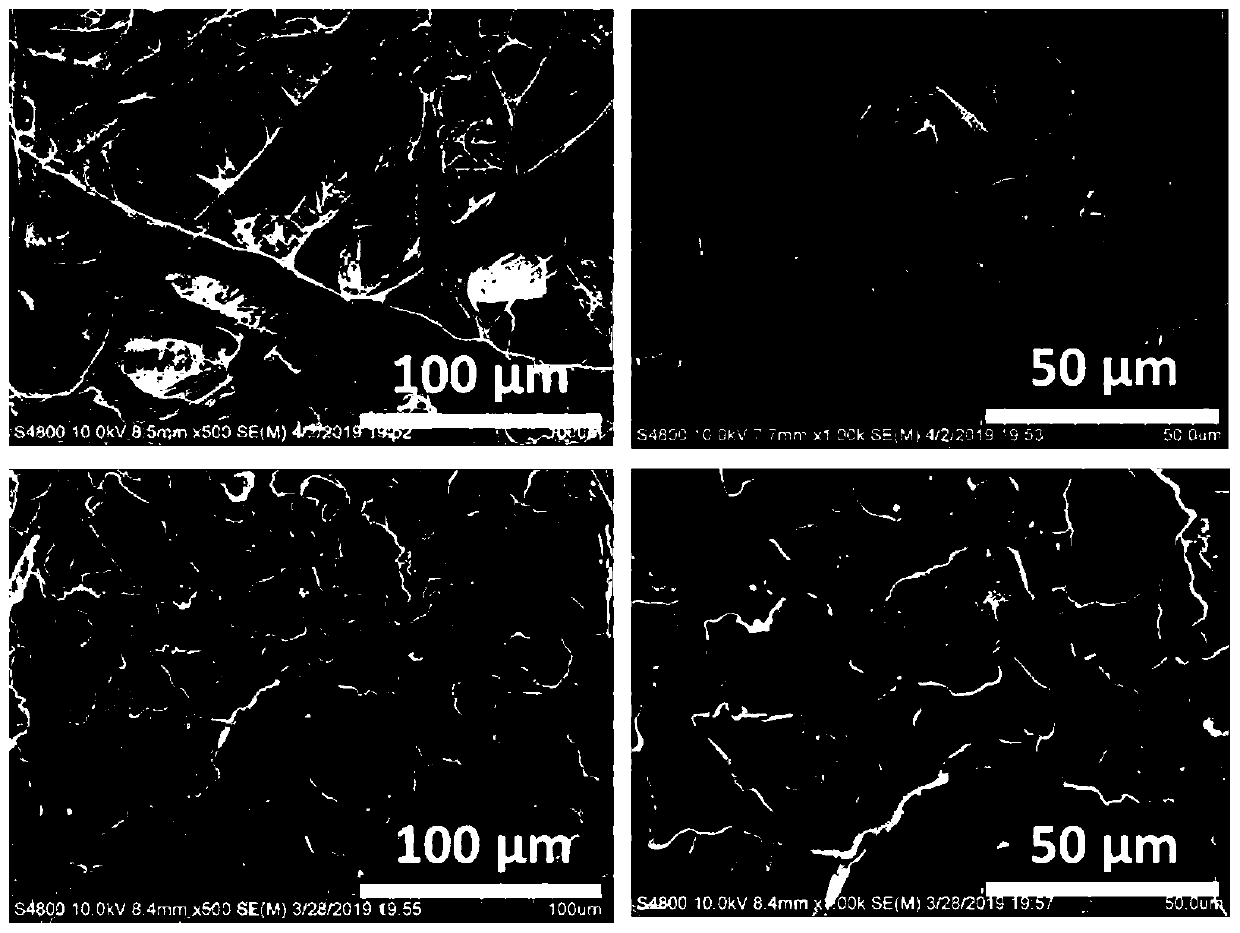

[0060] (1) Preparation of hydrophobic cellulose: crush the bleached kraft wood pulp into segmented materials with a length of 2-5 mm and a width of 1-2 mm, and vacuum-dry at 105° C. for 2 hours. Take 50g of dried cellulose (segmental kraft wood pulp), and mechanically compound 750g polytetrafluoroethylene (PTFE, molecular weight 5.2 million) in a QM-3SP4 planetary ball mill for 8 hours, and the grinding balls are 20mm (60g) in diameter, 10mm ( 220g), 6mm (260g) zirconia balls with a mass of 540g, the grinding speed is 540r / min. The composited cellulose powder was separated from excess PTFE with a stainless steel sieve to obtain 51 g of hydrophobic cellulose.

[0061] (2) Add 5g of film-forming agent polyvinyl butyral (PVB, molecular weight: 54,000) powder into 95g of ethyl acetate, stir and mix at room temperature to obtain a hydrophobic polymer solution (the...

Embodiment 2-4

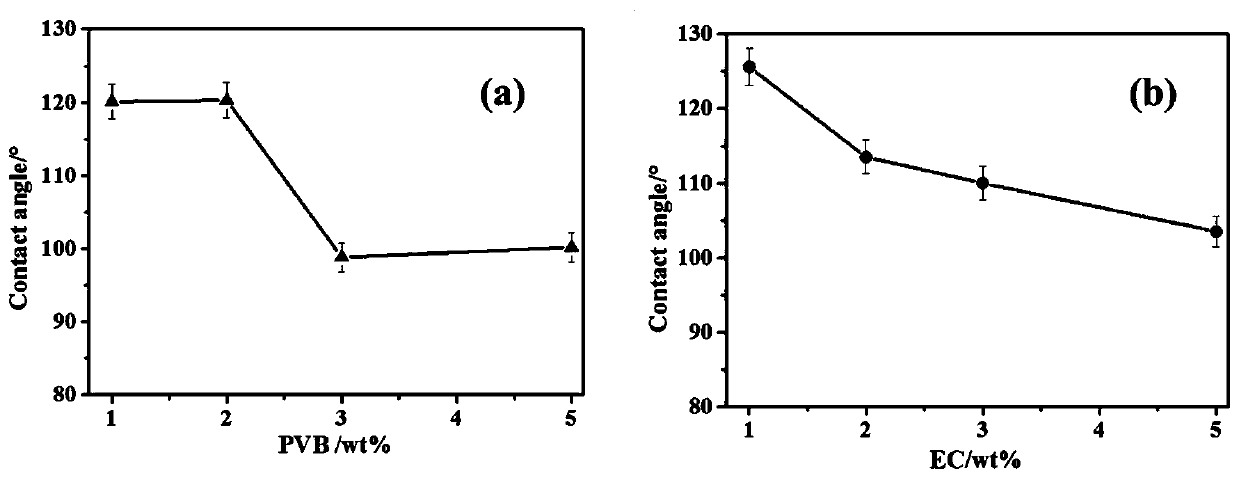

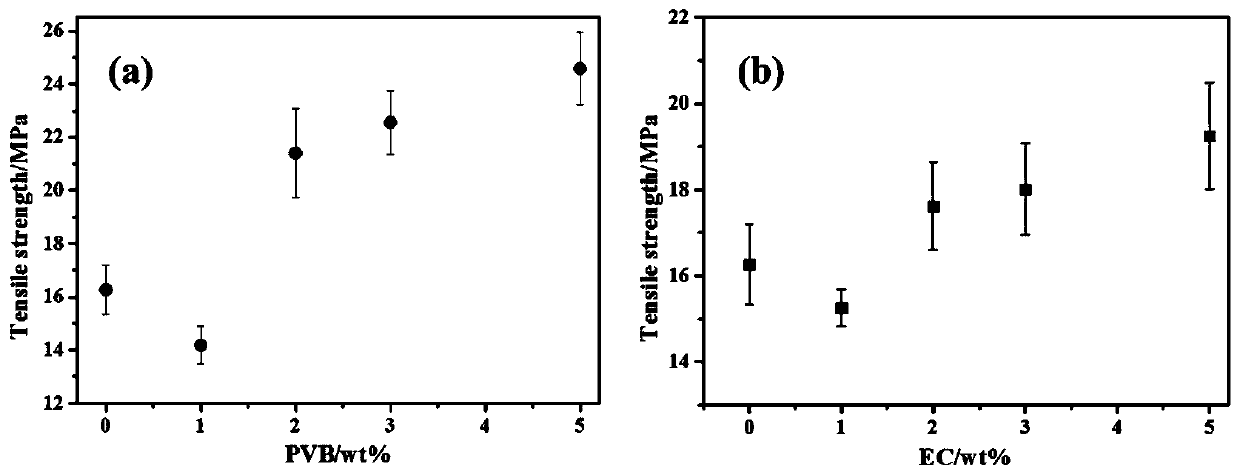

[0065] Embodiment 2-4 provides a kind of hydrophobic slurry and hydrophobic paper respectively, and they are identical with the preparation method of embodiment 1, and difference only is:

[0066] In the step (2) of embodiment 2, the consumption of polyvinyl butyral is 1g, and the consumption of ethyl acetate is 99g (that is, the concentration of PVB in the hydrophobic polymer solution is 1%);

[0067] In the step (2) of embodiment 3, the consumption of polyvinyl butyral is 2g, the consumption of ethyl acetate is 98g (that is, the concentration of PVB in the hydrophobic polymer solution is 2%);

[0068] In the step (2) of Example 4, the consumption of polyvinyl butyral is 3 g, and the consumption of ethyl acetate is 97 g (that is, the concentration of PVB in the hydrophobic polymer solution is 3%).

Embodiment 5-8

[0070] Embodiments 5-8 respectively provide a hydrophobic slurry and hydrophobic paper, which are prepared in the same way as in Example 1, except that the hydrophobic polymer (film-forming agent) is ethyl cellulose (EC, molecular weight: 26,000):

[0071] In the step (2) of Example 5, the amount of EC was 1 g, and the amount of ethyl acetate was 99 g (that is, the concentration of EC in the hydrophobic polymer solution was 1%);

[0072] In the step (2) of Example 6, the amount of EC was 2 g, and the amount of ethyl acetate was 98 g (that is, the concentration of EC in the hydrophobic polymer solution was 2%);

[0073] In the step (2) of Example 7, the amount of EC was 3 g, and the amount of ethyl acetate was 97 g (that is, the concentration of EC in the hydrophobic polymer solution was 3%);

[0074] In the step (2) of Example 8, the amount of EC used is 5 g, and the amount of ethyl acetate used is 95 g (that is, the concentration of EC in the hydrophobic polymer solution is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com