A kind of preparation method of water-based varnish

A technology of water-based varnish and water-based wetting agent, which can be used in inks, household utensils, applications, etc., and can solve problems affecting printing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

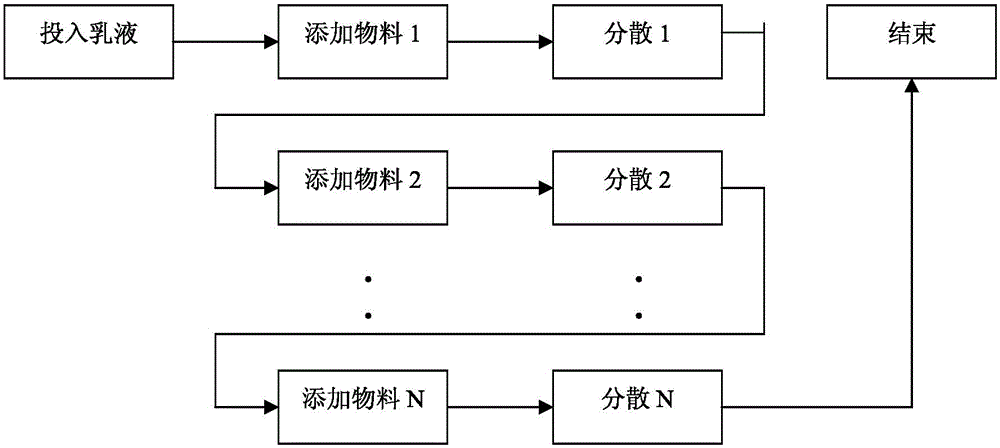

Method used

Image

Examples

Embodiment 1

[0030] Step 1. According to the formula, first put 30 parts of high glass transition temperature styrene-acrylic non-film-forming emulsion into a certain volume of agitable open tank.

[0031] Step 2: Add 20 parts of solid acrylic acid alkali-soluble resin liquid while dispersing at a speed of 800-1000 rpm, and then disperse at a speed of 1000 rpm for 15 minutes.

[0032] Step 3: Add 1 part of water-based leveling agent while dispersing at a speed of 1000 rpm, and then disperse at a speed of 1000 rpm for 10 minutes.

[0033] Step 4: Add 5 parts of ethanol while dispersing at a speed of 800 rpm, and then disperse for 5 minutes at a speed of 1000 rpm.

[0034] Step 5: Put in 1 part of water-based wetting agent while dispersing at a speed of 800 rpm, and then disperse at a speed of 1000 rpm for 8 minutes.

[0035] Step 6: Add 0.2 parts of water-based defoamer while dispersing at a speed of 1000 rpm, and disperse for 15 minutes at a speed of 1200 rpm.

[0036] Step 7: Put in 8 p...

Embodiment 2

[0040] Step 1. According to the formula, first put 20 parts of high glass transition temperature styrene-acrylic non-film-forming emulsion into a certain volume of agitable open tank.

[0041] Step 2: Add 10 parts of solid acrylic acid alkali-soluble resin liquid while dispersing at a speed of 800-1000 rpm, and then disperse at a speed of 1000 rpm for 15 minutes.

[0042] Step 3: Add 0.5 parts of water-based leveling agent while dispersing at a speed of 1000 rpm, and then disperse at a speed of 1000 rpm for 10 minutes.

[0043] Step 4: Add 2.5 parts of ethanol while dispersing at a speed of 800 rpm, and then disperse for 5 minutes at a speed of 1000 rpm.

[0044] Step 5: Add 0.5 parts of water-based wetting agent while dispersing at a speed of 800 rpm, and then disperse at a speed of 1000 rpm for 8 minutes.

[0045] Step 6: Add 0.1 part of water-based defoamer while dispersing at a speed of 1000 rpm, and disperse for 15 minutes at a speed of 1200 rpm.

[0046] Step 7: Add 4 ...

Embodiment 3

[0050]Step 1. According to the formula, first put 40 parts of high glass transition temperature styrene-acrylic non-film-forming emulsion into a certain volume of open tank that can be stirred.

[0051] Step 2: Add 30 parts of solid acrylic acid alkali-soluble resin liquid while dispersing at a speed of 800-1000 rpm, and then disperse at a speed of 1000 rpm for 15 minutes.

[0052] Step 3: Add 2 parts of water-based leveling agent while dispersing at a speed of 1000 rpm, and then disperse at a speed of 1000 rpm for 10 minutes.

[0053] Step 4: Add 10 parts of ethanol while dispersing at a speed of 800 rpm, and disperse for 5 minutes at a speed of 1000 rpm.

[0054] Step 5: Add 2 parts of water-based wetting agent while dispersing at a speed of 800 rpm, and then disperse at a speed of 1000 rpm for 8 minutes.

[0055] Step 6: Add 0.4 parts of water-based defoamer while dispersing at a speed of 1000 rpm, and disperse for 15 minutes at a speed of 1200 rpm.

[0056] Step 7: Put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com