Heat-deformation-resistant semiconductive polyethylene shielding material

A polyethylene and semi-conductive technology, applied in the field of cable shielding materials, can solve the problems of reduced physical and chemical properties and processing performance of shielding materials, poor thermal stability of semi-conductive shielding materials, poor surface smoothness of shielding layers, etc., and achieve excellent processing performance. , Shortening the volume resistance change rate, the effect of smooth extrusion surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

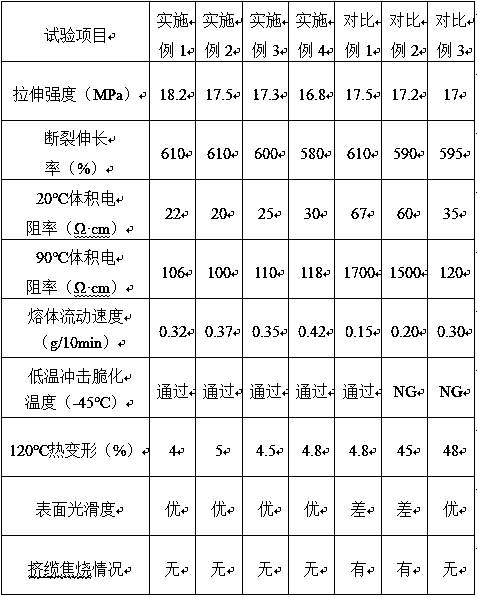

[0029] Embodiments 1-4: A heat-resistant deformation semi-conductive polyethylene shielding material, consisting of the following components by mass, as shown in Table 1:

[0030] Table 1

[0031]

Embodiment 1

[0032] The lubricant of embodiment 1 is zinc stearate, the lubricant of embodiment 2 is calcium stearate, the lubricant of embodiment 3 is the mixture of zinc stearate and stearic acid, and the lubricant of embodiment 4 is calcium stearate. A mixture of calcium stearate and stearic acid;

[0033] The polyolefin of embodiment 1 and embodiment 2 is the DF810 that Japanese Mitsui Chemicals produces, and the polyolefin of embodiment 3 and embodiment 4 is the DF805 that Japanese Mitsui Chemicals produces;

[0034] The ethylene-vinyl acetate copolymer of embodiment 1 and embodiment 3 is the V4610J that Yangzi BASF produces, and the ethylene-vinyl acetate copolymer of embodiment 2 and embodiment 4 is the V5110J that Yangzi BASF produces;

[0035] The conductive carbon black of embodiment 1 and embodiment 2 is VXC72R produced by American Capote, and the conductive carbon black of embodiment 3 and embodiment 4 is VXC72 produced by American Capote.

[0036] The above-mentioned heat-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com