A kind of co-extruded film for peritoneal dialysis fluid bag and preparation method thereof

A technology of peritoneal dialysis and co-extrusion membrane, which is applied in the field of co-extrusion membrane for peritoneal dialysis fluid bag and its preparation, which can solve the problem of migration, enter the human body with liquid medicine or blood, and is not resistant to 135°C high-temperature steam sterilization, welding heat sealing Single method and other problems, to achieve the effect of facilitating deterioration, ensuring the safety of medication, and less migration and precipitates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

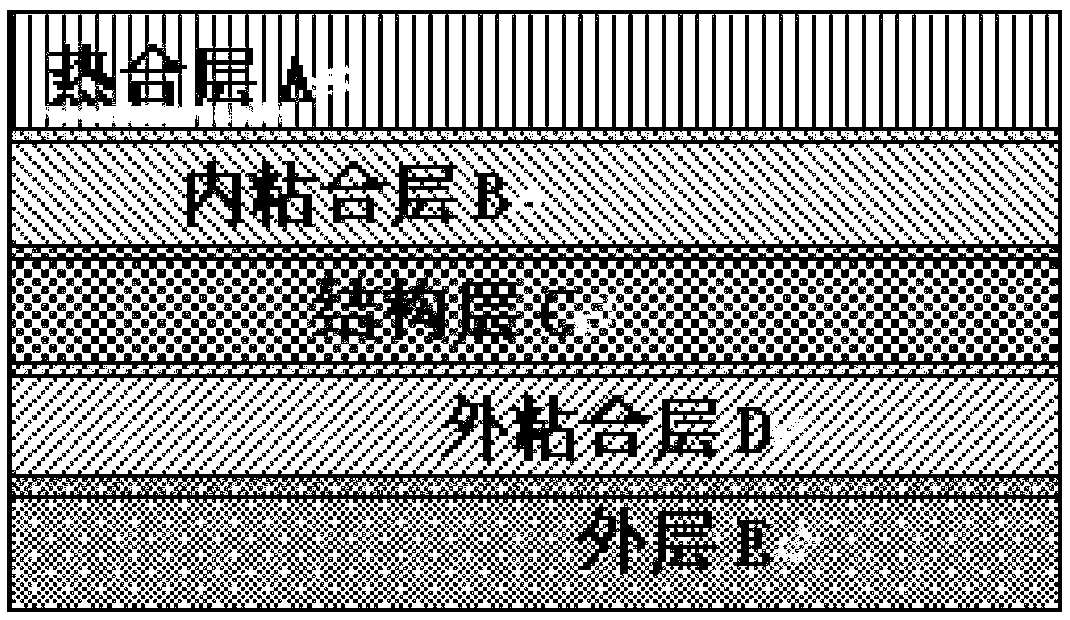

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. Now in conjunction with the following figure the present invention will be further described.

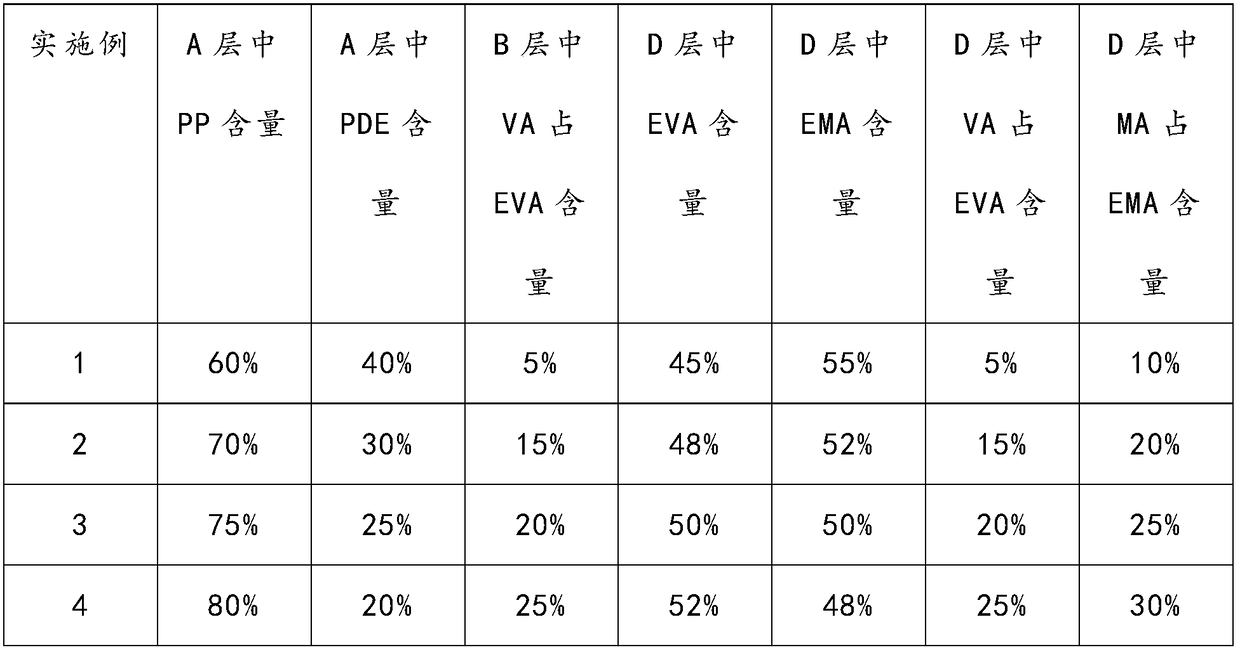

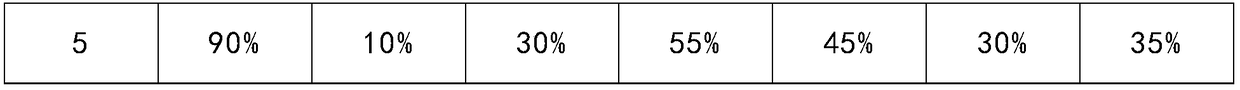

[0028] Such as figure 1 As shown, a co-extrusion film for peritoneal dialysis fluid bag provided by the present invention includes a heat-sealing layer A, an inner adhesive layer B, a structural layer C, an outer adhesive layer D and an outer layer E arranged sequentially from the inside to the outside; The material of heat sealing layer A is a mixed resin composed of modified polypropylene (PP) and ethylene octene copolymer (POE), the inner adhesive layer B is ethylene-vinyl acetate (EVA), and the structural layer C is polyethylene (PE ), the outer adhesive layer D is a mixed resin composed of ethylene-vinyl acetate copol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com