Flame-proof soft vinyl plastics for electric wire and cable

A technology of soft polyvinyl chloride, wire and cable, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of high flame retardancy and general flame retardancy, and achieve good low temperature embrittlement resistance and excellent flame retardancy , the effect of good soft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

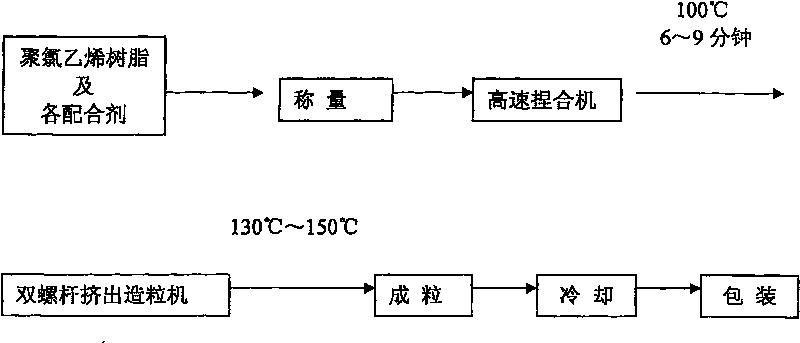

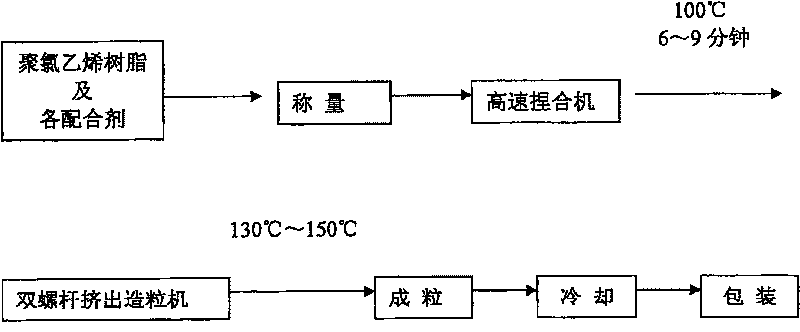

Method used

Image

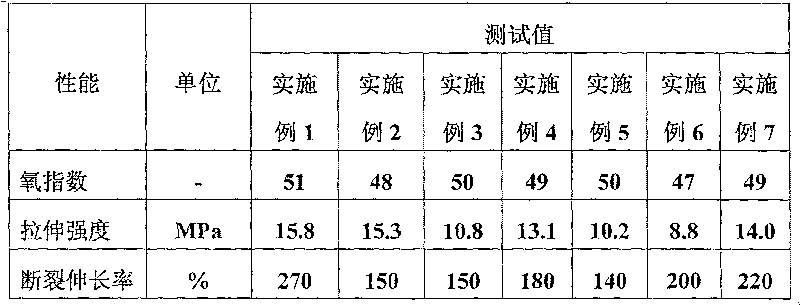

Examples

Embodiment 1

[0046] Ingredient parts by weight (quantity parts)

[0047] PVC resin (SG3 type) 100;

[0048] Trioctyl trimellitate (TOTM) 25;

[0049] Copolymer resin (Elvaloy 741) 40;

[0050] Lead cyanurate 8;

[0052] Zinc borate 25;

[0053] Aluminum hydroxide 30;

Embodiment 2

[0057] Ingredient parts by weight (quantity parts)

[0058] PVC resin (polymerization degree is 1300) 100;

[0059] Trioctyl trimellitate (TOTM) 30;

[0060] Copolymer resin (Elvaloy HP551) 15;

[0061] Lead cyanurate 12;

[0063] Zinc borate 25;

[0064]Aluminum hydroxide 50;

[0066] Lead stearate 1.2.

Embodiment 3

[0068] Ingredient parts by weight (quantity parts)

[0069] PVC resin (polymerization degree is 1300) 100;

[0070] Trioctyl trimellitate (TOTM) 32;

[0071] Diisodecyl phthalate (DIDP) 10;

[0072] Copolymer resin (Elvaloy HP551) 20;

[0073] Lead cyanurate 4;

[0075] Zinc borate 15;

[0076] Aluminum hydroxide 120;

[0077] Lead stearate 1.5;

[0078] Barium stearate 1;

[0079] Stearic acid amide 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com