Preparation method of semiconductive polyethylene shielding material

A technology of polyethylene and shielding materials, which is applied in the field of preparation of semi-conductive polyethylene shielding materials, can solve the problems of reduced physical and chemical properties and processing performance of shielding materials, poor thermal stability of semi-conductive shielding materials, and poor surface smoothness of shielding layers. Achieve excellent processing performance, shorten volume resistance change rate, and smooth extrusion surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

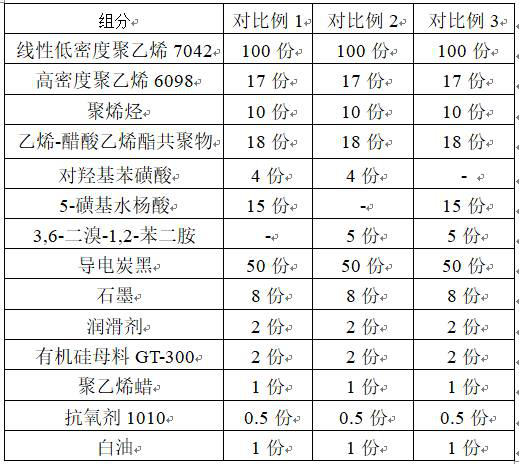

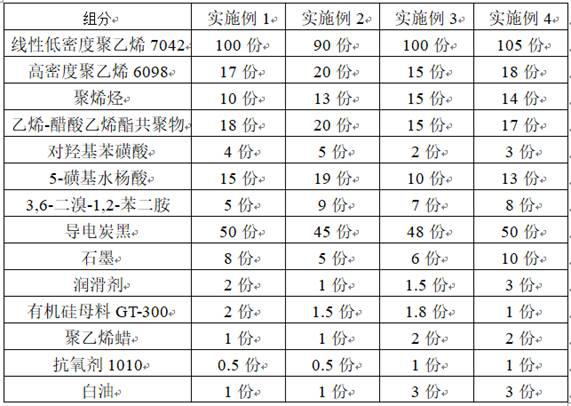

[0017] Embodiment 1~4: a kind of preparation method of semiconductive polyethylene shielding material, described semiconductive polyethylene shielding material is made up of the following components by mass, as shown in Table 1:

[0018] Table 1

[0019]

[0020] Include the following steps:

[0021] Step 1. Mix 90-105 parts of linear low-density polyethylene 7042, 15-20 parts of high-density polyethylene 6098, 10-15 parts of polyolefin, 15-20 parts of ethylene-vinyl acetate copolymer, and 40-50 parts of conductive carbon black parts, 2~5 parts of p-hydroxybenzenesulfonic acid, 10~20 parts of 5-sulfosalicylic acid and 5~10 parts of 3,6-dibromo-1,2-phenylenediamine, put into the dense Mixing machine for 2~3 minutes;

[0022] Step 2. Open the mixing chamber, and add 5~10 parts of graphite, 1~3 parts of lubricant, 1~2 parts of silicone masterbatch GT-300, 1~2 parts of polyethylene wax, and 0.5~ 1 part, and 1~3 parts of white oil 26#, put 1~3 parts into the internal mixer ac...

Embodiment 1

[0024] The lubricant of embodiment 1 is zinc stearate, the lubricant of embodiment 2 is calcium stearate, the lubricant of embodiment 3 is the mixture of zinc stearate and stearic acid, and the lubricant of embodiment 4 is calcium stearate. A mixture of calcium stearate and stearic acid;

[0025] The polyolefin of embodiment 1 and embodiment 2 is the DF810 that Japanese Mitsui Chemicals produces, and the polyolefin of embodiment 3 and embodiment 4 is the DF805 that Japanese Mitsui Chemicals produces;

[0026] The ethylene-vinyl acetate copolymer of embodiment 1 and embodiment 3 is the V4610J that Yangzi BASF produces, and the ethylene-vinyl acetate copolymer of embodiment 2 and embodiment 4 is the V5110J that Yangzi BASF produces;

[0027] The conductive carbon black of embodiment 1 and embodiment 2 is VXC72R produced by American Capote, and the conductive carbon black of embodiment 3 and embodiment 4 is VXC72 produced by American Capote.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com