Low temperature resistant transparent polypropylene compound for automobiles and preparation method of low temperature resistant transparent polypropylene compound

A transparent polypropylene and composite technology, applied in the field of automotive materials, can solve the problems of insufficient low temperature resistance, easy thermal oxidation aging, high temperature deformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

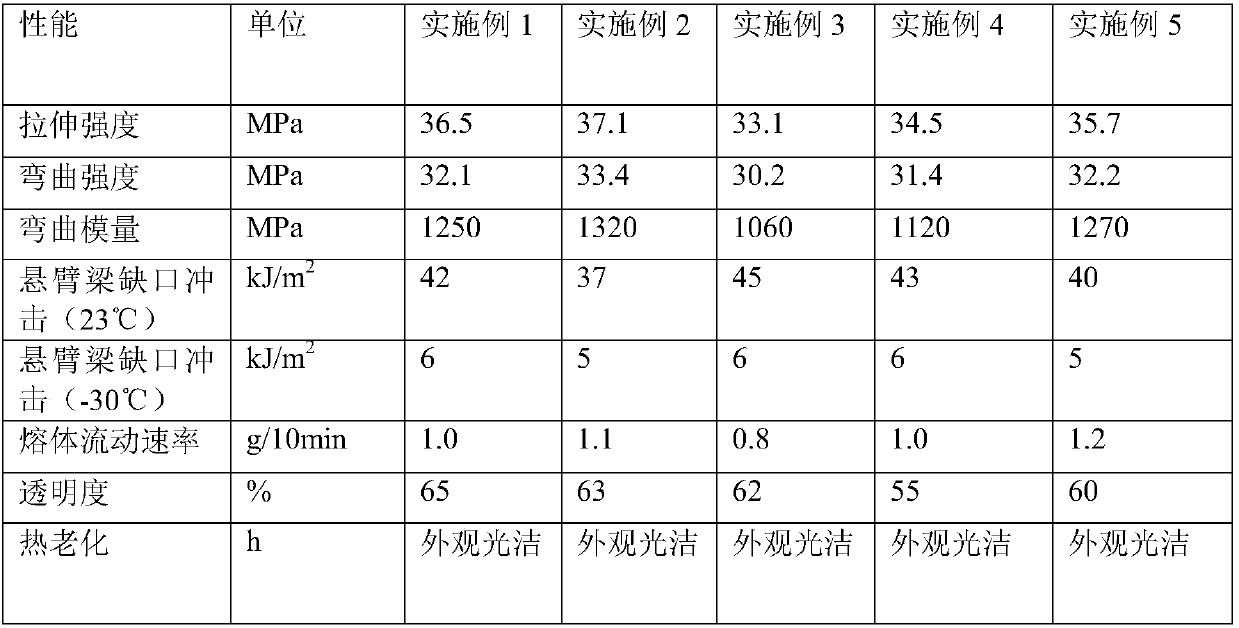

Examples

Embodiment 1

[0020] This embodiment is to prepare 100 kilograms of low-temperature-resistant transparent polypropylene composites for automobiles, according to the following steps:

[0021] Step S1, select materials, choose homopolypropylene 55kg, random copolymer polypropylene 35kg, toughening agent 3.2kg, polyethylene 5kg, heat-resistant agent 0.8kg, nucleating agent 1kg; at 230 degrees Celsius, load 2.16KG weight Under the condition, the melt index of its homopolypropylene is 6g / 10min, and the melt index of random copolymerized polypropylene is 6g / 10min.

[0022] Step S2, mixing evenly, put the homopolypropylene, random copolymerized polypropylene, toughening agent, polyethylene, heat-resistant agent, and nucleating agent in a high-speed mixer and mix evenly.

[0023] Step S3, melting and kneading, the uniformly mixed homopolypropylene, random copolymerized polypropylene, toughening agent, polyethylene, heat-resistant agent, and nucleating agent are melted and kneaded by a twin-screw ex...

Embodiment 2

[0027] According to the foregoing embodiment, another embodiment of the present invention is to prepare 100 kilograms of low-temperature-resistant transparent polypropylene composites for automobiles, according to the following steps:

[0028] Step S1, select materials, select homopolypropylene 60kg, random copolymer polypropylene 26kg, toughening agent 8.4kg, polyethylene 4kg, heat-resistant agent 0.8kg, nucleating agent 0.8kg; at 230 degrees Celsius, load 2.16KG weight Under the code condition, the melt index of homopolypropylene is 6g / 10min, and the melt index of random copolymerized polypropylene is 6g / 10min.

[0029] Step S2, mixing evenly, put the homopolypropylene, random copolymerized polypropylene, toughening agent, polyethylene, heat-resistant agent, and nucleating agent in a high-speed mixer and mix evenly.

[0030] Step S3, melting and kneading, the uniformly mixed homopolypropylene, random copolymerized polypropylene, toughening agent, polyethylene, heat-resistant...

Embodiment 3

[0035] According to the foregoing embodiment, another embodiment of the present invention is to prepare 200 kilograms of low-temperature-resistant transparent polypropylene composites for automobiles, according to the following steps:

[0036] Step S1, select materials, select homopolypropylene 160kg, random copolymer polypropylene 24kg, toughening agent 6.6kg, polyethylene 6kg, heat-resistant agent 2kg, nucleating agent 1.4kg; at 230 degrees Celsius, load 2.16KG weight Under conditions, the melt index of its homopolypropylene is 6g / 10min, and the melt index of random copolymerized polypropylene is 6g / 10min;

[0037] Step S2, mixing evenly, placing homopolypropylene, random copolymerized polypropylene, toughening agent, polyethylene, heat-resistant agent, and nucleating agent in a high-speed mixer for uniform mixing;

[0038] Step S3, melting and kneading, the uniformly mixed homopolypropylene, random copolymerized polypropylene, toughening agent, polyethylene, heat-resistant ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com