Graphene-bridged polythiophene-coated germanium nanoparticle composite material and its preparation method and application

A nanoparticle and composite material technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as capacity decay, limited development, electrode powder failure, etc., to improve capacity, improve Cycle performance, high conductivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

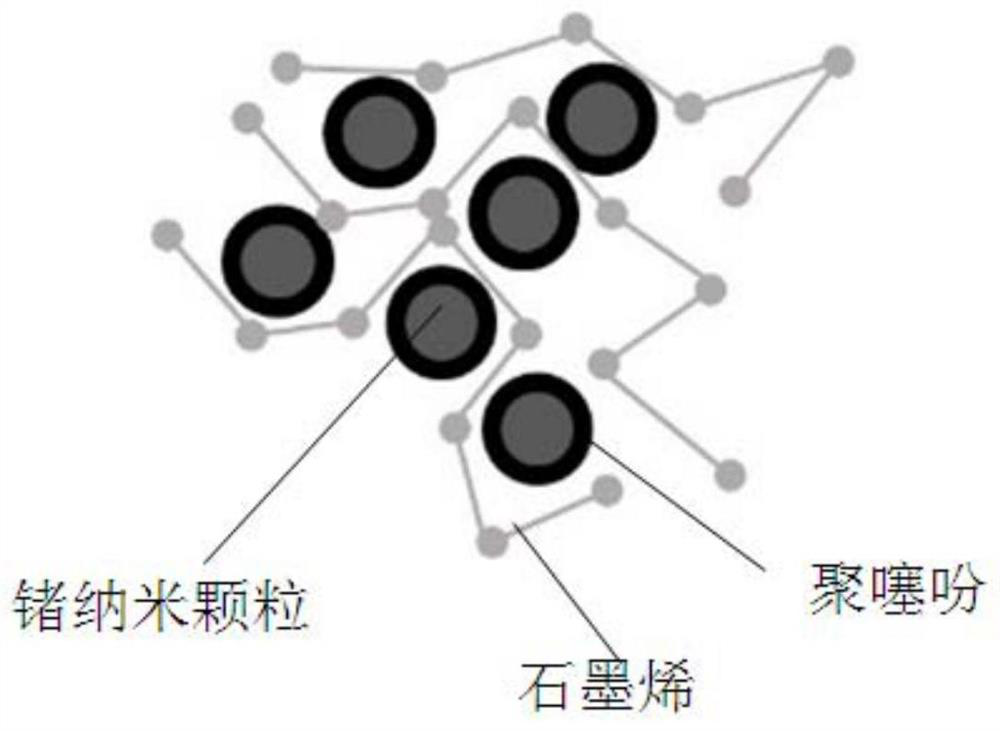

[0045] A germanium nanoparticle composite material coated with graphene bridged polythiophene of the present invention, such as figure 1 As shown, it is mainly composed of germanium nanoparticles, polythiophene and reduced graphene oxide, polythiophene is coated on the surface of germanium nanoparticles, and reduced graphene oxide is bridged to the polythiophene coated germanium nanoparticles. Polythiophene is specifically poly(3,4-ethylenedioxythiophene)-polystyrene sulfonic acid, abbreviated as PEDOT:PSS, in terms of mass fraction, the mass fraction of germanium nanoparticles is about 93.3%, and the content of PEDOT:PSS is 5.0 %, the content of reduced graphene oxide is about 1.7%.

[0046] In this embodiment, the particle size of the germanium nanoparticles is 1 nm˜50 nm.

[0047] A preparation method of the above-mentioned graphene-bridged polythiophene-coated germanium nanoparticle composite material of the present embodiment, comprising the following steps:

[0048] (1...

Embodiment 2

[0060] A germanium nanoparticle composite material coated with graphene bridged polythiophene of the present invention, such as figure 1 As shown, it is mainly composed of germanium nanoparticles, polythiophene and reduced graphene oxide, polythiophene is coated on the surface of germanium nanoparticles, and reduced graphene oxide is bridged to the polythiophene coated germanium nanoparticles. Polythiophene is specifically poly(3,4-ethylenedioxythiophene)-polystyrene sulfonate PEDOT:PSS, in terms of mass fraction, the mass fraction of germanium nanoparticles is about 81.0%, and the content of PEDOT:PSS is 14.6%. The content of graphene oxide is about 4.4%.

[0061] In this embodiment, the particle size of the germanium nanoparticles is 1 nm˜50 nm.

[0062] A preparation method of the above-mentioned graphene-bridged polythiophene-coated germanium nanoparticle composite material of the present embodiment, comprising the following steps:

[0063] (1) Add 40 mL of 0.5M ammonia ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com