A kind of nickel paste for electronic cigarette chemical core and preparation method thereof

An electronic cigarette and nickel paste technology, applied in metal processing equipment, transportation and packaging, printing and other directions, can solve the problems of high sintering process requirements, small amount of fog, poor taste of e-liquid, etc., and achieves low sintering process requirements, dispersion Good performance, large fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

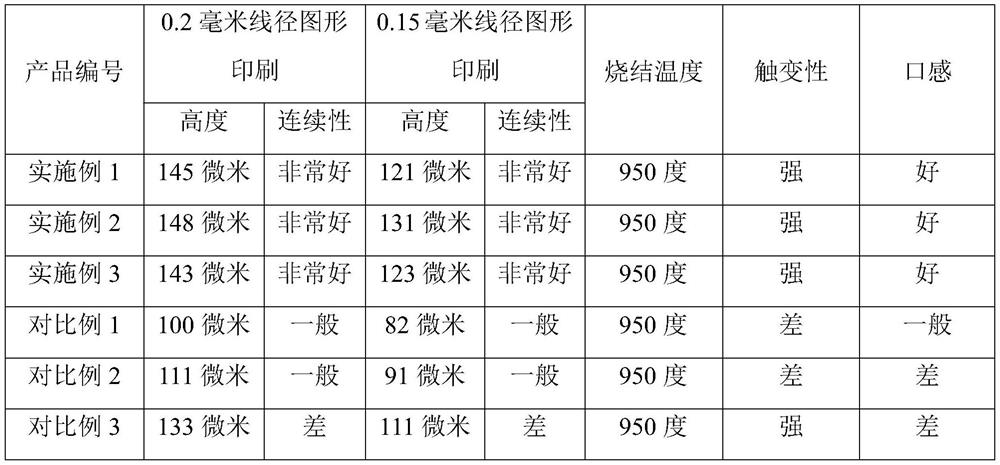

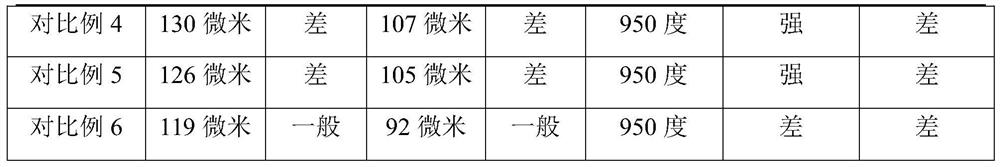

Examples

Embodiment 1

[0025] A preparation method of nickel slurry for electronic cigarette core:

[0026] (1) According to mass percentage, weigh 2% of ethyl cellulose STD-300, 8% of polymethacrylic resin, 10% of alcohol ester 12, 60% of diethylene glycol butyl ether acetate, 10% % oleic acid, 6% lecithin, 4% polyether silicone oil, heating and stirring at 50~100℃ to obtain organic carrier;

[0027] (2) Weigh 15 g of the organic carrier prepared in step (1), 60 g of nickel powder, 10 g of flake titanium hydride powder, and 15 g of glass powder of Bi-Si-B system; wherein, the average particle size of the nickel powder is 6.5 μm , the tap density is 3.6g / cm 3 , the average particle size of the titanium hydride powder is 2.5 μm, the average particle size of the glass powder is 2.0 μm, and the softening point is 600-700 ° C;

[0028] (3) The above-mentioned materials are stirred and mixed, and after stirring evenly, they are added to a three-roll mill for grinding and dispersion to obtain the nickel...

Embodiment 2

[0030] (1) By mass percentage, weigh 2% of rosin resin, 4% of phenolic resin, 15% of diethylene glycol butyl ether, 65% of diethylene glycol butyl ether acetate, 10% of terpineol, 2% lecithin, 2% polyether silicone oil, heating and stirring at 50~100℃ to obtain an organic carrier;

[0031] (2) Weigh 20 g of the organic carrier prepared in step (1), 70 g of nickel powder, 5 g of flake titanium hydride powder, and 5 g of glass powder of Bi-Si-B system; wherein, the average particle size of the nickel powder is 3.0 μm , the tap density is 4.5g / cm 3 , the average particle size of the titanium hydride powder is 1.8 μm, the average particle size of the glass powder is 1.0 μm, and the softening point is 600-700 ° C;

[0032] (3) The above-mentioned materials are stirred and mixed, and after stirring evenly, they are added to a three-roll mill for grinding and dispersion to obtain the nickel slurry for electronic cigarette core.

Embodiment 3

[0034] (1) According to mass percentage, weigh 4% of ethyl cellulose STD-300, 6% of rosin resin, 15% of alcohol ester 12, 50% of diethylene glycol butyl ether acetate, 15% of lemon Tributyl acid, 10% polyether silicone oil, heated and stirred at 50~100℃ to obtain organic carrier;

[0035](2) Weigh 9g of organic carrier prepared in step (1), 80g of nickel powder, 1g of flake titanium hydride powder, and 10g of glass powder of Bi-Si-B system; wherein, the average particle size of the nickel powder is 1.5 μm , the tap density is 6.5g / cm 3 , the average particle size of the titanium hydride powder is 1.0 μm, the average particle size of the glass powder is 3.0 μm, and the softening point is 600-700 ° C;

[0036] (3) The above-mentioned materials are stirred and mixed, and after stirring evenly, they are added to a three-roll mill for grinding and dispersion to obtain the nickel slurry for electronic cigarette core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com