Substrate heating device

A technology for substrates and supporting substrates, applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult and expensive manufacturing base 1, insufficient compensation for heat loss, etc., to improve coating quality and coating Layer properties, effect of uniform coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

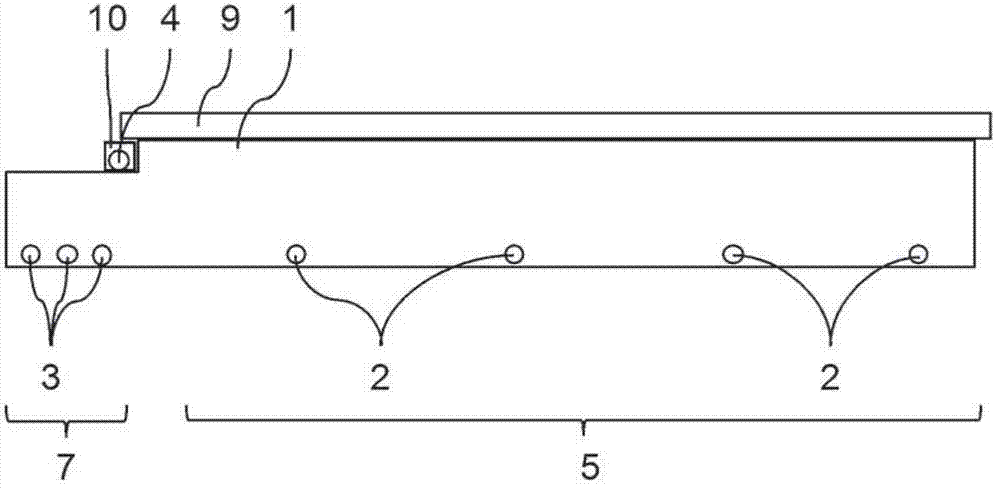

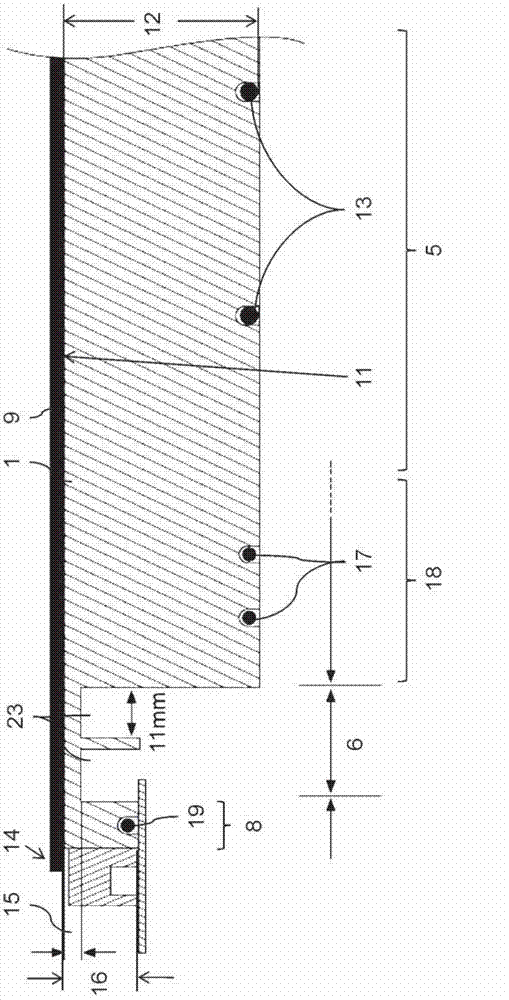

[0046] image 3 A thermal plate or susceptor 1 for supporting and thermally controlling a substrate 9 according to a preferred embodiment of the invention is shown in side view. The base 1 has a substantially flat plane 11 on which the substrate 9 is placed in thermally conductive contact; A specific, non-constant thickness 12.

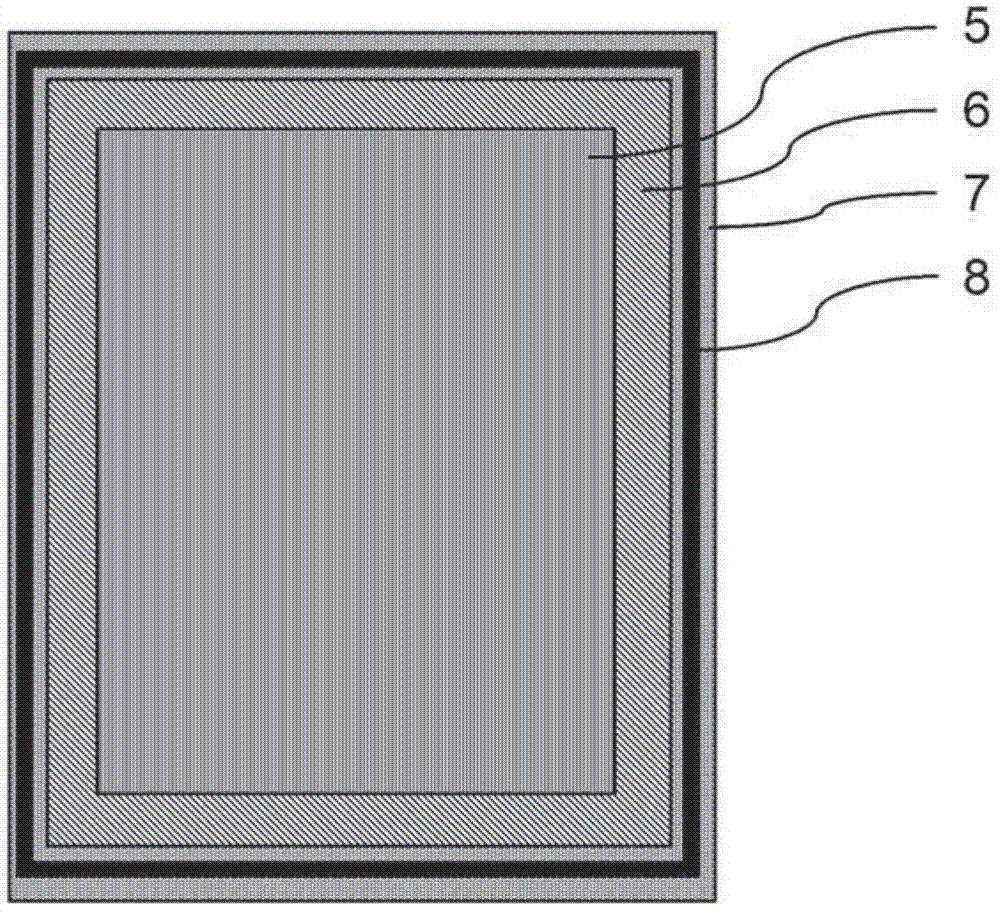

[0047] The plane 11 has at least three areas or regions 5 , 6 , 7 arranged concentrically around one another. The inner zone 5 is the innermost or central zone which has at least one inner heating element 13 influencing the inner zone 5 . The inner area 5 is completely surrounded by an outer or edge area 7 which also includes the area occupied by the edges and corners 14 of the substrate 9 during operation of the hot plate 1 .

[0048] The middle region 6 is arranged between an inner region 5 which completely surrounds the middle region 6 and an outer region 7 which completely surrounds the inner region 5 . According to the invention, the intermed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com