Series-parallel connection dual-evaporator refrigeration system, refrigerator provided with such system and control method

A double evaporator and refrigeration system technology, which is applied in the direction of compressors, refrigerators, and refrigeration components with multiple evaporators, can solve the problems of unfavorable food preservation in the refrigerator room and the inability to meet the refrigeration demand of the freezer room, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

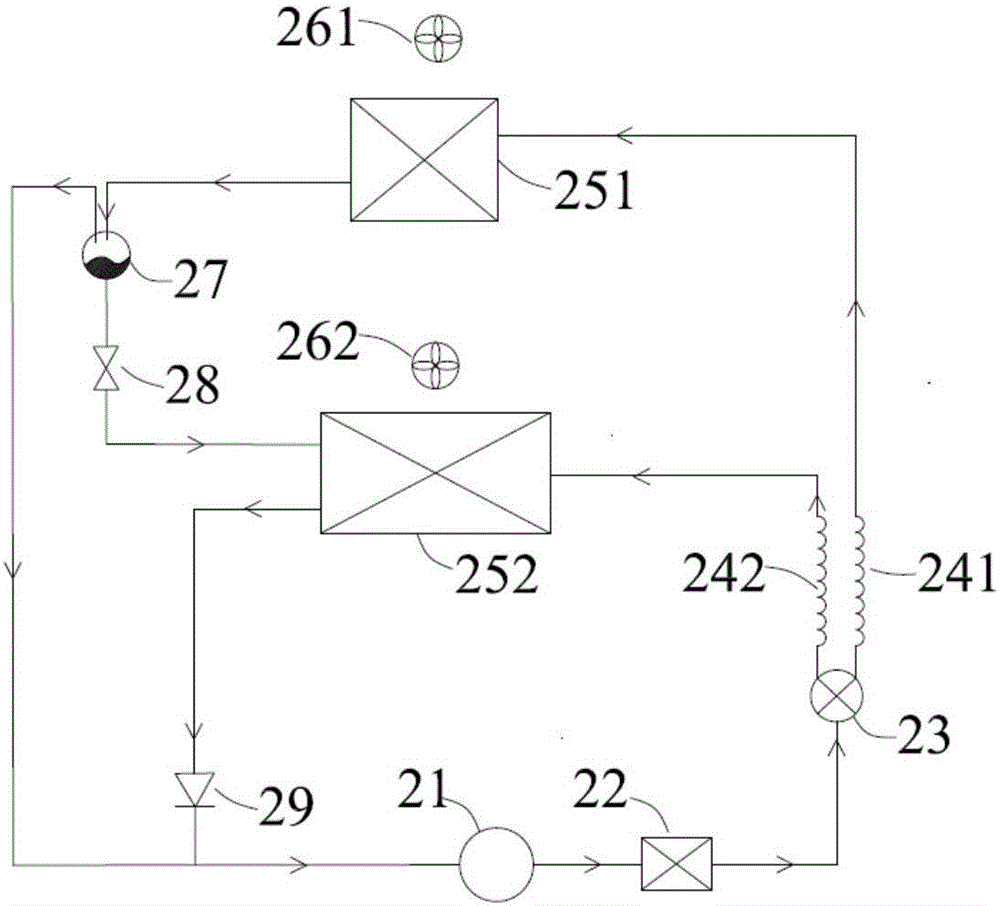

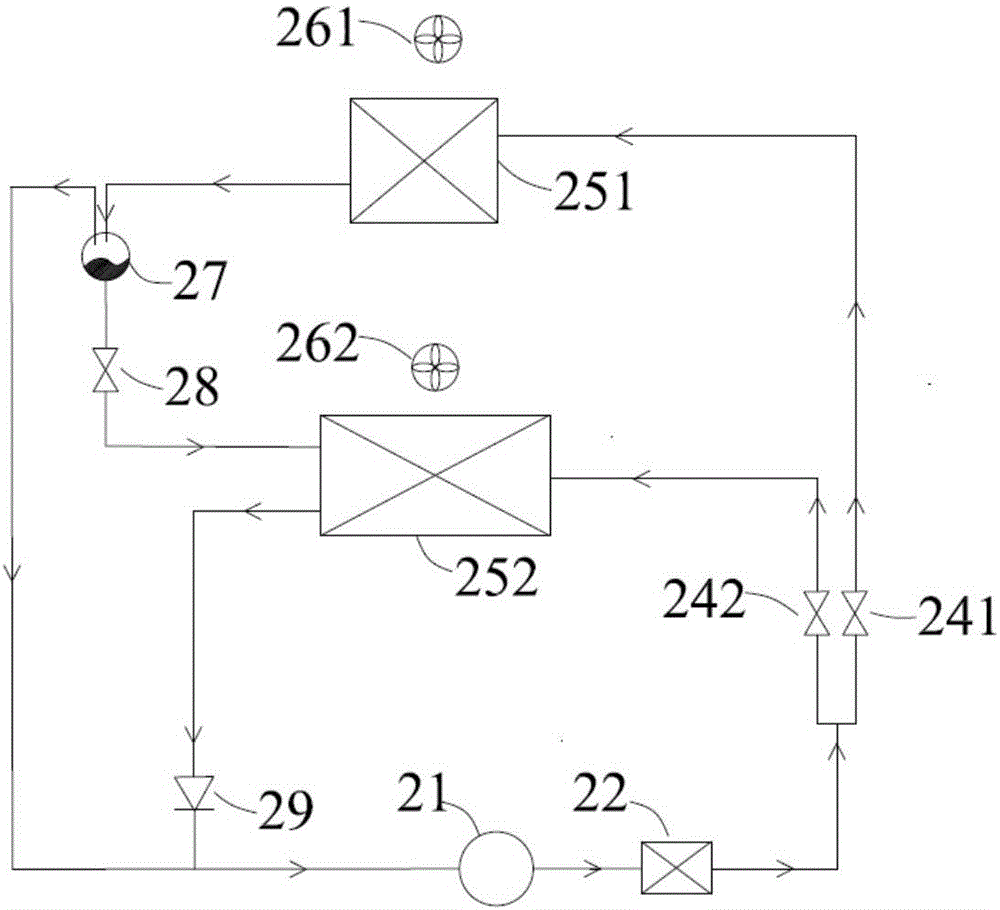

[0027] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings, please refer to figure 2 , image 3 As shown, they are two preferred embodiments of the present invention.

[0028] Such as figure 2 As shown, in an embodiment of the present invention, the series-parallel double evaporator refrigeration system includes a refrigeration refrigeration assembly and a refrigeration refrigeration assembly.

[0029] Wherein, the refrigerating and refrigerating assembly includes a compressor 21, a condenser 22, a first throttling device 242, and a refrigerating evaporator 252 for refrigerating the interior of the freezing chamber. 22. The first throttling device 242 and the refrigeration evaporator 252 form a circuit.

[0030] The refrigerating and refrigerating assembly includes a compressor 21 and a condenser 22 shared with the refrigerating and refrigerating assembly. The refrigerating and refrigerating as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com