Method for removing lignin from biomass by using alkaline electrolyzed functional water

A technology of electrogenerating functional water and lignin, which is applied in textiles, papermaking, and fiber raw material processing, etc., to achieve the effects of simple preparation, convenient preparation, and low-carbon economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

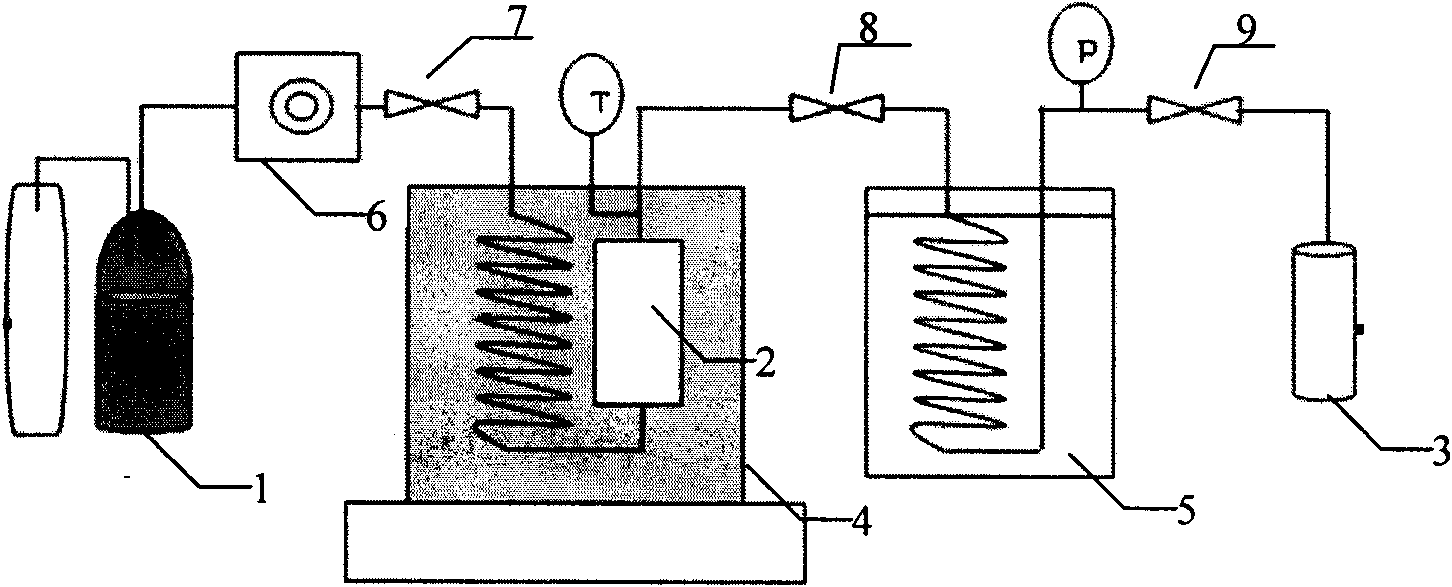

[0033] Example 1. Pretreatment of corn stalks with alkaline electro-generated functional water

[0034]The aqueous solution containing 1‰NaCl was electrolyzed for 30min at a voltage of 40V (the current changes during the electrolysis process and gradually increases, so a constant voltage electrolysis method is used, the same below), and the pH value is 11.5, and the redox potential is -867mV alkaline electrogenerated functional water. Take by weighing 2.0g of corn stalk powder dry weight (wherein, cellulose 35.23%, hemicellulose 24.75%, lignin 18.9%, other 21.12%) with a particle diameter of 40-80 mesh, put into a stainless steel continuous tube with a volume of 40ml type reactor, and make the reactor filled with the alkaline electrogenerated functional water, put the reactor into an oil bath with a temperature of 160°C, and pump the alkaline electrogenerated functional water at a flow rate of 8mL / min through a high-pressure pump Inject into continuous tubular reactor. The p...

Embodiment 2

[0035] Embodiment 2, alkaline electric functional water pretreatment corn cob

[0036] The aqueous solution containing 2‰NaCl was electrolyzed in an ice-water bath for 60 minutes at a voltage of 60V to obtain alkaline electrogenerated functional water with a pH value of 12.4 and an oxidation-reduction potential of -948mV. Take by weighing 2.0g of corn cob powder dry weight (wherein, cellulose 31.24%, hemicellulose 41.16%, lignin 12.53%, other 15.07%) with a particle diameter of 40-80 mesh, put into a stainless steel continuous tube with a volume of 40ml type reactor, and make the reactor filled with the alkaline electrogenerated functional water, put the reactor into an oil bath with a temperature of 170°C, and pump the alkaline electrogenerated functional water at a flow rate of 12mL / min through a high-pressure pump Inject into continuous tubular reactor. The pressure is controlled at 2MPa, the reaction time is 15min, and the hydrolyzate is collected through a condenser. Af...

Embodiment 3

[0037] Embodiment 3, alkaline electrogenic functional water pretreatment bagasse

[0038] 2L of aqueous solution containing 1‰NaCl is circulated by a water pump through the NdFeB magnetic field channel with a strength of 10000Gs in the normal direction, and the cross-sectional area of the channel is 5cm 2 , with a length of 20cm and a velocity of 2.5m·s -1 , the time is 3h. The magnetized electrolyte solution was electrolyzed in an ice-water bath for 5 minutes at a voltage of 60V to obtain alkaline electrogenerated functional water with a pH value of 12.5 and an oxidation-reduction potential of -967mV.

[0039] Take by weighing particle diameter and be the bagasse powder of 40-80 purpose (wherein, cellulose 35.79%, hemicellulose 25.78%, lignin 20.01%, other 18.42%) dry weight 2.0g, put into the stainless steel continuous tube that volume is 40ml type reactor, and make the reactor filled with the alkaline electrogenerated functional water, put the reactor into an oil bath w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com