Aerodynamic layout of high-speed aircraft with airframe double-side gas intake

A high-speed aircraft, aerodynamic layout technology, applied in aircraft, fuselage, motor vehicles and other directions, can solve the problems of inability to install radar, landing gear, reduce the practical value of high-speed aircraft, reduce the lift-to-drag ratio of the aircraft, and improve the lift-drag of the aircraft. ratio or adjust the longitudinal stability, improve the heading stability, and improve the effect of lift-drag ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

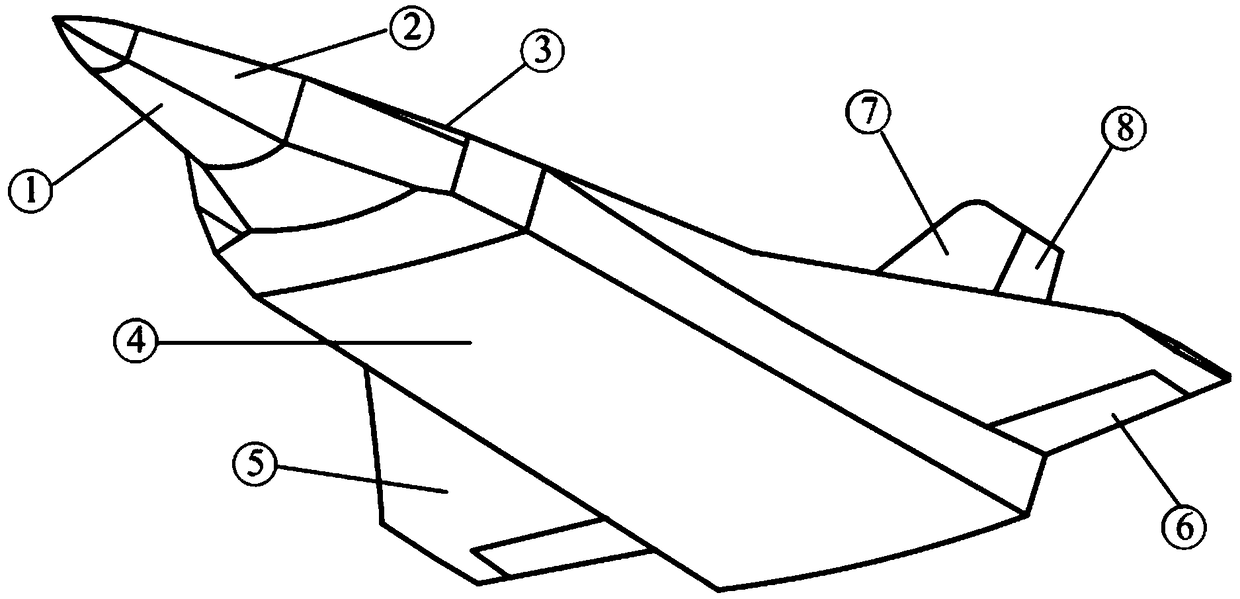

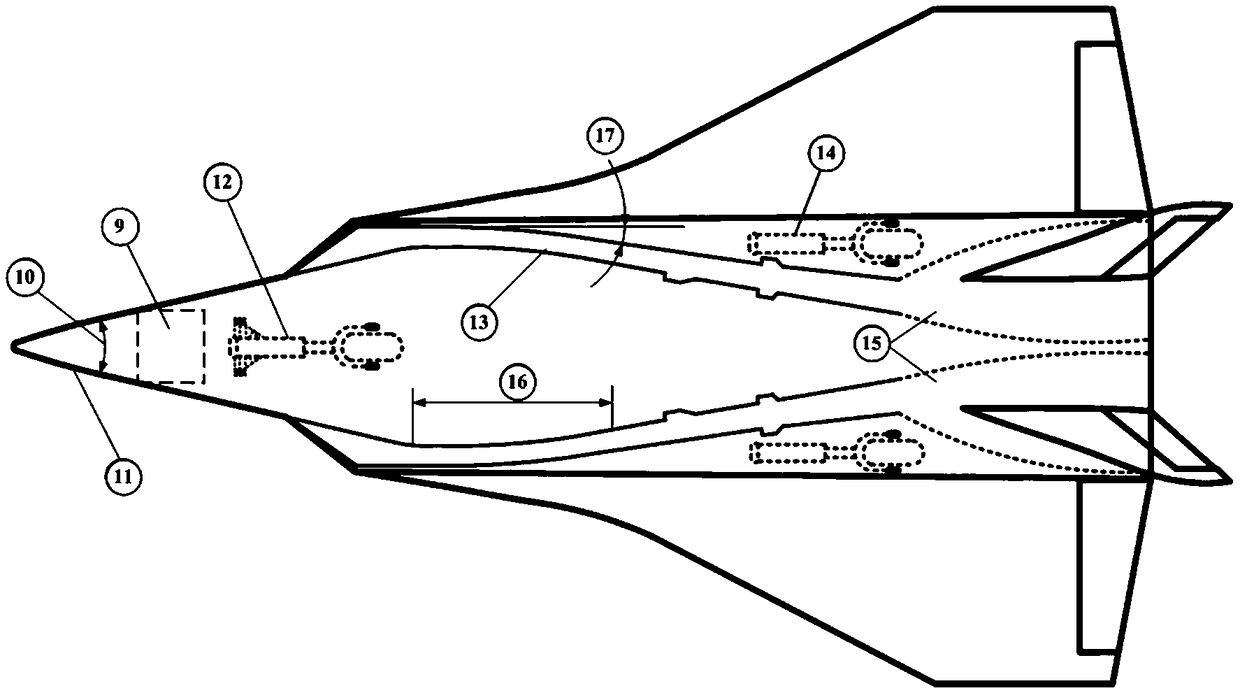

[0029] In a preferred embodiment, the overall length of the aircraft is 25000-30000mm. The two sides of the aircraft head profile are mainly used as the air inlet compression surfaces. According to the field of view of the radar 9 and the requirement of sufficient head loading space, the aircraft head, namely the front body 1, is designed as an axisymmetric cone.

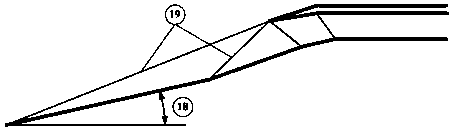

[0030] Install inlet ducts 2 on both sides of the precursor 1, the installation angle 20 is selected from 150° to 180°, and the inlet duct 2 adopts binary compression inlet ducts, according to the principle of "compression shock wave system 19 seals" The binary inlet profile design is carried out based on the oblique shock wave theoretical relation. The input conditions are: the capture area determined according to the overall performance index, the Mach number and the attack angle in the cruising...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Full length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com