Melamine hypophosphite modified lignin coated aluminum hypophosphite flame retardant as well as preparation method and application thereof in PA66 (polyamide 66)

A technology of melamine hypophosphite and aluminum hypophosphite coating is applied in the field of hypophosphorous acid modified lignin-coated aluminum hypophosphite flame retardant and its preparation, which can solve the problems of lowering tensile strength and mechanical properties, etc., so as to improve the surface The effect of good properties, compatibility and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

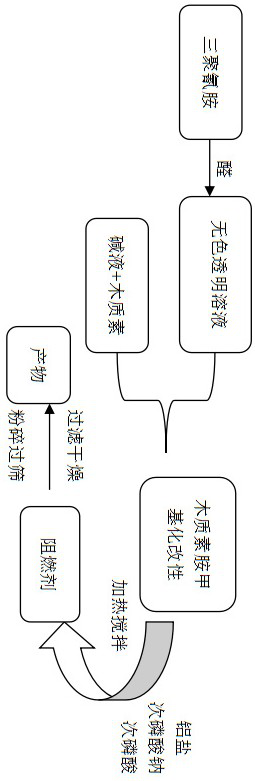

[0034] A preparation method of melamine hypophosphite modified lignin coated aluminum hypophosphite flame retardant comprises the following steps:

[0035] Wherein the structure of melamine hypophosphite modified lignin polymer is as follows:

[0036]

Embodiment 1

[0038]Weigh 0.2 g (0.005 mol) of sodium hydroxide in a beaker, add deionized water to make a sodium hydroxide solution with a concentration of 0.1 wt%, add 10 g of lignin into the sodium hydroxide solution, and make the lignin completely dissolved. Weigh 6.3 g (0.05 mol) of melamine and add it into deionized water to form a white turbid solution. Pour the white turbid solution into a three-necked flask equipped with a magnetic stirrer and a reflux condenser. Raise it to 70 °C, add 0.025 mol of formaldehyde after the temperature is stable, and slowly drop the lignin alkali solution into the three-necked flask with a separatory funnel, and continue the heat preservation reaction for 1 h. Weigh 8.8 g (0.1 mol) of sodium hypophosphite and 9.9 g (0.015 mol) of aluminum sulfate octadecahydrate, and prepare 100 ml of salt solution with deionized water. Use a separatory funnel to slowly drop the aluminum sulfate eighteen water solution into the three-necked flask, then drop the sodiu...

Embodiment 2

[0040] Weigh 0.56 g (0.01 mol) of potassium hydroxide into a beaker, add deionized water to make a potassium hydroxide solution with a concentration of 0.2 wt%, add 15 g of lignin into the potassium hydroxide solution, and make the lignin completely dissolved. Weigh 31.5 g (0.25 mol) of melamine and add it into deionized water to form a white turbid solution. Pour the white turbid solution into a three-necked flask equipped with a magnetic stirrer and a reflux condenser. Raise to 80 °C, add 0.1 mol of acetaldehyde after the temperature stabilizes, slowly drop lignin alkali solution into the three-necked flask with a separatory funnel, and continue to keep warm for 2 h. Weigh 13.2 g (0.15 mol) of sodium hypophosphite and 9.4 g (0.025 mol) of aluminum nitrate nonahydrate, and prepare 200 ml of salt solution with deionized water. Use a separating funnel to slowly drop the aluminum nitrate nonahydrate solution into the three-necked flask, then drop the sodium hypophosphite soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com