A kind of zinc oxide porous nanotube synergistic anti-ultraviolet and halogen-free flame-retardant polypropylene composite material and its preparation method

A technology of flame-retardant polypropylene and composite materials, which is applied in the field of ultraviolet-resistant halogen-free flame-retardant polypropylene composite materials and their preparation, and can solve problems such as easy migration and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

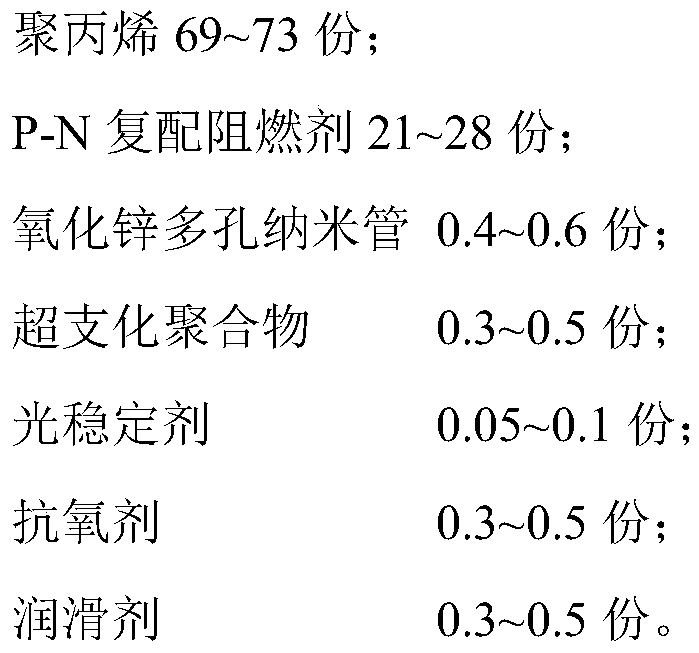

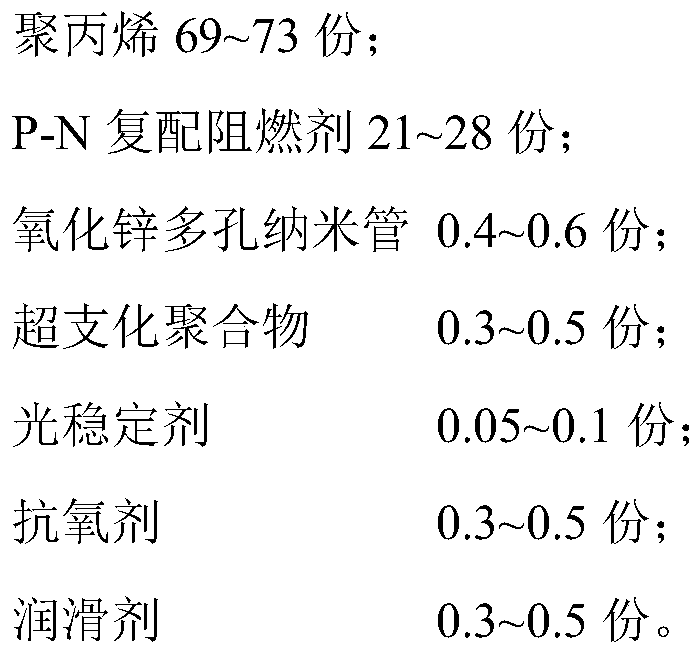

Method used

Image

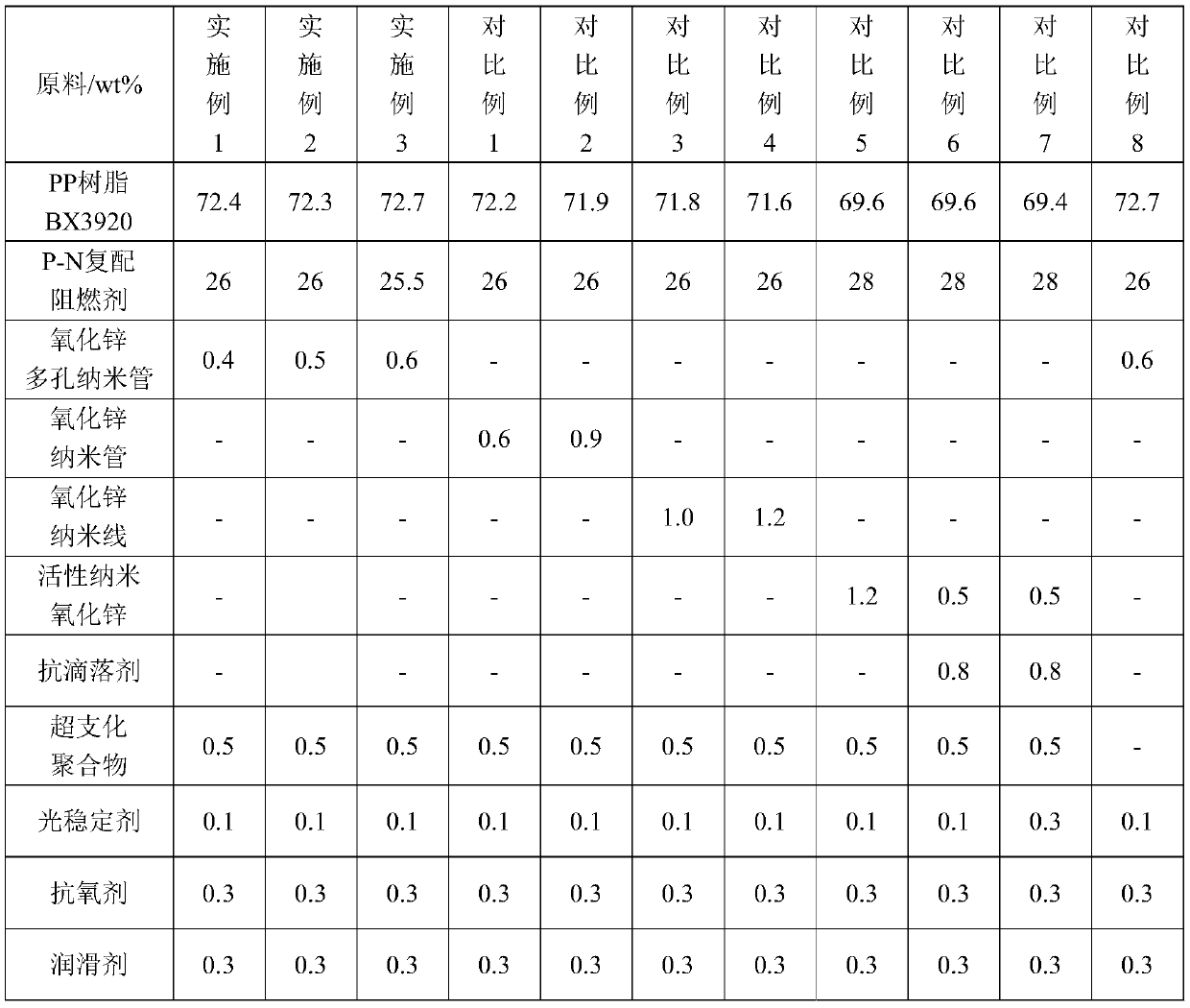

Examples

preparation example Construction

[0036] The preparation method of the zinc oxide porous nanotube synergistic anti-ultraviolet halogen-free flame-retardant polypropylene composite material comprises the following steps:

[0037] 1) take raw material by weighing above-mentioned composition;

[0038] 2) Mix polypropylene, zinc oxide porous nanotubes, hyperbranched polymers, light stabilizers, antioxidants and lubricants, and add the resulting mixture to the main feeding port of the twin-screw extruder, and P-N compound flame retardant The agent is added from the side feeding port of the twin-screw extruder, extruded, and granulated to obtain an ultraviolet-resistant halogen-free flame-retardant polypropylene composite material with synergistic effect of zinc oxide porous nanotubes.

[0039] Preferably, in the preparation method, the process parameters of the twin-screw extruder are as follows: aspect ratio (36-44): 1; processing temperature is 160°C-185°C; host speed is 200r / min-400r / min; vacuum degree ≥ 0.06 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com