A kind of halogen-free flame-retardant cross-linked polypropylene and its preparation method and application

A technology for cross-linking polypropylene and polypropylene, applied in the field of polymer materials, can solve the problems of low smoke performance improvement and other problems, achieve the effects of good fluidity, good flame retardant and heat resistance, and avoid uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

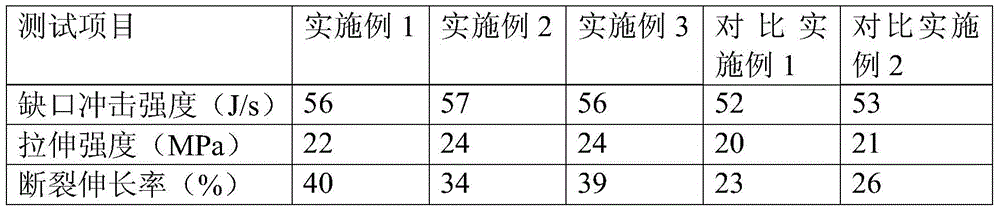

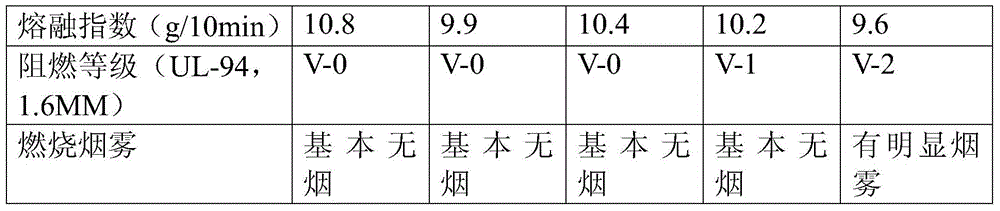

Examples

Embodiment 1

[0031] Take 50 parts by mass of homopolypropylene (melt flow rate is 17g / 10min), 25 parts of melamine, 0.5 part of crosslinking agent dicumyl peroxide, polymer nano-organic silicon grafted with potassium perfluorosulfonate (purchased from Dongguan Shenghua Plastic Technology Co., Ltd.) 0.2 parts, lubricant N, N-ethylene bisstearamide (EBS) 0.4 parts and antioxidant tetrakis[β-(3,5-di-tert-butyl 4 0.2 parts of -hydroxyphenyl)propionic acid]pentaerythritol ester were mixed evenly, then added to a twin-screw machine, melted and extruded, and granulated to obtain a halogen-free flame-retardant cross-linked polypropylene.

[0032] The conditions for the melt extrusion are: in the temperature control section of the twin-screw machine, the temperature in the first zone is 180-200°C, the temperature in the second zone is 190-210°C, the temperature in the third zone is 200-220°C, and the temperature in the fourth zone is 190°C. ~210°C, the head temperature of the twin-screw machine is ...

Embodiment 2

[0034] Take 37.5 parts by mass of homopolypropylene (melt flow rate is 16g / 10min), 25 parts of melamine, 0.1 part of crosslinking agent dicumyl peroxide, polymer nano-organic silicon grafted with potassium perfluorosulfonate (purchased from Dongguan Shenghua Plastic Technology Co., Ltd.) 0.03 parts, lubricant N, N-ethylene bisstearamide (EBS) 0.8 parts and antioxidant tetrakis[β-(3,5-di-tert-butyl 4 0.4 parts of -hydroxyphenyl) propionic acid] pentaerythritol ester were mixed uniformly, then added to a twin-screw machine, melted and extruded, and granulated to obtain a halogen-free flame-retardant cross-linked polypropylene.

[0035] The conditions for the melt extrusion are: in the temperature control section of the twin-screw machine, the temperature in the first zone is 180-200°C, the temperature in the second zone is 190-210°C, the temperature in the third zone is 200-220°C, and the temperature in the fourth zone is 190°C. ~210℃, the head temperature of the twin-screw mach...

Embodiment 3

[0037] Take 45 parts by mass of homopolypropylene (melt flow rate is 15g / 10min), 25 parts of melamine, 0.6 part of crosslinking agent dicumyl peroxide, polymer nano-organic silicon grafted with potassium perfluorosulfonate (purchased from Dongguan Shenghua Plastic Technology Co., Ltd.) 0.1 part, lubricant N, N-ethylene bisstearamide (EBS) 0.6 part and antioxidant tris(2,4-di-tert-butylphenyl) ) 0.3 parts of the ester were uniformly mixed, then added to a twin-screw machine, melted and extruded, and granulated to obtain a halogen-free flame-retardant cross-linked polypropylene.

[0038] The conditions for the melt extrusion are: in the temperature control section of the twin-screw machine, the temperature in the first zone is 180-200°C, the temperature in the second zone is 190-210°C, the temperature in the third zone is 200-220°C, and the temperature in the fourth zone is 190°C. ~210°C, the head temperature of the twin-screw machine is 210~230°C, the residence time is 3min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com