Flame-retardant antibacterial polypropylene material and preparation method thereof

An antibacterial polypropylene and polypropylene technology is applied in the field of flame retardant and antibacterial polypropylene materials and their preparation, which can solve the problems of high price and easy discoloration, and achieve the effects of reduced production cost, excellent product performance and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

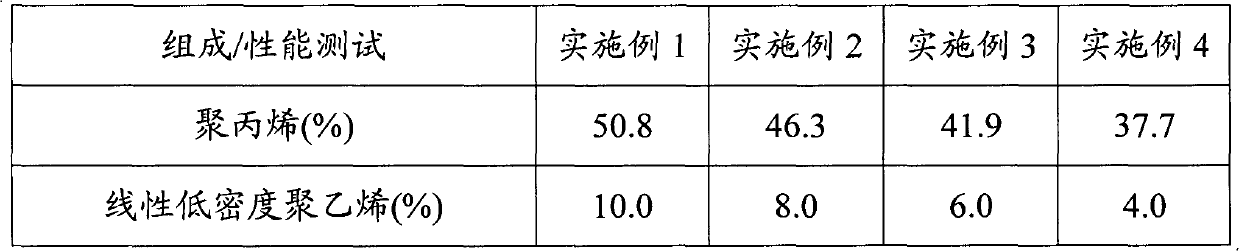

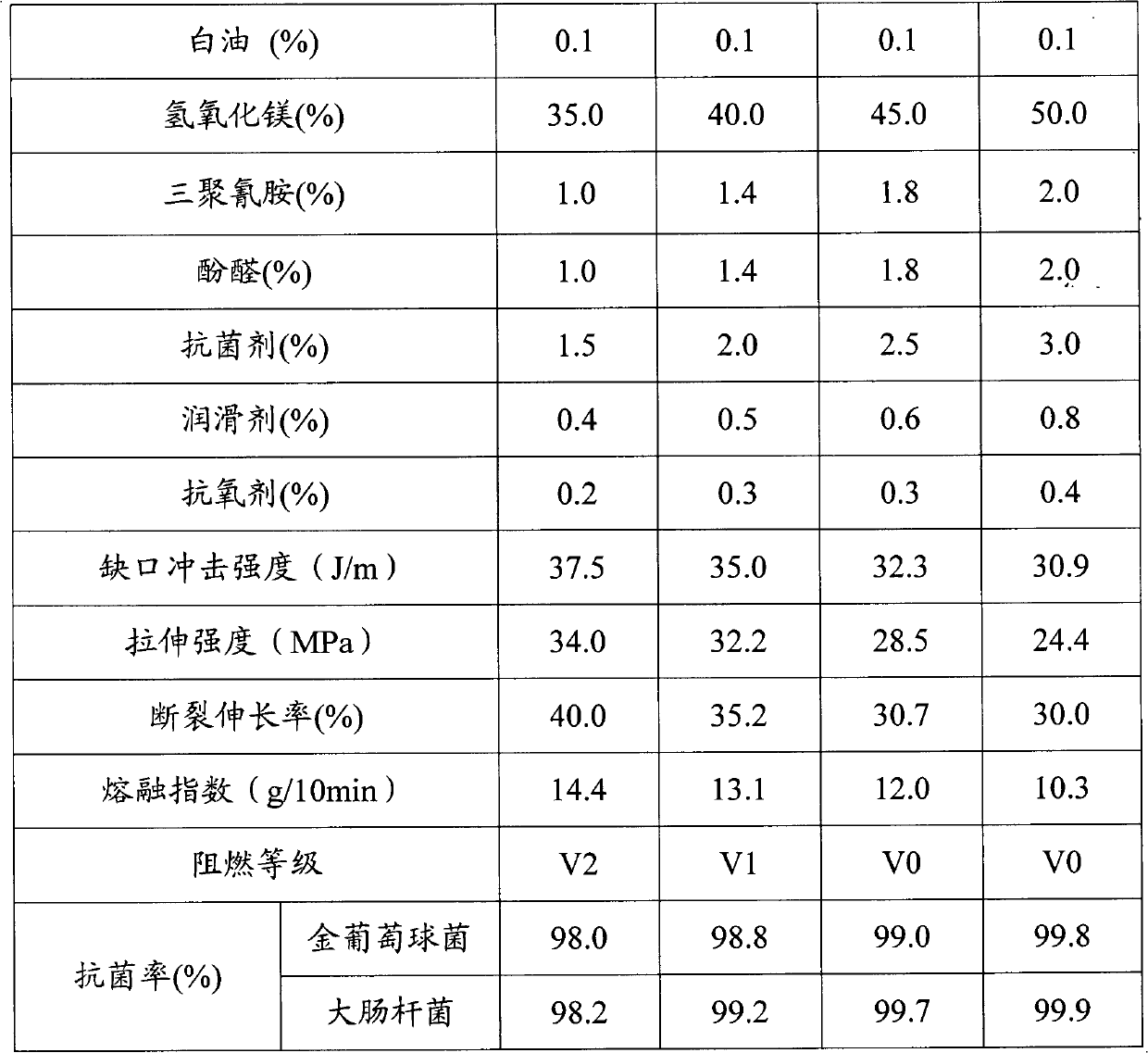

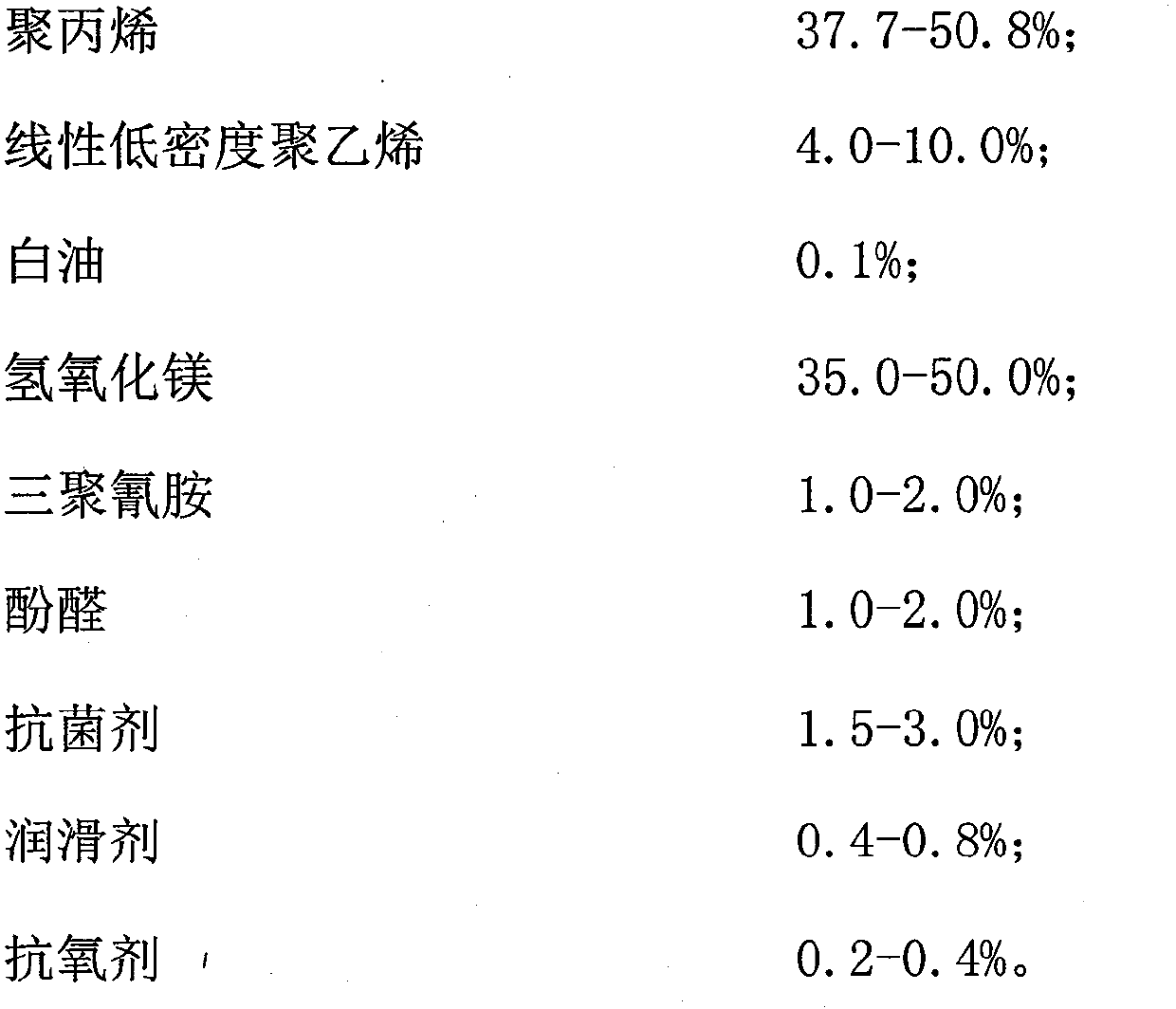

Embodiment 1

[0055] Mixing by weight, polypropylene 50.8%; linear low density polyethylene 10.0%; white oil 0.1%; magnesium hydroxide 35.0%; melamine 1.0%; phenolic 1.0%; antibacterial agent 1.5%; lubricant 0.4%; Oxygen 0.2%. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: in the temperature control section of the twin-screw machine, the temperature of the first zone is 210°C; the temperature of the second zone is 230°C; the temperature of the third zone is 240°C; the temperature of the fourth zone is 220°C; The head temperature of the screw machine is 240°C; the residence time is 3 to 4 minutes. The pressure is 15MPa.

Embodiment 2

[0057] Mixing by weight, polypropylene 46.3%; linear low density polyethylene 8.0%; white oil 0.1%; magnesium hydroxide 40.0%; melamine 1.4%; phenolic 1.4%; Oxygen 0.3%. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: in the temperature control section of the twin-screw machine, the temperature of the first zone is 210°C; the temperature of the second zone is 240°C; the temperature of the third zone is 240°C; the temperature of the fourth zone is 230°C; The head temperature of the screw machine is 240°C; the residence time is 3 to 4 minutes. The pressure is 15MPa.

Embodiment 3

[0059] Mixing by weight, polypropylene 41.9%; linear low density polyethylene 6.0%; white oil 0.1%; magnesium hydroxide 45.0%; melamine 1.8%; phenolic 1.8%; Oxygen 0.3%. . The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are as follows: in the temperature control section of the twin-screw machine, the temperature of the first zone is 200°C; the temperature of the second zone is 250°C; the temperature of the third zone is 250°C; the temperature of the fourth zone is 220°C; The head temperature of the screw machine is 230°C; the residence time is 3 to 4 minutes. The pressure is 15MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com