Patents

Literature

47results about How to "Increased strength and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC (polyvinyl chloride) plastic floor

InactiveCN105038033AIncreased strength and wear resistanceImprove thermal stabilitySynthetic resin layered productsSilicon nitrideFormaldehyde free

The invention discloses a PVC (polyvinyl chloride) plastic floor. The PVC plastic floor is formed by a double-layer structure, wherein a surface layer is formed by auxiliary materials; a bottom layer is formed by main materials. The PVC plastic floor has the beneficial effects that as silicon nitride nanopowder is added to the materials of the floor, the wear resistance and strength of the floor are greatly enhanced, the heat stability is high, the oxidation resistance is strong, the floor is not easy to deform or crack, and the fire resistance of the floor is also enhanced; the floor has better infrared health care functions, clear and natural patterns, elegant appearance and natural marble grains and is elastic, so that people feel very comfortable when walking on the floor; the floor can be widely applied to the places, such as hospitals, schools, office buildings, shopping malls, traffics, industrial places, homes and gyms, is not suitable for using adhesives, is formaldehyde-free, avoids fungi, does not contain heavy metals and can be recycled.

Owner:ANHUI YOSEMITE PLASTIC TECH CO LTD

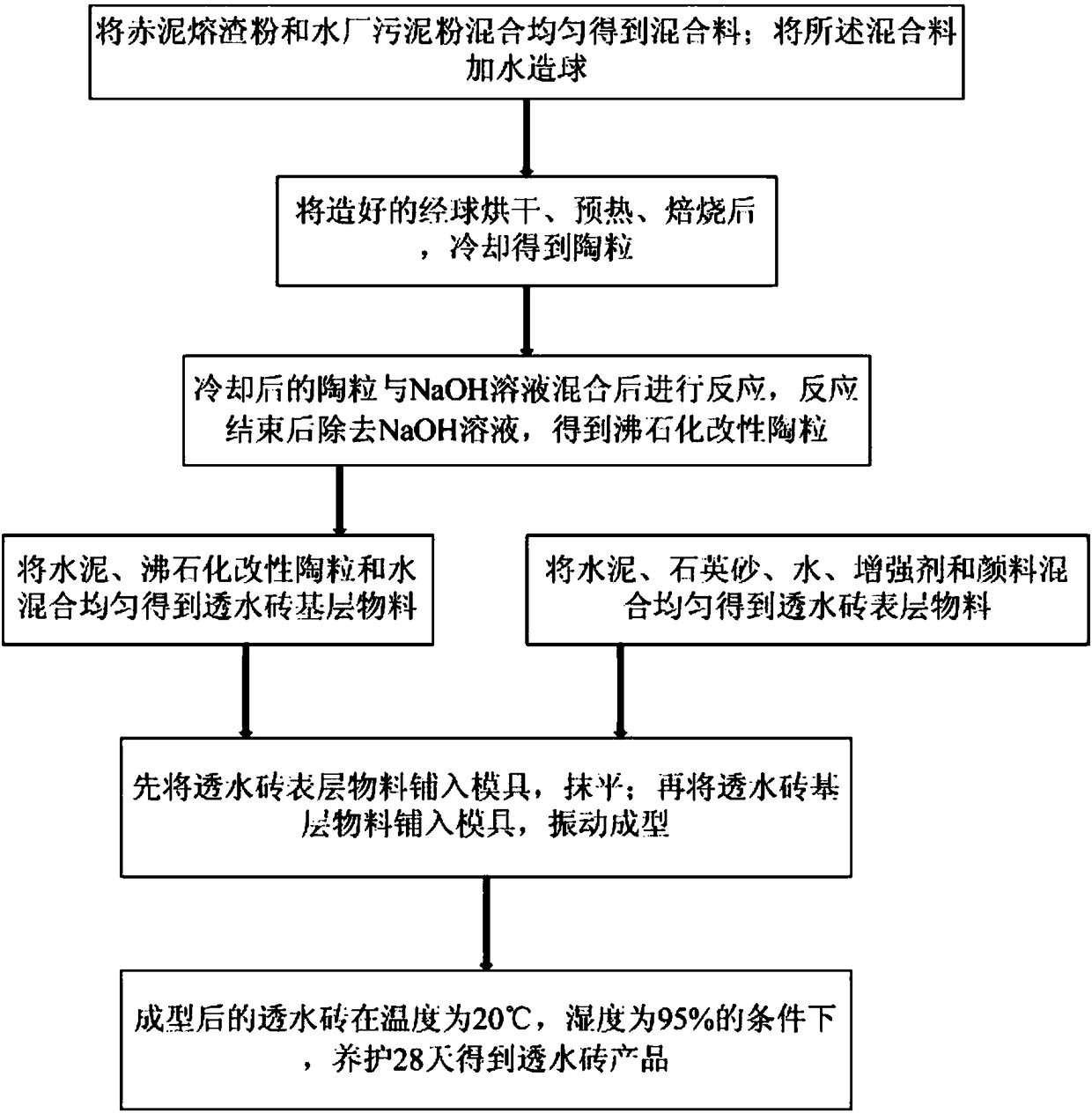

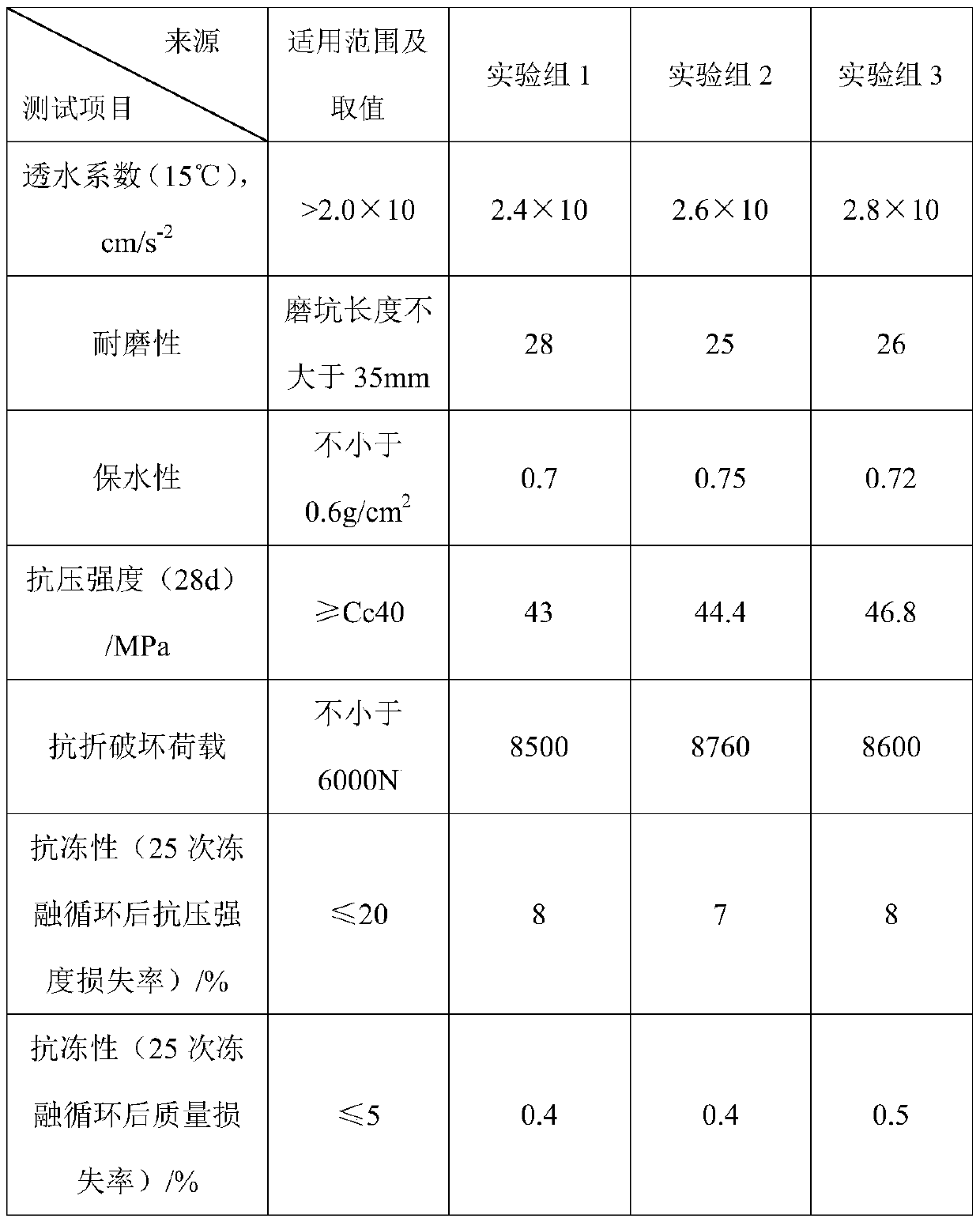

Water permeable brick purifying rainwater and preparation method of water permeable brick

PendingCN108117322AIncreased strength and wear resistancePrevent water permeability dropCeramic materials productionCeramicwareHeavy metalsStormwater

The invention relates to a water permeable brick purifying rainwater. The water permeable brick is divided into an upper layer and a lower layer, wherein the upper layer is a surface layer; the lowerlayer is a base layer; and a thickness ratio of the surface layer to the base layer is 1:(5-6). The invention further relates to a method of preparing the water permeable brick purifying the rainwater. Ceramsite in the base layer of the water permeable brick can absorb suspended matter and organic matter (VOCs (volatile organic compounds)); the reduction of a water permeable rate of the water permeable brick due to gap obstruction after long-term usage is avoided; the ceramsite after zeolitization modification can absorb a small quantity of heavy metals in the rainwater; and pollution of ground water is avoided.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Preparation method of graphene-polyurethane elastomer

InactiveCN107573676AIncreased strength and wear resistanceSimple and efficient operationCvd grapheneCorrosion

The invention relates to a preparation method of a graphene-polyurethane elastomer. The preparation method comprises the following steps: preparing graphene powder; mixing three raw materials, namelypolyester polyol, isocyanate and butanediol, thus obtaining a mixture A; uniformly mixing a catalyst, an antioxidant, a lubricant, an ultraviolet absorbent and a hydrolysis resistance agent, thus obtaining a mixture B; mixing the mixture A with the mixture B, solidifying the final mixture to be a sheet bar, granulating the sheet bar, and carrying out co-blending reaction on the graphene powder anda coupling agent, thus obtaining graphene-polyurethane elastomer. According to the preparation method, the coupling agent reacts with polyurethane and a graphene surface active group respectively; graphene is coped into a polyurethane elastomer; as the graphene has properties of superlight weight, high intensity, high corrosion resistance and the like, the intensity and the corrosion resistance of a graphene-polyurethane elastomer material are improved.

Owner:六安永吉纳米材料科技有限公司

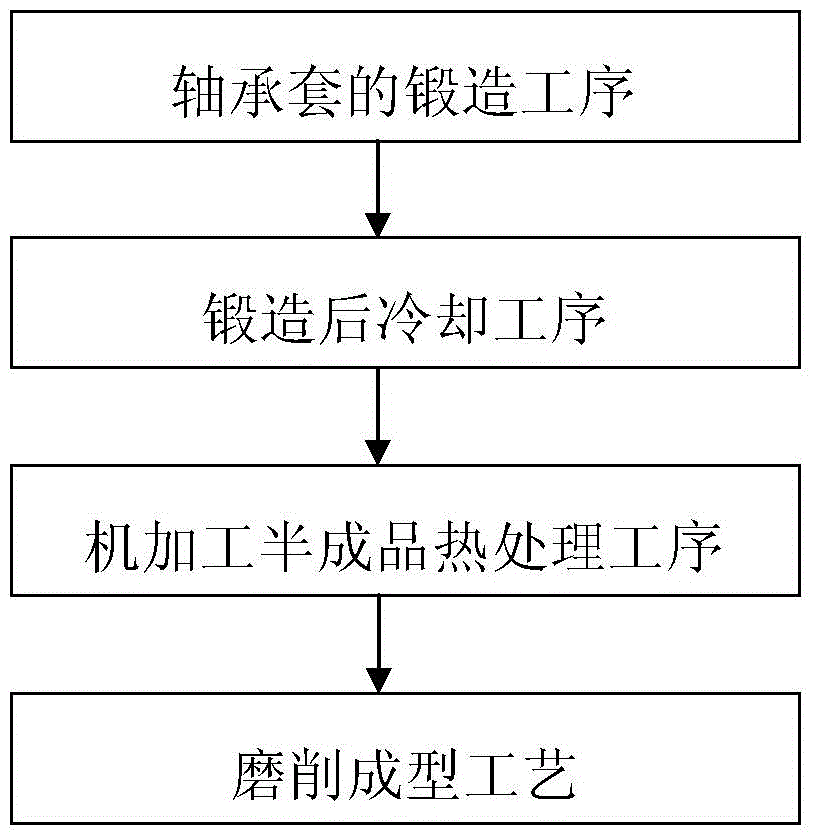

Machining technology of mud pump shaft bearing sleeve

ActiveCN104942192AIncreased strength and wear resistanceExtended service lifeFurnace typesHeat treatment furnacesQuenchingAsbestos

This invention provides a machining technology of a mud pump shaft bearing sleeve. The machining technology is mainly composed of a forging procedure of the bearing sleeve, the cooling procedure performed after forging and the thermal treatment procedure of a machined semi-finished product. The procedures include the following steps that the initial forging temperature of 4Cr13 used for manufacturing the bearing sleeve is controlled between 1100-1150 DEG C, the final forging temperature is controlled at 880 DEG C, the charging temperature of blanks is lower than 400 DEG C, heating is slow before the temperature reaches 850 DEG C, and then, the temperature is fast raised to the initial forging temperature; a bearing sleeve casting is placed in a furnace with the temperature being 200 DEG C or so or in an asbestos heat-preserving box to be cooled, or the bearing sleeve casting is placed in a furnace with the temperature being 600 DEG C so that the heat can be preserved and the bearing sleeve casting is cooled along with the furnace; the bearing sleeve casting is placed in a quenching furnace and heated to 1000-1050 DEG C, when the pre-heating temperature reaches 400 DEG C, the temperature is slowly raised to 850 DEG C, then, the temperature is fast raised to quenching temperature, a semi-finished bearing sleeve is placed into a tempering furnace to be heated after quenching ends, and the tempering temperature is controlled between 200-250 DEG C. The bearing sleeve manufactured through the machining technology is high in strength and abrasion resistance, and the service life of the bearing sleeve is prolonged.

Owner:CCCC TDC ENVIRONMENTAL PROTECTION DREDGING

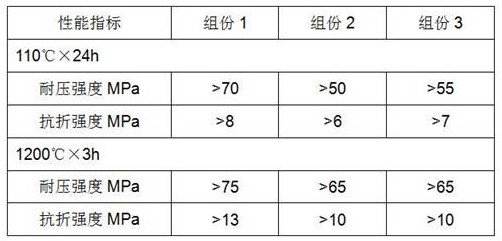

Cordierite-containing composite refractory material for working linings of coke dry quenching tank and bin body

PendingCN111978077AIncreased strength and wear resistanceHigh strengthCoke quenchingSilicon nitrideCement Material

The invention discloses a cordierite-containing composite refractory material for working linings of a coke dry quenching tank and a bin body. The refractory material is prepared from the following raw materials in parts by weight: 20-45 parts of 1-3mm fused mullite, 10-45 parts of 3-5 mm fused mullite, 10-20 parts of 0-1mm cordierite, 15-40 parts of 1-3 mm cordierite, 5-20 parts of 200-mesh corundum fine powder, 3-8 parts of silicon nitride fine powder, 4-15 parts of calcium aluminate cement, 2-6 parts of silica powder, 1-7 parts of aluminum oxide micro powder and 0.5-2 parts of asbestos fiber, wherein the adding amount of a composite additive accounts for 0.1-10% of the total weight of the raw materials. The refractory material has good coating performance, is used for positions with construction difficulty, narrow space and irregular working surface, solves the problem of short service life of a whole coke tank caused by severe deformation, cracks and abrasion of a heat-resistant steel lining plate, prolongs the service life of the tank body, improves the operation rate of the tank body, saves energy and reduces consumption.

Owner:HENAN HAOYUNXIANG REFRACTORY MATERIAL CO LTD

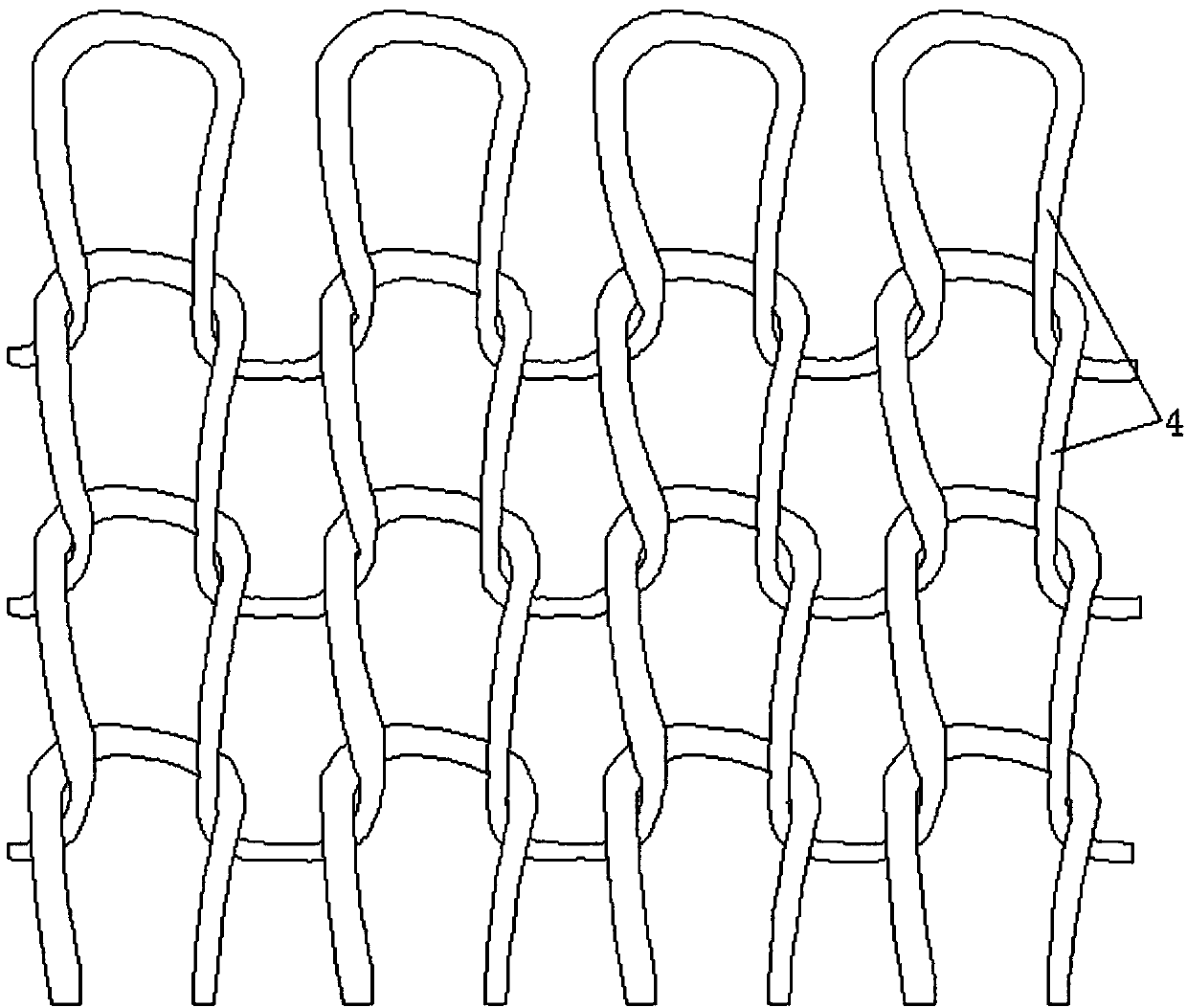

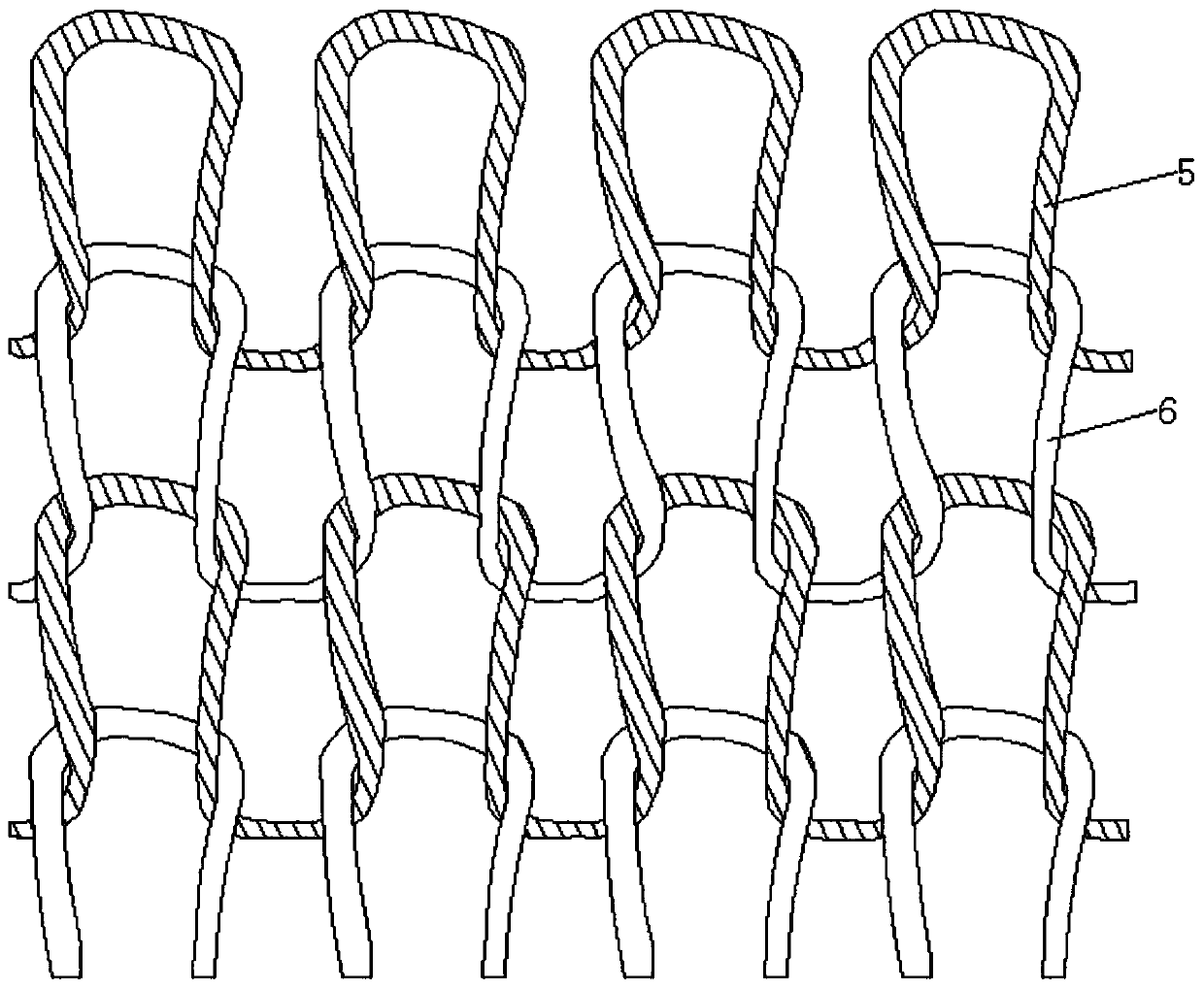

Method for producing slurry-free self-sizing fabric containing low-melting fiber yarn

InactiveCN108893833ALow costIncreased strength and wear resistanceWoven fabricsYarnThermal bondingYarn

Provided is a method for producing slurry-free self-sizing fabric containing low-melting fiber yarn. The method for producing the slurry-free self-sizing fabric containing low-melting fiber yarn is characterized in that the method includes the following steps of opening and cleaning cotton, carding, drawing, roving, spinning, winding, warping, yarn thermal bonding and weaving; for opening and cleaning the cotton, main fibers and low melting point fibers conduct disc mixing to be made into cotton rolls; for carding, the rolls with the main fibers and the low melting point fibers mixed well arecombed, the fibers are separated into a single state to form silver blended with the main fibers and the low melting point fibers; for drawing, the blended sliver is blended through a drawing machinewith low melting point fiber mass percentage to be 5-35% and the main fiber mass percentage 65-95% to prepare mixed drawn sliver. With a certain proportion of the low melting point fibers added to thefibers during spinning, yarn containing the low melting point fibers heated during subsequent processing, and low melting point fibers melted as an adhesive for the yarn, the method for producing theslurry-free self-sizing fabric containing the low-melting fiber yarn has the advantages of improving the strength and wear resistance of the yarn and attaching hairiness, and improving yarn weavability with no use of slurry.

Owner:SHIJIAZHUANG CHANGSHAN BEIMING TECH CO LTD

High-reliability cement

InactiveCN104478401AReduce manufacturing costIncreased strength and wear resistanceSolid waste managementMagnesium chloride hexahydrateOxide

The invention discloses high-reliability cement. The cement is prepared from raw materials in percentage by weight as follows: 53%-60% of active magnesium oxide, 10%-12% of magnesium chloride hexahydrate, 18%-20% of glass powder and 12%-15% of low-temperature rice hull ash. The high-reliability cement has low production cost, is environment-friendly and energy-saving and has higher strength and wear resistance, excellent water resistance and fire resistance and wide market application prospect.

Owner:江苏一箭建设工程有限公司常熟分公司

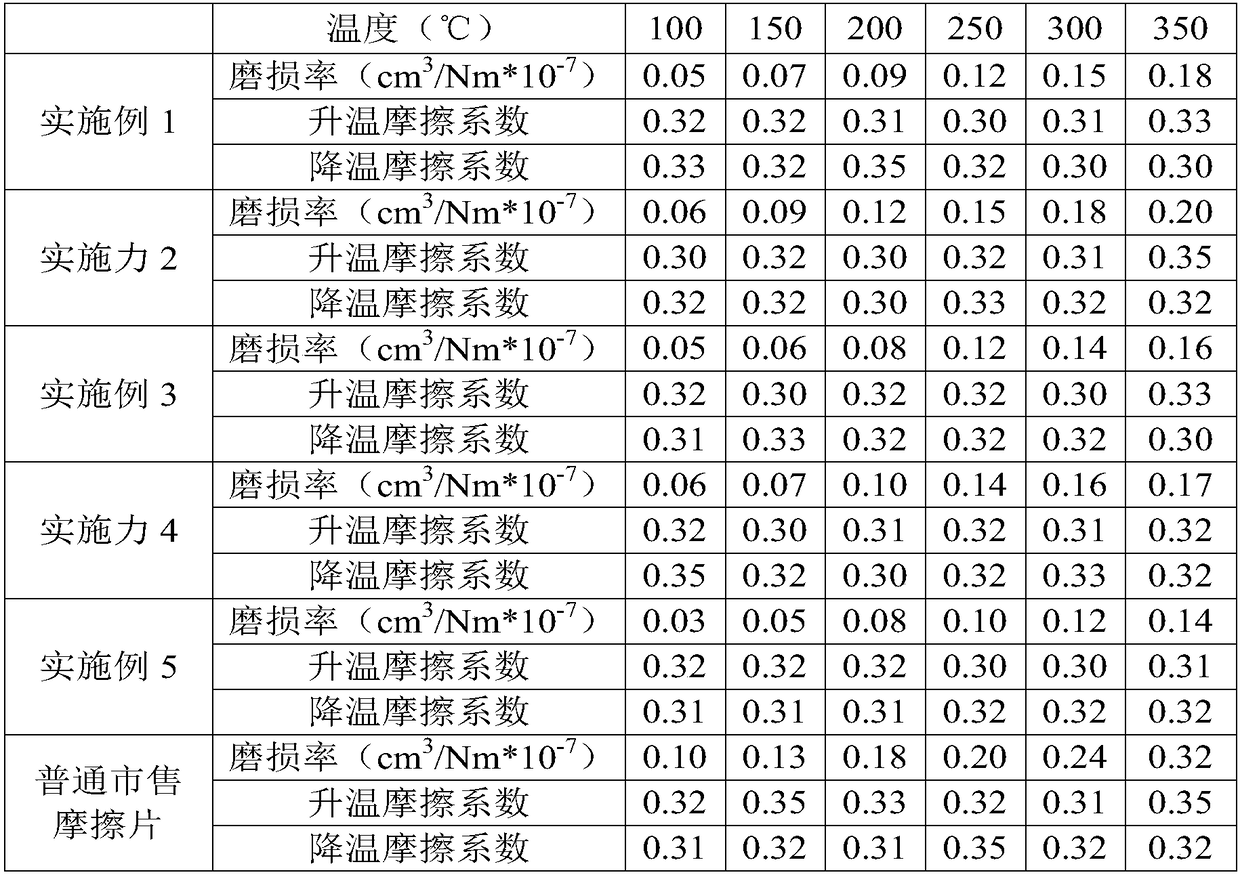

Friction material and preparation method thereof

ActiveCN108468736AIncreased strength and wear resistanceEnhance internal bondingOther chemical processesFriction liningNoise pollutionHydroquinone Compound

The invention belongs to the technical field of friction materials, and particularly relates to a friction material and a preparation method thereof. The friction material is composed of synthetic fibers, magnesium oxide, aluminum oxide, barium sulfate, boron oxide, sodium bicarbonate, tert-butyl hydroquinone, ethanol and a structure enhancer. The raw materials of the friction material are matchedwith each other to prepare the friction material, the defects that the friction material has strength difference, is easy to oxidize and poor in wear resistance are improved, and the problems that the manufacturing process is complex, the consumed time is long, and the production cost is high are solved, the friction material has a special elastic effect, the performance problem of a traditionalfriction material can be changed, the wear resistance of the friction material is improved, the friction material is light in texture, environment-friendly and anti-oxidation, high pressure resistanceand material selection are achieved, and noise pollution caused by friction is effectively avoided.

Owner:HANGZHOU POLYTECHNIC

Aramid pulp-modified highly-sealed PVC-NBR composite foaming plate and preparation method thereof

InactiveCN106188972AIncreased strength and wear resistanceImprove sealingHydroxy fatty acidMaterials science

The invention discloses an aramid pulp-modified highly-sealed PVC-NBR composite foaming plate and a preparation method thereof. According to the composite foaming plate, a PVC-NBR blended material is taken as a composite plate base material, aramid pulp is added to serve as a reinforced modifying material, effectively improves the strength and the wear resistance of the composite plate and improves the leakproofness of the composite material together with polyhydroxyalkanoate, the very good barrier property on water vapor is achieved, and under cooperation of other materials, the finally-prepared composite foaming plate is uniform in foaming, high in strength, firm and wearproof in surface, good in flame retardance, closed, waterproof, environmentally friendly and nontoxic and has the outstanding application advantages on home decoration materials.

Owner:CHUZHOU HONGYUAN SPRAYING

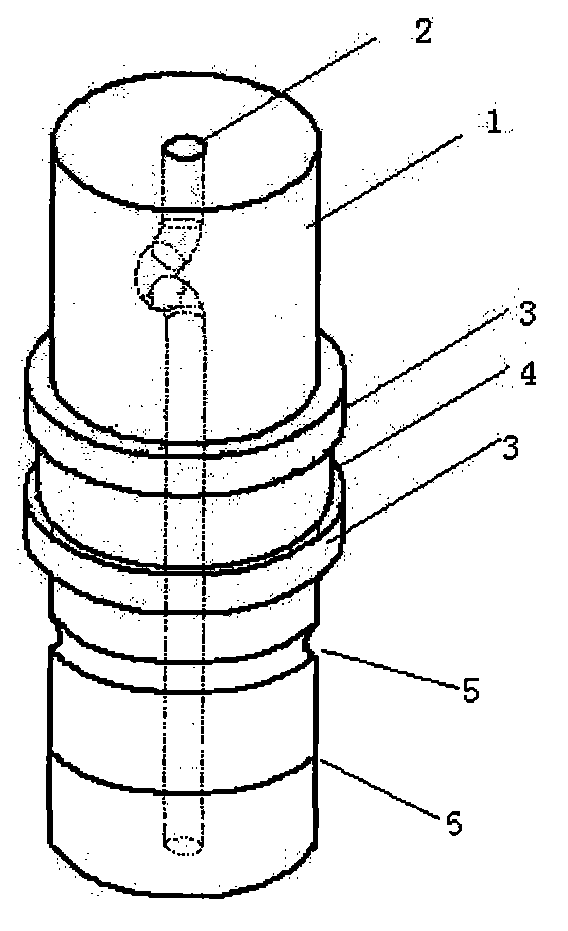

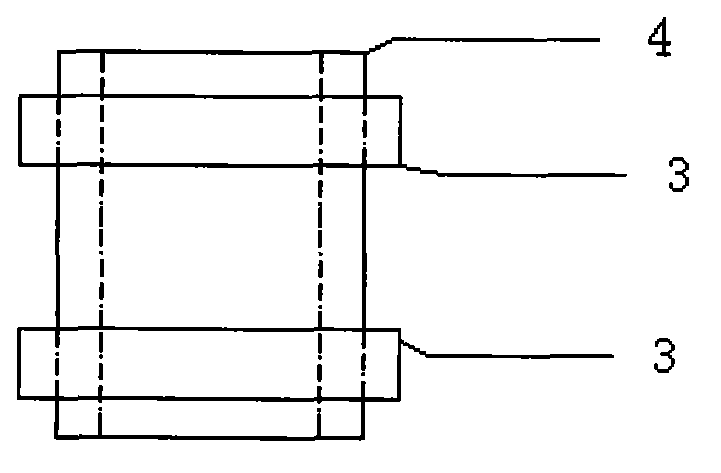

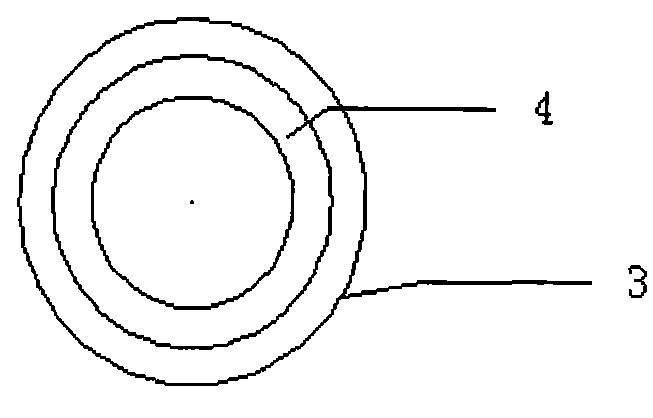

Bearing system

InactiveCN1779280AIncreased strength and wear resistanceAvoid contact frictionPump componentsBearing componentsEngineeringPolymer

A bearing system comprises bearing sleeve, bearing core and lubricant layer between them. To the outer surface of the bearing core or the inner surface of the bearing sleeve is coated with nanometer coating. The lubricant layer in between is a polymer material of dual functional of hydrophilic and hydrophoby, which reduces friction and prolong life time.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Steel for excavator slewing bearing and production process thereof

InactiveCN105886939AIncreased strength and wear resistanceImprove hardenabilityManufacturing convertersSlewing bearingSmelting

The invention discloses steel for an excavator slewing bearing and a production process thereof, and belongs to the technical field of slewing bearing materials. The steel is prepared from, by mass, 0.48-0.54% of C, 0.17-0.32% of Si, 0.70-0.85% of Mn, 0.04-0.18% of Cr, 0.20-0.24% of Mo, 0.022% or below of P, 0.022% or below of S, 0.30% or below of Ni, 0.018% or below of Cu, 0.10% of below of V and the balance Fe. The production process comprises converter smelting, LF refining, vacuum degassing (VD), continuous casting and steel billet examination and storage. The production process has the advantage that the strength and wear resistance of the steel for the slewing bearing can be effectively improved.

Owner:许炳初

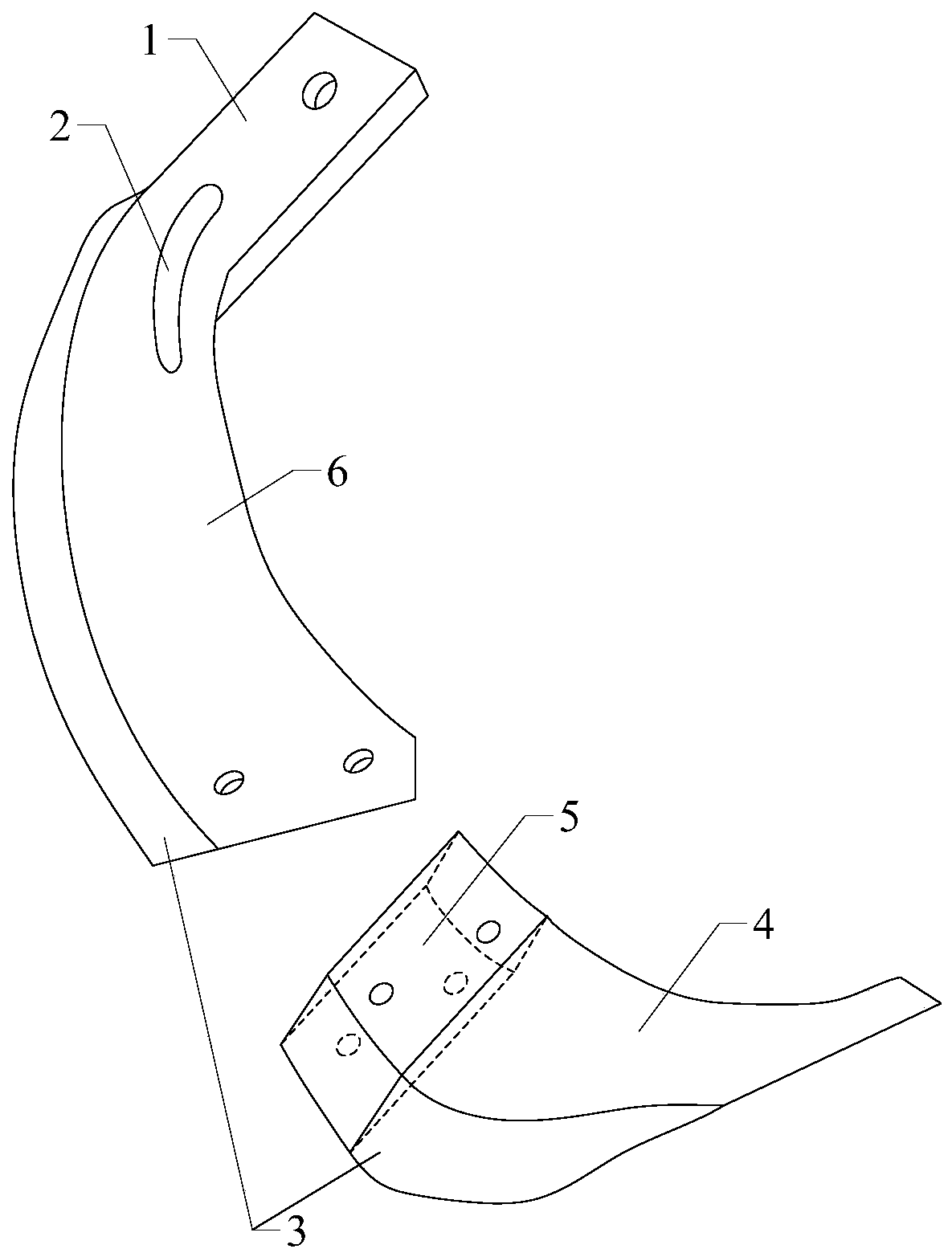

High-strength wear-resistant rotary cutter and production technology thereof

PendingCN109997429AImprove the efficiency of arable landIncreased strength and wear resistanceTilling equipmentsFurnace typesWear resistantEngineering

The invention discloses a high-strength wear-resistant rotary cutter which comprises a main cutter body and a cutter body formed by a cutter handle fixedly connected to one end of the main cutter body. The main cutter body and the cutter handle are on the same plane; the high-strength wear-resistant cutter further comprises an auxiliary cutter body, one end of the auxiliary cutter body is pluggedwith the other end of the main cutter body through a plugging sleeve, bolts penetrate the plugging sleeve to be connected with the main cutter body in a positioned manner, and the other end of the auxiliary cutter body is raised at the angle of 120-160 degrees along the side part of the main cutter body. By the above structure, the auxiliary cutter body can be directly installed at one end of themain cutter body in second ploughing, and ploughing efficiency is improved; through the adoption of an alloy layer and a strengthening rib, wear resistance and strength of a blade are increased, and the service life of the blade is prolonged.

Owner:廊坊津锡农业机械股份有限公司

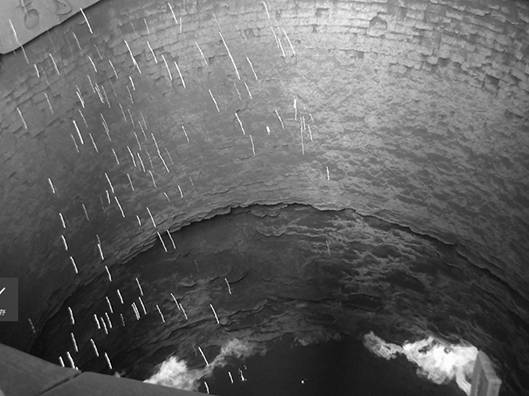

Remote-control thermal-state wet-process injection lining making method

PendingCN113604619AIncreased strength and wear resistanceStrong wear resistanceBlast furnace componentsBlast furnace detailsHot blastChemistry

The invention relates to a repairing and maintaining method for a blast furnace lining, in particular to a remote-control thermal-state wet-process injection lining making method. The remote-control thermal-state wet-process injection lining making method comprises the following steps that S1, equipment enters a site, specifically, a spraying manipulator is mounted in a blast furnace and is connected with an injection workstation outside the blast furnace in a matched manner; S2, banking fire is performed, specifically, the internal environment of the blast furnace is adjusted; S3, cleaning is performed, specifically, washing is performed on to-be-repaired positions of the inner wall of the blast furnace for multiple times so as to perform spraying, repairing and lining making; S4, injection is performed, specifically, the spraying manipulator is controlled to perform spraying repairing on the inner wall of the blast furnace; S5, the furnace is dried, specifically, hot air is supplied into the furnace to bake the interior of the blast furnace; and S6, the furnace is opened, specifically, the furnace is opened for normal production after the interior of the furnace reaches a specified state. By means of the remote-control thermal-state wet-process injection lining making method, the hot repair efficiency of the blast furnace can be rapidly improved and the service life of the blast furnace can be prolonged to the maximum extent during the damping-down time of the blast furnace, particularly gunning in a hot state.

Owner:HENAN HUAXI FURNACE REFRACTORY

Die alloy

InactiveCN104911450AThe ratio of ingredients is scientific and reasonableIncreased strength and wear resistanceTungstenZinc

The invention relates to a die alloy, which comprises the following components by weight part: 2-5 parts of copper, 10-15 parts of iron, 12-18 parts of zinc, 6-10 parts of tungsten, 12-15 parts of silicon, 8-10 parts of calcium, 2-3 parts of niobium. The die alloy has the advantages that the composition proportion is scientific and reasonable, wear resistance and intensity are high, service life is greatly prolonged, manufacture cost is reduced, and enterprise requirement can be satisfied.

Owner:ZXSY KUNSHAN METAL TECH

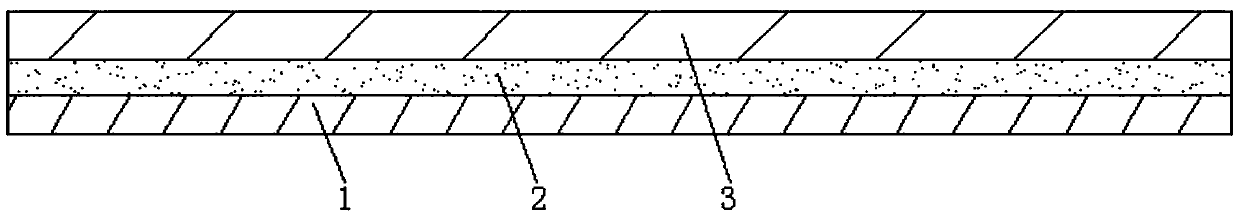

Knitted fabric

InactiveCN109648978AGood elasticityIncreased strength and wear resistanceSynthetic resin layered productsClothingsCoil structureBamboo charcoal

The invention discloses a knitted fabric, which comprises an inner layer, an intermediate layer and an outer layer which are successively arranged from the inside to the outside. The inner layer has atwo-coil structure interwoven by spandex core-spun yarns; the intermediate layer has a two-coil structure interwoven by flame-retardant terylene and conductive fiber; the outer layer has a two-coil structure interwoven by chinlon and bamboo charcoal fiber; and the chinlon is composed of a monofilament which is a cruciform structure having a through-hole at the center. Garment made of the knittedfabric has good elasticity and high wear resistance and strength, is comfortable to wear, and has flame-retardant and antistatic, antibacterial and antibacterial and anti-ultraviolet characteristics.

Owner:绍兴柯桥名瑶纺织品有限公司

Low-temperature sintering method for enhancing strength of ceramic green body

InactiveCN110342944AIncreased strength and wear resistanceLower sintering temperatureCeramic shaping apparatusMicrowaveMoisture

The invention mainly relates to the technical field of ceramic processing, and discloses a low-temperature sintering method for enhancing the strength of a ceramic green body. The low-temperature sintering method comprises the steps of primary drying, spraying, secondary drying, primary sintering, secondary sintering and post-treatment; according to the low-temperature sintering method for enhancing the strength of the ceramic green body, a sintering temperature is low, the strength and wear resistance of the ceramic green body can be significantly improved, the surface is smooth, the practicability of ceramic is improved, and the service life of the ceramic is prolonged; firstly, a ceramic green is subjected to intermittent microwave drying, part of moisture in the green is uniformly andslowly removed, gas and voids in the ceramic green are reduced to enable particles in the green to be closer, and the sintering temperature of the green is reduced; and a surface care agent is uniformly sprayed on the surface of the green twice continuously after primary drying, the surface care agent is prepared from a variety of nano materials, and can form a uniform protective layer on the surface of the green, so that cracks of the green in the subsequent processing process are avoided, and the strength and wear resistance of the ceramic are improved.

Owner:阜阳创启工艺品有限公司

Functional fabric for outdoor backpacks and manufacturing process of functional fabric for outdoor backpacks

InactiveCN107130439AExcellent wear resistanceIncreased strength and wear resistanceWoven fabricsYarnDyeingPolytetrafluoroethylene

The invention belongs to the field of outdoor backpacks and manufacturing processes thereof and discloses a functional fabric for the outdoor backpacks and a manufacturing process of the functional fabric for the outdoor backpacks. The functional fabric is prepared from, by weight, 50-80 parts of basic fibers, 110-200 parts of fireproof fibers, 100-180 parts of wear-proof fibers and 90-155 parts of PTFE (polytetrafluoroethylene) microparticles. The manufacturing process includes steps of raw material preparation, yarn spinning, dyeing, weaving, impregnating, drying, sintering and the like. Since the provided fabric raw materials include the fireproof fibers, the wear-proof fibers and the PTFE microparticles, the wear-proof fibers can make up shortcomings of the fireproof fibers, and strength and wear resistance of the fabric are greatly improved on the basis of normal fabrics; by adoption of the appropriate process for manufacturing the fabric, evident effective fireproof, wear-proof and waterproof performances of the fabric are achieved, the adoption rate of the fabric applied to the outdoor backpacks is further increased, the use value of the outdoor backpacks made of the fabric is increased, and market competitiveness is improved.

Owner:骆驼(福建)户外用品有限公司

Calcium carbonate filler capable of improving stability of plastic product and preparing method thereof

InactiveCN105860135AIncreased strength and wear resistanceImprove compatibilityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSodium polyacrylateOxide

The invention discloses a calcium carbonate filler for improving the stability of plastic products and a preparation method thereof. The calcium carbonate filler consists of 0.2 parts of sodium bicarbonate, 0.8 parts of stannous chloride, 1.4 parts of sodium polyacrylate and 4 parts of nano iron slag , 0.9 parts of isopropyl palmitate, 0.9 parts of pregelatinized starch, 1.1 parts of magnesium stearate, 0.9 parts of cerium dioxide, 230 parts of heavy calcium carbonate, 8 parts of auxiliary agents, and 30 parts of water; its preparation method Yes: add sodium bicarbonate, stannous chloride, sodium polyacrylate, and cerium oxide into water, and stir to obtain a slurry; blow hot air to heavy calcium carbonate to make it tumbling, and then spray mist into the tumbling powder After fully mixing, keep the temperature at 70-80°C, continue to tumbling for 30-40 minutes, then dry, add to the high-speed kneader, add other remaining ingredients, then raise the temperature to 110-120°C, keep warm and knead for 15- After 20 minutes, grind it into 5-40μm particles.

Owner:李文东

Color-changing baking-free water-permeable brick by using solid waste and preparation method

ActiveCN110156424AIncreased strength and wear resistanceGuaranteed water permeabilityScrapConstruction aggregate

The invention discloses a color-changing baking-free water-permeable brick by using a solid waste and a preparation method, solves the problem of the large energy consumption of the water-permeable brick product in the prior art, and has the beneficial effects that the existing solid waste can be fully utilized, the energy is saved, and the social environment is protected. The scheme is as follows: the color-changing baking-free water-permeable brick by using the solid waste comprises a surface layer and a base layer, wherein the surface layer and the base layer are combined together, the surface layer comprises a ceramic waste, a water glass solution, color-changing glass particles and water, the base layer comprises a red mud, a ferrous aluminate cement, an aggregate, a water reducing agent and an early strength agent, and the ceramic waste, the color-changing glass particles, the red mud, the ferrous aluminate cement and the aggregate are all derived from the solid waste.

Owner:SHANDONG UNIV

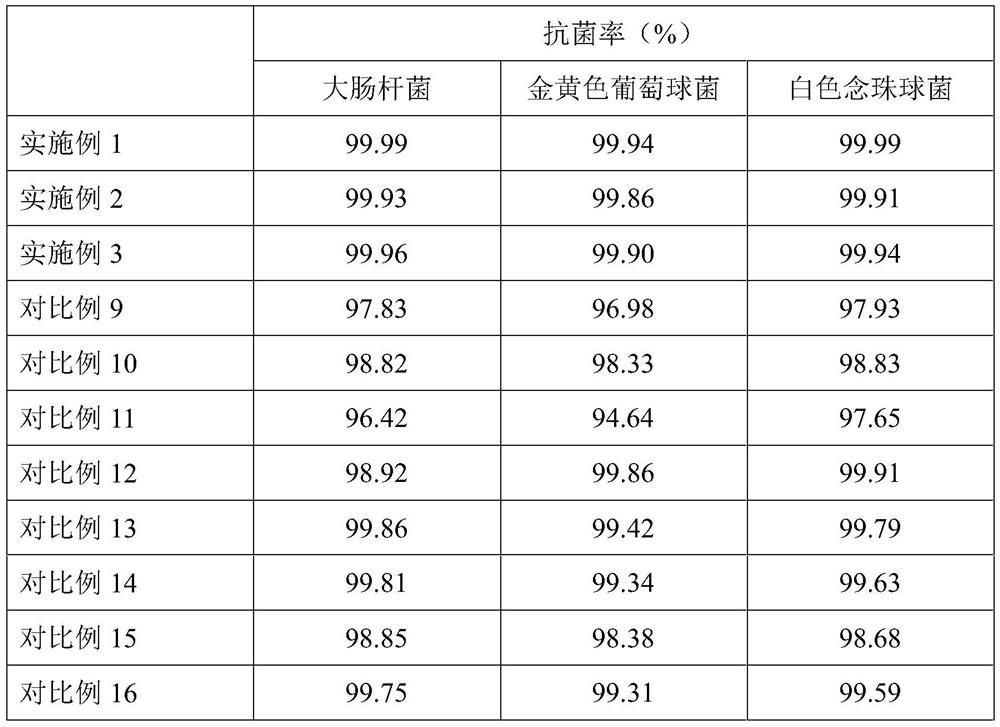

Antibacterial and abrasion-resistant aerated brick and method for preparing same

InactiveCN108658559AGood antibacterial propertiesIncreased strength and wear resistanceCeramicwareKetoneCorrosion

The invention discloses an antibacterial and abrasion-resistant aerated brick and a method for preparing the same. The method for preparing the antibacterial and abrasion-resistant aerated brick includes mixing and grinding gypsum powder, dolomite, bentonite and calcium carbonate whiskers with one another to obtain mixtures, adding tap water into the mixtures and uniformly stirring the tap water and the mixtures to obtain slurry; adding plant fibers into deionized water to obtain first mixtures, ultrasonically dispersing the first mixtures, adding inorganic gel and modified graphite powder into the first mixtures to obtain second mixtures, heating and stirring the second mixtures, simultaneously adding water reducing agents, foaming agents and polyaryl ether ketone into the second mixturesto obtain third mixtures, then adding antibacterial agents and sodium tripolyphosphate into the third mixtures and continuously carrying out stirring reaction to obtain mixed slurry; sequentially pouring the slurry and the mixed slurry into molds to obtain green bricks and carrying out steam curing to obtain the antibacterial and abrasion-resistant aerated brick. The antibacterial and abrasion-resistant aerated brick and the method have the advantages that the calcium carbonate whiskers and the modified graphite powder are added, accordingly, the strength of the antibacterial and abrasion-resistant aerated brick can be improved, the toughness and the abrasion resistance of the antibacterial and abrasion-resistant aerated brick can be enhanced, and the service life of the antibacterial andabrasion-resistant aerated brick can be prolonged; the water reducing agents, the foaming agents, the antibacterial agents, the sodium tripolyphosphate and the polyaryl ether ketone are added, and accordingly the antibacterial property and the corrosion resistance of the antibacterial and abrasion-resistant aerated brick can be enhanced.

Owner:贵州华帅新型环保建材有限公司

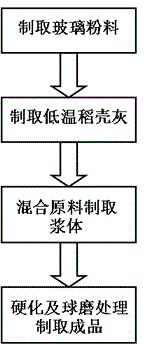

Formula of sound-absorbing foam glass

InactiveCN104844009AIncreased strength and wear resistanceNot easy to agglomerateCalcium carbonateFiber

The invention discloses a formula of sound-absorbing foam glass, which belongs to the field of foam glass. In percentage by mass, the formula comprises 70-80% of broken glass powder, 1-2% of a foaming agent, 1-3% of a foaming promoter, 2-3% of a reinforcing fiber and 8-10% of industrial alcohol. Due to the adoption of the neutral foaming agent calcium carbonate, the foam glass is not dyed during foaming; due to the adoption of the reinforcing fiber, the strength and wear resistance of the foam glass are improved; due to the adoption of the industrial alcohol, the glass powder, the foaming agent and the foaming promoter are uniformly mixed and are not easily agglomerated, so that the yield is increased; and due to the adoption of broken glass, an effect of waste utilization is achieved; therefore, the formula is low in cost and is friendly to the environment.

Owner:张阳康

High-strength plastic, and preparation method and application thereof

PendingCN111040369AIncreased strength and wear resistanceImprove friction resistanceCarbide siliconHeat deflection temperature

The invention discloses a high-strength plastic, and a preparation method and an application thereof. The high-strength plastic comprises, by weight, 30-40 parts of ABS resin, 5-10 parts of nanometertitanium dioxide, 5-10 parts of nanometer silicon carbide, 6-8 parts of calcium sulfate whiskers, 3-5 parts of epoxy resin, 2-6 parts of butyl titanate, 6-8 parts of chopped glass fibers and 3-5 partsof a dispersing agent. The high-strength plastic is obtained by mixing the raw materials in batches according to the parts by weight, heating, stirring and granulating. The prepared plastic has excellent bearing strength and tensile strength, and meanwhile, the thermal deformation temperature is as high as 231 DEG C; and the high-strength plastic can be applied to various fields such as automobiles, agriculture and living goods.

Owner:FOSHAN UNIVERSITY

Antibacterial wear-resistant domestic ceramic and preparation method thereof

PendingCN114195388AIncreased strength and wear resistancePromotes non-abnormal swellingSodium triphosphateSodium lignosulfonate

The invention belongs to the technical field of domestic ceramics, and particularly relates to an antibacterial wear-resistant domestic ceramic and a preparation method thereof. The antibacterial wear-resistant domestic ceramic comprises a domestic ceramic green body and a glaze layer, wherein the glaze layer is prepared from the following raw materials in parts by weight: 35-45 parts of zircon sand; 15 to 20 parts of baddeleyite; 4-8 parts of magnesite; 2-6 parts of calcite; 1-3 parts of molybdenum powder; 2-4 parts of erbium oxide; 2-4 parts of neodymium oxide; 3-7 parts of zinc oxide; 3-7 parts of tungsten oxide; 2-4 parts of silver powder; 3-5 parts of sodium lignin sulfonate; 3-5 parts of sodium tripolyphosphate; and 25-35 parts of water. According to the antibacterial wear-resistant domestic ceramic disclosed by the invention, through mutual matching of the components and control of the preparation method, the obtained product has excellent wear resistance and antibacterial property.

Owner:苏长全

False-twist rotor with constant-temperature heating device

InactiveCN103668592AChanging Yarn Fiber TransferIncreased strength and wear resistanceTextiles and paperElectric heatingYarn

The invention provides a false-twist rotor with a constant-temperature heating device. The false-twist rotor is characterized in that a first circular ring copper electrode and a second circular ring copper electrode are respectively installed on the outer circle of a ceramic circular ring in a sleeved mode, and the ceramic circular ring provided with a longitudinal hole and a spiral hole is arranged on a cylindrical ceramic column in a sleeved mode; two leads of an electric heating coil in a groove formed in the inner circle surface of the ceramic circular ring are jointly connected and fixed to the first circular ring copper electrode and the second circular ring copper electrode respectively; two electric brushes jointly contact the first circular ring copper electrode and the second circular ring copper electrode respectively; wires on the electric brushes are connected with a direct current power cord, wherein an electric control switch is arranged between the wires and the power cord. The electric brushes are used for power supplying and heating of the electric heating coil and then heat transmission to the cylindrical ceramic column, as a result, the cylindrical ceramic column can keep a certain constant temperature, and a bearing installed on the lower portion of the cylindrical ceramic column in a sleeved mode can be installed on a mounting base; under the circumstance that the width of a twisting triangular area is kept unchanged, the length of the twisting triangular area is reduced, gather fibers for twisting are enhanced, as a result, fiber migration of yarn is changed, and the strength and abrasive resistance of the yarn are improved.

Owner:JIHUA 3542 TEXTILE CO LTD

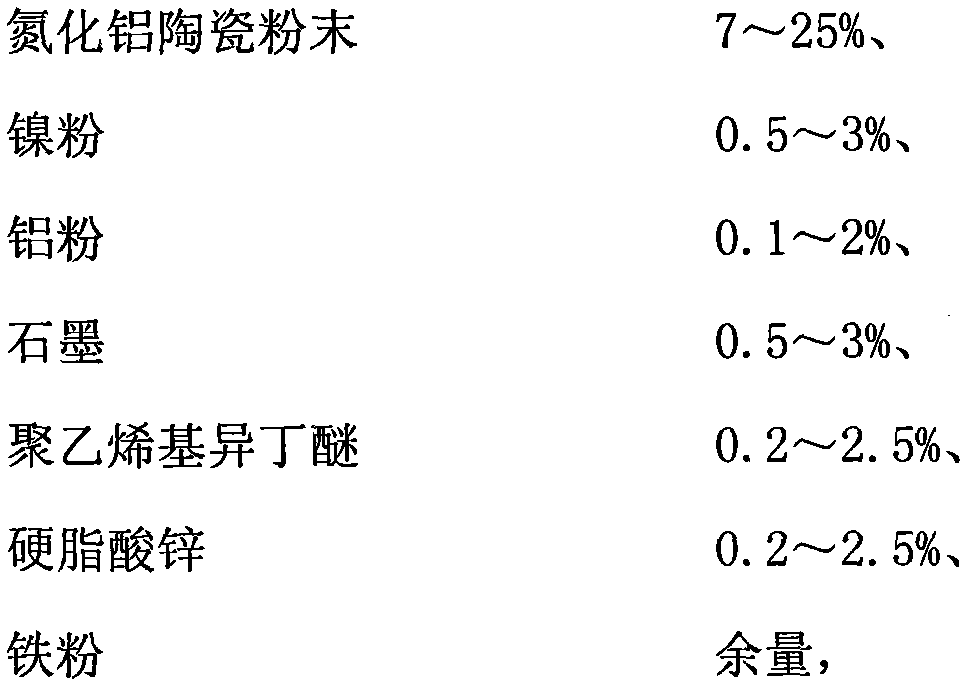

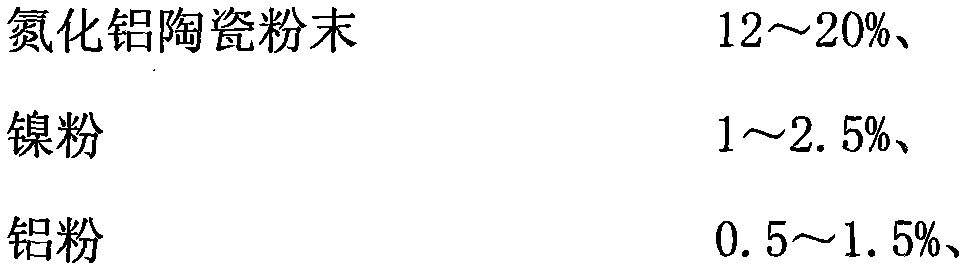

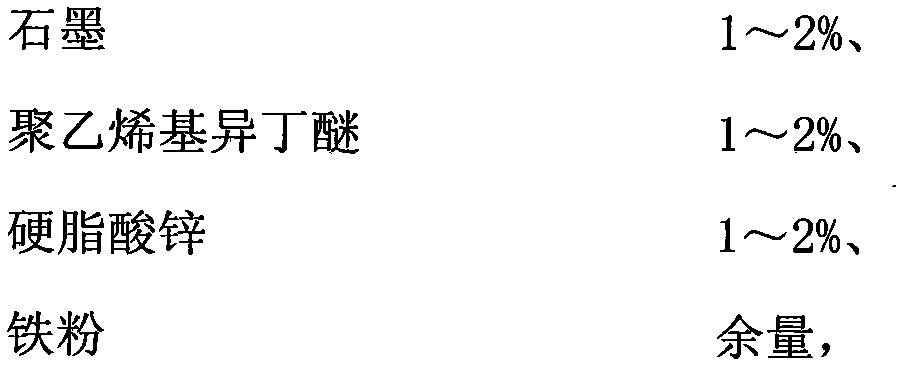

Novel special material for powder metallurgy gear case

InactiveCN105880570AIncreased strength and wear resistanceImprove refinementPowder metallurgyStearic acid

The invention discloses a novel special material for a powder metallurgy gear case. The novel special material for the powder metallurgy gear case comprises the following components of, by weight, 7-25% of aluminum nitride ceramic powder, 0.5-3% of nickel powder, 0.1-2% of aluminum powder, 0.5-3% of graphite, 0.2-2.5% of poly(isobutyl vinyl ether), 0.2-2.5% of zinc stearate, and the balance of iron powder; and the sum of the weight percentages of the components is 100%. A metal ceramic compound is formed by the iron powder and the aluminum nitride ceramic powder, through addition of a trace amount of the nickel powder and a trace amount of the aluminum powder, refining of a two-phase micro-interface is promoted, and wear resistance and strength of the manufactured gear case are further improved.

Owner:包敢锋

Composite abrasion-resistant rubber liner plate and preparation method thereof

InactiveCN107020779AIncreased strength and wear resistanceImprove impact resistanceRubber layered productsBuffering agentMagnesium borate

The invention relates to a composite abrasion-resistant rubber liner plate and a preparation method thereof. The rubber liner plate is formed by bonding a surface layer composite rubber plate and a lower layer elastic rubber plate, and the composite rubber plate is formed by mixing isoprene rubber, composite fibers, a reinforcing agent, a filler, a vulcanizing agent and composite resin; and the reinforcing agent is prepared from sepiolite fabric, nano zinc powder and ethyl orthosilicate, and the filler is prepared from nanocrystalline boehmite, ammonium fluoride, boric acid, monatomic silicon powder and magnesium borate whiskers. The rubber liner plate is formed by the surface layer composite rubber plate and the lower laser elastic rubber plate, and the reinforcing agent and filler of special components and the composite resin are added into the surface layer composite rubber plate, the abrasion resistance and the strength are greatly improved; and moreover, a buffering agent is added into the lower layer elastic rubber plate, and the impact force transferred by the surface layer composite rubber plate can be absorbed, so that the impact resistance, fracture resistance and abrasion resistance of the whole rubber liner plate can be improved.

Owner:穆琳瑛

Die alloy

InactiveCN104911448AThe ratio of ingredients is scientific and reasonableIncreased strength and wear resistanceRosinTungsten

The invention relates to a die alloy, which comprises the following components by weight part: 2-5 parts of chromium, 10-15 parts of iron, 12-18 parts of zinc, 6-10 parts of tungsten, 12-15 parts of rosin, 8-10 parts of calcium, 2-3 parts of niobium. The die alloy has the advantages that the composition proportion is scientific and reasonable, wear resistance and intensity are high, service life is greatly prolonged, manufacture cost is reduced, and enterprise requirement can be satisfied.

Owner:ZXSY KUNSHAN METAL TECH

Micro-fluidic chip mold

ActiveCN104387642AComponent coordination is reasonable and reliableIncreased strength and wear resistanceMicro fluidicMicrofluidic chip

The present invention discloses a micro-fluidic chip mold, which adopts 30-50 parts by weight of a macromolecule polymer as a raw material, and further comprises, by weight, 10-15 parts of a filler, 1-3 parts of a plasticizer, 8-10 parts of gypsum, 3-5 parts of bamboo charcoal, 5-8 parts of aluminum powder, and 20-25 parts of iron powder. The micro-fluidic chip mold has the following beneficial effects that: the component matching is reliable and reasonable, the aluminum powder and the iron powder are added, the wear resistance and the strength of the micro-fluidic chip mold can be substantially enhanced, the service life of the mold can be effectively prolonged, and the production cost is substantially reduced.

Owner:西安医安仁芯生物科技有限公司

Adhesive suitable for multi materials

InactiveCN104403599AIncreased strength and wear resistanceExtended service lifeNon-macromolecular adhesive additivesMacromolecular adhesive additivesMulti materialOrganosolv

An adhesive suitable for multi materials is prepared from the following raw materials in parts by weight: 8-16 parts of chloroprene rubber, 3-9 parts of an organic solvent, 2-7 parts of a thickener, 5-10 parts of butadiene rubber, 3-7 parts of thermoplastic synthetic resin, 2-6 parts of Portland cement, 1-5 parts of sodium hydroxide, 4-9 parts of coumarone resin, 3-6 parts of zinc oxide, 4-7 parts of zeolite powder, 2-7 parts of acrylate, 1-3 parts of a coupling agent and 5-8 parts of benzothiazole mercaptan. The adhesive suitable for multi materials can effectively bond multi materials of a conveying belt, improves the strength and wear resistance of the conveying belt, and improves the service life.

Owner:张桂华

Alloy steel formula for bearing

InactiveCN103805881AIncreased strength and wear resistanceCold deformation shape is goodChromiumAlloy steel

The invention discloses an alloy steel formula for a bearing. The alloy steel formula comprises the following components in percentage by weight: 0.37-0.45 percent of carbon, 0.24-0.29 percent of molybdenum, 0.33-0.39 percent of zirconium, 0.17-0.37 percent of silicon, 0.50-0.80 percent of manganese, less than 0.4 percent of sulfur, less than 0.05 percent of phosphorus, less than or equal to 0.25 percent of chromium, less than 0.25 percent of nickel, less than 0.25 percent of copper, less than 0.1 percent of other inevitable impurities and the balance of iron. The alloy steel has high strength and wear resistance, high cold deformation shaping and high surface abrasion resistance, the overall quality of the bearing product is improved, and the service life is prolonged, so that the continuous operating time of equipment is effectively improved, the maintenance period of the equipment is prolonged, and the use cost of the equipment is saved.

Owner:俞政

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com