Water permeable brick purifying rainwater and preparation method of water permeable brick

A technology of permeable bricks and rainwater, which is applied in the field of building materials, can solve the problems of complex preparation process of filter elements and reduce the permeable area, so as to reduce the cost of raw materials, prevent the decrease of water permeability, and improve the strength and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A permeable brick for purifying rainwater, the permeable brick is divided into an upper layer and a lower layer; the upper layer is the surface layer, the lower layer is the base layer, and the ratio of the thickness of the surface layer to the base layer is 1:5, wherein:

[0048] The components of the surface layer include 17wt% cement, 70wt% quartz sand, 5wt% water, 5wt% iron oxide red pigment and 3wt% silicon fluorine reinforcing agent;

[0049] The components of the base layer include 20wt% cement, 75wt% zeolite-modified ceramsite and 5wt% water.

[0050] The particle size of quartz sand is 1-3mm;

[0051] The particle size of zeolite modified ceramsite is 5-10mm, the macropore diameter of zeolite modified ceramsite is 1-5μm, the micropore diameter of zeolite modified ceramsite is 0.1-1nm, the zeolite modified ceramsite The porosity is 50-70%.

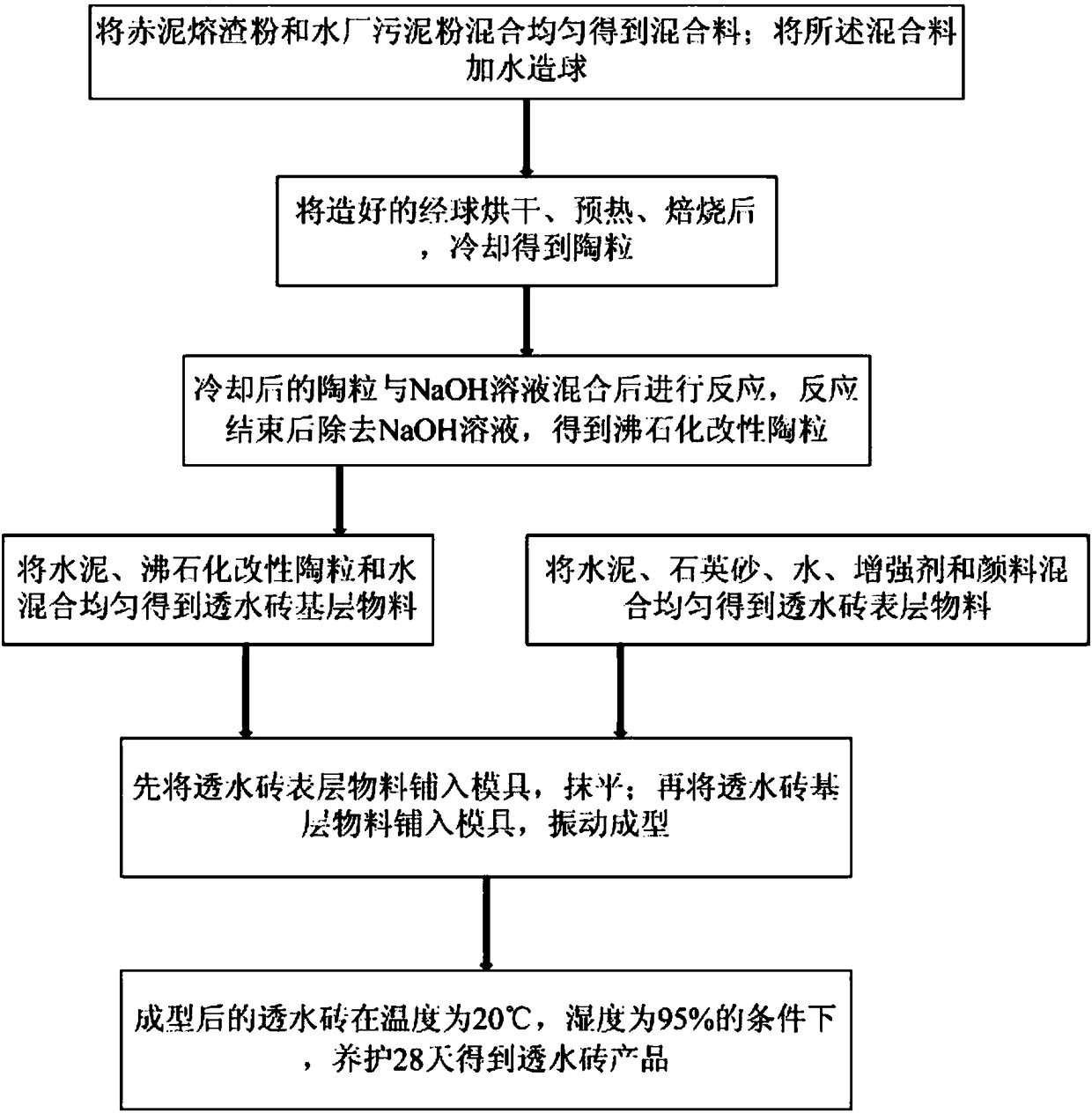

[0052] Such as figure 1 As shown, the preparation method of the permeable brick for purifying rainwater is as follows: ...

Embodiment 2

[0057] A permeable brick for purifying rainwater, the permeable brick is divided into an upper layer and a lower layer; the upper layer is the surface layer, the lower layer is the base layer, and the ratio of the thickness of the surface layer to the base layer is 1:6, wherein:

[0058] The components of the surface layer include 15wt% cement, 73wt% quartz sand, 6wt% water, 4wt% iron oxide yellow pigment and 2wt% silicon fluorine strengthening agent;

[0059] The components of the base layer include 22wt% cement, 70wt% zeolite-modified ceramsite and 8wt% water.

[0060] The particle size of quartz sand is 1-3mm;

[0061] The particle size of zeolite modified ceramsite is 5-10mm, the macropore diameter of zeolite modified ceramsite is 1-5μm, the micropore diameter of zeolite modified ceramsite is 0.1-1nm, the zeolite modified ceramsite The porosity is 50-70%.

[0062] Such as figure 1 As shown, the preparation method of the permeable brick for purifying rainwater is as foll...

Embodiment 3

[0067] A permeable brick for purifying rainwater, the permeable brick is divided into an upper layer and a lower layer; the upper layer is the surface layer, the lower layer is the base layer, and the ratio of the thickness of the surface layer to the base layer is 1:5, wherein:

[0068] The components of the surface layer include 20wt% cement, 70wt% quartz sand, 4wt% water, 4wt% iron blue pigment and 2wt% silicon fluorine strengthening agent;

[0069] The components of the base layer include 20wt% cement, 73wt% zeolite-modified ceramsite and 7wt% water.

[0070] The particle size of quartz sand is 1-3mm;

[0071] The particle size of zeolite modified ceramsite is 5-10mm, the macropore diameter of zeolite modified ceramsite is 1-5μm, the micropore diameter of zeolite modified ceramsite is 0.1-1nm, the zeolite modified ceramsite The porosity is 50-70%.

[0072] Such as figure 1 As shown, the preparation method of the permeable brick for purifying rainwater is as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Large hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com