Cordierite-containing composite refractory material for working linings of coke dry quenching tank and bin body

A refractory material and cordierite technology, applied in the field of refractory materials, can solve the problems of cracks, deformation of heat-resistant steel lining plates, shortened service life of coke tanks, etc., and achieve the effects of high efficiency, reduced heat transfer, and improved operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

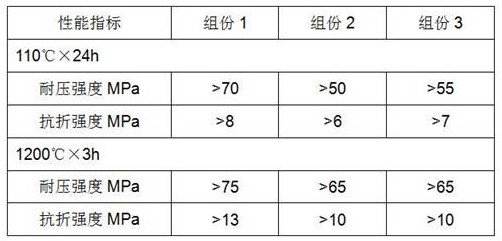

Embodiment 1

[0017] Example 1 has better fluidity and is suitable for casting prefabrication.

[0018] The parts by weight of raw materials in the present invention are: 20 parts of fused mullite of 1-3mm, 45 parts of fused mullite of 3-5mm, 10 parts of cordierite of 0-1mm, 10 parts of cordierite of 1-3mm 40 parts of cordierite, 20 parts of 200-mesh corundum fine powder, 3 parts of silicon nitride fine powder, 4 parts of calcium aluminate cement, 2 parts of silicon micropowder, 7 parts of alumina micropowder, 2 parts of asbestos fiber, sodium tripolyphosphate addition It is 0.15% of the total weight of raw materials, the addition of citric acid is 1% of the total weight of raw materials, and the addition of rubber powder is 2% of the total weight of raw materials.

[0019] Pour the above components into a blender and dry mix for 3-5 minutes, then add 8-10% tap water or industrial water and stir for 5-10 minutes, after uniformity, then pour into a mold, naturally maintain, and dry for use. ...

Embodiment 2

[0021] Embodiment 2: It has better smearing performance, wide application range, low cost, and convenient construction, and is used for difficult construction, narrow space, irregular working surface, etc.; it is mainly used for silos and ash hoppers.

[0022] The parts by weight of raw materials in the present invention are: 45 parts of fused mullite of 1-3mm, 10 parts of fused mullite of 3-5mm, 10 parts of cordierite of 0-1mm, 10 parts of cordierite of 1-3mm 40 parts of cordierite, 5 parts of 200 mesh corundum fine powder, 8 parts of silicon nitride fine powder, 4 parts of calcium aluminate cement, 6 parts of silicon micropowder, 7 parts of alumina micropowder, 0.5 part of asbestos fiber, sodium tripolyphosphate and six Sodium metaphosphate is 0.15% of the total weight of raw materials, soft clay is 3% of the total weight of raw materials, rubber powder is 0.05% of the total weight of raw materials, and sodium carboxymethyl cellulose is 0.1% of the total weight of raw materia...

Embodiment 3

[0025] Component 3: suitable for spraying, wide application range, convenient construction, high efficiency, low cost, etc.; mainly used for silos and ash hoppers.

[0026] 35 parts by mass of fused mullite 3-1mm, 10 parts of fused mullite 1-0mm, 20 parts of cordierite 1-0mm, 5 parts of corundum powder 200 mesh, 20 parts of calcium aluminate cement, 1 part of alumina micropowder , 1 part of silicon micropowder, 8 parts of silicon nitride fine powder, 1 part of asbestos fiber, the addition of soft clay is 2% of the total weight of raw materials, carboxymethyl cellulose is 0.5% of the total weight of raw materials, polymer glue Powder is 0.5% of the total weight of raw materials, and 8% sodium carbonate and sodium silicate solution is 1% of the total weight of raw materials.

[0027] Pour the above components (excluding sodium carbonate and sodium silicate solution) into the mixer and dry mix for 3 minutes, then add 9-11 parts of tap water or industrial water, continue to stir f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com