Antibacterial wear-resistant domestic ceramic and preparation method thereof

A wear-resistant, daily-use technology, applied in the field of daily-use ceramics, can solve the problems of antibacterial performance and low wear resistance, achieve excellent antibacterial performance, improve antibacterial performance, and promote the effect of improving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

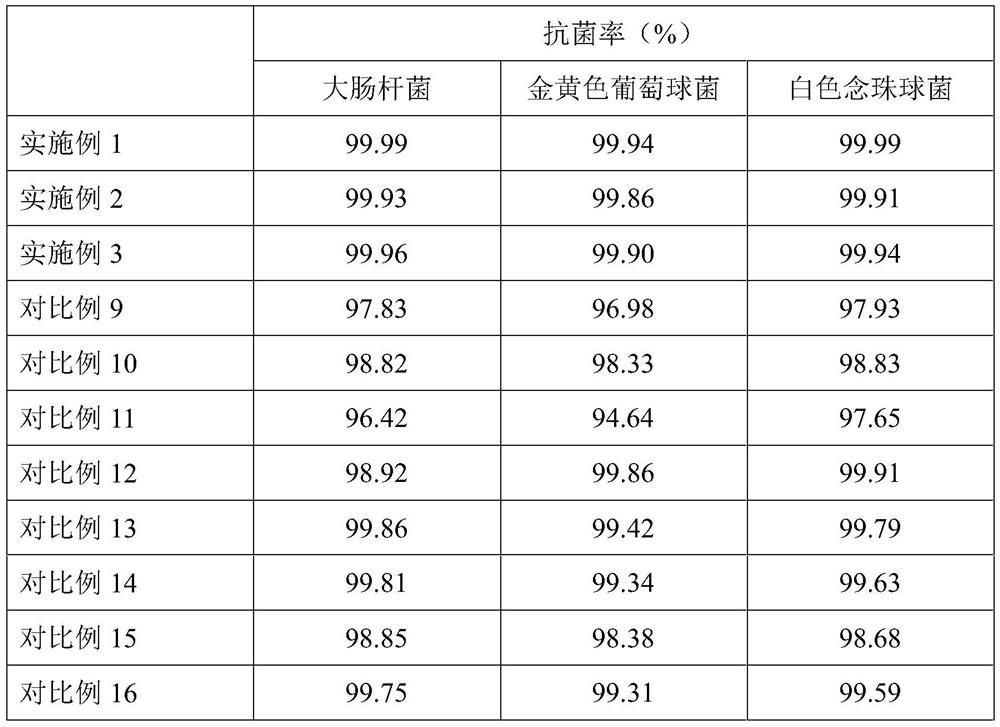

Examples

Embodiment 1

[0035] An antibacterial and wear-resistant daily-use ceramic, comprising a daily-use ceramic body and a glaze layer, the glaze layer is made of the following raw materials in parts by weight:

[0036] 40 parts of zircon sand; 18 parts of baddeleyite; 6 parts of magnesite; 4 parts of calcite; 2 parts of molybdenum powder; 3 parts of erbium oxide; 3 parts of neodymium oxide; 5 parts of zinc oxide; 5 parts of tungsten oxide; 3 parts of silver powder ; 4 parts of sodium lignosulfonate; 4 parts of sodium tripolyphosphate; 30 parts of water.

[0037] The particle size of the zircon sand is 6 μm, the particle size of the baddeleyite is 5 μm, the particle size of the nepheline magnesite is 8 μm; the particle size of the calcite is 6 μm; the particle size of the molybdenum powder is 20 nm; The particle size of erbium oxide is 15nm; the particle size of neodymium oxide is 15nm; the particle size of zinc oxide is 8nm; the particle size of tungsten oxide is 8nm; the particle size of silve...

Embodiment 2

[0044] An antibacterial and wear-resistant daily-use ceramic, comprising a daily-use ceramic body and a glaze layer, the glaze layer is made of the following raw materials in parts by weight:

[0045] 45 parts of zircon sand; 15 parts of baddeleyite; 8 parts of magnesite; 2 parts of calcite; 3 parts of molybdenum powder; 2 parts of erbium oxide; 4 parts of neodymium oxide; 3 parts of zinc oxide; 7 parts of tungsten oxide; 2 parts of silver powder ; 5 parts of sodium lignosulfonate; 3 parts of sodium tripolyphosphate; 35 parts of water.

[0046] The particle size of the zircon sand is 8 μm, the particle size of the baddeleyite is 3 μm, the particle size of the nepheline magnesite is 10 μm; the particle size of the calcite is 4 μm; the particle size of the molybdenum powder is 25 nm; The particle size of erbium oxide is 10nm; the particle size of neodymium oxide is 20nm; the particle size of zinc oxide is 5nm; the particle size of tungsten oxide is 10nm; the particle size of sil...

Embodiment 3

[0053] An antibacterial and wear-resistant daily-use ceramic, comprising a daily-use ceramic body and a glaze layer, the glaze layer is made of the following raw materials in parts by weight:

[0054] 35 parts of zircon sand; 20 parts of baddeleyite; 4 parts of magnesite; 6 parts of calcite; 1 part of molybdenum powder; 4 parts of erbium oxide; 2 parts of neodymium oxide; 7 parts of zinc oxide; 3 parts of tungsten oxide; 4 parts of silver powder ; 3 parts of sodium lignosulfonate; 5 parts of sodium tripolyphosphate; 25 parts of water.

[0055] The particle size of the zircon sand is 4 μm, the particle size of the baddeleyite is 6 μm, the particle size of the nepheline magnesite is 6 μm; the particle size of the calcite is 8 μm; the particle size of the molybdenum powder is 15 nm; The particle size of erbium oxide is 20nm; the particle size of neodymium oxide is 10nm; the particle size of zinc oxide is 10nm; the particle size of tungsten oxide is 5nm; the particle size of silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com