High-reliability cement

A reliability and cement technology, applied in the field of cement and high reliability cement, can solve the problems of low strength, low brine resistance, high cost, etc., achieve excellent water resistance and flame retardancy, broad market application prospects, high strength and the effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

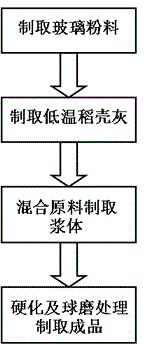

[0017] figure 1 It is a process step diagram of the method for preparing high-reliability cement in the embodiment of the present invention; the high-reliability cement is made of the following raw materials in weight percentage: 53-60% of activated magnesium oxide, 10-12% of magnesium chloride hexahydrate, and 18% of glass powder ~20%, low-temperature rice husk ash 12-15%; the preparation method of the high-reliability cement includes the following steps: a) preparing glass powder, b) preparing low-temperature rice husk ash, c) mixing raw materials to prepare slurry , d) hardening and ball milling to produce finished products.

[0018] The high-reliability cement mentioned in the present invention uses traditional magnesium oxychloride cement as the main body, and the strength, wear resistance and water resistance of the cement are significantly improved by adding filler glass powder and modifier low-temperature rice husk ash. Compared with Portland cement, which is widely u...

Embodiment 1

[0020] The specific preparation method is as follows:

[0021] a) To prepare glass powder, put the ordinary recycled glass into a special pulverizer to obtain fine glass powder with a particle size of 0.3-0.5 mm and coarse glass powder with a particle size of 1.2-1.4 mm, and then mix the fine glass powder and Coarse glass powder is mixed according to the mass ratio of 1.5:1 to prepare glass powder.

[0022] b) To prepare low-temperature rice husk ash, put the ordinary recycled rice husk in a muffle furnace, burn it at 500-600°C for 40 minutes, then cool the rice husk ash to room temperature, grind it with a pulverizer and Pass through a 180-mesh sieve to obtain low-temperature rice husk ash powder.

[0023] c) Mix raw materials to prepare slurry. The specific preparation process is: firstly weigh 60% active magnesium oxide, 10% magnesium chloride hexahydrate, 18% glass powder, and 12% low-temperature rice husk ash according to weight percentage; Dissolve magnesium chloride h...

Embodiment 2

[0026] The specific preparation method is as follows:

[0027] a) To prepare glass powder, put the ordinary recycled glass into a special pulverizer to obtain fine glass powder with a particle size of 0.3-0.5 mm and coarse glass powder with a particle size of 1.2-1.4 mm, and then mix the fine glass powder and Coarse glass powder is mixed according to the mass ratio of 1.5:1 to prepare glass powder.

[0028] b) To prepare low-temperature rice husk ash, put the ordinary recycled rice husk in a muffle furnace, burn it at 500-600°C for 40 minutes, then cool the rice husk ash to room temperature, grind it with a pulverizer and Pass through a 180-mesh sieve to obtain low-temperature rice husk ash powder.

[0029] c) Mixing raw materials to prepare slurry, the specific preparation process is as follows: firstly weigh 53% active magnesium oxide, 12% magnesium chloride hexahydrate, 20% glass powder, and 15% low-temperature rice husk ash according to weight percentage; Dissolve magnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Baume degrees | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com