False-twist rotor with constant-temperature heating device

A false-twist rotor and constant temperature heating technology, applied in textiles and papermaking, can solve problems such as affecting subsequent processing and increasing yarn rigidity, reducing fiber stiffness, changing yarn fiber transfer, increasing strength and wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

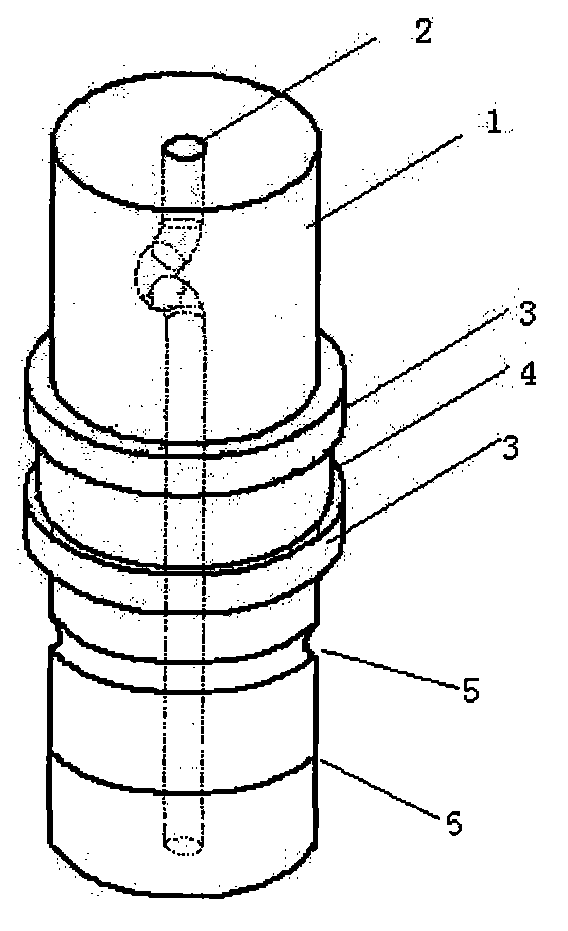

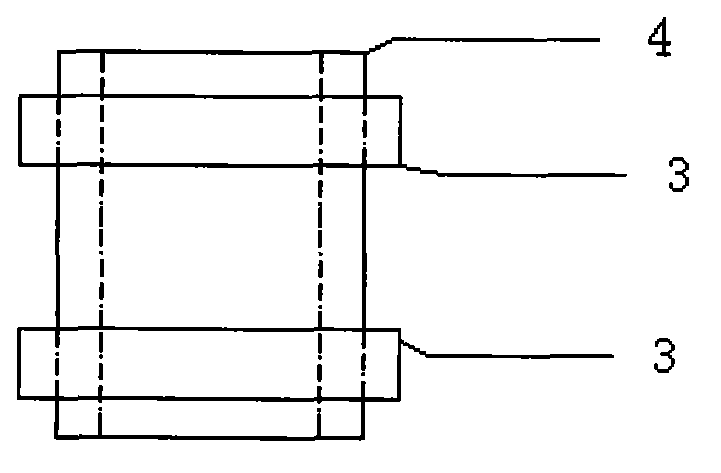

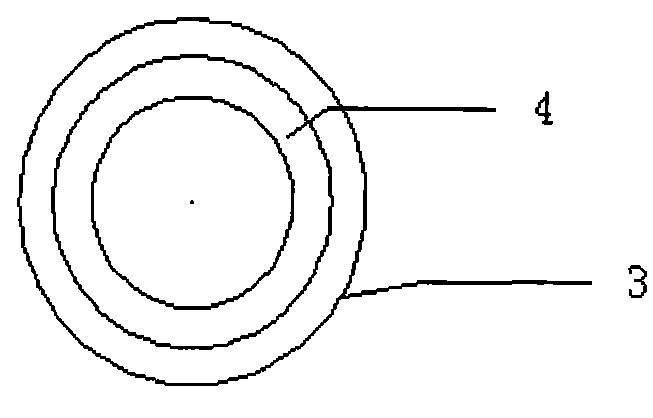

[0015] In the present invention figure 1 , figure 2 , image 3 and Figure 4 In the shown embodiment, the first ring copper electrode 3 and the second ring copper electrode 3' are respectively set on the outer circles of the two ends of the ceramic ring 4, grooves are arranged on the inner surface of the ceramic ring 4, and the electric The heating coil is installed in the groove on the inner surface of the ceramic ring 4, and the ceramic ring 4 is set on the cylindrical ceramic column 1, and the longitudinal hole and the spiral hole 2 provided in the center of the cylindrical ceramic column 1 are through holes; The two lead wires of the electric heating coil in the groove of the inner circular surface of the ring 4 are respectively connected and fixed together with the first ring copper electrode 3 and the second ring copper electrode 3', and the two electric brushes are respectively connected with the ceramic ring The first ring copper electrode 3 and the second ring cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com