Color-changing baking-free water-permeable brick by using solid waste and preparation method

A technology for permeable bricks and solid waste is applied in the field of discoloration and non-burning permeable bricks and their preparation, which can solve the problems of inability to achieve energy-saving development, high energy consumption in cement production, and high production costs, so as to ensure water permeability, reduce production costs, and enhance strength. and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

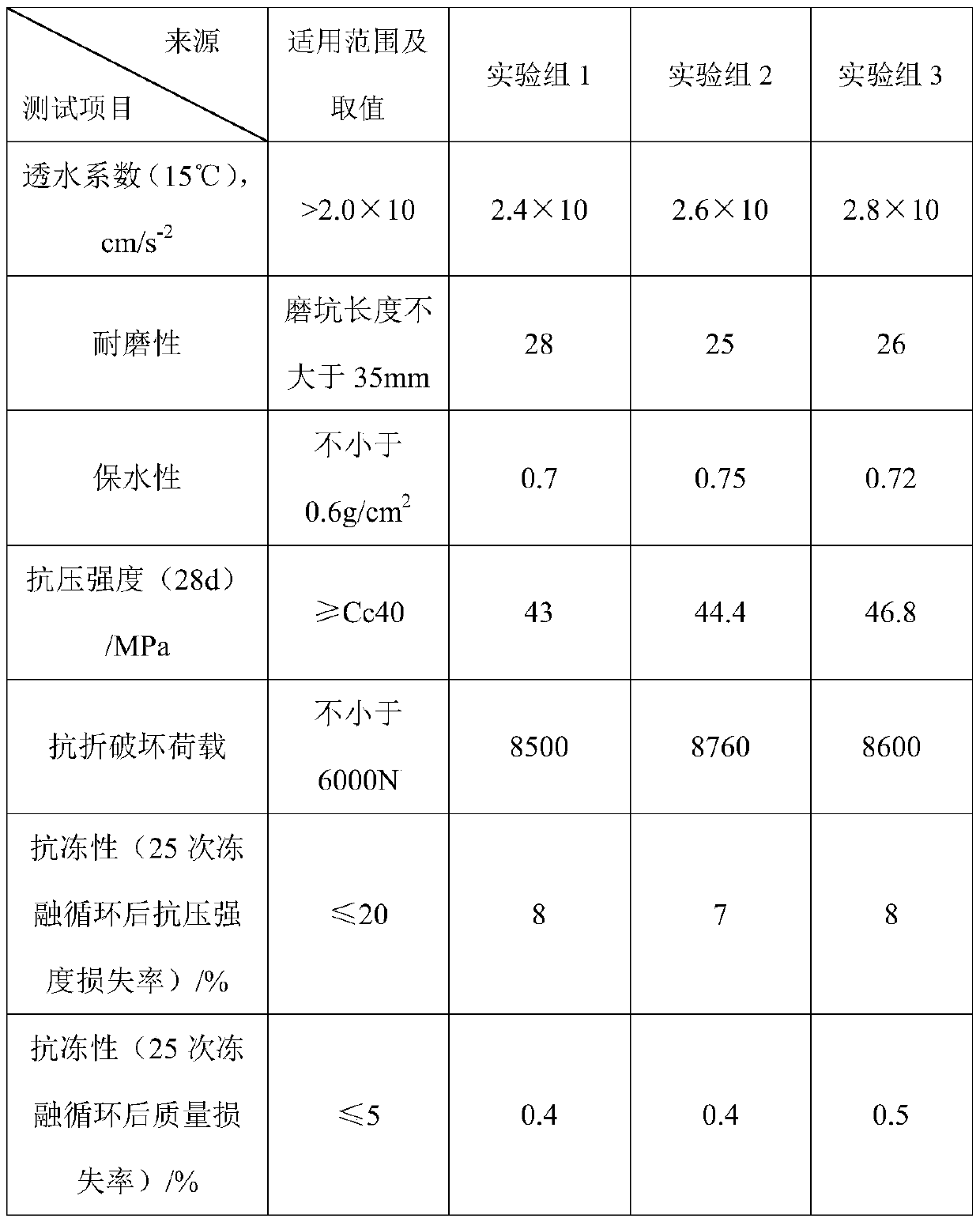

Examples

preparation example Construction

[0034] A method for preparing a color-changing burn-free permeable brick utilizing solid waste, comprising the following contents:

[0035] 1) Weigh the red mud, aluminate cement and steel slag in proportion, and add the corresponding proportion of early strength agent and water reducer. According to the percentage by weight, the red mud is 40-60 parts, and the aluminate cement is 5 to 25 parts, 30 to 50 parts of aggregate (a mixture of steel slag and iron tailings), 0.2 to 0.4 parts of water reducing agent, 0.2 to 0.6 parts of early strength agent, 20 to 50 parts of water, and mix well to obtain the base layer mixture .

[0036] 2) Weigh ceramic waste, water glass solution, color-changing glass particles and water in proportion. According to the percentage by weight, the amount of ceramic waste is 45-65 parts, the water glass solution is 1-15 parts, the color-changing glass particles is 20-30 parts, and the water is 12-18 parts. Mix well to obtain a topping mix.

[0037] 3...

Embodiment 1

[0039] A color-changing fire-free permeable brick utilizing solid waste, comprising a surface layer and a base layer, the surface layer and the base layer are combined by an adhesive, the mass ratio of the surface layer to the base layer is 1:7-9, and the mass of the base layer is greater than that of the surface layer , to effectively ensure the strength and wear resistance of permeable bricks. The surface layer includes ceramic waste, water glass solution, color-changing glass particles and water, and the base layer includes red mud, iron-aluminate cement, aggregate, water reducing agent and early strength agent. Among them, ceramic waste, color-changing glass particles, red mud, ferric chlorate cement and aggregates are all derived from solid waste. Color-changing glass particles effectively realize the color-changing effect of permeable bricks. The aggregate has a pressure effect through the binder and can The base layer is effectively bonded together, and the aggregate mak...

Embodiment 2

[0050] A method for preparing a color-changing burn-free permeable brick utilizing solid waste, comprising the following contents:

[0051] 1) Take 40 parts of red mud, 30 parts of ferri-aluminate cement, 30 parts of aggregate (a mixture of steel slag and iron tailings), 0.2 part of water reducing agent, 0.2 part of early strength agent, 20 parts of water, and stir evenly to prepare into the grassroots.

[0052] 2) Take 55 parts of ceramic waste, 15 parts of water glass solution, 30 parts of color-changing glass particles, and 18 parts of water, and stir evenly to make a surface layer.

[0053] 3) Put the above materials in a mixer and stir evenly, then first fill the metal mold with the color-changing surface layer mixture 6mm, then fill it with the binder and the base layer mixture, and then press molding at one time, the pressure 20MPa, and finally cured for 14 days to obtain formed permeable bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com