High-strength wear-resistant rotary cutter and production technology thereof

A high-strength technology for rotary tillage blades, applied in the field of rotary tillage blades, can solve the problems of poor wear resistance of the blade body, increase the cost of rotary tillage, and reduce the efficiency of cultivated land, so as to increase wear resistance and strength, increase service life, and improve The effect of cultivated land efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

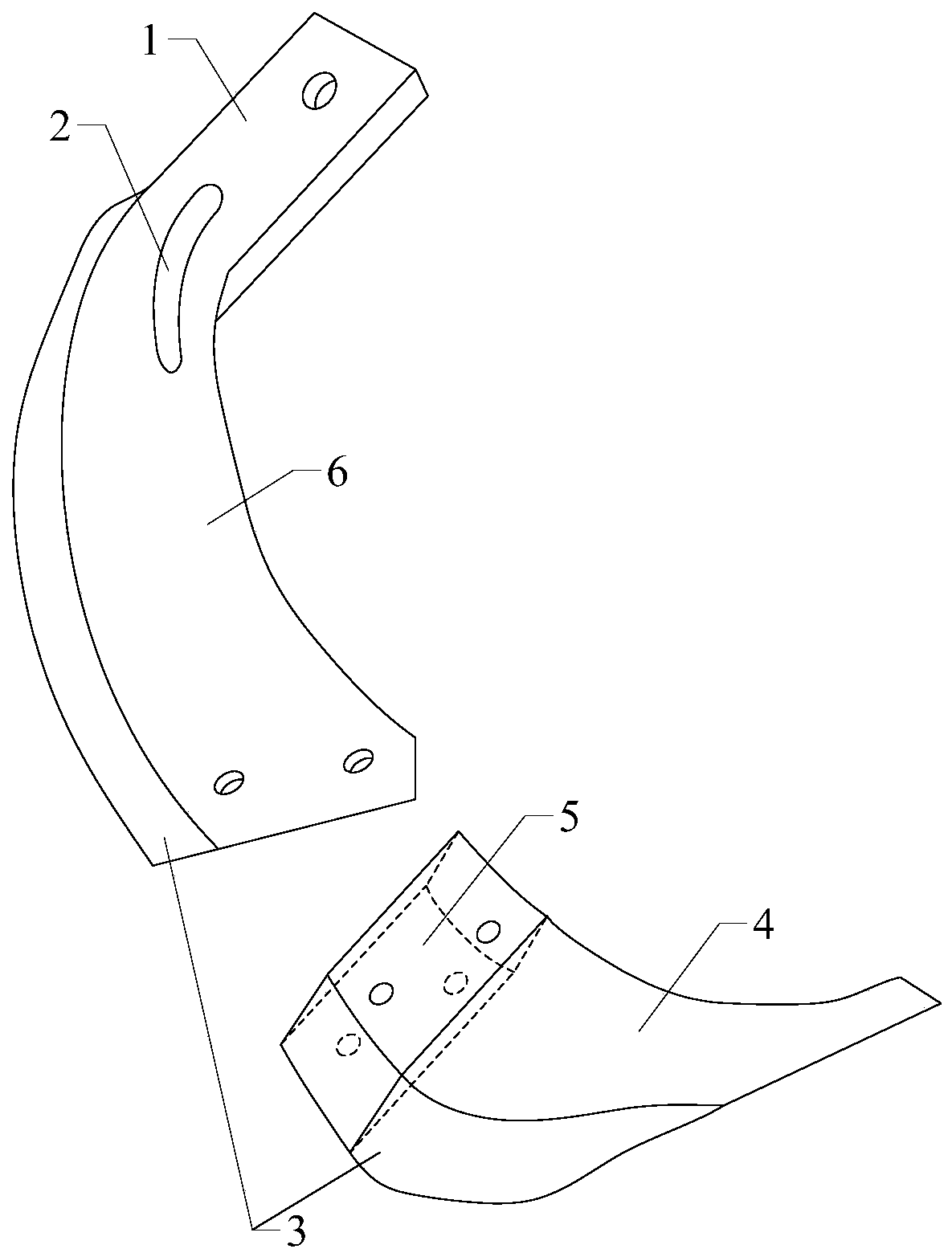

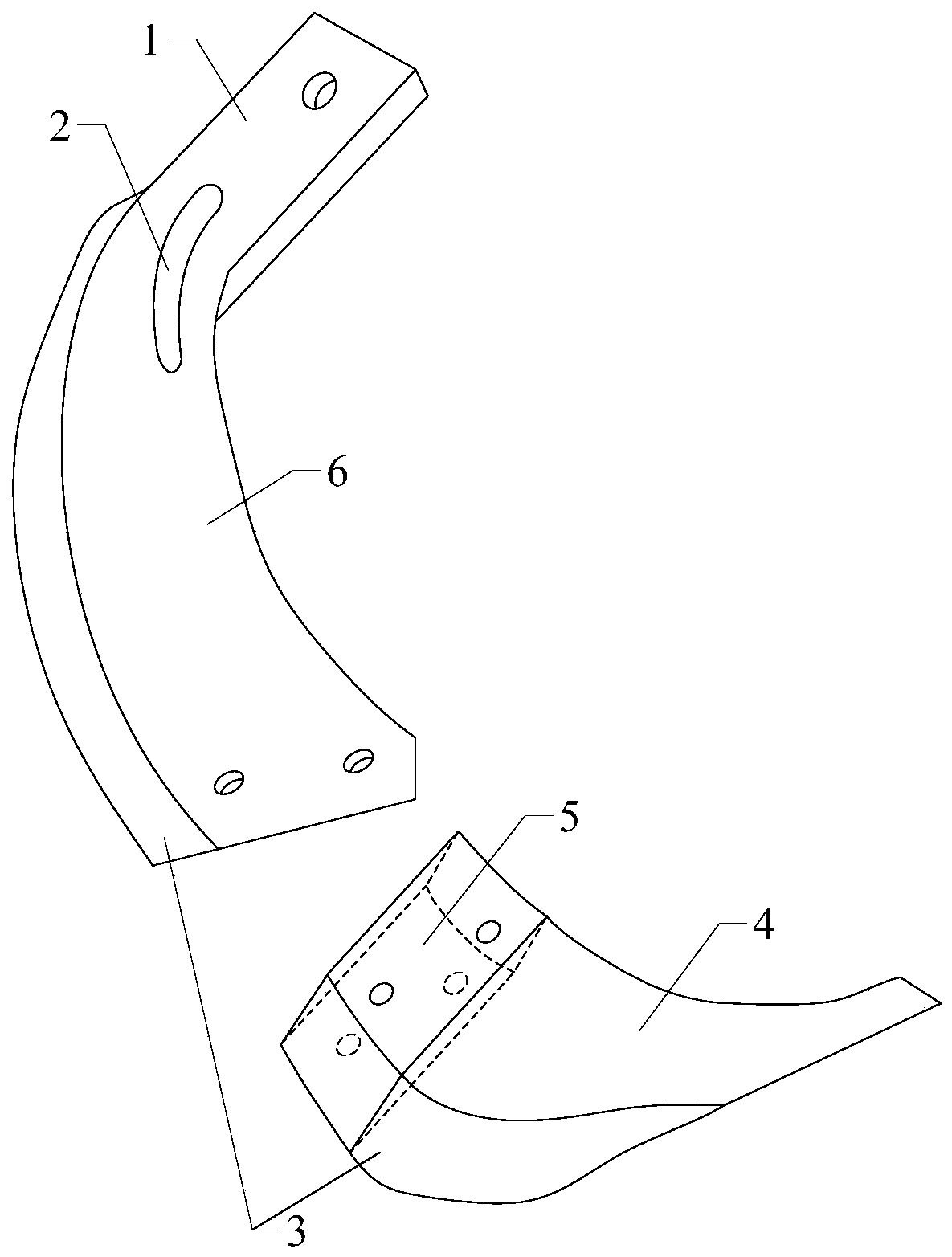

[0030] figure 1 It is a schematic structural view of a high-strength wear-resistant rotary cultivator according to an embodiment of the present invention, as figure 1 As shown, the structure of the present invention includes a knife body composed of a main knife body 6 and a knife handle 1 fixedly connected to one end of the main knife body 6, and the main knife body 6 is located on the same horizontal plane as the knife handle 1, and the present invention also Including the auxiliary blade body 4, one end of the auxiliary blade body 4 is plugged with the other end of the main blade body 6 through the sleeve 5, the auxiliary bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com