Tracked cultivator

A crawler and cultivating machine technology, which is applied in the direction of tillage equipment, crawler vehicles, motor vehicles, etc., can solve the problems of only working in dry fields and hard fields, affecting farming efficiency, and affecting farmers' income, so as to improve the ability to resist subsidence , Reduce labor intensity and improve the efficiency of cultivated land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

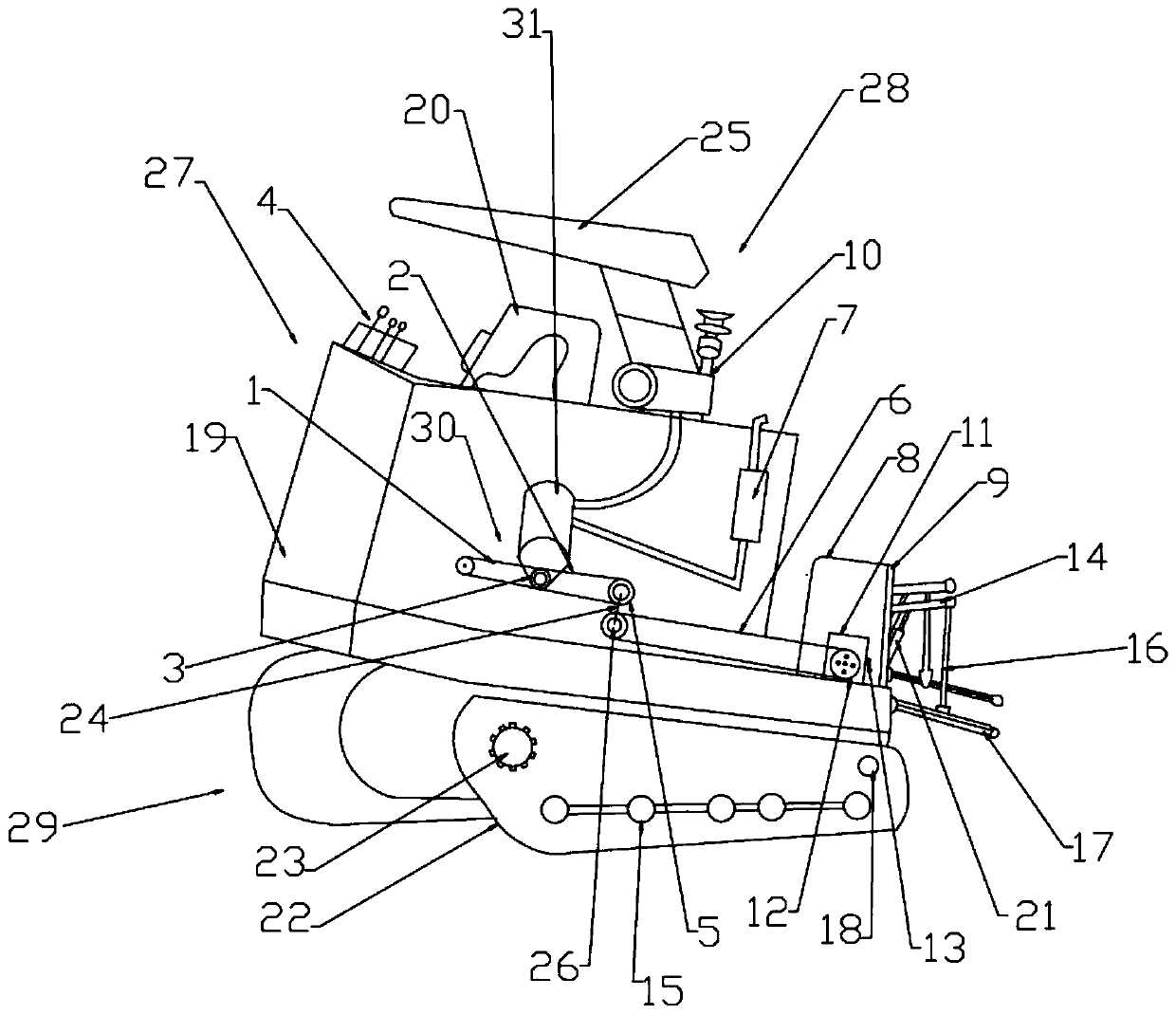

[0018] Such as figure 1 A kind of crawler type cultivator shown comprises cultivator body 27, and organic body case 19, driver's cabin 28 and walking device 29 are arranged on 27 on the cultivator body, and the upper side of body case 19 is provided with driver's cabin 28, and lower A running device 29 is provided on the side, and a power system 30, a guard bar 8, a gear box 11 and a muffler 7 are arranged in the body cover 19, a gear box 11 is arranged below the guard bar 8, and a half shaft 13 is connected to the rear side of the gear box. , the rear side of the body cover 19 is provided with a square pipe 9, and the rear side of the square pipe 9 is connected with an oil cylinder 21. There are two oil cylinders 21, and each oil cylinder 21 is provided with a supporting back 17 on the lower side, and the supporting back 17 is provided on the upper side. There is a pull rod 16, a lifting rod 14 is arranged on the upper side of the pulling rod, and the lifting rod 14 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com