Processing method of sweet potato sheet jelly

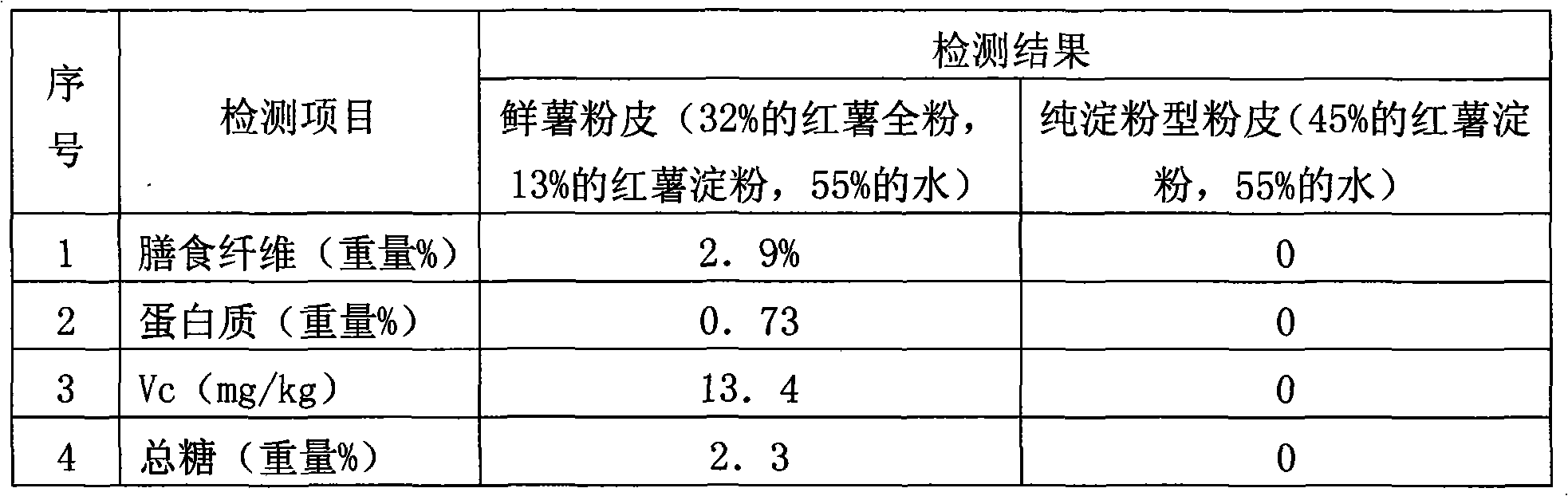

A processing method and technology of sweet potato flour, applied in the field of food or food preparation, can solve the problems of discontinuous production process, loss of nutrients, environmental pollution, etc., and achieve the goal of improving human immunity, reducing vitamin loss, and avoiding by-product pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A processing method for sweet potato vermicelli, comprising the following steps:

[0031] a. Cleaning and crushing: After cleaning the fresh sweet potatoes (which can be peeled or not) with water, they are continuously transported to the pulverizer and crushed into sweet potato slurry with a particle size of less than 3mm;

[0032] B, batching and mixing pulp: known through testing: the weight percent content of water in the sweet potato slurry is 65%, and the sweet potato slurry is the mixed slurry;

[0033]c. Mature molding: send the mixed pulp into a screw extrusion molding machine (this equipment is the prior art, and can be heated by water or steam), and extrude at a speed of 600 to 1200r / min and a temperature of 80°C-140°C Aged and formed into vermicelli, the thickness of the vermicelli can be 0.5-10 mm, and the width can be 2-50 mm;

[0034] d. Continuous conveying: the vermicelli is transported through continuous conveying equipment, so that the vermicelli is c...

Embodiment 2

[0039] A processing method of sweet potato vermicelli, comprising:

[0040] In the step (b) of mixing the ingredients, 0.01 to 5% of the weight of the mixed pulp is added to the mixed pulp, or 0.01 to 20% of esterified modified starch or acetic acid modified starch or hydroxylated modified starch or phosphorylated modified starch is added. Denatured starch, and mix well.

[0041] Others are the same as in Example 1, omitted.

Embodiment 3

[0043] A processing method of sweet potato vermicelli, comprising:

[0044] Step (b) In the mixing of ingredients, 0.01 to 20% of the weight of the mixed pulp is added to the mixed pulp, dietary fiber, β-carotene or taurine, or edible salt of iron, calcium, zinc, etc., and mixed evenly ; Can be made into nutrient-enhanced powder skin.

[0045] Others are the same as in Example 1, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com