System and method for treating red mud through electric arc furnace

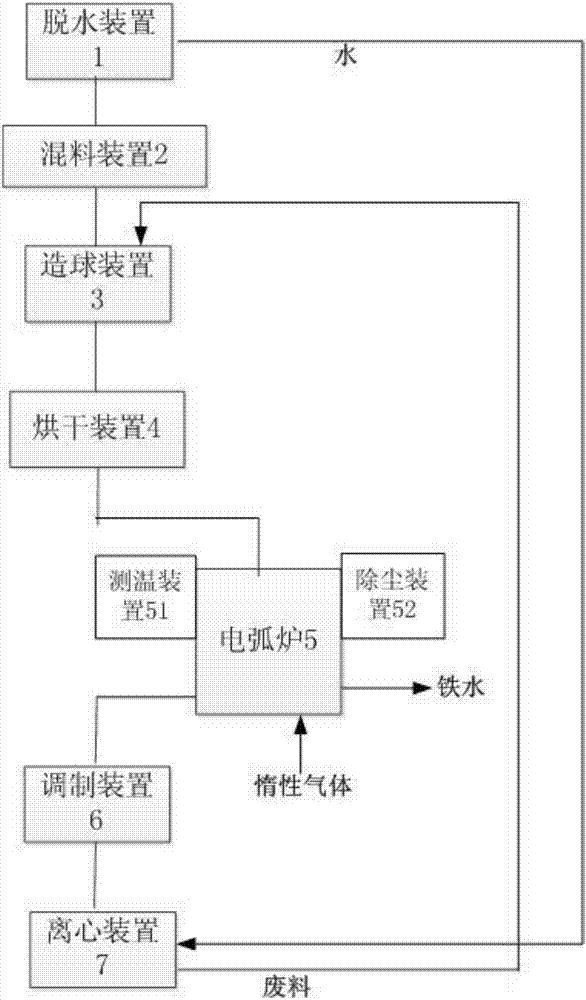

An electric arc furnace and red mud technology, applied in the field of solid waste recycling, can solve the problem that red mud slag cannot be used in large quantities, and achieve the effects of solving solid waste stacking, satisfying the quality of fiber products and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

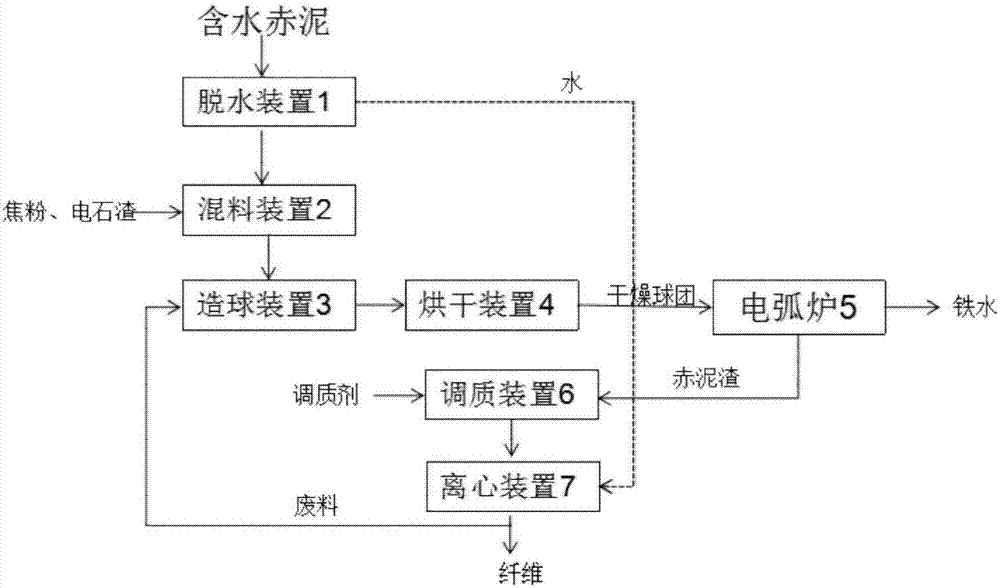

[0059] Such as figure 2 As shown, in this embodiment, the above-mentioned system is used to process red mud, and the red mud of the alkali aluminum plant is used as raw material. The water content of the red mud is 38%. The chemical composition of its main elements is analyzed in Table 1 below.

[0060] Table 1 The main chemical composition of red mud wt.%

[0061]

[0062] R 2 O is a basic oxide, such as Na 2 O and K 2 One or two mixtures of O, because the elements are not fixed, so this representation is used.

[0063] The red mud with a water content of 38% is sent to the dehydration device for dehydration, and the water content of the red mud after pre-dehydration is reduced to 10%. Then the dehydrated red mud enters the mixing device through the belt conveyor, and a certain amount of coke powder and carbide slag enters the mixing device through the lower hopper to form a mixture. Among them, the proportion of coke powder and carbide slag ground to less than 200 m...

Embodiment 2

[0068] Such as figure 2 As shown, in this embodiment, the above-mentioned system is used to process red mud, and the red mud from the Alkali Aluminum Plant is used as the raw material. The water content of the red mud is 32%. The chemical composition of its main elements is analyzed in Table 3 below.

[0069] Table 3 The main chemical composition of red mud wt.%

[0070]

[0071] R 2 O is a basic oxide, such as Na 2 O and K 2 One or two mixtures of O, because the elements are not fixed, so this representation is used.

[0072] The red mud with a water content of 32% is sent to the dehydration device for dehydration, and the water content of the red mud after pre-dehydration is reduced to 10%. Then the dehydrated red mud enters the mixing device through the belt conveyor, and a certain amount of coke powder and carbide slag enters the mixing device through the lower hopper to form a mixture. Among them, the proportion of coke powder and carbide slag ground to less than...

Embodiment 3

[0077] Such as figure 2 As shown, in this embodiment, the above-mentioned system is used to process red mud, and the red mud of the alkali aluminum plant is used as raw material, and the water content of the red mud is 30%.

[0078] Table 5 Main chemical composition of red mud wt.%

[0079]

[0080] R 2 O is a basic oxide, such as Na 2 O and K 2 One or two mixtures of O, because the elements are not fixed, so this representation is used.

[0081] The red mud with a water content of 30% is sent to the dehydration device for dehydration, and the water content of the red mud after pre-dehydration is reduced to 10%. Then the dehydrated red mud enters the mixing device through the belt conveyor, and a certain amount of coke powder and carbide slag enters the mixing device through the lower hopper to form a mixture. Among them, the proportion of coke powder and carbide slag ground to less than 200 mesh is more than 60%, and the mass ratio of red mud, carbide slag and coke p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com