Patents

Literature

32results about How to "Fully participate in the response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bamboo charcoal-polyvinyl formal biological carrier and preparation thereof

InactiveCN101428901AImprove toughnessHigh strengthSustainable biological treatmentBiological water/sewage treatmentPolyvinyl alcoholEconomic benefits

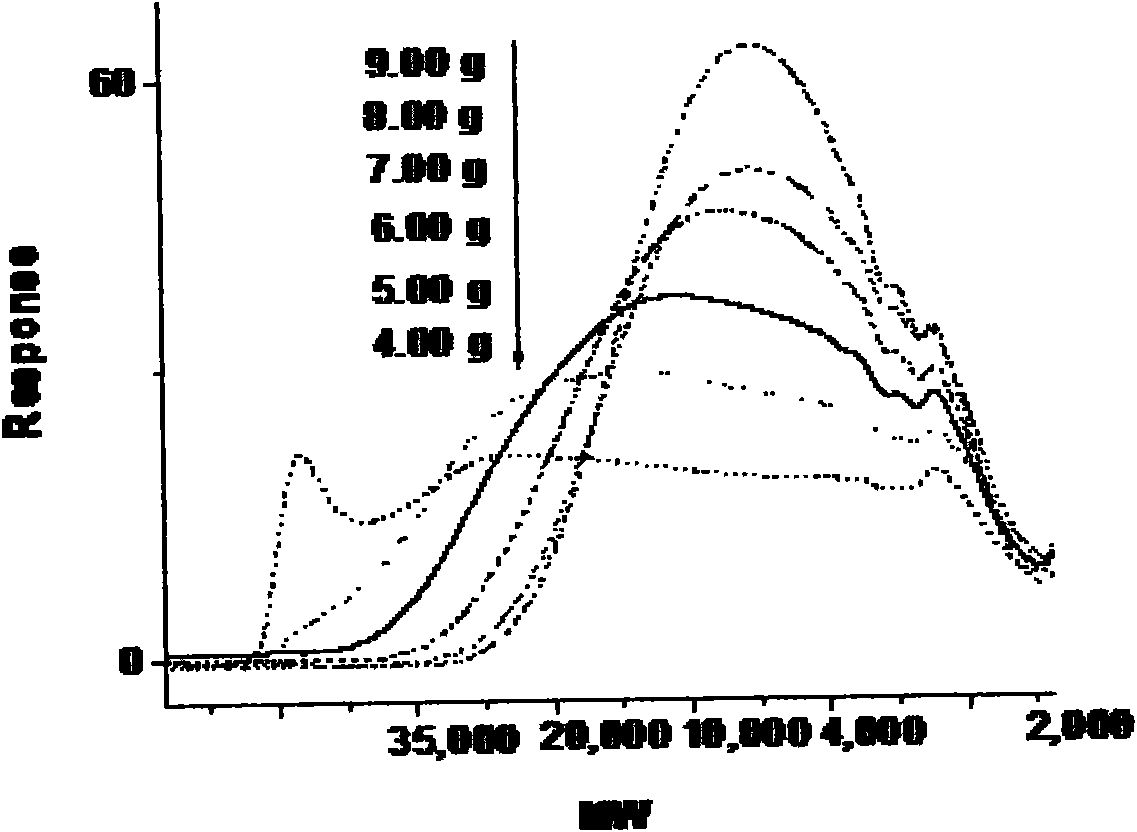

The invention provides a bamboo carbon-polyvinyl formal biological carrier for water treatment and a process for preparing the same. The bamboo carbon-polyvinyl formal biological carrier is designed for solving the technical problems of high price, high abrasion ratio, large density, easy fragile, and difficult cleaning and replacement in the prior biological carrier active carbon and the inorganic carrier, and is produced by using polyvinyl formal as the organic polymer carrier, and adding filler such as bamboo-carbon for foaming treatment of calcium carbonate and citric acid. The prepared product has the characteristics of communication pore, multiple pores, micro pores, has large specific surface and biological compatibility, facilitates bacteria laminating and carries a large amount of bacteria, can fully meet the application requirements of suspended filler for water treatment, has great scientific and social significance, and can create good environmental, social and economic benefits if being popularized and applied.

Owner:SHENYANG NORMAL UNIV

Diffusion welding connecting method adopting Cu foil and Ti foil as composite interlayer

ActiveCN109014549AForm to avoidFully consider compatibilityWelding/soldering/cutting articlesNon-electric welding apparatusRoom temperatureHeating furnace

The invention relates to a method for connecting a nickel-based superalloy with a Ti2AlNb alloy or a Ti3Al-based alloy, in particular to a diffusion welding connecting method adopting Cu foil and Ti foil as a composite interlayer. The diffusion welding connecting method comprises the steps that the nickel-based superalloy and the Ti2AlNb alloy or the Ti3Al-based alloy are processed into the neededsizes, ground and polished; the Cu foil and the Ti foil are subjected to oxidation film removing, and are placed into acetone with a welded base material to be subjected to ultrasonic cleaning; and the Cu foil makes contact with the nickel-based superalloy, the Ti foil makes contact with the Ti2AlNb alloy or the Ti3Al-based alloy, and thus a welded test piece with the structure of the Ti2AlNb alloy or the Ti3Al-based alloy / the Ti foil / the Cu foil / the nickel-based superalloy is obtained, a welded workpiece is placed into a vacuum heating furnace, the pressure is applied, and welding is completed after heating, heat preservation and cooling heat circulating. The welding temperature can be lowered, forming of a brittle phase of a joint is controlled, and the property of the joint is improved; and the obtained shearing strength of the joint at the room temperature reaches 240-310 MPa.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

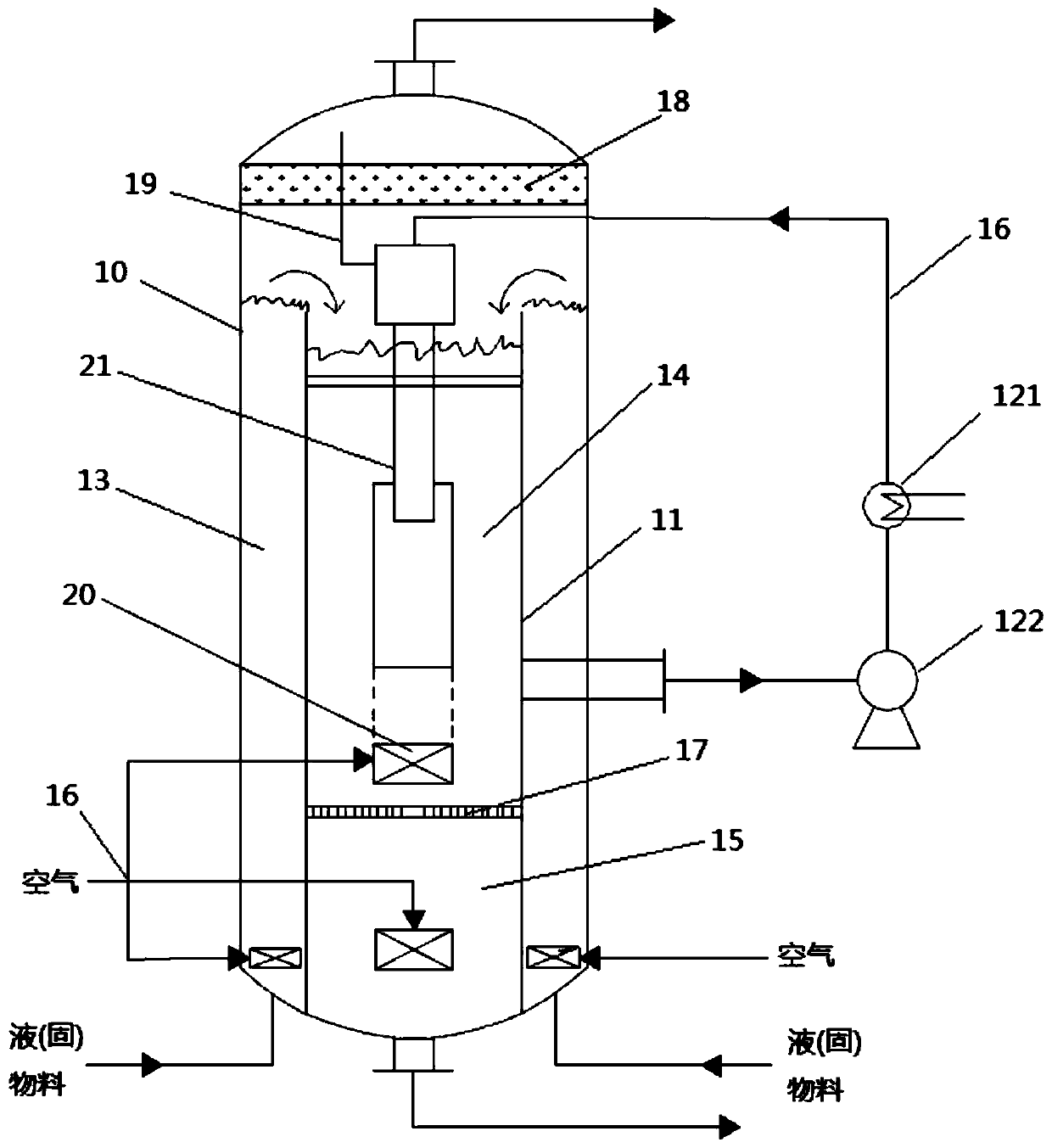

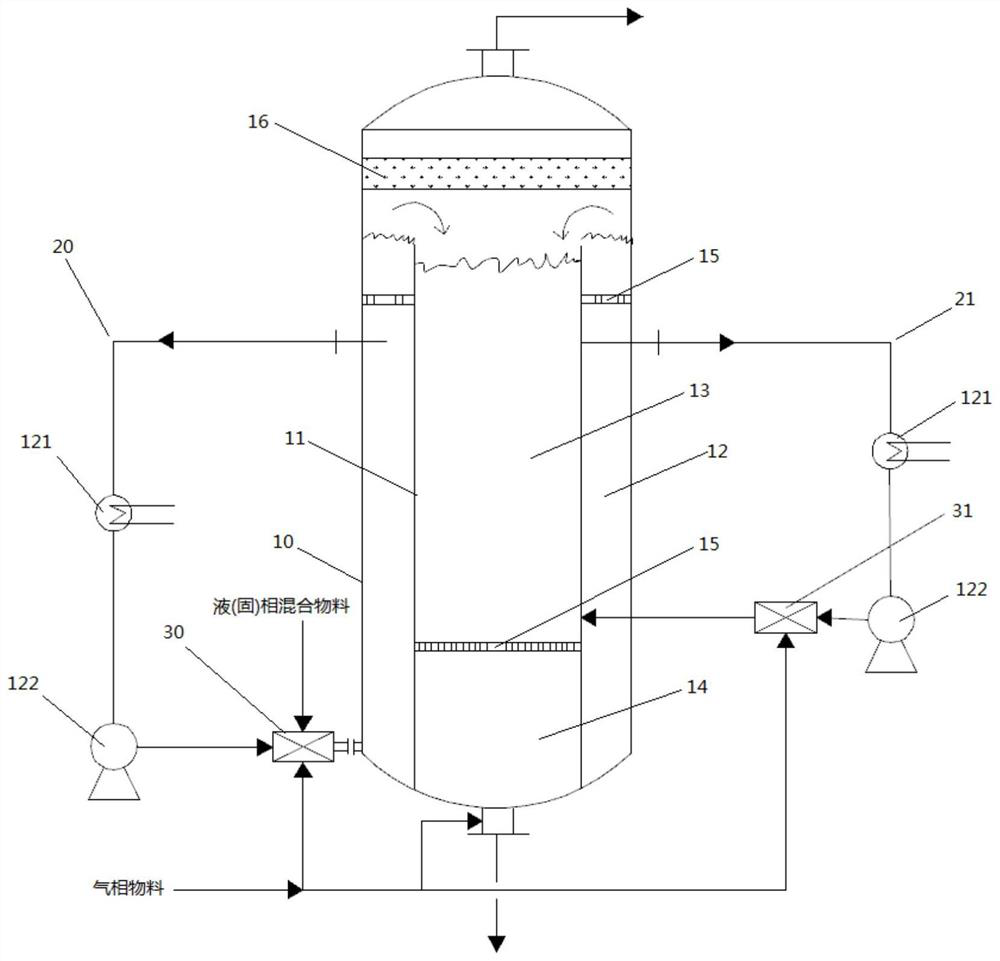

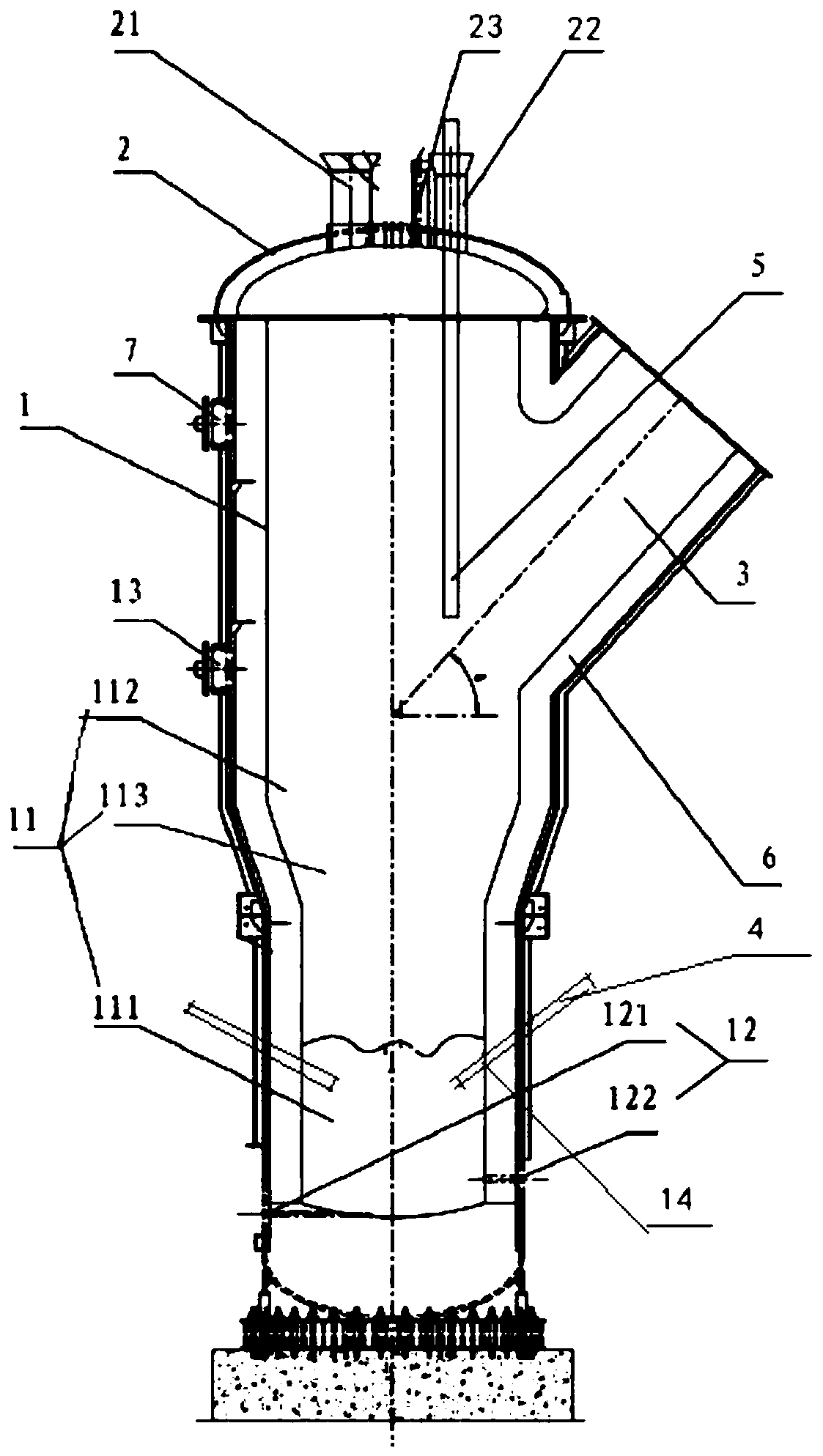

Built-in micro-interface unit enhanced reaction system for producing PTA through PX and process thereof

ActiveCN111389314ASolve the contradiction of not being able to withstand high temperature oxidation conditionsReduce energy consumptionLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationAcetic acidEthylic acid

The invention provides a built-in micro-interface unit enhanced reaction system for producing PTA through PX and a process thereof. The system comprises a reactor and a micro-interface unit arranged in the reactor. The reactor comprises a shell, an inner barrel concentrically arranged in the shell, and a circulating heat exchange device partially arranged outside the shell; wherein the bottom endof the inner cylinder is connected to the inner bottom surface of the shell in a closed manner, the top end of the inner cylinder is open, an area between the shell and the inner cylinder is a first reaction area, a second reaction area and a third reaction area are sequentially arranged in the inner cylinder from top to bottom, and the circulating heat exchange device is respectively connected with the inner cylinder and the micro-interface unit. According to the method, the problems that a large amount of reaction solvent acetic acid is wasted at high temperature and high pressure and a product TA cannot be taken out in time in the existing process of producing PTA through PX are effectively solved, so that the energy consumption is greatly reduced, an acetic acid solvent is saved, and the reaction efficiency is improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

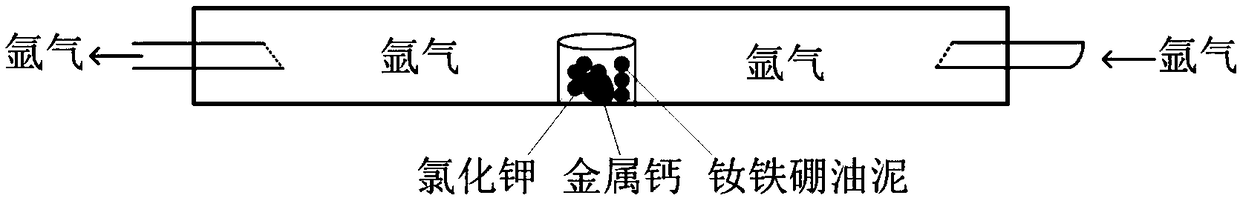

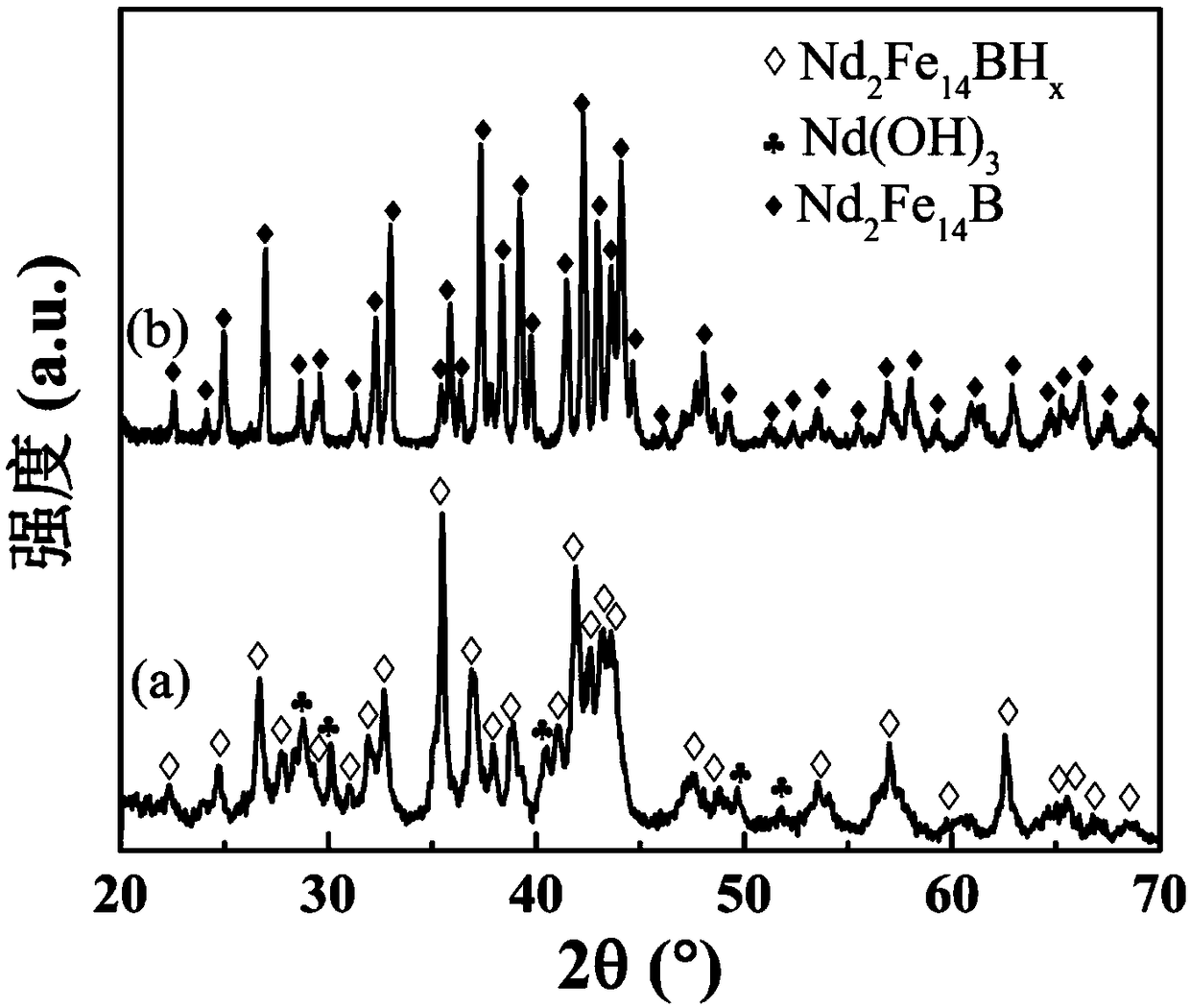

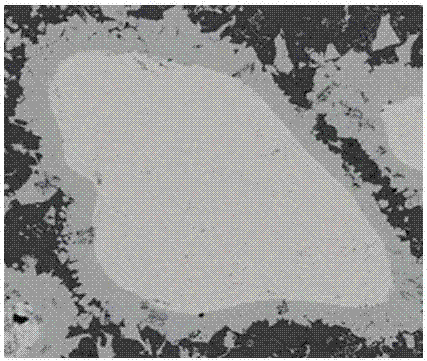

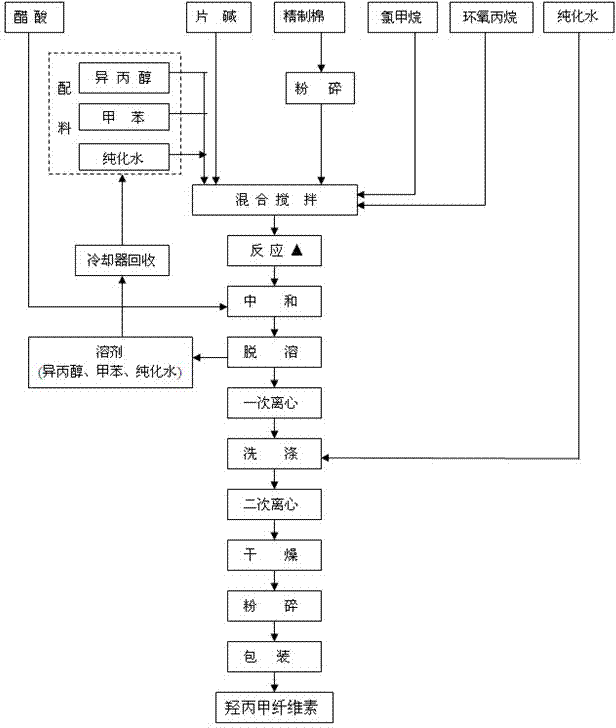

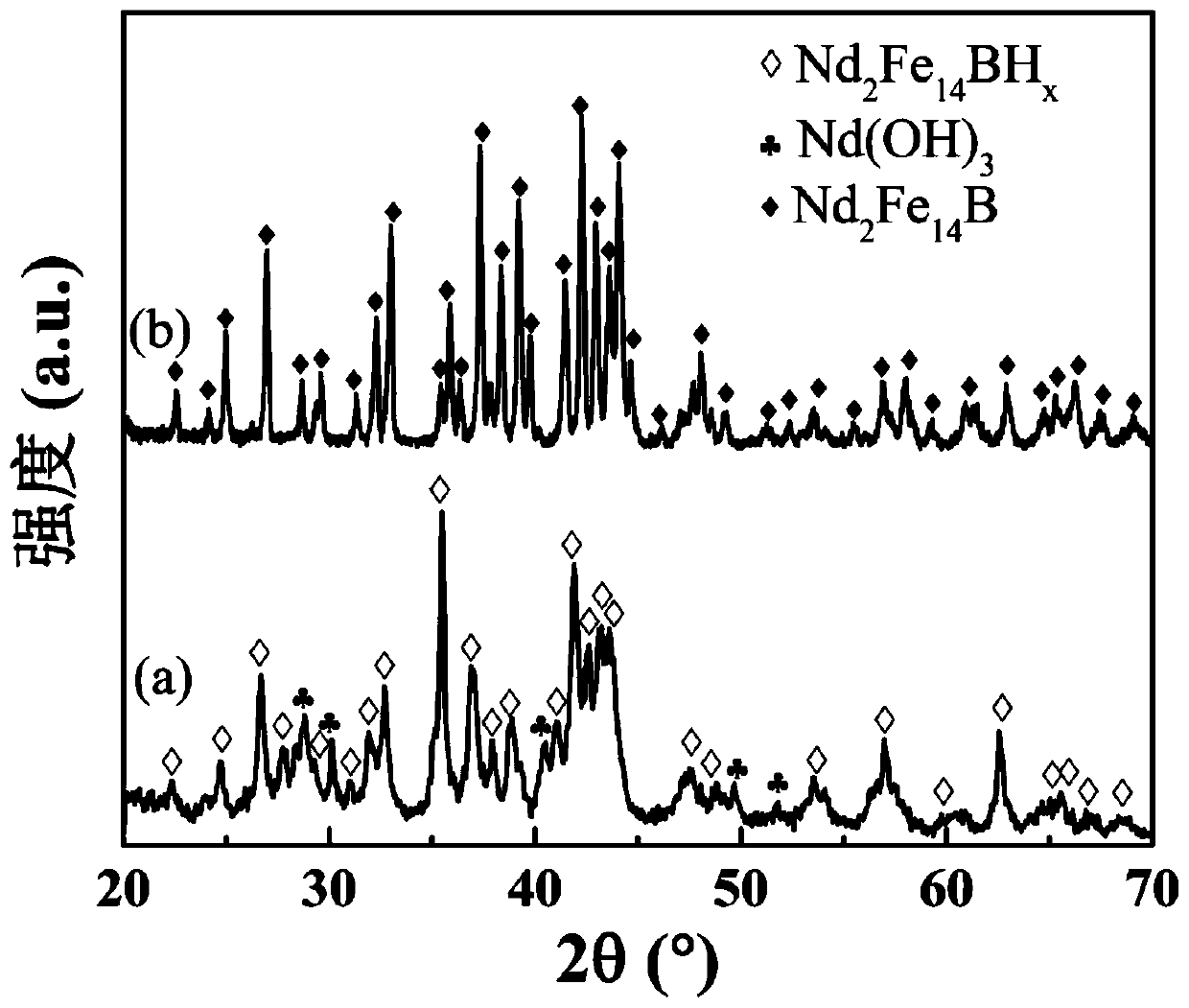

Method for recovering neodymium iron boron trepanning oil sludge waste through Ca-chloride reduction diffusion technology

ActiveCN109338113AHigh recovery rateAchieve recyclingTransportation and packagingMetal-working apparatusSintered magnetsOil sludge

The invention discloses a method for recovering neodymium iron boron trepanning oil sludge waste through a Ca-chloride reduction diffusion technology, and belongs to the technical field of recycling of rare-earth permanent-magnet industrial solid waste. The method includes the technological processes of drying of the oil sludge waste containing sintered neodymium iron boron, Ca-chloride reductiondiffusion, low-temperature soaking and calcium removal, doping of rare-earth-rich alloy powder, sintering, heat treatment and the like. The neodymium iron boron trepanning oil sludge waste serves as araw material, Ca-KCl is used for direct reduction diffusion to obtain regenerated neodymium iron boron magnetic powder, the powder is recycled, and a regenerated sintered magnet is prepared through the sintering technology. In the method, potassium chloride serves as a low-melting-point auxiliary agent so that the reaction temperature can be reduced, the reaction time can be shortened, the recycling rate is increased, and the use amount of metal calcium is reduced. Low-temperature calcium removal is adopted, the powder can be prevented from being oxidized, and the calcium removal efficiency is improved. By using the rare-earth-rich alloy, rare earth can be supplemented, and component adjustment and industrial production are facilitated. According to the method, the purposes of shorteningthe recycling technology, reducing the recycling cost, reducing the environmental burden and increasing the waste utilization rate are achieved.

Owner:BEIJING UNIV OF TECH

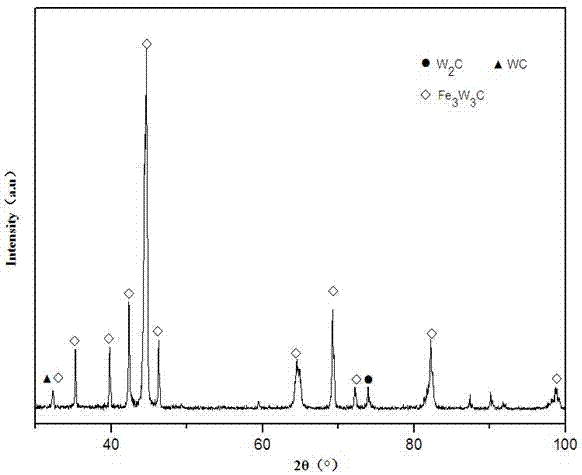

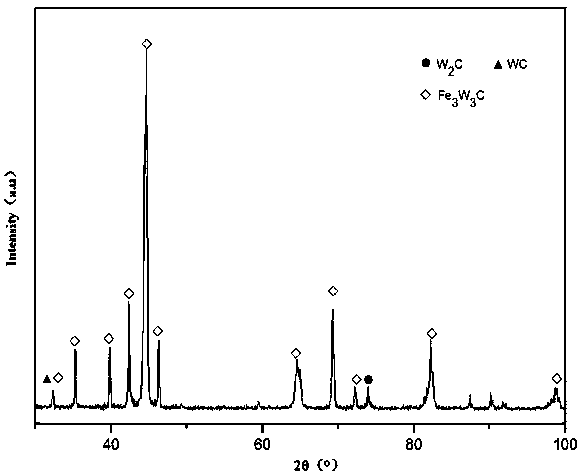

Preparation method of M6C type alloy carbide Fe3W3C

ActiveCN107227416AHigh purityAccurate Mechanical PropertiesPhase analysisMechanical properties of carbon nanotubes

The invention discloses a preparation method of M6C type alloy carbide Fe3W3C and belongs to the technical field of new materials. The method comprises the steps that Fe powder and WC powder are used as raw materials, and after the raw materials are uniformed mixed, sintering is conducted through a spark plasma sintering (SPS) and vacuum interface remelting method; then, after an obtained sintering sample is crushed, phase analysis is conducted; other impurity phases are removed through an acid pickling method, and deacidification treatment, drying treatment and the like are conducted on the powder; and then, sintering is conducted on the powder, so that a ternary carbide Fe3W3C material is finally obtained. The ternary phase carbide Fe3W3C prepared through the method contains few impurities; in addition, the preparation temperature is low; an obtained structure is uniform and good in mechanical performance; and great significance is achieved for researching microcosmic interfaces of tungsten-carbide-reinforced-steel (iron)-based composites.

Owner:KUNMING UNIV OF SCI & TECH

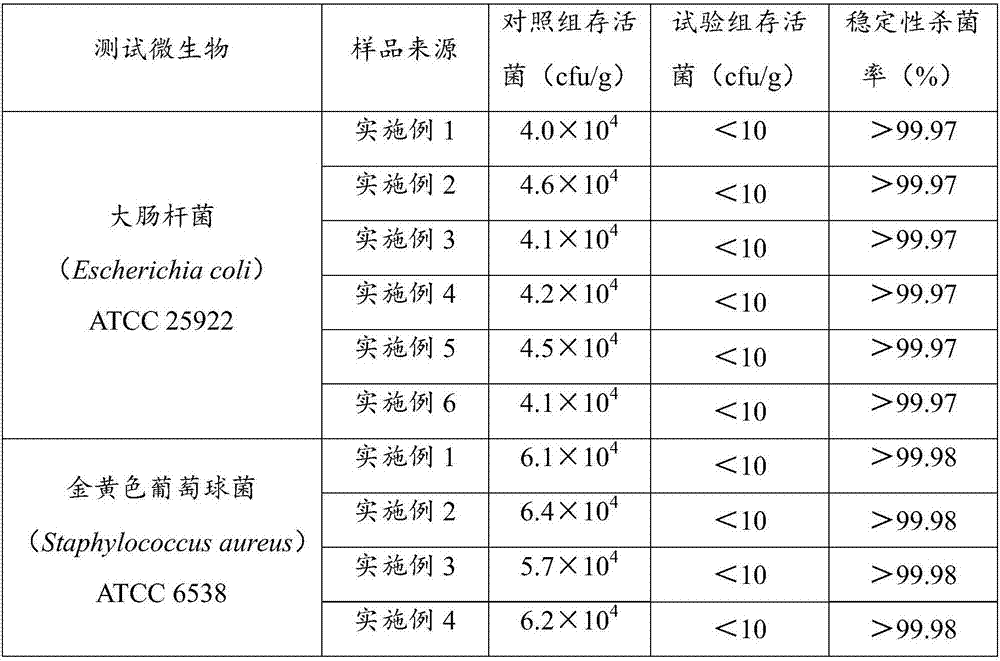

Ozone vegetable oil emulsifier composite and preparation method and application thereof

InactiveCN107028817ASignificant antibacterial and bactericidal effectQuality improvementCosmetic preparationsHair cosmeticsVegetable oilHair follicle

The invention discloses an ozone vegetable oil emulsifier composite and a preparation method and application thereof, relates to the technical field of additives of daily chemical products, and aims at solving the technical problems that an existing emulsifier cannot effectively achieve oxygen supplying for the skin, cleaning of skin and follicles pili dirt, mite removing and inflammation diminishing. The ozone and vegetable oil emulsifier composite is mainly prepared from the following components in percentage by weight: 30-50% of ozone vegetable oil, 10-20% of emulsifier, 25-50% of water, 1-8% of humectant, and 9-15% of surfactant. The invention also provides the preparation method of the ozone and vegetable oil emulsifier composite. The method has the advantages of being simple in process, and outstanding in product quality. The invention also provides the application of the ozone and vegetable oil emulsifier composite. Wash supplies adopting the ozone vegetable oil emulsifier composite has the effects of supplying oxygen to the skin, cleaning the skin and follicles pili dirt, removing mite, and diminishing inflammation.

Owner:安徽嘉宝诺生物科技有限公司

Method for remelting and smelting metal electro slag

The invention discloses a method for remelting and smelting metal electro slag. The electro slags are placed into a crystallizer, an electrode is inserted from an upper position, then the electrode is energized to enable the electrode, the electro slags and short net guide wires in the crystallizer to be switched on to form a current loop, and during the energizing, joule heat is discharged by the electrode and a slag pool, metal slag in the slag pool are molten, the molten metal is converged into a liquid state to flow through the slag pool to fall into the crystallizer to form a metal molten pool, and then the metal molten pool is solidified to form steel ingots; at the same time, during the smelting, auxiliary materials using aluminum particles as the main bodies are added, and the deoxygenation is carried out. The method is characterized in that during the smelting, the electrode is firstly inserted into the upper positions of the electro slags, the electro slags start to melt to fall into the crystallizer to form the metal molten pool, the electrode is controlled to slowly move downwards to be smelted, and the auxiliary materials are continuously and uniformly fed in a linkage control manner when the electrode move downwards. The method has the advantages of low cost, easy implement, automatic feeding of the auxiliary materials during smelting, stable and reliable feeding control process of the auxiliary materials, good smelting effect and the like.

Owner:宝武特冶航研科技有限公司

Method for treating nitrobenzene waste water

ActiveCN102417249ALow costSolve the emission problemWater contaminantsMultistage water/sewage treatmentCoal waterEmulsion polymerization

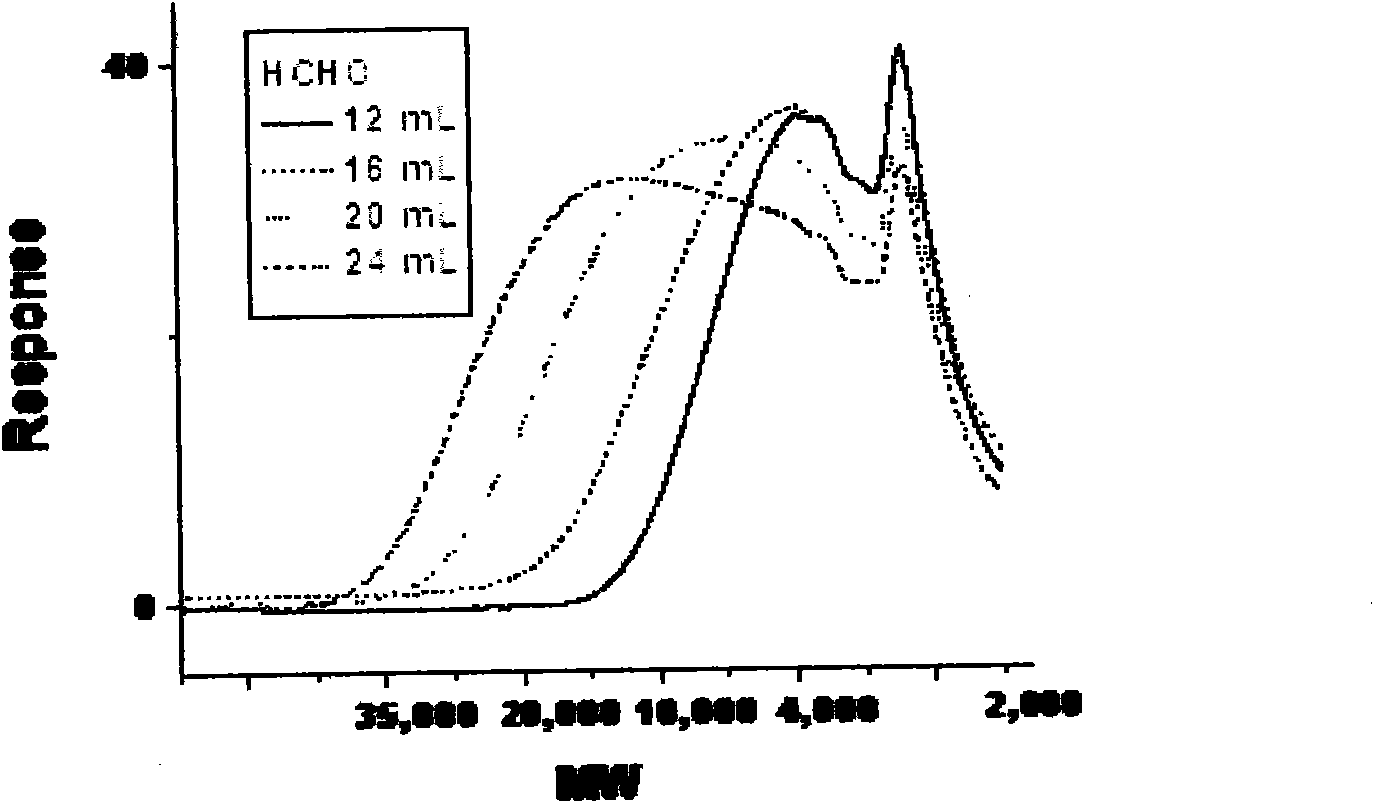

The invention relates to a method for treating nitrobenzene waste water. The method comprises steps of: step 1. according to a molar ratio, taking 50 parts of nitrobenzene waste water with a pH of 9-13 and adding 0.2-0.4 parts of sulfonating agent; step 2. adding 1-2 parts of ketone compound or acrylic acid compound into the nitrobenzene waste water for acetone sulfonation reaction; step 3. adding 2-4 parts of aldehyde compound or oxirane into nitrobenzene waste water for condensation polymerization; step 4. adding 450-950 parts of nitrobenzene waste water, continuing the condensation polymerization in step 3. for 0.5-1.0 h, thereby preparing a coal water slurry additive with an effective concentration of 0.5-1%. According to the method for treating nitrobenzene waste water of the invention, the coal water slurry additive is prepared in the waste water phase through solution polymerization, so as to avoid environmental pollution caused by discharge of nitrobenzene waste water and realize reuse of nitrobenzene waste water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ozone vegetable oil emulsifier composition for toothpaste and preparation method thereof

InactiveCN107028816AGood sterilization and anti-inflammatoryActive synergyCosmetic preparationsToilet preparationsVegetable oilMathematical Calculus

The invention discloses an ozone vegetable oil emulsifier composition for toothpaste and a preparation method thereof, and relates to the technical field of additives of daily chemical products. The technical problems that an oral cavity oxygen supply effect cannot be realized by utilizing an existing emulsifier and effects of sterilizing and diminishing inflammation to an oral cavity and clearing dental calculus are poor are solved. The ozone vegetable oil emulsifier composition for the toothpaste disclosed by the invention is prepared from the following components in percentage by weight: 20 to 40% of ozone vegetable oil, 8 to 20% of an emulsifier, 20 to 40% of water, and 30 to 50% of a friction agent. The invention also provides a preparation method of the ozone vegetable oil emulsifier composition for the toothpaste, which comprises a step of dissolving and mixing all components to prepare the ozone vegetable oil emulsifier composition for the toothpaste. The ozone vegetable oil emulsifier composition has the advantages of simple method, good quality of products and the like, and is mainly applied to production and preparation of the ozone vegetable oil emulsifier composition for the toothpaste.

Owner:安徽嘉宝诺生物科技有限公司

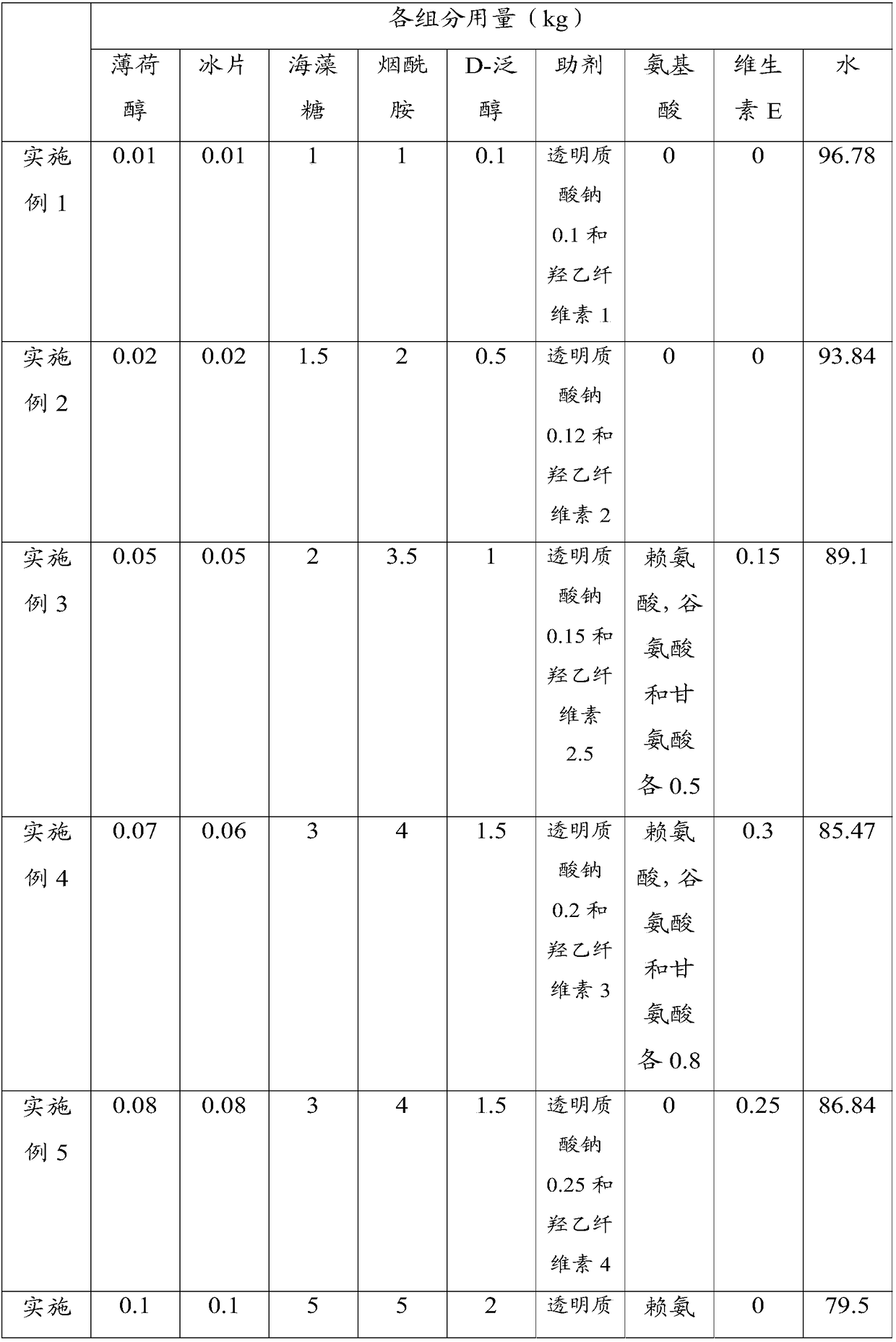

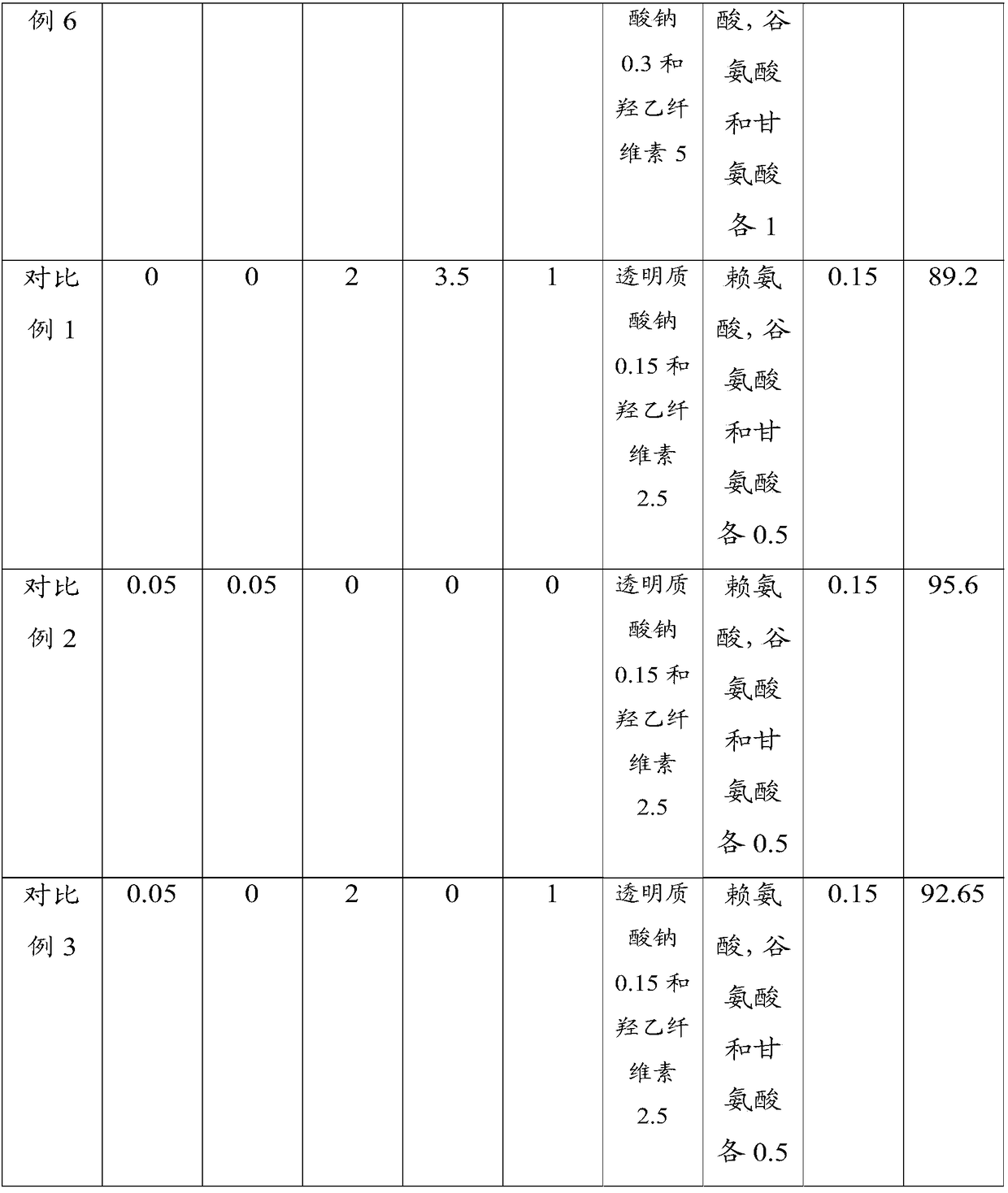

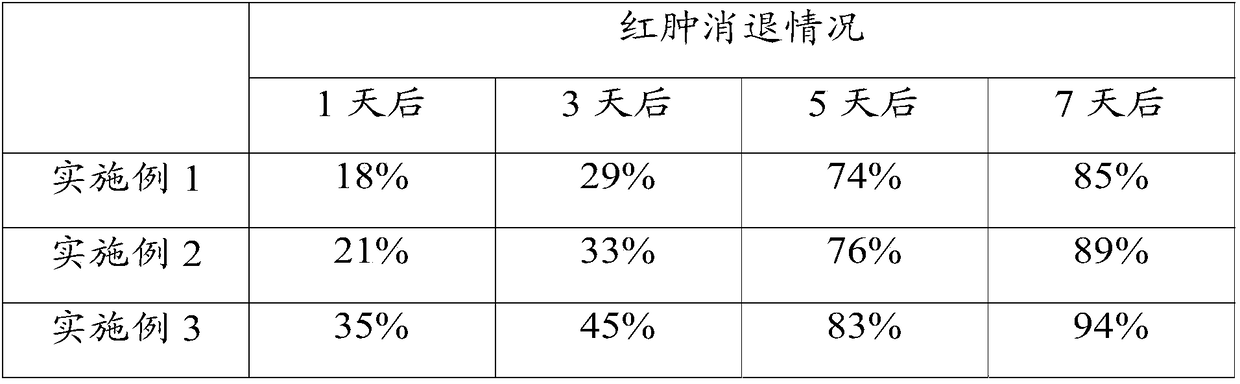

Medicine for repairing skin injuries and preparation method thereof

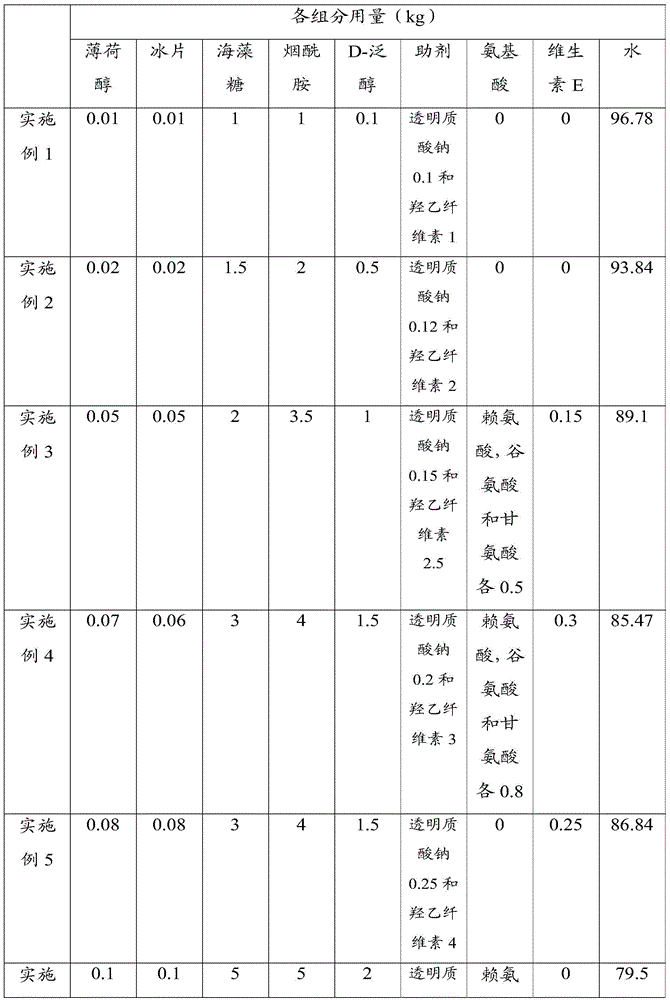

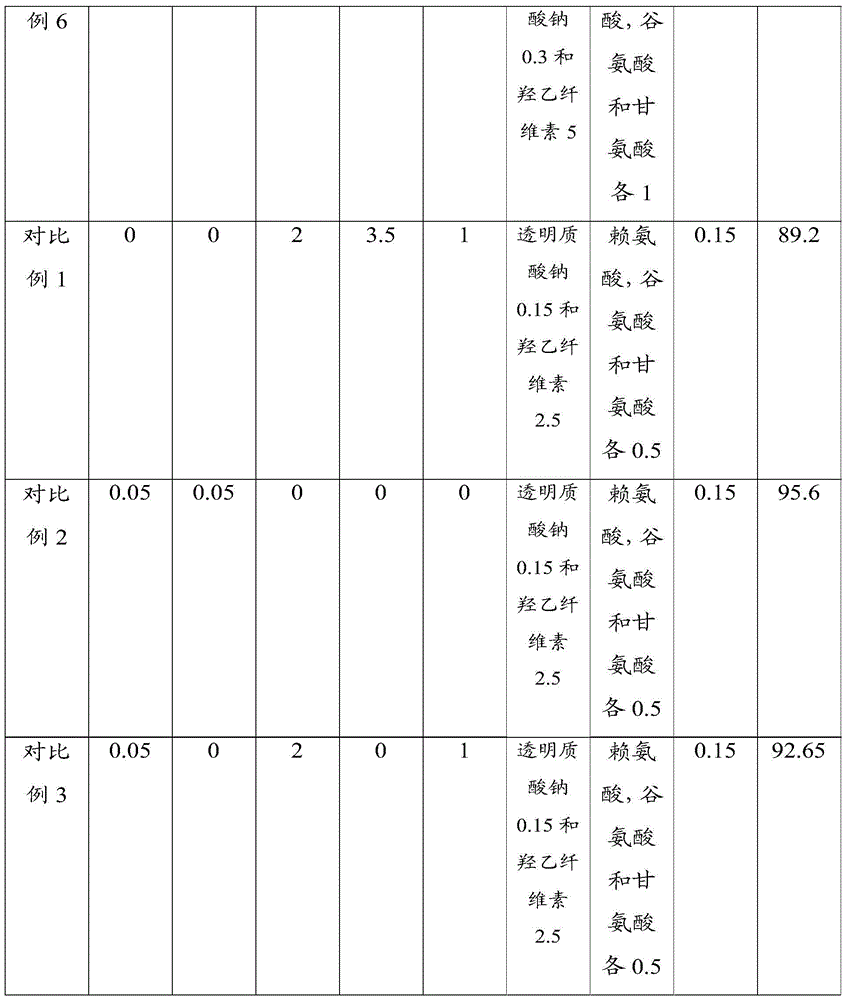

ActiveCN105412141ANo side effectsAvoid stimulationHydroxy compound active ingredientsAntipyreticMentholSkin surface

The invention provides a medicine for repairing skin injuries and a preparation method thereof. The medicine is prepared from, by weight, 0.01-0.1 part of menthol, 0.01-0.1 part of borneol, 1-5 parts of trehalose, 1-5 parts of niacinamide, 0.1-2 parts of D-panthenol, 0.1-0.3 part of sodium hyaluronate, 1-5 parts of hydroxyethyl cellulose and 82-97 parts of water. The preparation method includes the steps that water, menthol, borneol, trehalose, niacinamide, sodium hyaluronate and hydroxyethyl cellulose are mixed and heated, then the mixture is cooled, D-panthenol is added, and the medicine is obtained after mixing. According to the medicine, due to the fact that menthol, borneol, trehalose, niacinamide and D-panthenol are used for compatibility according to scientific matching, the components have a positive synergistic effect, the medicine can relieve swelling and pain and has the relieving and calming effect, a layer of breathable protective film is formed on the surface of injured skin, the outside world is prevented from stimulating the injured skin, and therefore the injured skin can be fast repaired.

Owner:长睿生物技术(成都)有限公司

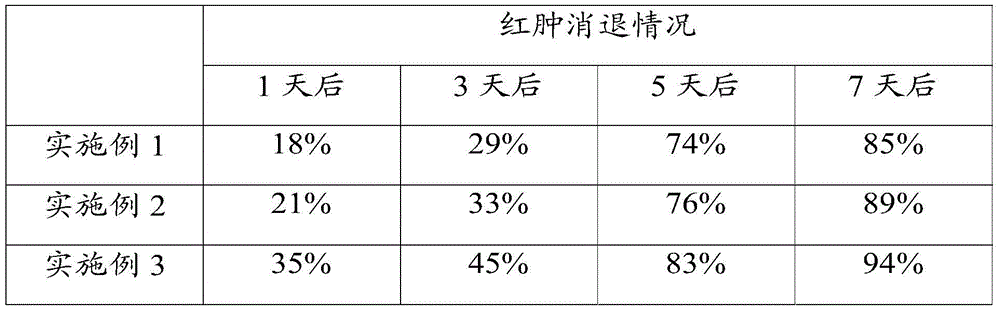

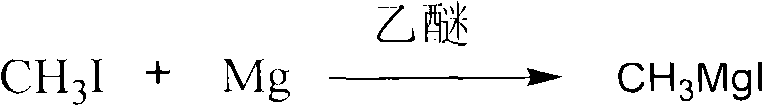

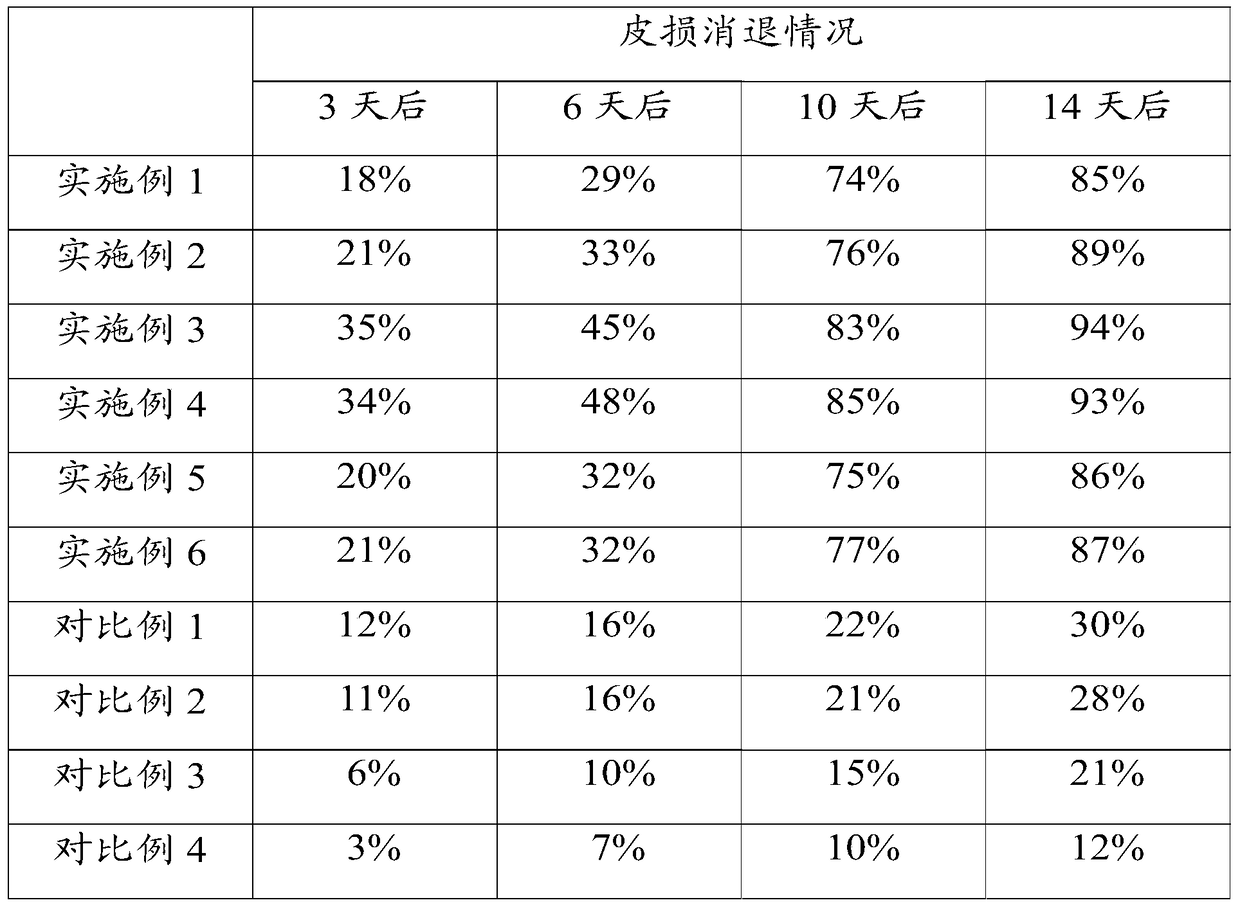

Chemical reaction device for fully recycling gas raw material

ActiveCN101898105ALow costEasy to operateOrganic compound preparationChemical/physical/physico-chemical processesSiphonChemical reaction

The invention relates to a chemical reaction device for fully recycling a gas raw material. The chemical reaction device is characterized by comprising a reactor, two cooling devices, two anti-siphon bubbling devices and two nitrogen bubbling devices, wherein the cooling devices are connected with the reactor through two gas pipes which are provided with pipe clamps; the cooling devices are connected with the anti-siphon bubbling devices through a gas pipe, and a three-way valve is connected on the gas pipe between the cooling devices and the anti-siphon bubbling devices; and the nitrogen bubbling devices are connected on the three-way valve. The chemical reaction device has the advantages of convenient operation, capabilities of recycling the gas raw material and making the gas raw material fully participate in the reaction, and furthest reduction of the use cost of the gas raw material.

Owner:无锡贝塔医药科技有限公司

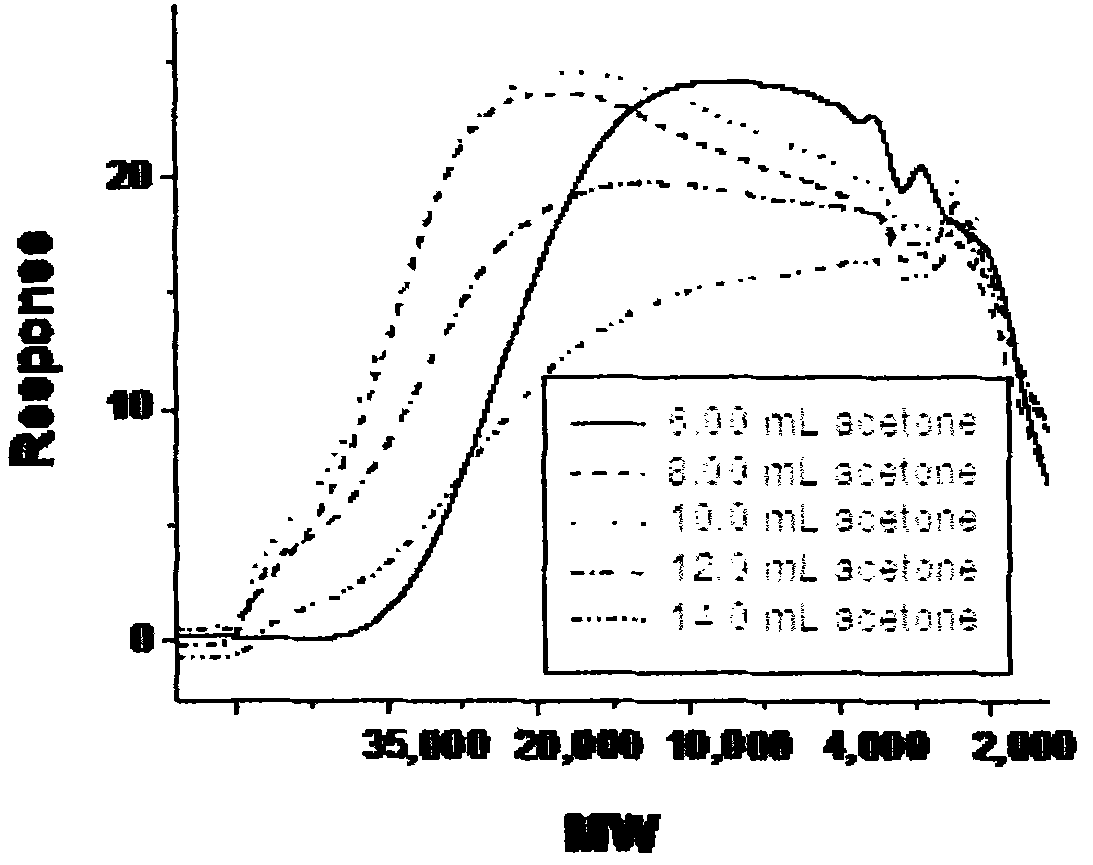

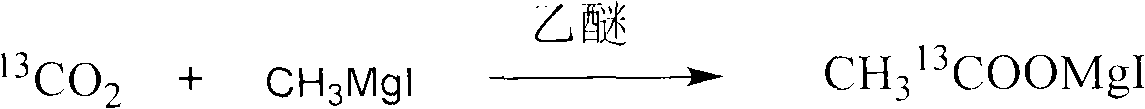

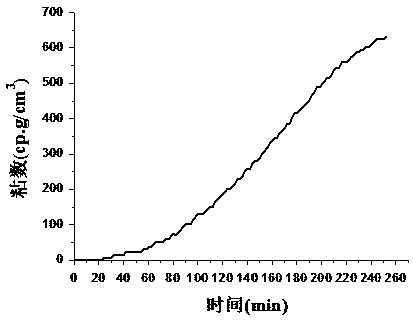

Process for producing pharmaceutical auxiliary material hydroxypropyl methylcellulose through slurry process

InactiveCN103788215AIncrease productionReduce indicator variancePharmaceutical non-active ingredientsPharmacySlurry

The invention belongs to the technical field of pharmacy, and particularly relates to a process for producing pharmaceutical auxiliary material hydroxypropyl methylcellulose through a slurry process. The process comprises the following steps of: blending; reacting; desolventizing; washing; drying; packaging. By adopting the process, the single batch output of the hydroxypropyl methylcellulose is increased, and the single batch output is increased nearly twice from the output in a common method; because the indices of batches have certain difference, larger single batch output can better reduce the index difference of the batches. The process disclosed by the invention is larger in single batch output and reduces the processing cost of ton products.

Owner:山东光大科技发展有限公司

A method for recovering NdFeB casing sludge waste by ca-chloride reduction diffusion technology

ActiveCN109338113BHigh recovery rateAchieve recyclingTransportation and packagingMetal-working apparatusSintered magnetsOil sludge

Owner:BEIJING UNIV OF TECH

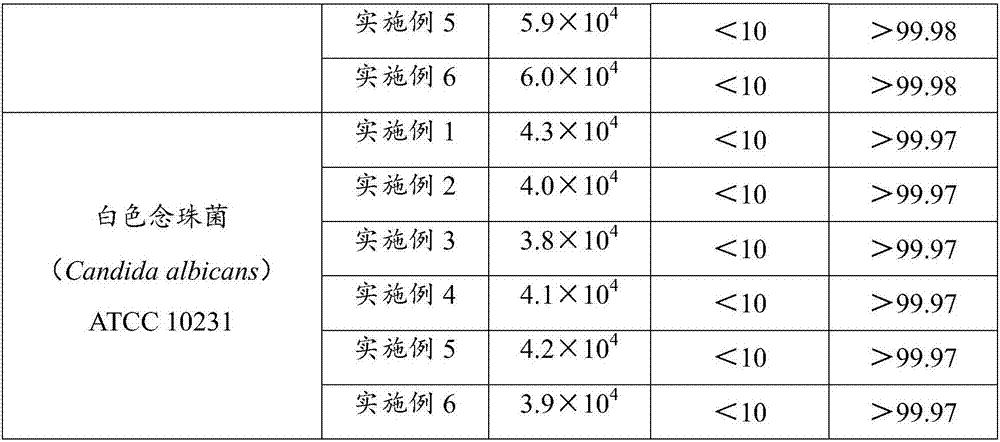

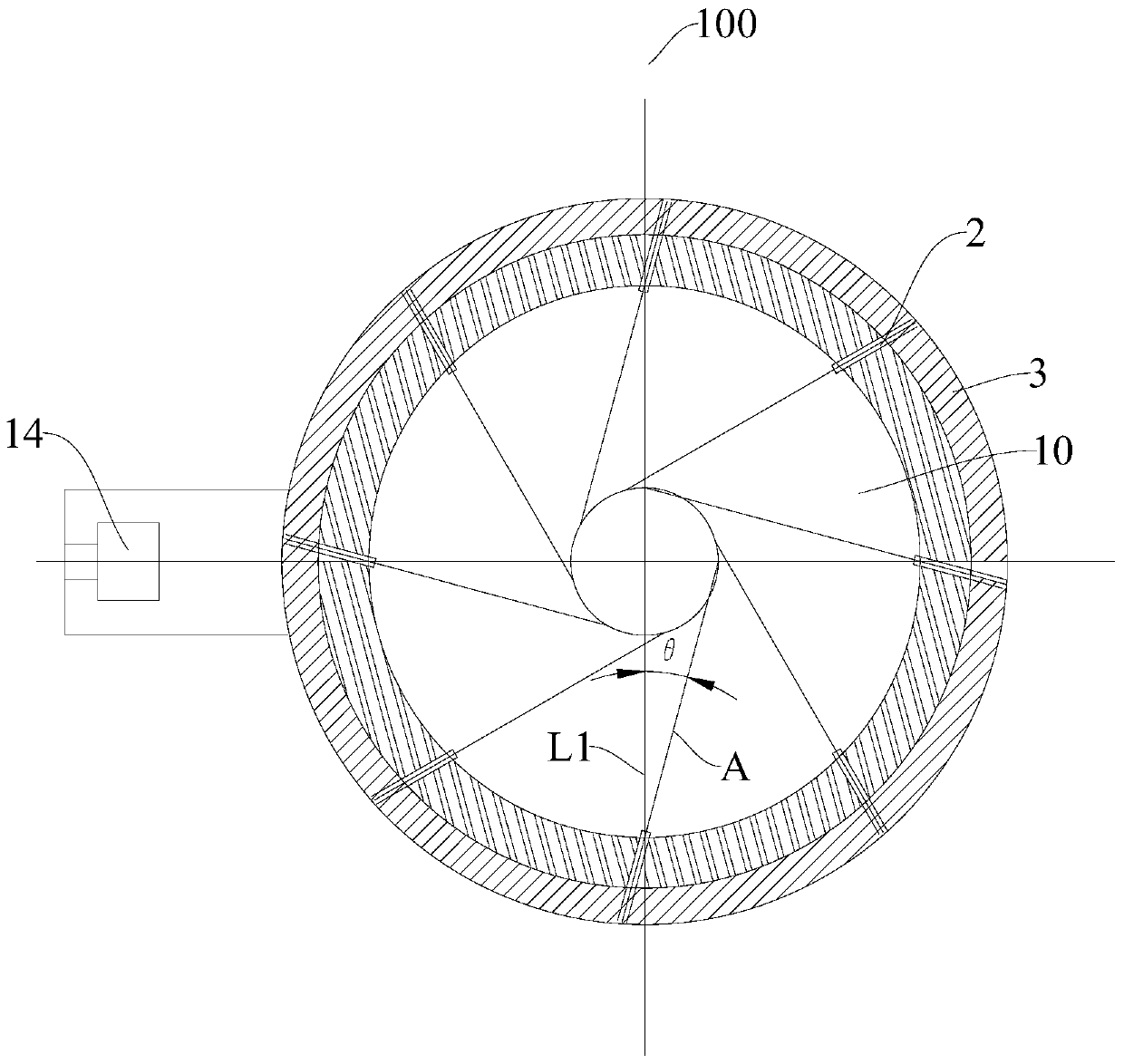

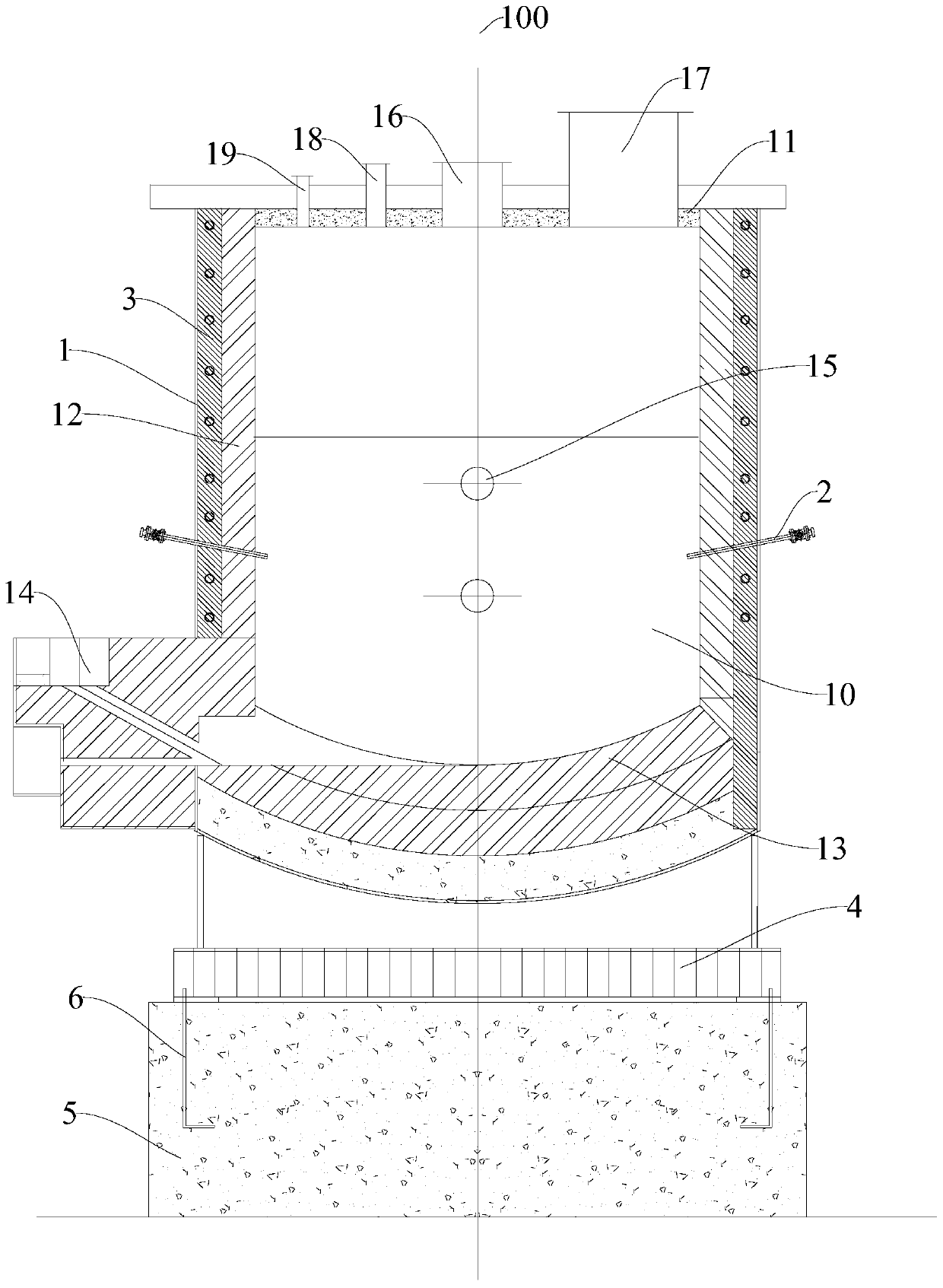

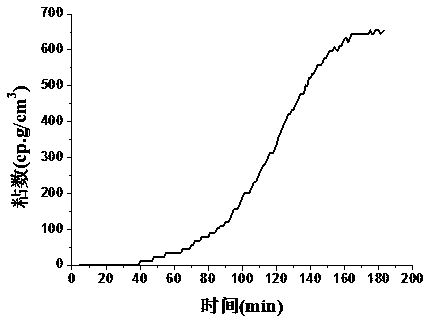

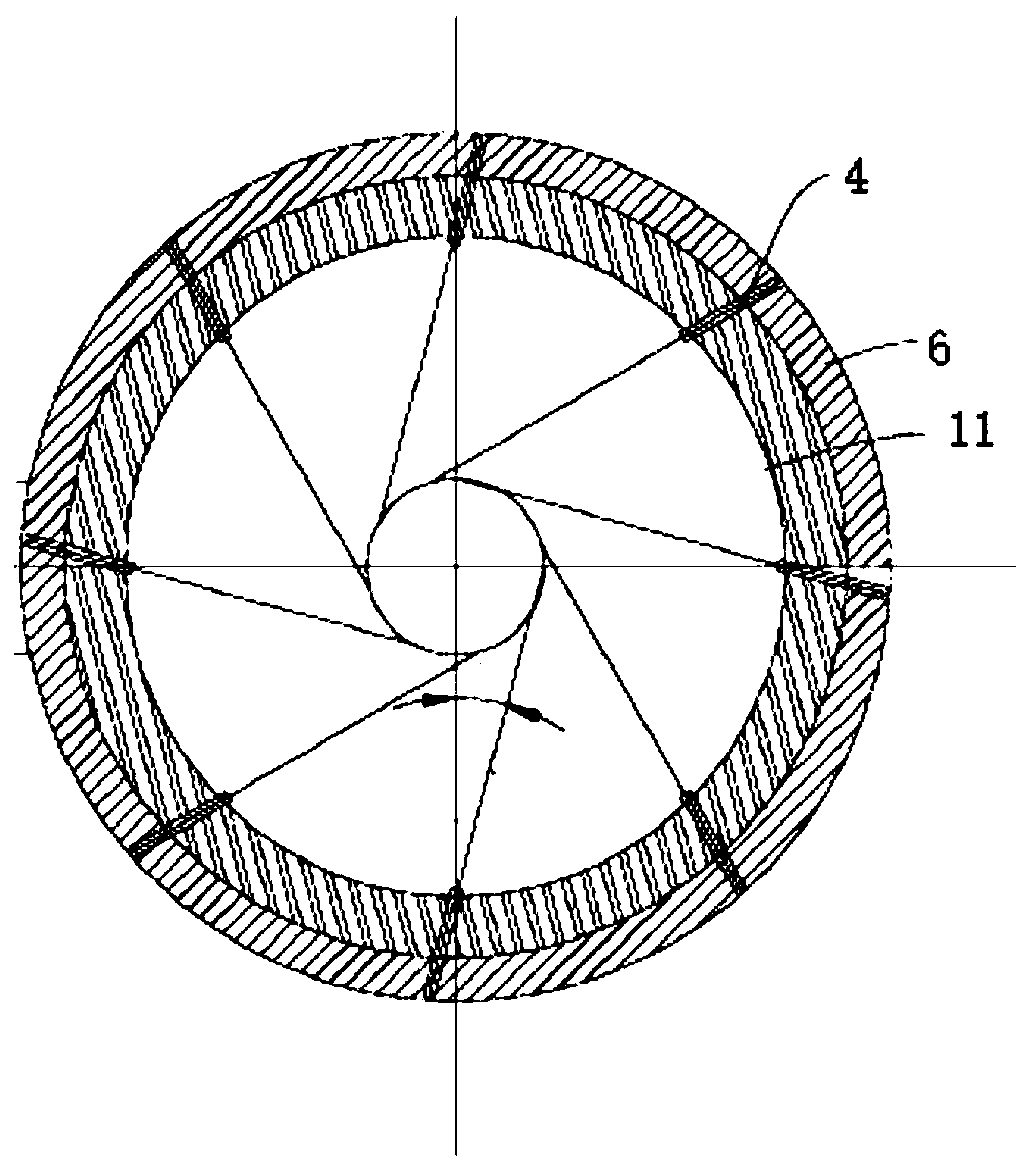

Melting pool melting furnace

ActiveCN104848682BSpeed up meltingEasy to handleFurnace cooling arrangementsCrucible furnacesPower consumptionSmelting

The invention discloses a molten pool smelting furnace, which comprises: a furnace body and a plurality of spray guns. The furnace body has a furnace chamber with a circular cross section. multiple spray gun sockets. The spray guns are inserted into the spray gun sockets, and the multiple spray guns deviate from the center of the circular cross-section of the furnace cavity along the same direction. The melting pool melting furnace according to the embodiment of the present invention has the advantages of low energy consumption and good melting effect.

Owner:CHINA ENFI ENGINEERING CORPORATION

Silicon-magnesium laterite-nickel ore cold sintering ball and preparation method thereof

InactiveCN101705354AStrong water absorptionReduce nickel contentProcess efficiency improvementSlagCoke rate

The invention discloses a silicon-magnesium laterite-nickel ore cold sintering ball concretely, which is characterized by being prepared from silicon-magnesium laterite-nickel raw ore and a consolidation agent, wherein the consolidation agent is selected from one or more of steel slag powder, wood chip, reed canes and paper scrap and accounts for 5-10% of the total weight; and the diameter of the cold sintering ball is 30-60mm and the strength is 50-200kg / cm2. A preparation method of the cold sintering ball comprises the following working procedures: (1) drying the silicon-magnesium laterite-nickel ore in air until moisture is smaller than or equal to 20%; (2) grinding the silicon-magnesium laterite-nickel ore until granularity is smaller than or equal to 0.5mm; (3) mixing the silicon-magnesium laterite-nickel ore with the consolidation agent with granularity less than or equal to 0.5mm; and (4) using a ball forming mill for cold pressing the mixture into silicon-magnesium laterite-nickel ore cold sintering ball with diameter of 30-60mm and strength of 50-200kg / cm2. The preparation method of the cold sintering ball has the advantages of good furnace conditions when smelting nickel, good slag flowability, good air permeability, uniform combustion, high bed output ability, low coke rate, and low nickel content of slag.

Owner:张玉山

Silicon-magnesium laterite-nickel ore cold sintering ball and preparation method thereof

InactiveCN101705354BStrong water absorptionReduce nickel contentProcess efficiency improvementCombustionSlag

Owner:张玉山

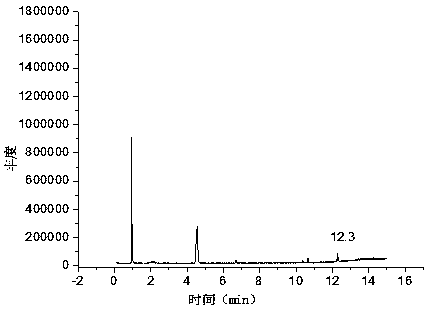

A kind of preparation method of pet copolyester

Owner:ZHEJIANG HENGYI HIGH TECH MATERIAL

Esterification conversion method of gulonic acid

PendingCN110746388AReduce moistureShorten the high temperature reaction timeOrganic chemistrySodium bicarbonateSodium ascorbate

The invention relates to an esterification conversion method of gulonic acid. The method comprises: uniformly mixing industrial methanol and concentrated sulfuric acid, adding a gulonic acid dry product in a stirring state, carrying out a methyl esterification reaction in a staged temperature changing manner, sequentially adding sodium bicarbonate and deionized water, heating, carrying out a conversion reaction, cooling after the reaction is finished, and carrying out centrifugal separation to obtain the sodium ascorbate. According to the invention, the gulonic acid esterification conversion method is simple in process, easy to operate, low in cost, capable of greatly increasing the molar conversion rate from gulonic acid to VC sodium (increased by 1.5-3.2% compared with the prior art) andsuitable for large-scale production.

Owner:NINGXIA QIYUAN PHARMA

A kind of sulfone polymer composition and its preparation method and thermoplastic molding composition composed of it

A sulfone polymer composition and preparation method thereof, and thermoplastic molding composition therefrom, comprising: (A) at least one aromatic sulfone polymer; (B) one compound of 4,4′-dichlorodiphenyl sulfone; wherein, based on the total weight of the sulfone polymer composition, 4,4′-dichlorodiphenyl sulfone weight content is less than 600 ppm. In the preparation method, tetramethylene sulfone is used as a solvent, 4,4′-dichlorodiphenyl sulfone and 4,4′-Dihydroxydiphenyl sulfone or 4,4′-dihydroxy biphenyl are used as reactive monomers, while the mixed salt of sodium carbonate and potassium carbonate is used as salt-forming agent, the composition may be obtained by polymerization with solution polymerization techniques; wherein the molar ratio of the said potassium carbonate and sodium carbonate is 0.1: 100-5: 100. The sulfone polymer composition has a transmittance greater than 85%, a haze less than 4%, and a yellowness index less than 5, enjoying a significantly improved transparency and color levels.

Owner:KINGFA SCI & TECH CO LTD

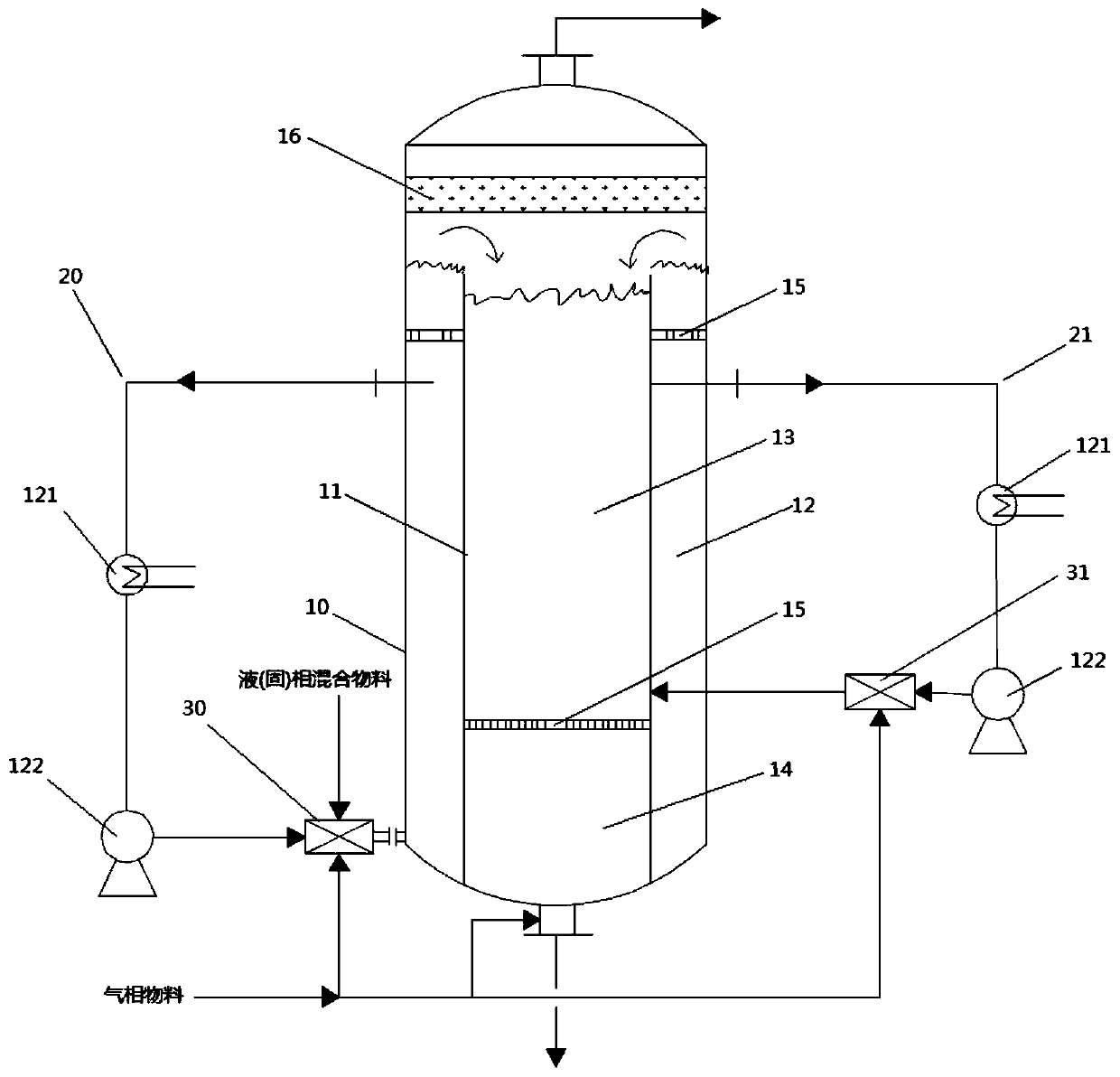

External micro-interface unit enhanced oxidation system for producing PTA from PX

ActiveCN111569814ASolve wasteReduce energy consumptionLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationChemistryProcess engineering

The invention provides an external micro-interface unit enhanced oxidation system for producing PTA from PX. The external micro-interface unit enhanced oxidation system comprises a reactor, a circulating heat exchange device and a micro-interface unit, wherein the reactor comprises a shell and an inner barrel concentrically arranged in the shell; the circulating heat exchange device is arranged outside the reactor, is separately connected with the shell and the inner barrel, and is used for adjusting the reaction temperatures of a first reaction zone, a second reaction zone and a third reaction zone in the reactor in the reaction process; and the micro-interface unit is arranged between and connected with the reactor and the circulating heat exchange device and is connected with an external feeding pipeline of the reactor. The system of the invention overcomes the problems that a large amount of a reaction solvent, namely acetic acid is wasted at high temperature and high pressure anda product TA cannot be taken out in time in the existing process of producing PTA from PX, so energy consumption is greatly reduced, the acetic acid solvent is saved, and reaction efficiency is improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

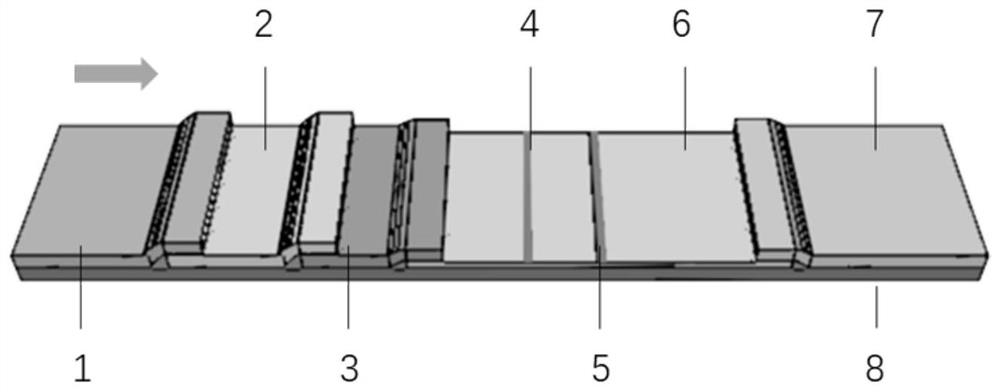

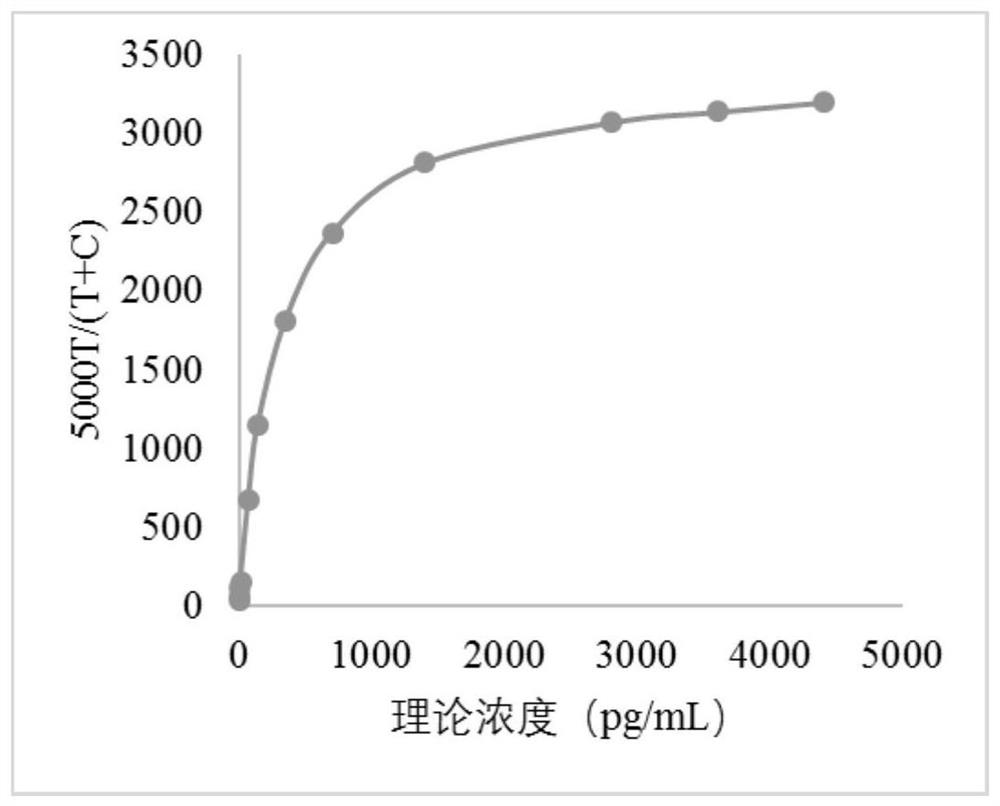

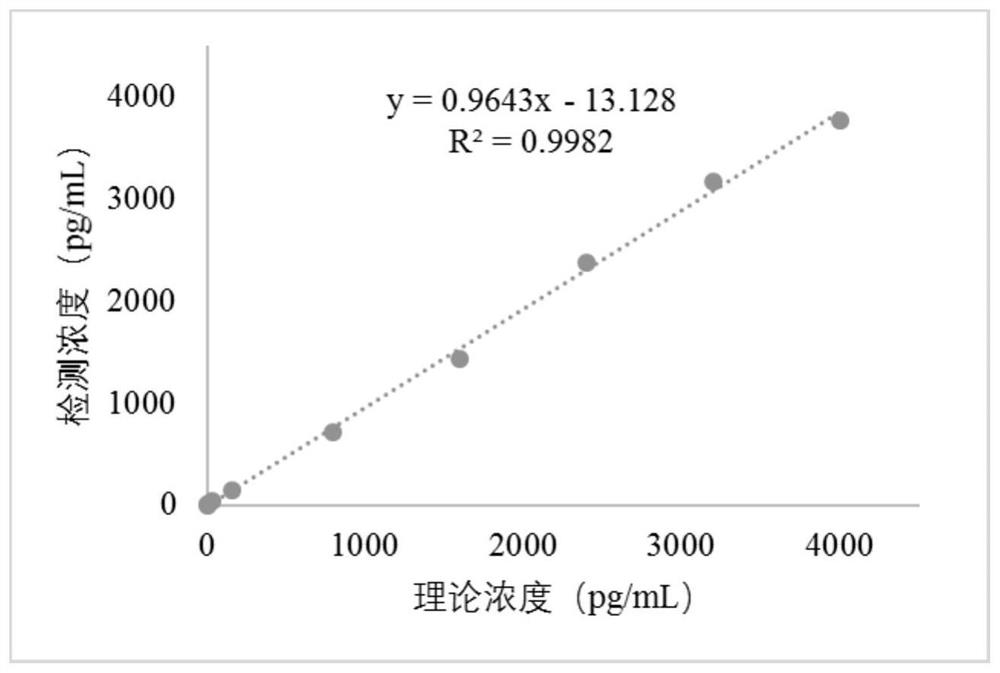

IL-6 fluorescence immunochromatography kit and preparation method thereof

PendingCN114594251AHigh detection sensitivityImprove detection accuracyMaterial analysisMedicineMicrosphere

The invention discloses an IL-6 fluorescence immunochromatography kit and a preparation method thereof, and relates to the technical field of biological medicines. The kit comprises a sample pad, a combination pad, a buffer pad, a coating film and an absorption pad which are arranged on a bottom plate, the combination pad is provided with an anti-IL-6 monoclonal antibody marked with fluorescent latex microspheres and a DNP-BSA antibody marked with fluorescent latex microspheres, the coating film is provided with a detection T line and a quality control C line, the detection T line is coated with the anti-IL-6 monoclonal antibody, the quality control C line is coated with the DNP-BSA antibody, and the quality control C line is coated with the DNP-BSA antibody. And the quality control C line is coated with an X anti-DNP polyclonal antibody. The kit can improve the detection sensitivity of IL-6, improve the detection accuracy and shorten the detection time.

Owner:上海艾瑞德生物科技有限公司

PX produces PTA's external micro-interface unit to strengthen the oxidation system

ActiveCN111569814BSolve the contradiction of not being able to withstand high temperature oxidation conditionsReduce energy consumptionLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationAcetic acidThermodynamics

The present invention provides an enhanced oxidation system with an external micro-interface unit for producing PTA from PX, comprising: a reactor, a circulation heat exchange device and a micro-interface unit; wherein, the reactor includes a shell and is concentrically arranged inside the shell The inner cylinder; the circulation heat exchange device is arranged outside the reactor, and is connected with the outer shell and the inner cylinder respectively, so as to adjust the first reaction zone and the second reaction zone inside the reactor. And the reaction temperature in the reaction process of the third reaction zone; the micro-interface unit is connected between the reactor and the circulation heat exchange device, and is connected with the external feed pipe of the reactor. The present invention effectively solves the problem that the reaction solvent acetic acid is wasted in large quantities under high temperature and high pressure in the existing PX production process of PTA, and the problem that the product TA cannot be taken out in time at the same time, thereby greatly reducing energy consumption, saving acetic acid solvent, and improving the Reaction efficiency.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Smelting furnace

InactiveCN110145936AEasy to handleFully participate in the responseCrucible furnacesFurnace floorsSmelting

The invention provides a smelting furnace. The furnace comprises a furnace body and a plurality of spray guns, wherein a cavity with an open upper end is defined in the furnace body, the cavity is provided with a small-diameter area and a large-diameter area located above the small-diameter area, the inner diameter of the large-diameter area is larger than the inner diameter of the small-diameterarea, a discharge port and a plurality of spray gun ports are formed in the small-diameter area, and the plurality of spray gun ports are distributed at intervals along the circular cross section of the small-diameter area; and the spray guns are inserted into the spray gun ports, the plurality of spray guns deviate from the circle center of the circular cross section of the furnace body at the same angle in the same direction, the spray guns are arranged obliquely downwards relative to the horizontal direction, and the included angle between connection lines of the spray-blowing ends of the spray guns and the circle center of the circular cross section of the small-diameter area and the spray-blowing direction of the spray guns is 15 degrees. The smelting furnace has the advantages of lowenergy consumption, good smelting effect, and further being capable of reducing emission of harmful gas and avoiding environment pollution.

Owner:HAIAN HAITAI CASTING

Medicine for repairing skin damage and preparation method thereof

ActiveCN105412141BNo side effectsAvoid stimulationHydroxy compound active ingredientsAntipyreticMentholMedicine

The invention provides a medicine for repairing skin damage and a preparation method thereof. In parts by weight, the raw material components of the drug include: 0.01-0.1 parts of menthol, 0.01-0.1 parts of borneol, 1-5 parts of trehalose, 1-5 parts of nicotinamide, 0.1-2 parts of D-panthenol, transparent 0.1-0.3 parts of sodium hyaluronate, 1-5 parts of hydroxyethyl cellulose and 82-97 parts of water. The preparation method includes: mixing water, menthol, borneol, trehalose, nicotinamide, sodium hyaluronate and hydroxyethyl cellulose Heating after mixing, then cooling down, then adding D-panthenol, mixing to obtain the drug. The drug combines menthol, borneol, trehalose, nicotinamide, and D-panthenol in accordance with the scientific ratio. The various components have a positive synergistic effect, which can reduce swelling, relieve pain, relieve sedation, and protect the damaged skin surface. Form a layer of breathable protective film to prevent the damaged skin from external stimulation, so that the damaged skin can be repaired quickly.

Owner:长睿生物技术(成都)有限公司

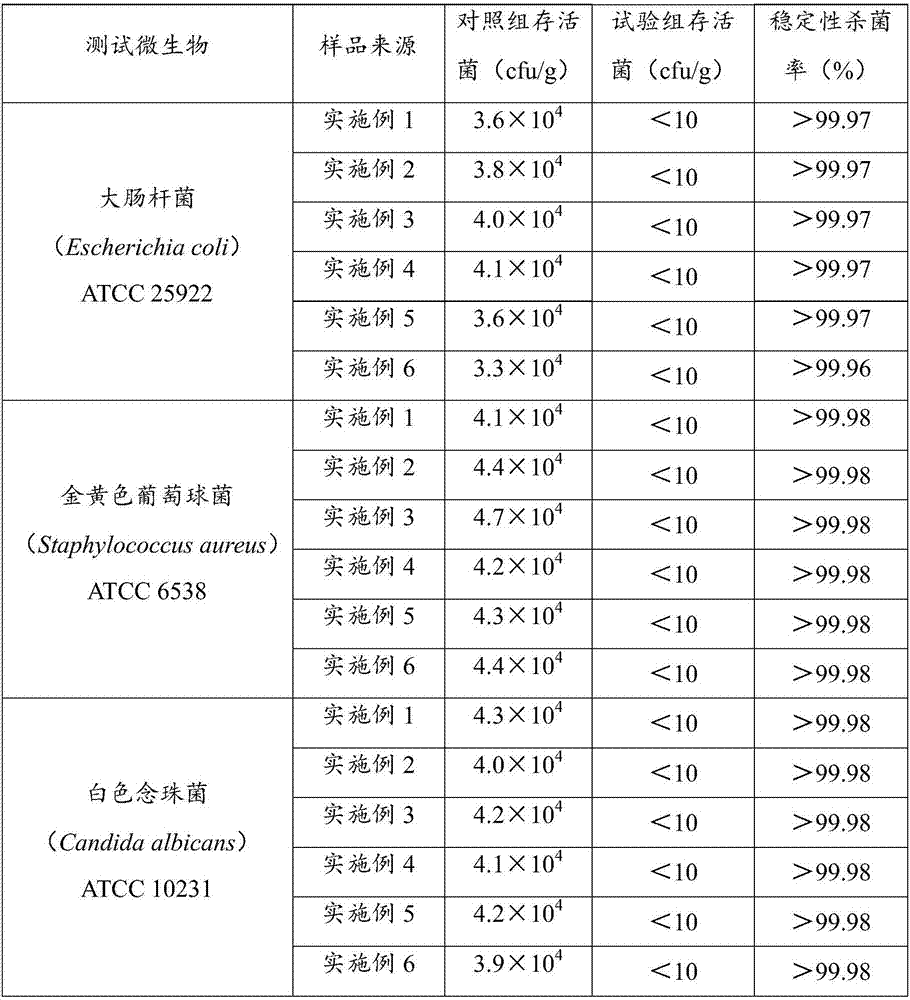

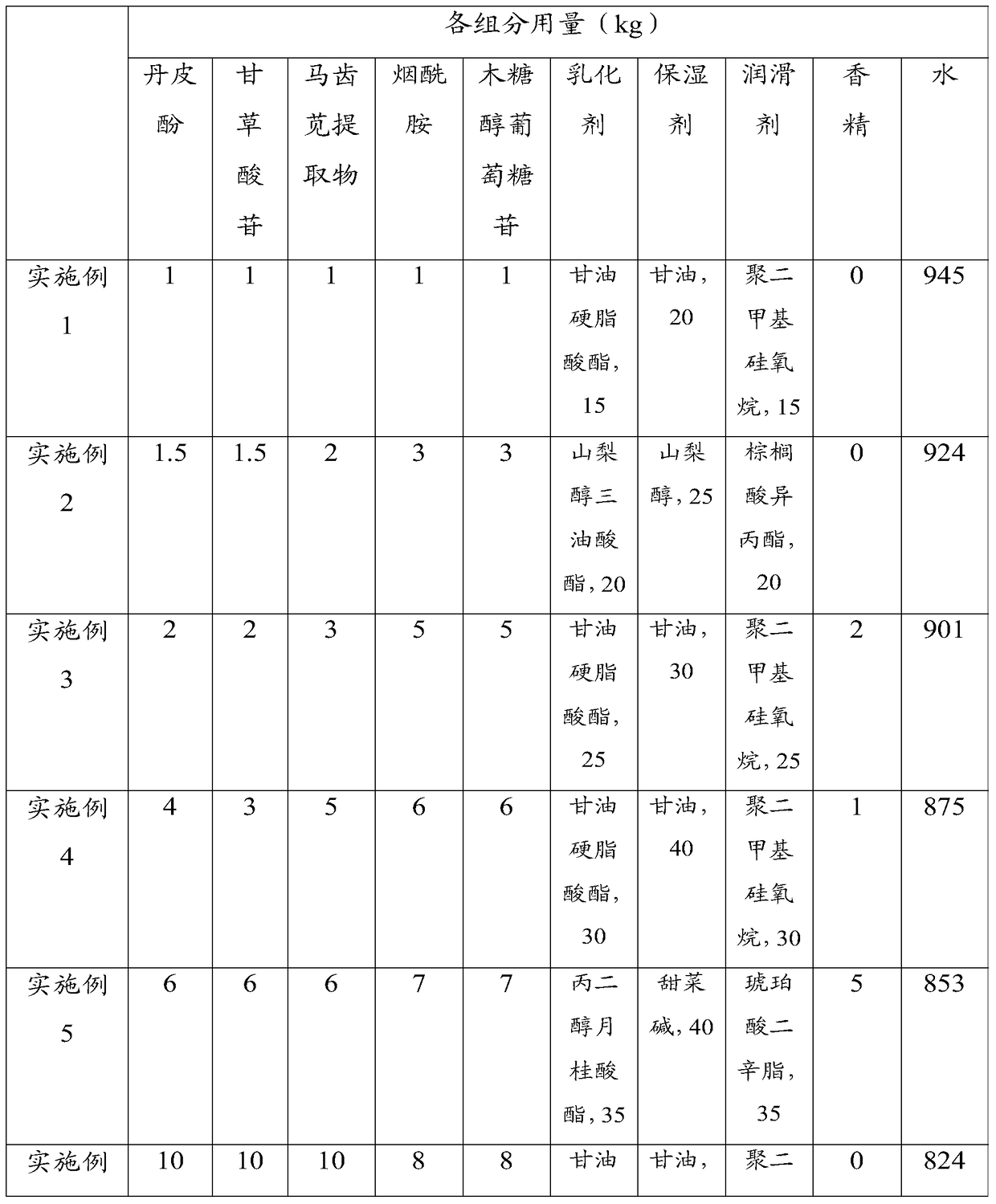

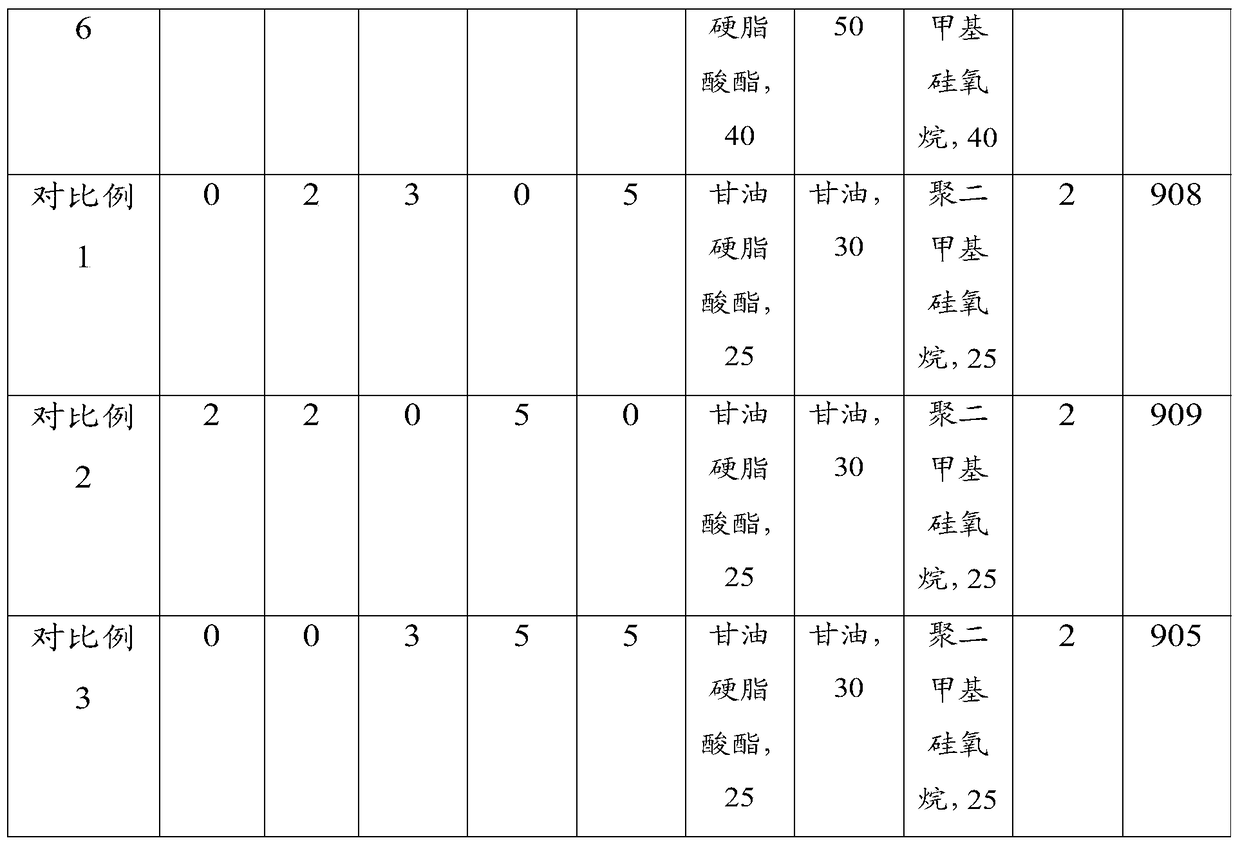

A kind of anti-acne composition and preparation method thereof

ActiveCN105232595BHeals fastNo side effectsCosmetic preparationsToilet preparationsXYLITYLGLUCOSIDESide effect

The invention provides an acne-removing composition and a preparation method thereof. In parts by weight, the raw material components of the anti-acne composition include: 0.1-1.0 parts of paeonol, 0.1-1.0 parts of glycyrrhizin, 0.1-1.0 parts of purslane extract, 0.1-0.8 parts of nicotinamide, wood 0.1-0.8 parts of sugar alcohol glucoside, 1.5-4 parts of emulsifier, 2-5 parts of humectant, 1.5-4 parts of lubricant and 82.5-94.5 parts of water. The composition combines paeonol, glycyrrhizin, purslane extract, nicotinamide and xylitol glucoside according to the scientific ratio, and the various components have a positive synergistic effect, which can inhibit the secretion of sebaceous glands Sebum, unclogs pores, and also has excellent antibacterial and bactericidal effects. It can remove acne from many aspects and completely eliminate acne. At the same time, it has fast healing speed, no toxic side effects, will not cause skin allergies, and will not leave scars after healing. or pigmentation benefits.

Owner:长睿生物技术(成都)有限公司

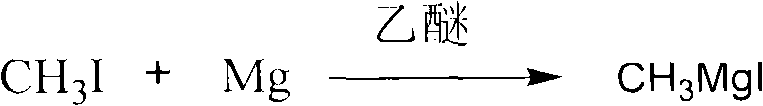

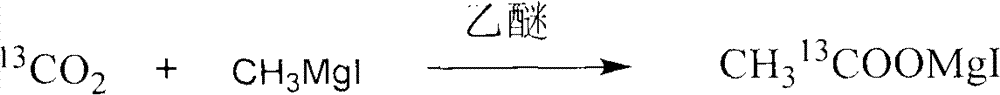

Chemical reaction device for fully recycling gas raw material

ActiveCN101898105BLow costEasy to operateOrganic compound preparationChemical/physical/physico-chemical processesSiphonChemical reaction

The invention relates to a chemical reaction device for fully recycling a gas raw material. The chemical reaction device is characterized by comprising a reactor, two cooling devices, two anti-siphon bubbling devices and two nitrogen bubbling devices, wherein the cooling devices are connected with the reactor through two gas pipes which are provided with pipe clamps; the cooling devices are connected with the anti-siphon bubbling devices through a gas pipe, and a three-way valve is connected on the gas pipe between the cooling devices and the anti-siphon bubbling devices; and the nitrogen bubbling devices are connected on the three-way valve. The chemical reaction device has the advantages of convenient operation, capabilities of recycling the gas raw material and making the gas raw material fully participate in the reaction, and furthest reduction of the use cost of the gas raw material.

Owner:无锡贝塔医药科技有限公司

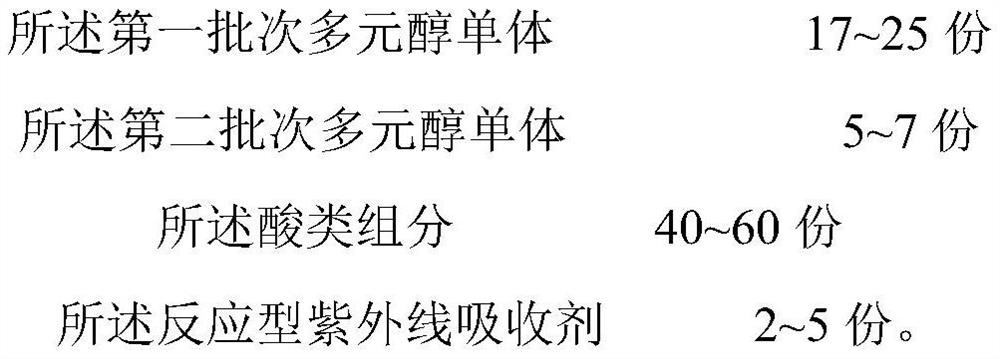

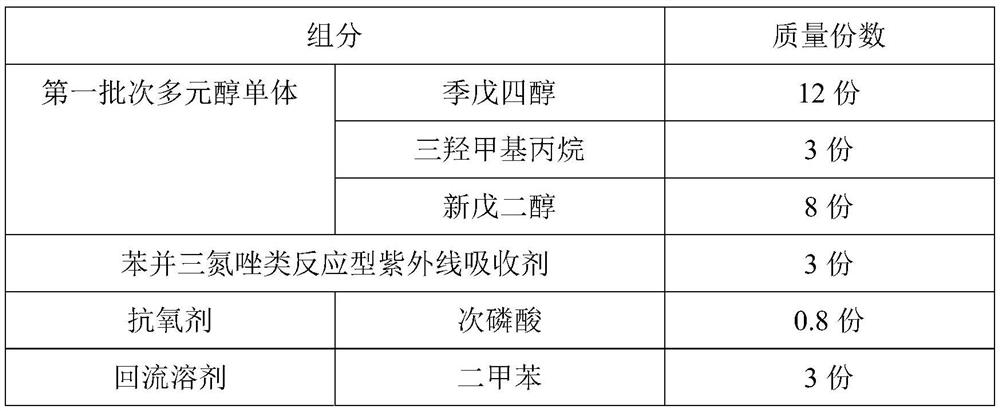

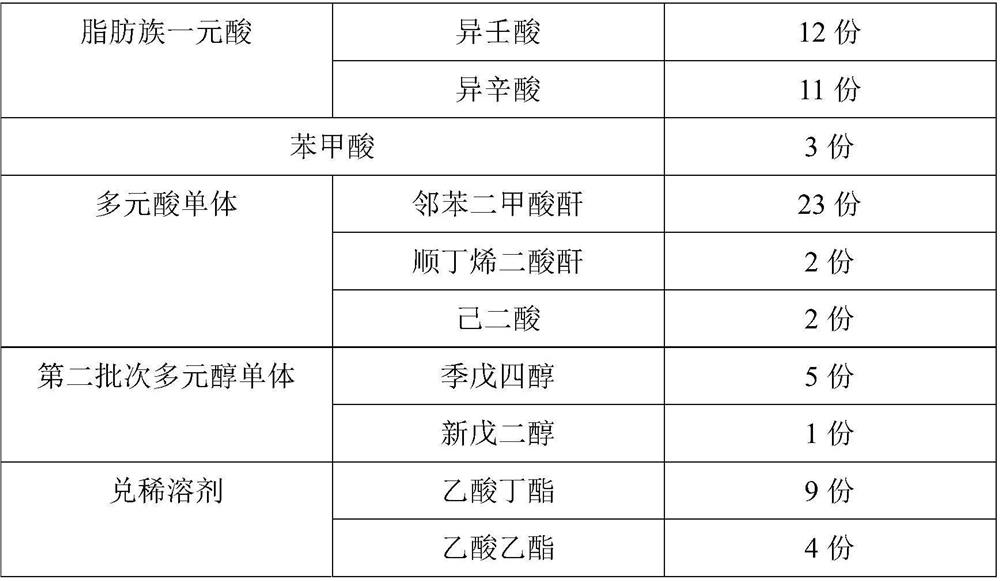

Method for preparing alkyd resin for dyed veneers and application thereof

PendingCN112358606AAvoid mixingAvoid Compatibility IssuesWood treatment detailsPolymer sciencePolyol

The invention provides a method for preparing alkyd resin for dyed veneers. The method comprises the following steps: step 1, mixing a reactive ultraviolet light absorber, a first batch of polyol monomers and an acid component to initiate esterification co-polymerization reaction; and step 2, adding a second batch of polyol monomers into the reaction liquid obtained after the step 1 is completed,and initiating esterification co-polymerization reaction; wherein the reactive ultraviolet light absorber comprises at least two esterification reaction active groups, and each esterification reactionactive group is independently selected from hydroxyl or carboxyl; the first batch of polyol monomers and the second batch of polyol monomers independently comprise at least two of dihydric alcohol monomers, trihydric alcohol monomers and tetrahydric alcohol monomers; and the acid monomer includes a polybasic acid monomer. According to the invention, the reactive ultraviolet absorber, the first batch of polyol monomers and the second batch of polyol monomers are jointly used as monomers for esterification polymerization reaction, so that the prepared alkyd resin has excellent permeability, yellowing resistance and discoloration resistance.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

A kind of preparation method of m6c type alloy carbide fe3w3c

The invention discloses a preparation method of M6C type alloy carbide Fe3W3C and belongs to the technical field of new materials. The method comprises the steps that Fe powder and WC powder are used as raw materials, and after the raw materials are uniformed mixed, sintering is conducted through a spark plasma sintering (SPS) and vacuum interface remelting method; then, after an obtained sintering sample is crushed, phase analysis is conducted; other impurity phases are removed through an acid pickling method, and deacidification treatment, drying treatment and the like are conducted on the powder; and then, sintering is conducted on the powder, so that a ternary carbide Fe3W3C material is finally obtained. The ternary phase carbide Fe3W3C prepared through the method contains few impurities; in addition, the preparation temperature is low; an obtained structure is uniform and good in mechanical performance; and great significance is achieved for researching microcosmic interfaces of tungsten-carbide-reinforced-steel (iron)-based composites.

Owner:KUNMING UNIV OF SCI & TECH

Method for increasing yield of rubber accelerator TBBS

The invention discloses a method for increasing the yield of the rubber accelerator TBBS, belonging to the field of fine chemical engineering. According to the invention, the accelerator MBT, tert-butylamine and sodium hypochlorite are used as raw materials, water is used as a medium, and sodium chloride and sodium dodecyl benzene sulfonate are added into a reaction system to synthesize the rubberaccelerator TBBS. The dispersion degree of MBT particles in water is increased by utilizing the dispersion effect of the surfactant, and after tert-butylamine is added, the contact surface of the MBTparticles and the tert-butylamine is increased, so the synthesis rate of an M-amine salt is increased; and since NaCl is added to increase the polarity of a reaction environment, the M-amine salt isbetter dissolved in the polar environment, is in full contact with sodium hypochlorite molecules and fully participates in the reaction, so a conversion rate is increased, and the consumption of tert-butylamine is reduced. NaCl and the surfactant sodium dodecyl benzene sulfonate are added, so product yield is greatly improved and is 96% or above; and meanwhile, the synthesized material is white inappearance, high in melting point and high in purity.

Owner:SHANDONG SUNSINE CHEM

A kind of method that improves rubber accelerator tbbs yield

ActiveCN110577502BGood dispersionIncrease contact surfaceOrganic chemistryActive agentSurface-active agents

The invention discloses a method for increasing the yield of the rubber accelerator TBBS, belonging to the field of fine chemical engineering. According to the invention, the accelerator MBT, tert-butylamine and sodium hypochlorite are used as raw materials, water is used as a medium, and sodium chloride and sodium dodecyl benzene sulfonate are added into a reaction system to synthesize the rubberaccelerator TBBS. The dispersion degree of MBT particles in water is increased by utilizing the dispersion effect of the surfactant, and after tert-butylamine is added, the contact surface of the MBTparticles and the tert-butylamine is increased, so the synthesis rate of an M-amine salt is increased; and since NaCl is added to increase the polarity of a reaction environment, the M-amine salt isbetter dissolved in the polar environment, is in full contact with sodium hypochlorite molecules and fully participates in the reaction, so a conversion rate is increased, and the consumption of tert-butylamine is reduced. NaCl and the surfactant sodium dodecyl benzene sulfonate are added, so product yield is greatly improved and is 96% or above; and meanwhile, the synthesized material is white inappearance, high in melting point and high in purity.

Owner:SHANDONG SUNSINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com