Chemical reaction device for fully recycling gas raw material

A chemical reaction and raw material technology, applied in organic chemistry, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased production cost, high cost, and increased operational difficulty, so as to increase productivity, facilitate operation, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

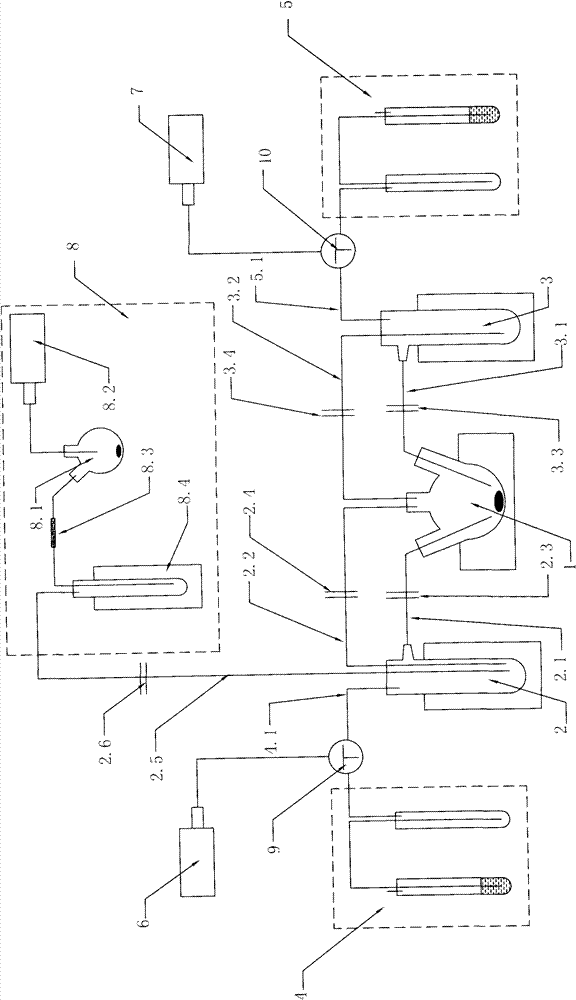

[0016] like figure 1 As shown, a chemical reaction device that fully recycles gas raw materials includes a reactor 1, two cooling devices 2, 3, two anti-suckback bubbling devices 4, 5 and two nitrogen bubbling devices 6, 7; the cooling device 2 is connected with the reactor 1 through two gas delivery pipes 2.1, 2.2, the gas delivery pipe 2.1 is provided with a pipe clamp 2.3, and the gas delivery pipe 2.2 is provided with a pipe clamp 2.4; the cooling device 3 is connected with the reaction reactor through two gas delivery pipes 3.1, 3.2 connected to the device 1, the air pipe 3.1 is provided with a pipe clamp 3.3, and the air pipe 3.2 is provided with a pipe clamp 3.4; the cooling device 2 is connected with the anti-suckback bubbling device 4 through the air pipe 4.1, and the cooling device 3 is connected through the air pipe 5.1 and the anti The suck-back bubbling device 5 is connected; the air delivery pipe 4.1 between the cooling device 2 and the anti-suck-back bubbling de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com