Patents

Literature

44results about How to "Accurate Mechanical Properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

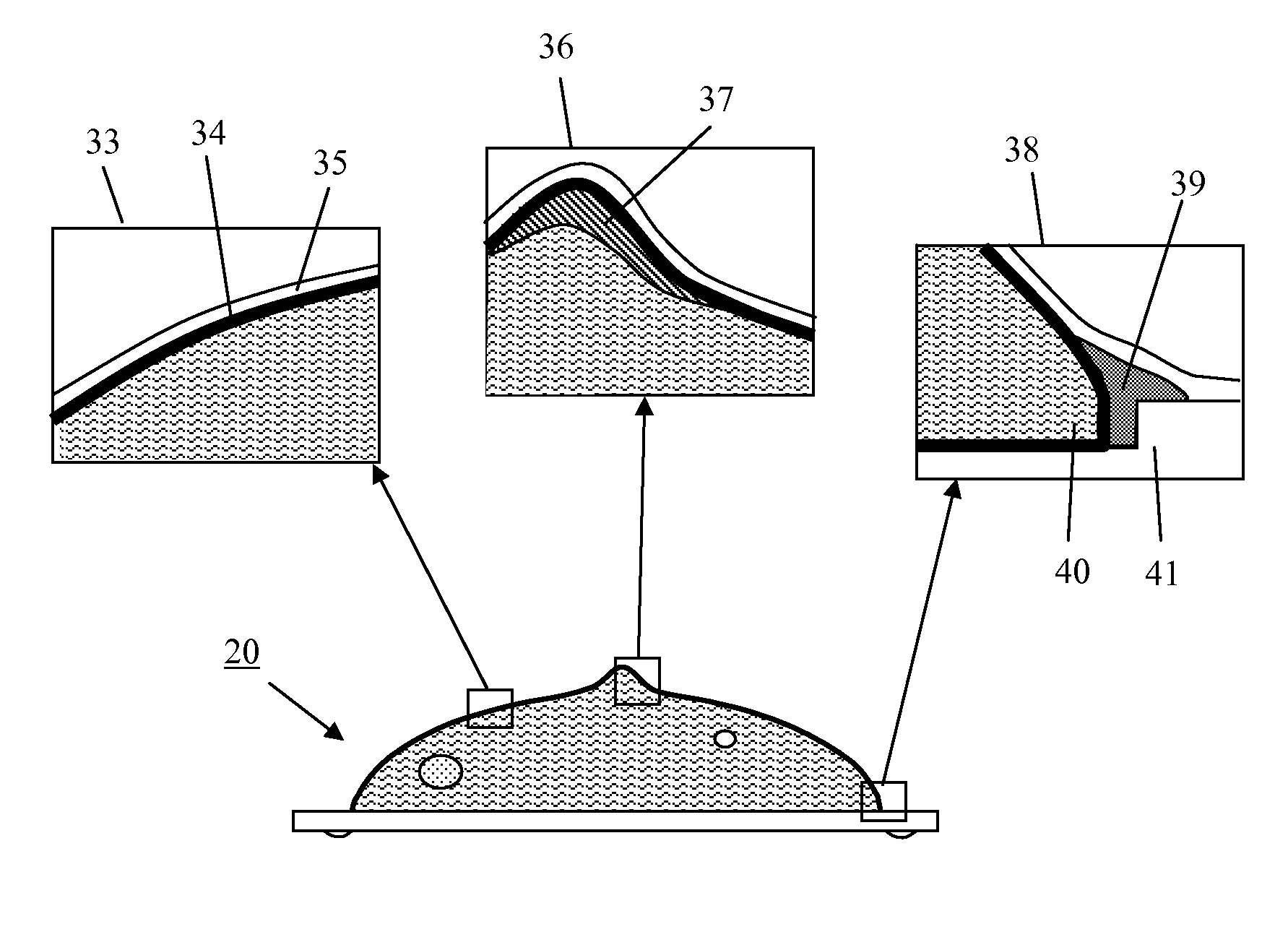

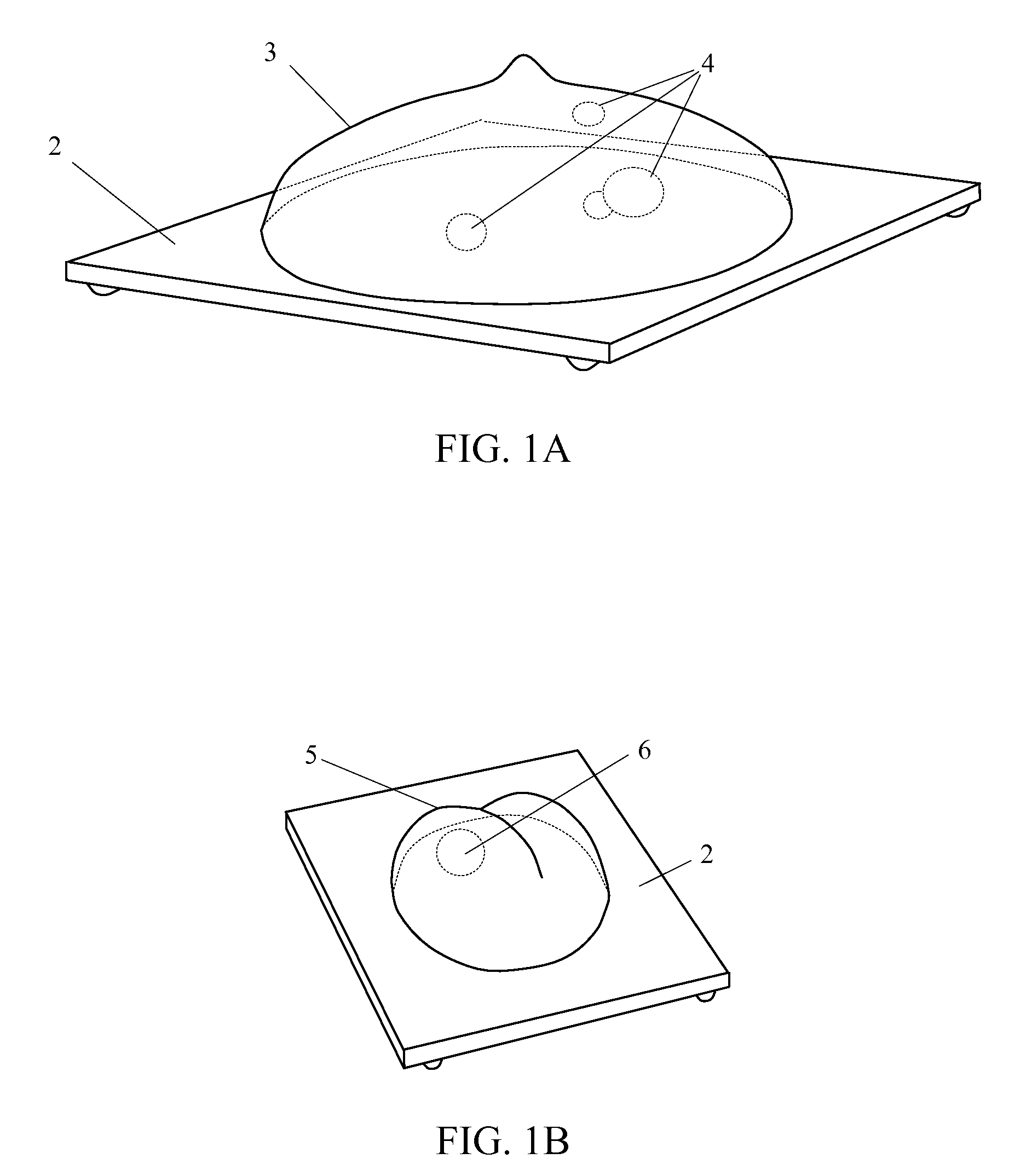

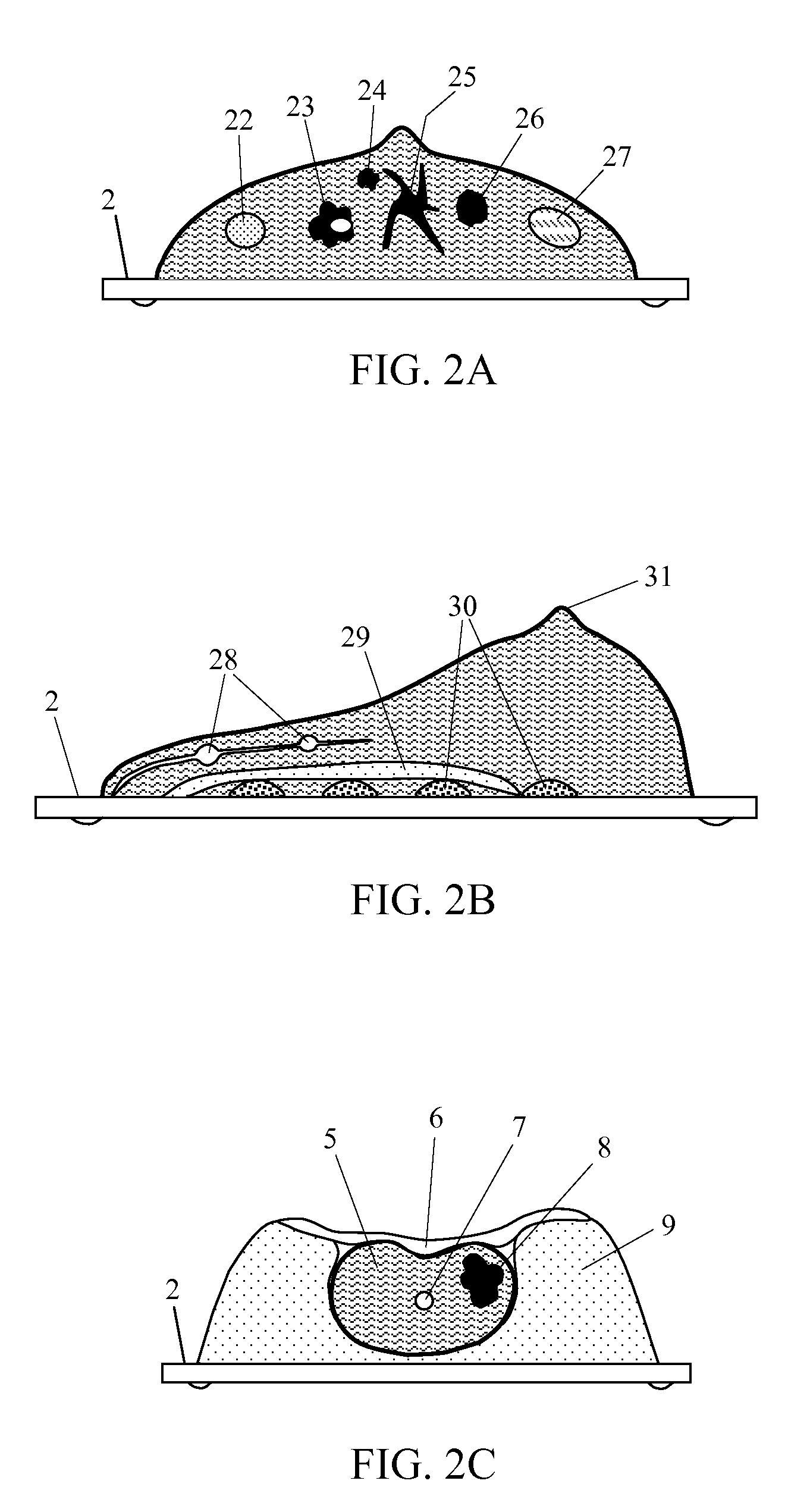

Human tissue phantoms and methods for manufacturing thereof

Disclosed are human tissue phantoms mimicking the mechanical properties of real tissue, and methods for manufacturing thereof including the steps of obtaining a computer aided three-dimensional design of a phantom mimicking the tissue in shape and size; fabrication of a mold form facilitating the production of the designed phantom; molding said phantom with the use of two-component silicon gels as a bulk tissue-mimicking material having Young's modulus in the range of 2 to 30 kPa; filling the enclosed volume of said phantom with anatomical and pathological tissue structures mimicking their respective mechanical properties and having Young's modulus in the range of about 30 to 600 kPa; covering said phantom by a protective layer having mechanical properties to a human tissue protective layer; and securing the phantom perimeter on a supporting plate by a rubber barrier. The example of used tissue-mimicking material is a two-component silicone SEMICOSIL gel with variable elastic properties and Young's modulus from 3 kPa to 600 kPa as a result of changing the silicon component ratio. As examples, the breast and prostate phantom tissue and their fabrication procedures are described.

Owner:ARTANN LAB

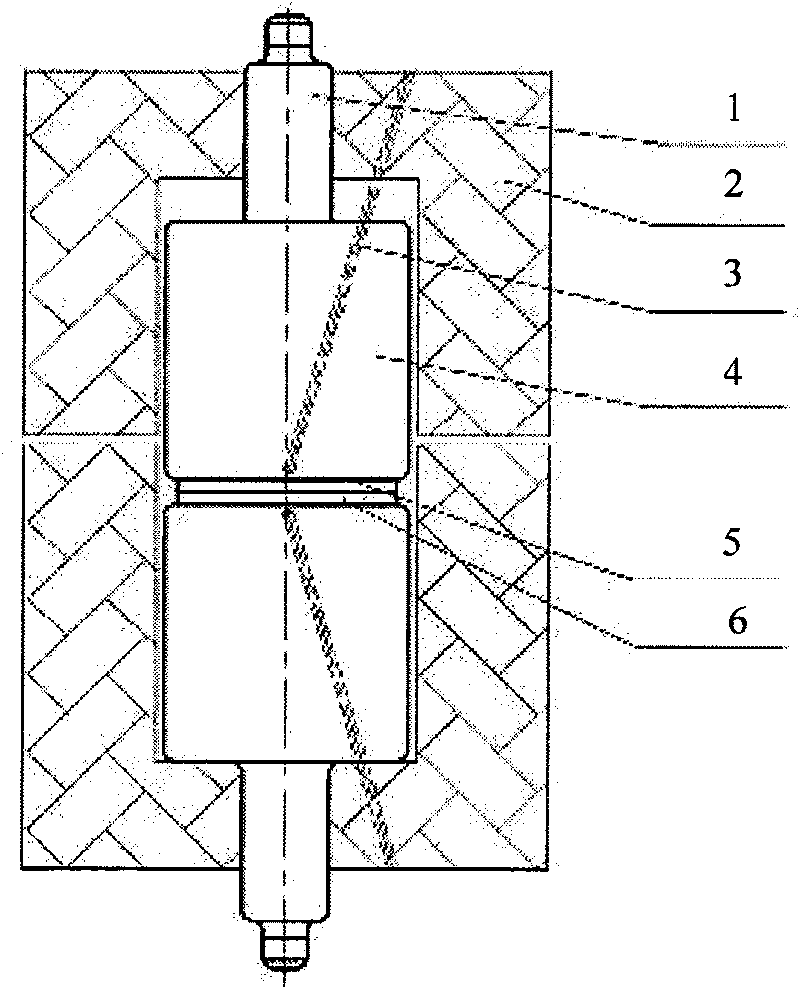

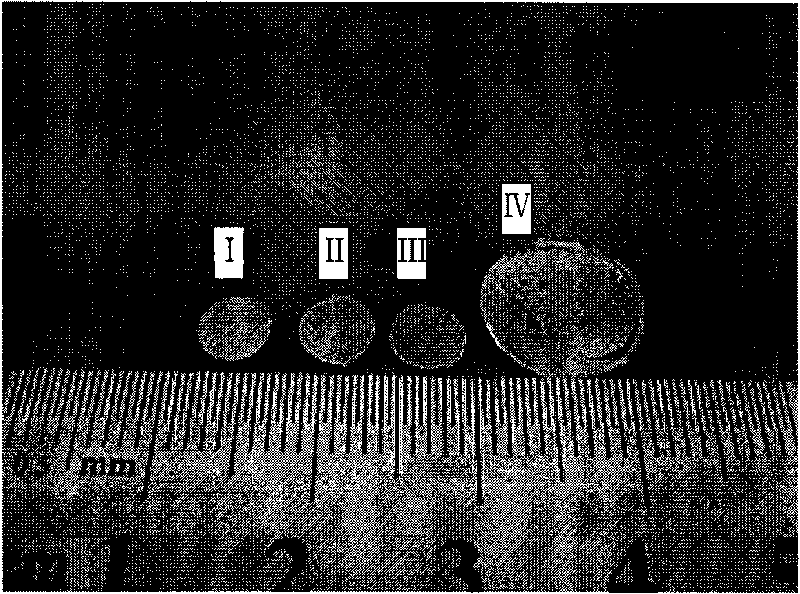

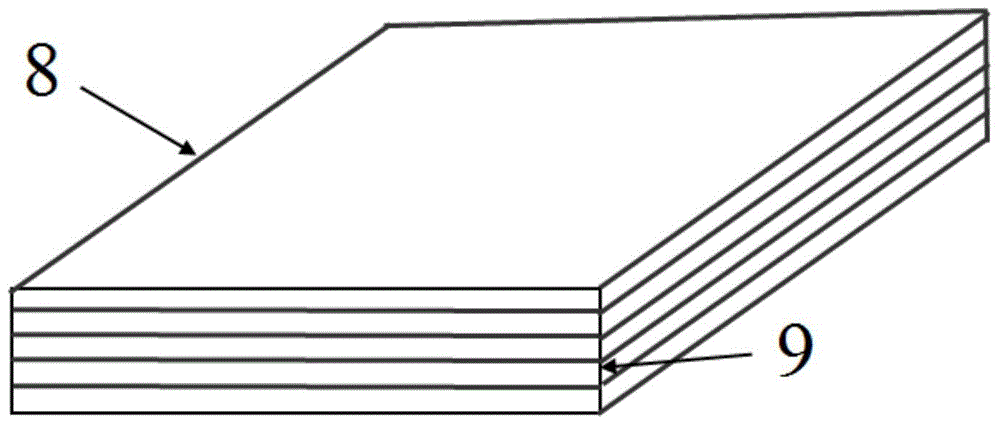

Method and device for preparing large-size bulk amorphous composite materials

The invention provides a method for preparing large-size bulk amorphous composite materials, which belongs to the field of preparing amorphous alloy (metallic glass) and composite materials thereof. The method applies to superplastic diffusion bonding of bulk amorphous substances and fiber, and is characterized in that the bulk amorphous substances and the fiber are arranged in a certain mode (such as a layered mode and the like), put into a mold, pressurized and thermally insulated under gas protection or vacuum for superplastic diffusion bonding; pressure is released after a certain period of time; and workpieces are taken out of the mold. The invention also provides a novel device for preparing large-size bulk amorphous, fiber / amorphous composite materials through superplastic diffusion bonding. The device consists of a heating system, a heat insulation system, a mold system, a loading system, a gas protection system and a cooling system. The method and the device have the advantages of reinforcing the fiber, enabling the shape of amorphous alloy-base composite materials to be designed, enabling the volume of the fiber in the composite materials to be controlled and enabling the fiber to be used in other various amorphous alloy systems low in amorphous formation capability, and are applicable to armor boards, armor-piercing shells and the like.

Owner:UNIV OF SCI & TECH BEIJING

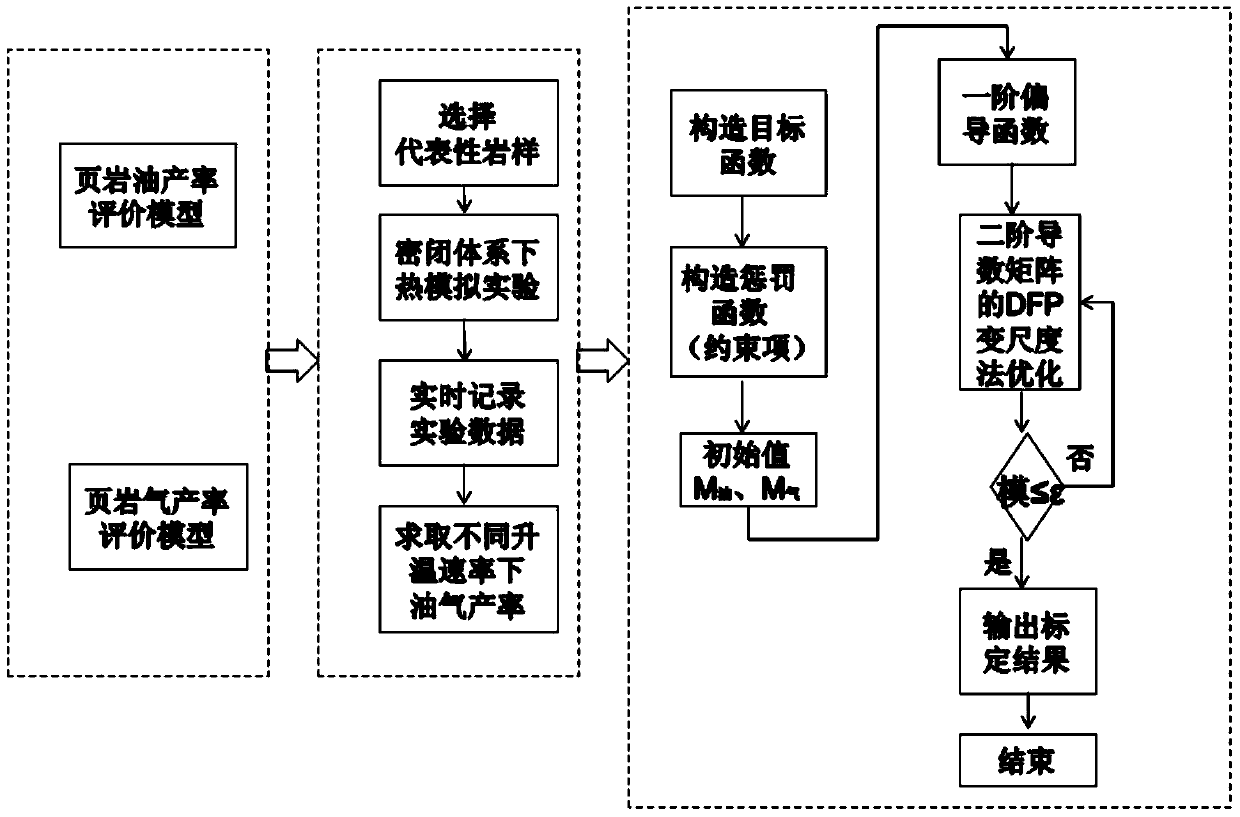

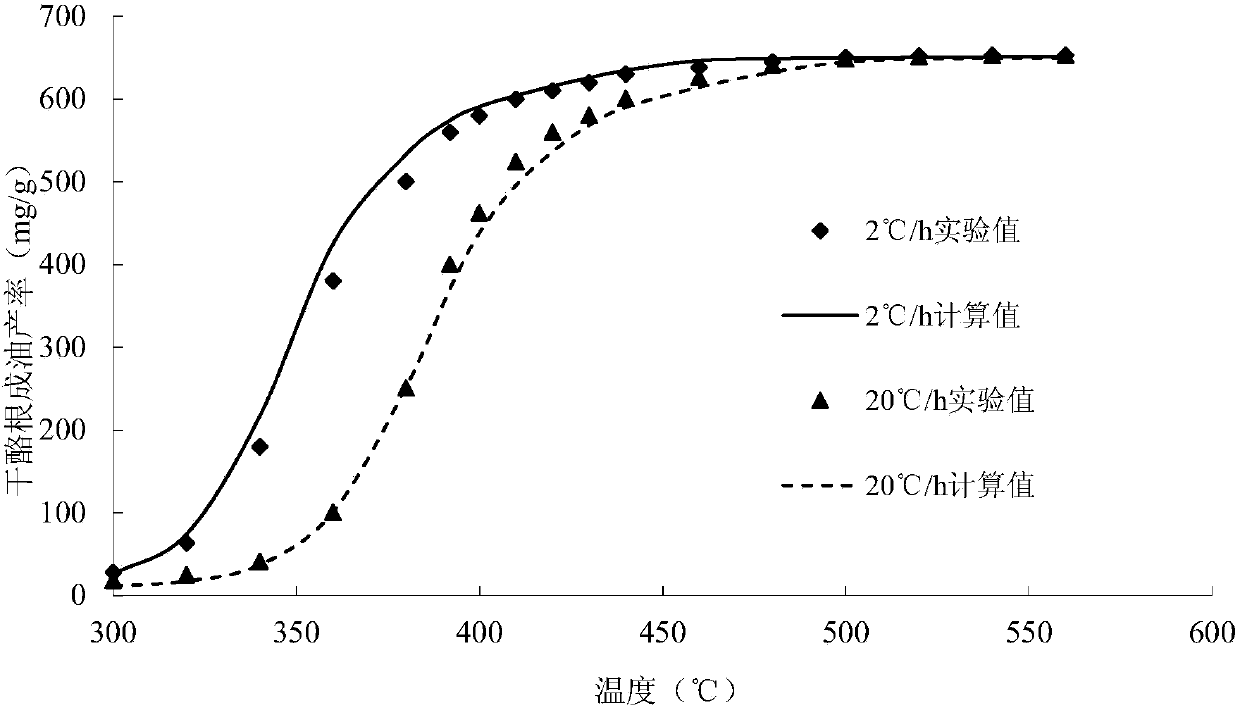

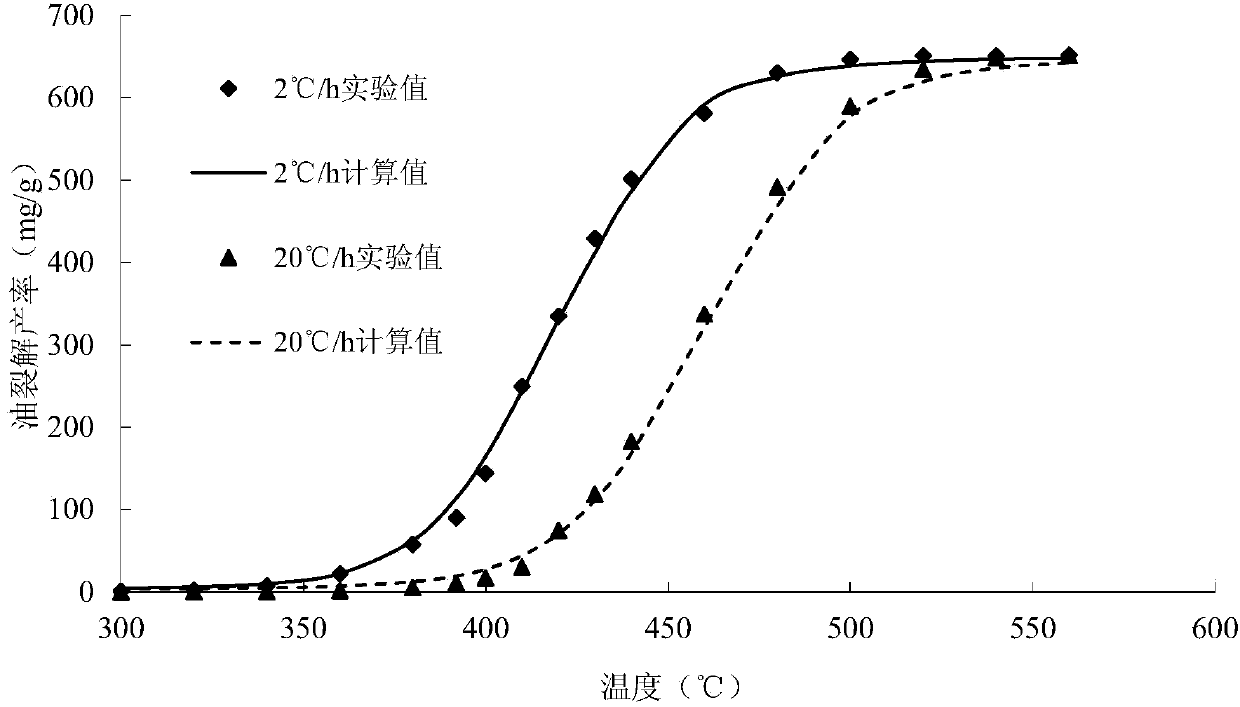

Shale oil and gas yield evaluation model building and parameter calibrating method applied under closed system

InactiveCN104156593ASolving descriptions of complex processesFlexible settingsSpecial data processing applicationsShale oil extractionShale oil and gas

The invention relates to a shale oil and gas yield evaluation model building and parameter calibrating method applied under a closed system. The method includes the following steps of (1) building a shale oil yield evaluation model, (2) building a shale gas yield evaluation model, (3) measuring the shale oil yield and the shale gas yield through experiments, and (4) calibrating dynamic parameters in the shale oil yield evaluation model and the shale gas yield evaluation model. Due to the facts that shale oil generation and secondary cracking are considered at the same time and the shale oil yield evaluation model and the shale gas yield evaluation model are built in the closed system, considering from the degree of approximation between an experiment condition and a geological condition, the method effectively achieves description of the complex process that shale oil generation and secondary cracking exist at the same time under the closed system, and can describe shale oil and gas characteristics quantificationally and dynamically. The shale oil and gas dynamic parameters calibrated according to the method are combined with the thermal history of the burial history of an actual basin for geological extrapolation, and obtained shale oil and gas hydrocarbon generation history information is more accurate and reliable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

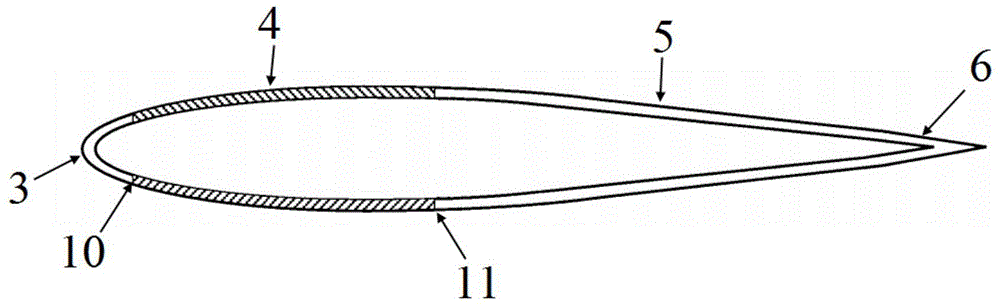

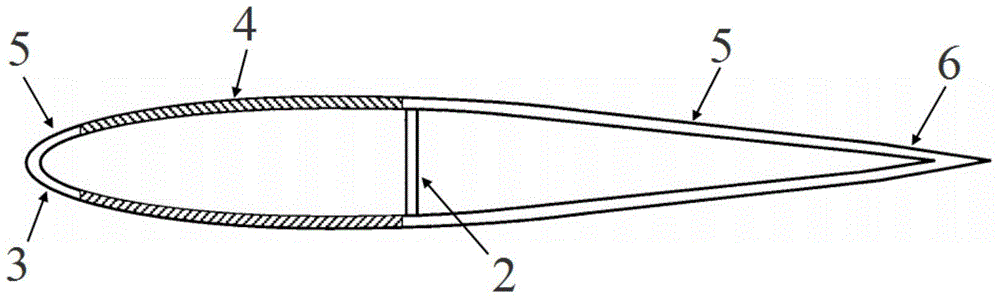

Piezoelectric composite material helicopter blade structure and control method thereof

InactiveCN104590558AImprove performanceExtended service lifeAircraft assemblyRotocraftElectricityEngineering

The invention discloses a piezoelectric composite material helicopter blade structure and a control method thereof. A piezoelectric composite material is embedded into a composite material lamination structure of a rotor blade. An analysis model is established and is capable of accurately describing the motion rule of the rotor blade based on a structure model, an aerodynamic force model, a piezoelectric composite material model and the like, and further accurately calculates the dynamics characteristics of the rotor blade. According to the control method, a controller is employed for controlling the rotor blade, a Kalman observer is employed for obtaining rotor blade data under the condition of white noise interference, and the rotor blade data is taken as input variable for controlling, and further by using the controller to control the input voltage of the piezoelectric composite material, the purpose of controlling blade dynamics response and deformation is finally realized. The provided model establishing method and the control method have relatively high versatility and accuracy, help to accurately obtain dynamics characteristics of the helicopter rotor blade, and are high in control efficiency.

Owner:HUNAN UNIV

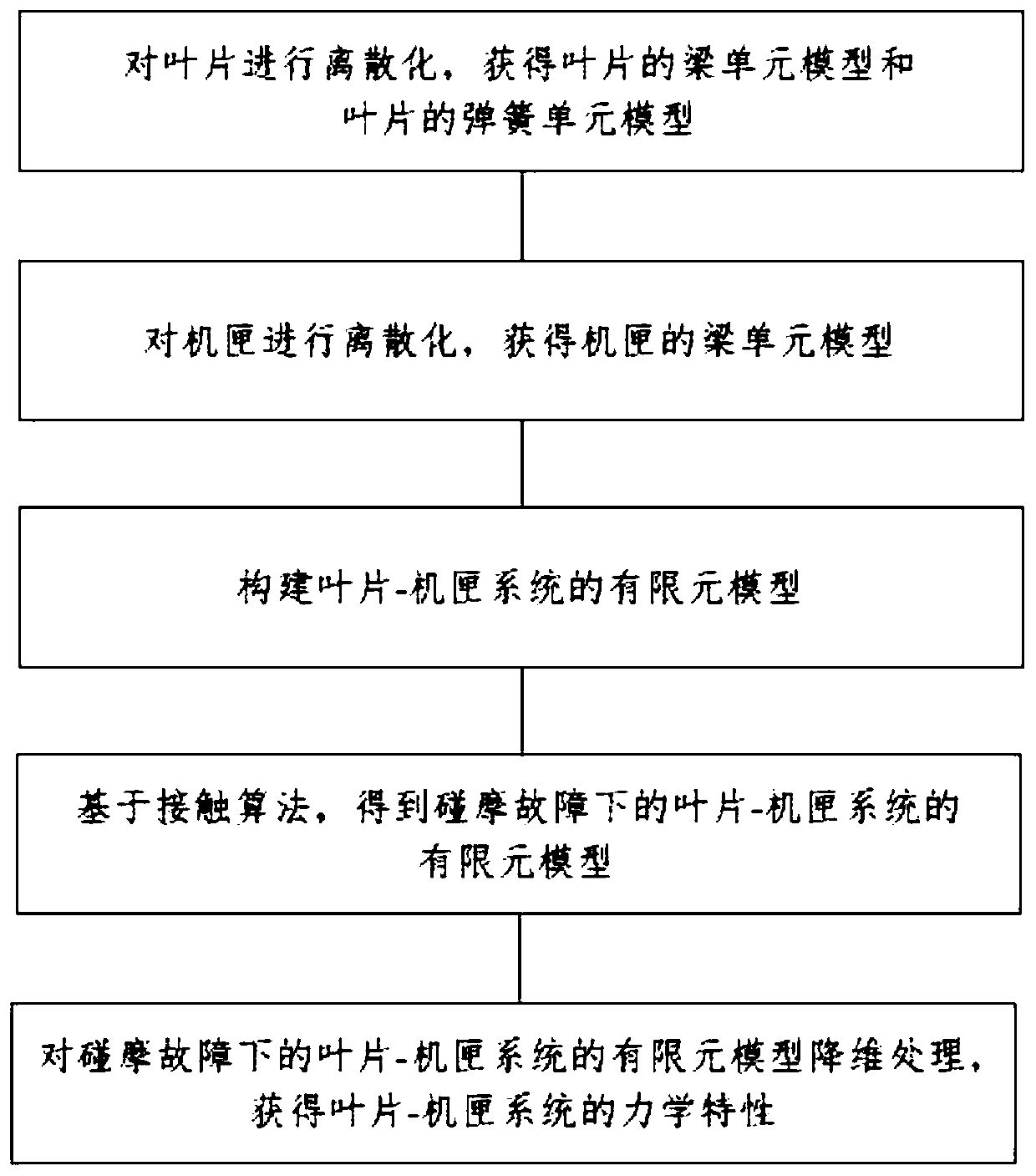

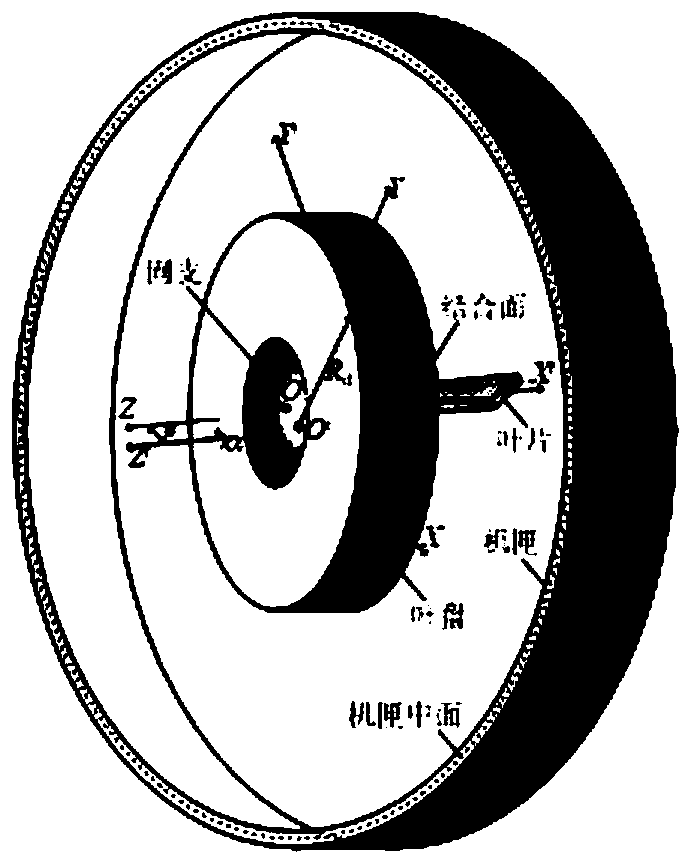

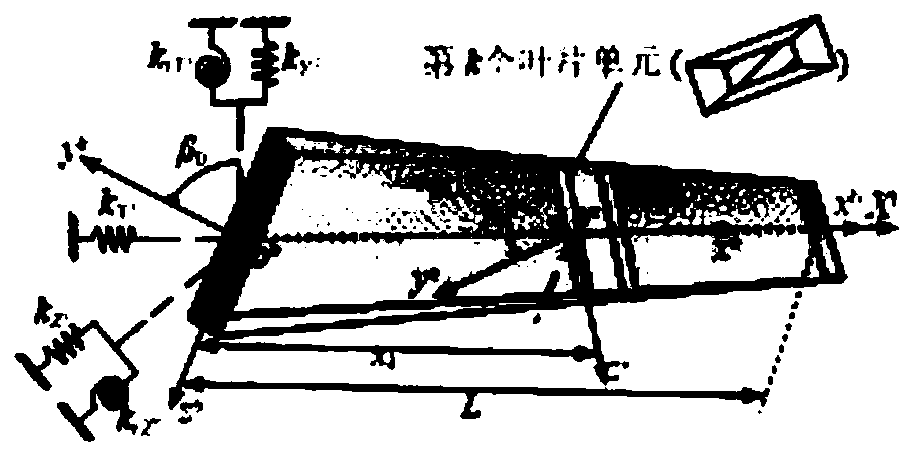

Mechanical property analysis method of blade and cartridge receiver system under rub-impact fault

ActiveCN110610049AImprove computing efficiencyAccurate Mechanical PropertiesSpecial data processing applicationsElement modelClassical mechanics

The invention belongs to the technical field of mechanical simulation of rotor and stator systems, and particularly relates to a mechanical property analysis method of a blade and a cartridge receiversystem under rub-impact faults. The method comprises the following steps of A1, discretizing the blade to obtain a beam element model of the blade and a spring element model of the blade; A2, discretizing a cartridge receiver to obtain a beam element model of the cartridge receiver; A3, based on the beam element model of the blade, the spring element model of the blade and the beam element modelof the cartridge receiver, constructing a finite element model of the blade and the cartridge receiver system; A4, based on a contact algorithm and in combination with the constructed finite element model of the blade and the cartridge receiver system, obtaining the finite element model of the blade and the cartridge receiver system under the rub-impact fault; and A5, carrying out dimension reduction processing on the finite element model of the blade and cartridge receiver system under the rub-impact fault, thereby obtaining the mechanical properties of the blade and the cartridge receiver system. According to the analysis method, the elastic support problem of the blade root is considered, and the obtained mechanical property is more accurate.

Owner:NORTHEASTERN UNIV

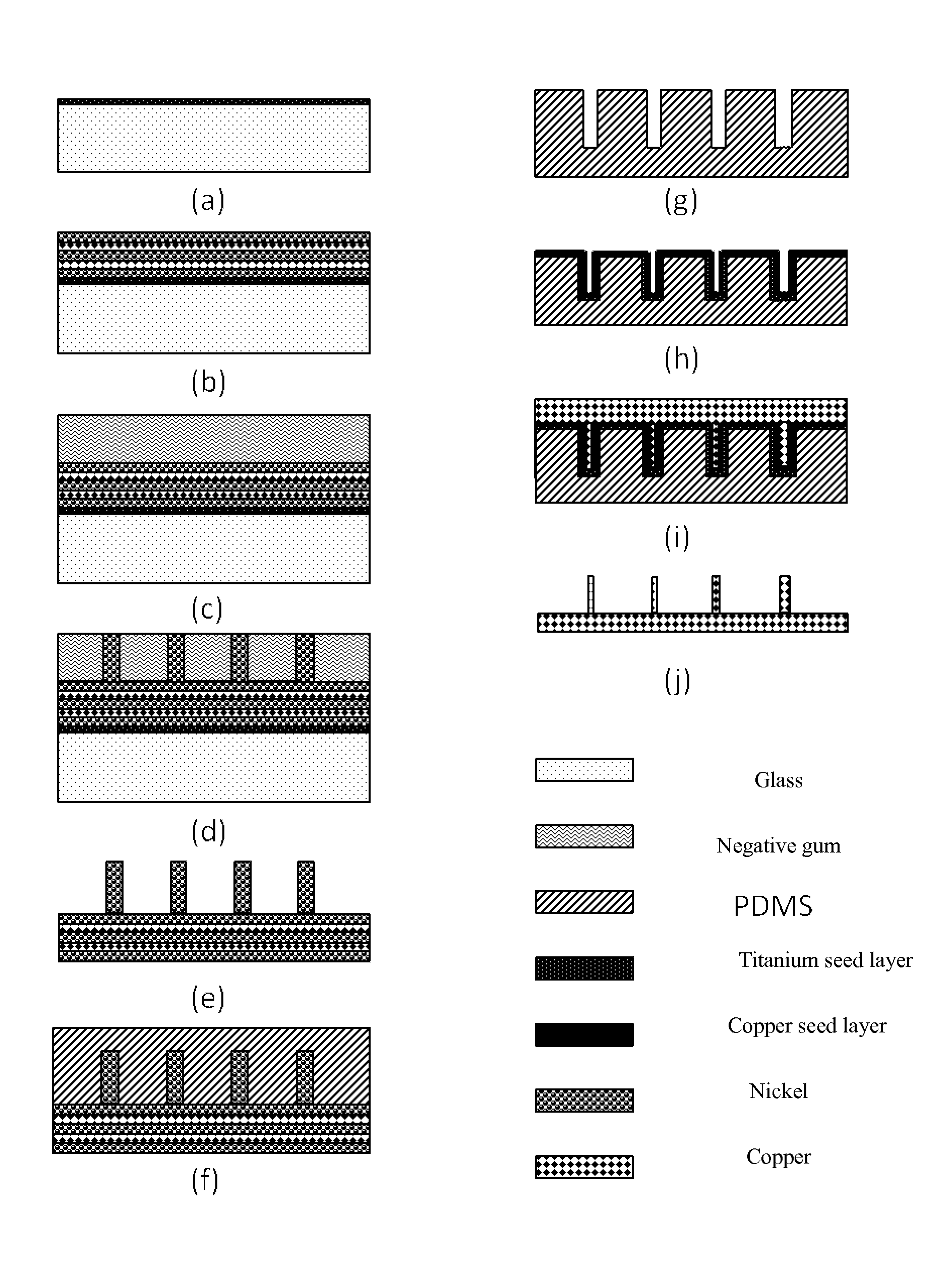

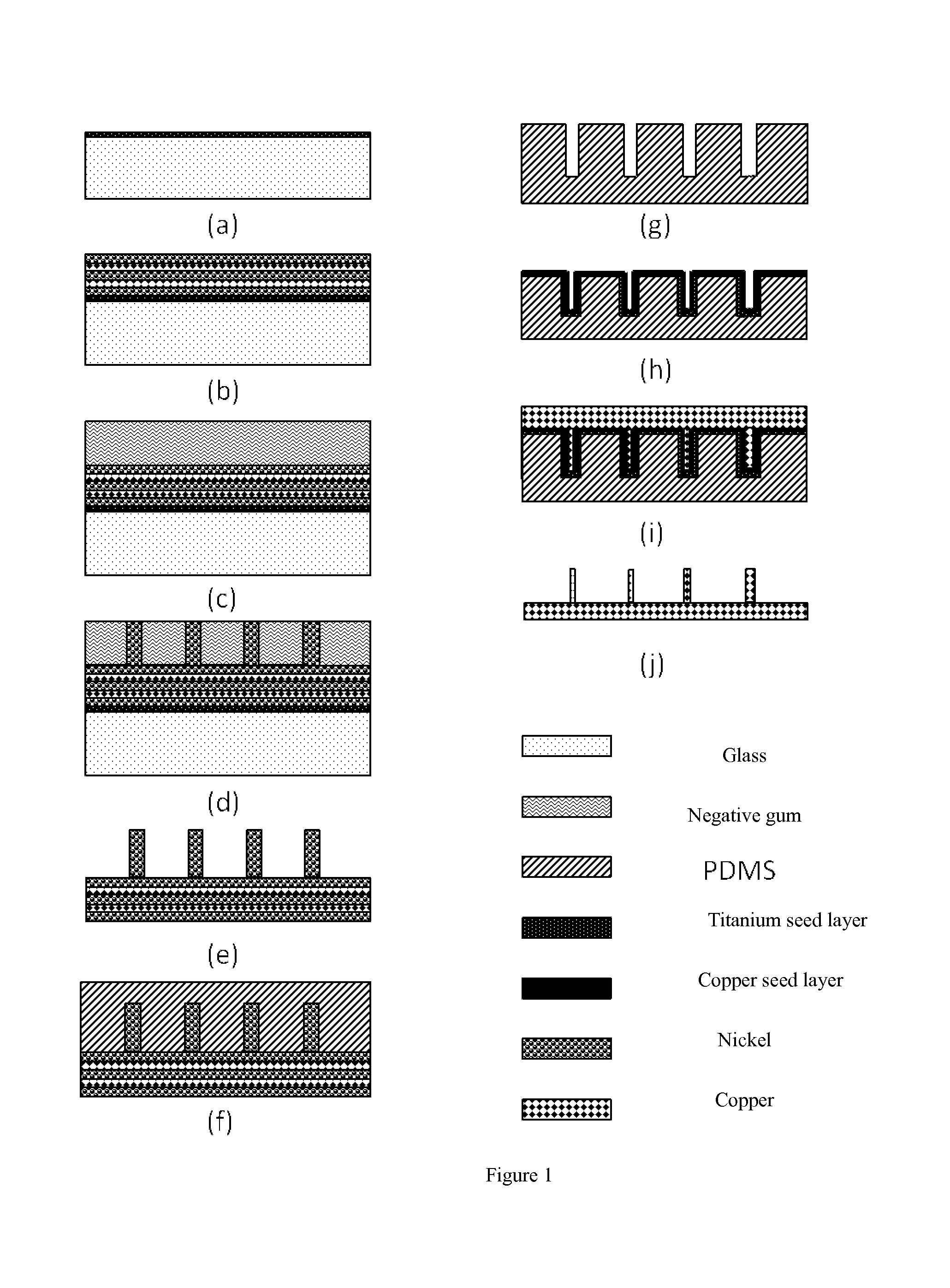

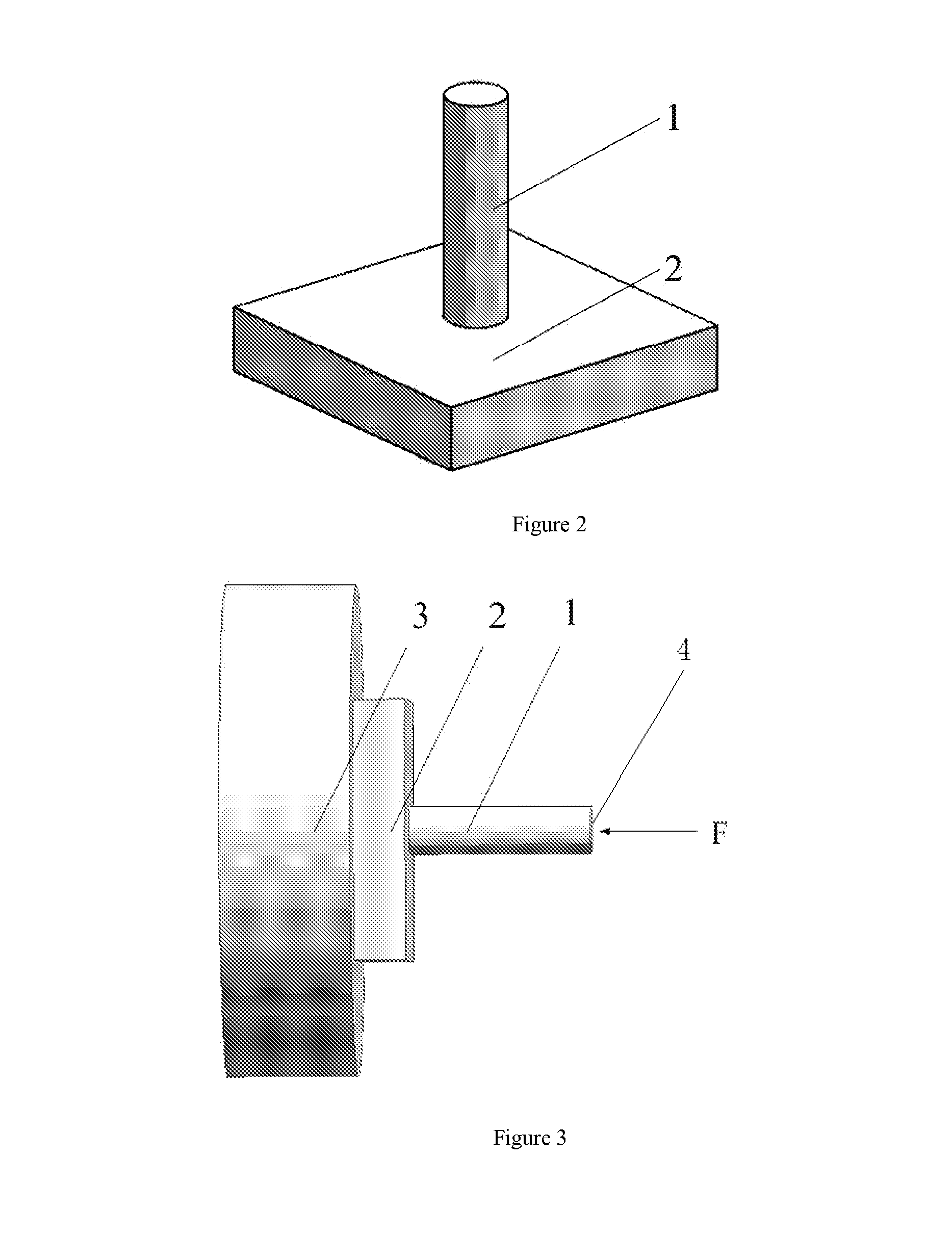

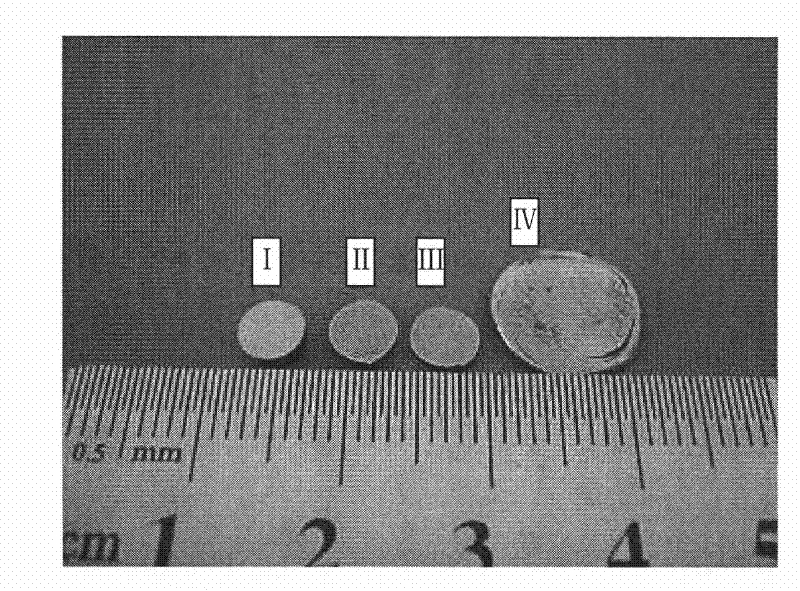

In-situ Compressed Specimen for Evaluating Mechanical Property of Copper Interconnection Micro Column and Preparation Method thereof

InactiveUS20140242407A1Accurate Mechanical PropertiesHigh aspect ratioLayered productsDecorative surface effectsMicro columnInterconnection

An in-situ compressed specimen of copper interconnection micro column, which is a circular metal column formed in a PDMS hole, includes: a specimen part and a fixed end part for fixing the specimen; wherein the fixed end part is a circular or square plate structure, the specimen part is an upper part of the fixed end part; a main body of the present invention is of micron order, a forced direction of the specimen is consistent with a growth direction of the metal column. A method of electroplating copper column by adopting PDMS as template substrate is applied to overcome a problem that TSV is corrosive to the copper column during a silicon etching process so as to affect a mechanical property accuracy test, the method is advanced in shortening test process period, achieving good reproducibility and high yield.

Owner:SHANGHAI JIAO TONG UNIV

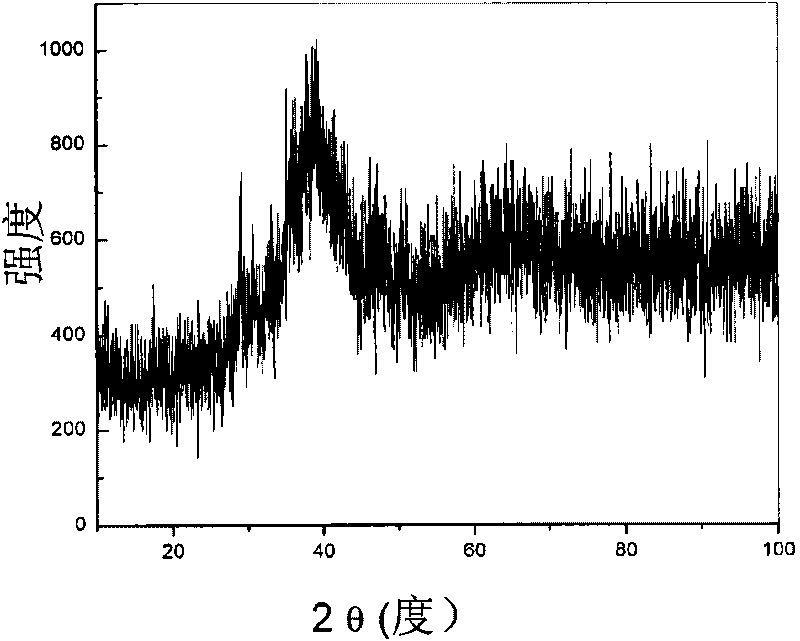

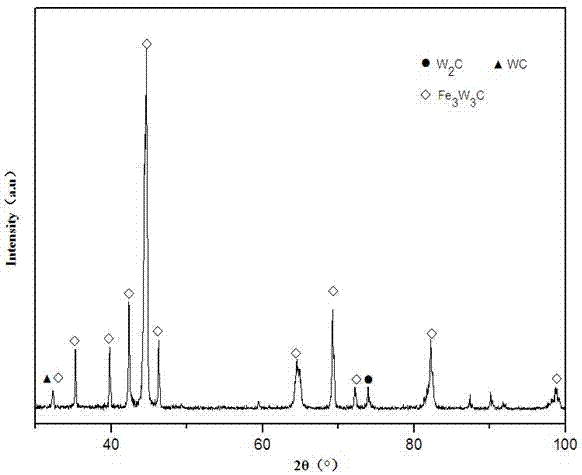

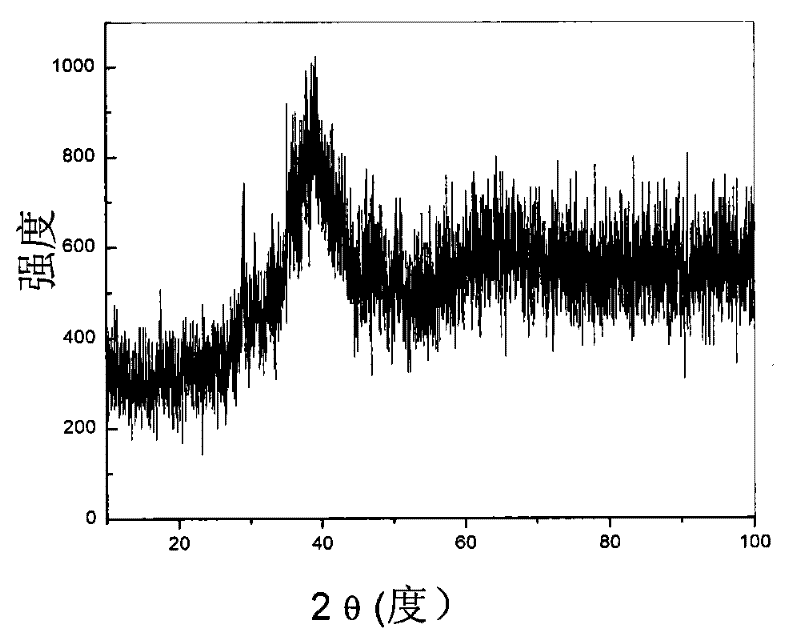

Preparation method of M6C type alloy carbide Fe3W3C

ActiveCN107227416AHigh purityAccurate Mechanical PropertiesPhase analysisMechanical properties of carbon nanotubes

The invention discloses a preparation method of M6C type alloy carbide Fe3W3C and belongs to the technical field of new materials. The method comprises the steps that Fe powder and WC powder are used as raw materials, and after the raw materials are uniformed mixed, sintering is conducted through a spark plasma sintering (SPS) and vacuum interface remelting method; then, after an obtained sintering sample is crushed, phase analysis is conducted; other impurity phases are removed through an acid pickling method, and deacidification treatment, drying treatment and the like are conducted on the powder; and then, sintering is conducted on the powder, so that a ternary carbide Fe3W3C material is finally obtained. The ternary phase carbide Fe3W3C prepared through the method contains few impurities; in addition, the preparation temperature is low; an obtained structure is uniform and good in mechanical performance; and great significance is achieved for researching microcosmic interfaces of tungsten-carbide-reinforced-steel (iron)-based composites.

Owner:KUNMING UNIV OF SCI & TECH

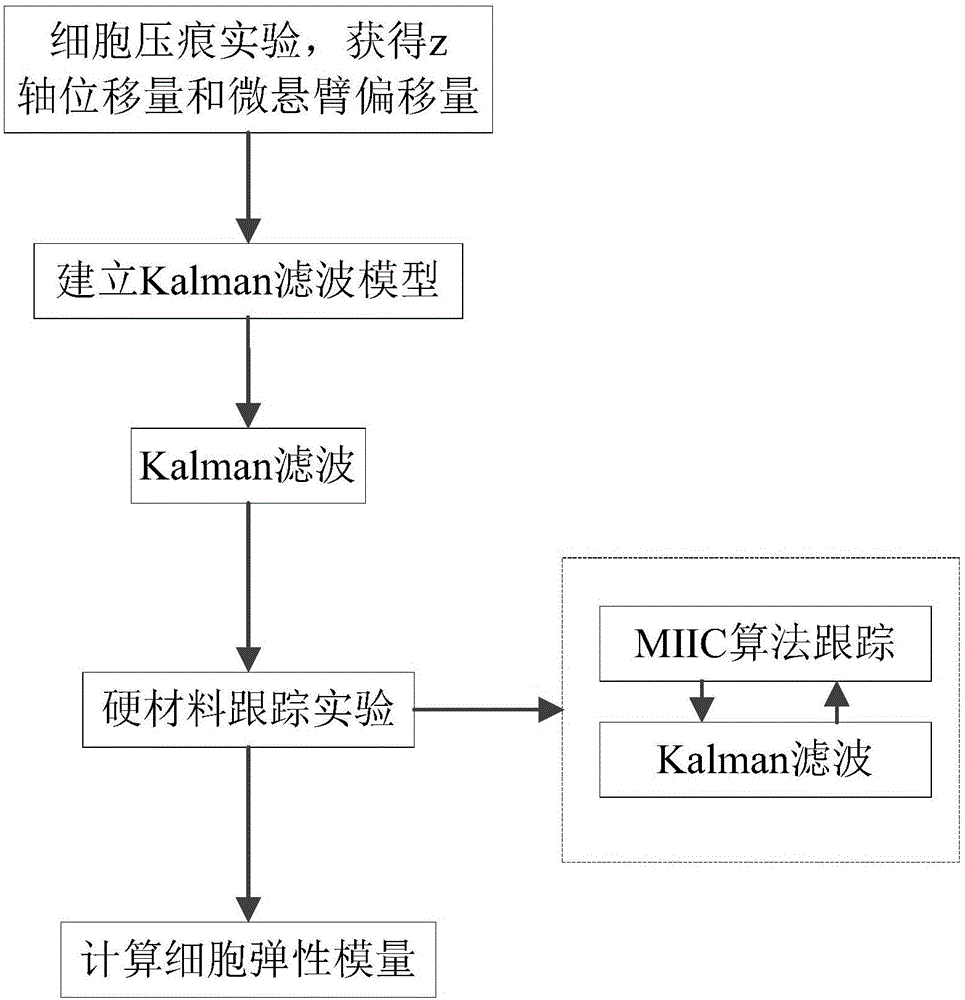

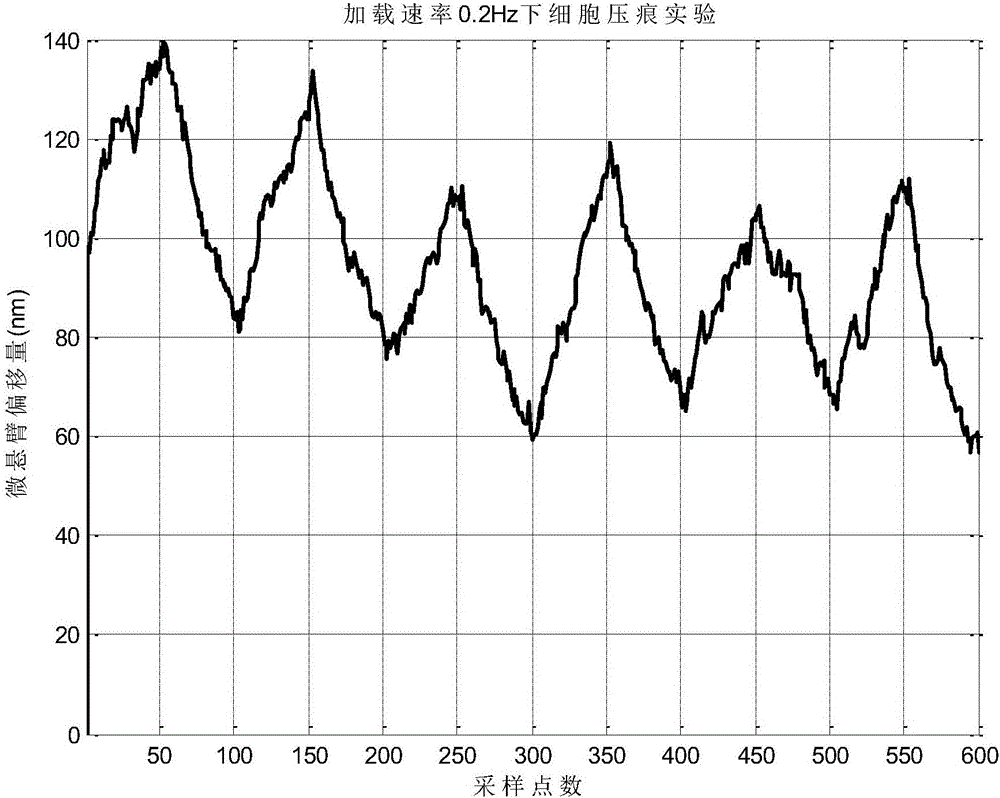

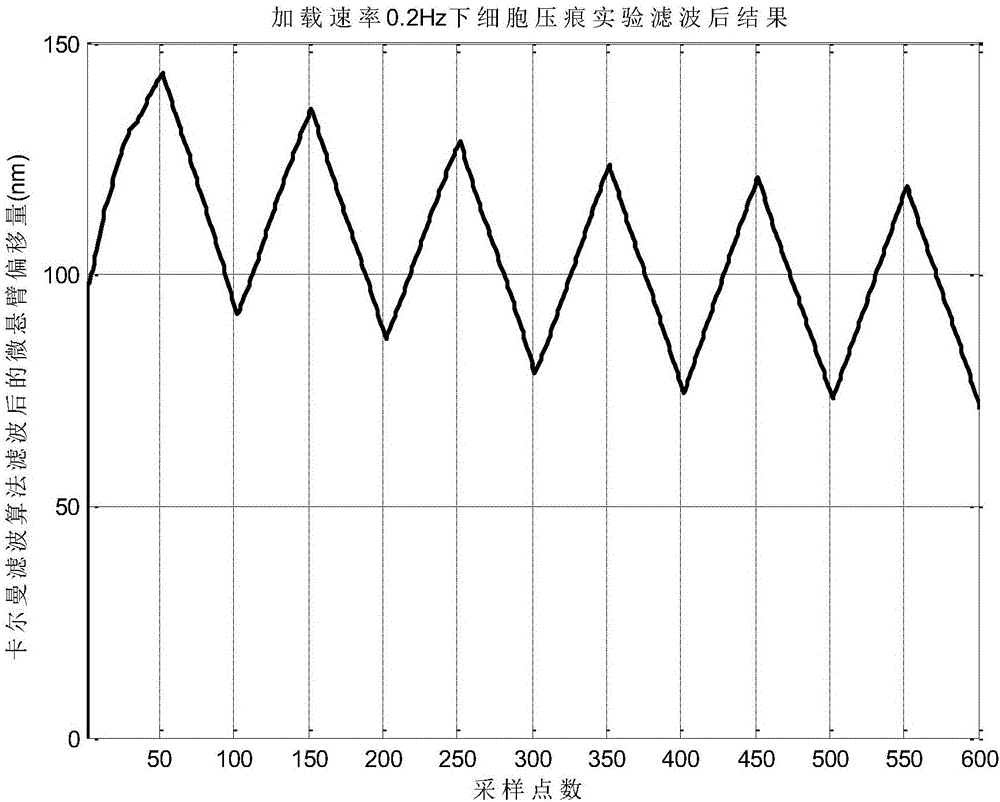

Kalman filtering based method for detecting mechanical property of cell through AFM (Atomic Force Microscope)

InactiveCN106769471AReduce noiseReduce clutterMaterial strength using tensile/compressive forcesAtomic force microscopyIterative learning control

The invention discloses a Kalman filtering based method for detecting the mechanical property of a cell through an AFM (Atomic Force Microscope). The method conducts Kalman filtering on the micro-cantilever offset obtained in a cell indentation experiment to obtain an optimal estimated value for the micro-cantilever offset; an MIIC (modeling-free inversion-based iterative learning control) algorithm is used to iteratively track the optimal estimated value on a hard material, meanwhile, the micro-cantilever offset of the hard material obtained in each iterative process is subjected to Kalman filtering, a z-axis displacement is obtained after the iteration is terminated; and the elasticity modulus of the cell is calculated according to a Hertz model. The micro-cantilever offsets obtained in the cell indentation experiment and the hard material tracking experiment are filtered through a Kalman filtering model to obtain the optimal estimated value of the micro-cantilever offset, the noise and the clutter introduced in the experiment process are reduced, so that the MIIC algorithm effectively tracks the hard material in the tracking experiment, the operation efficiency is improved, meanwhile, the more accurate cell indentation depth value is acquired, and the measurement accuracy of the mechanical property of the cell is improved.

Owner:LESHAN NORMAL UNIV

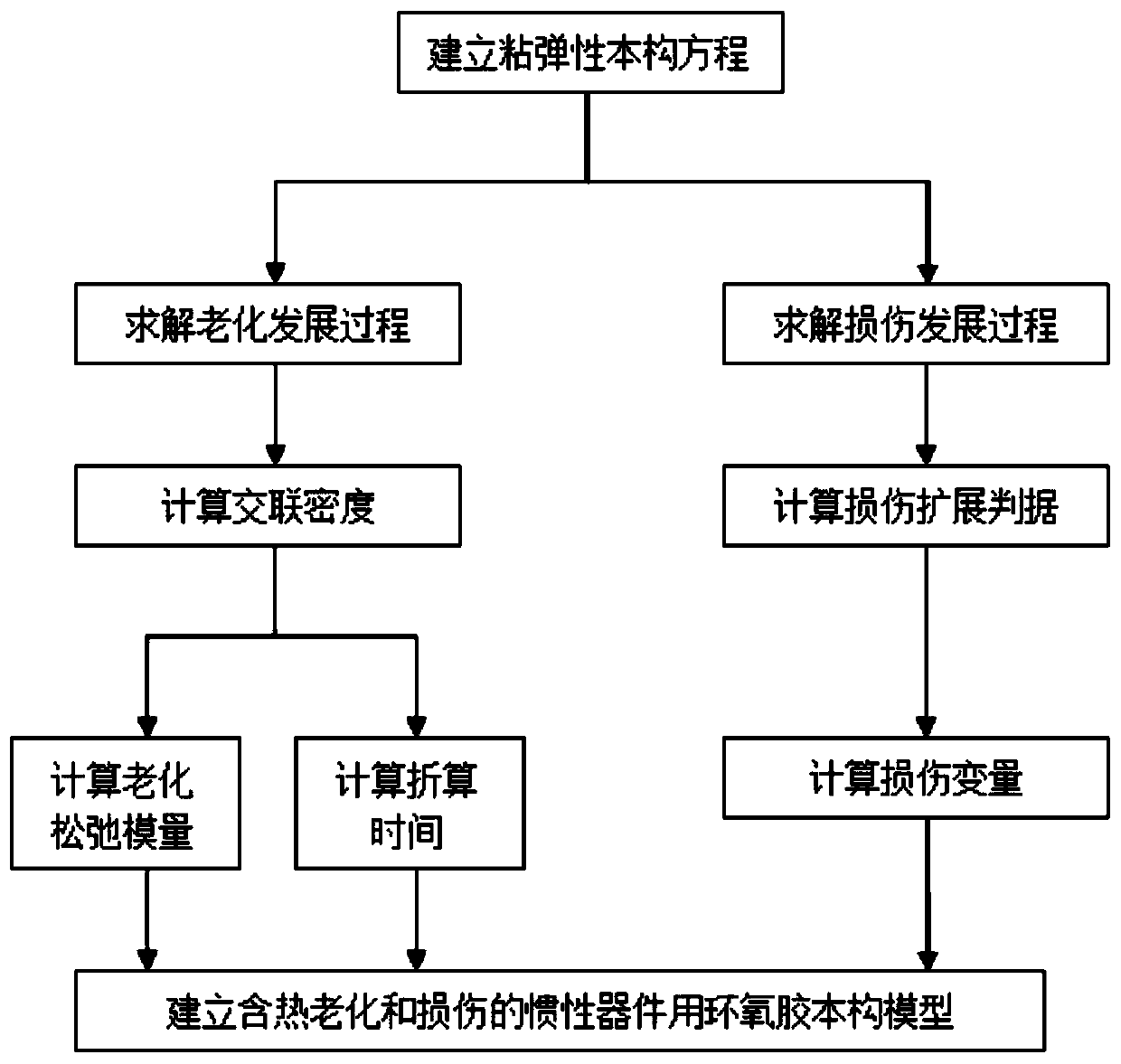

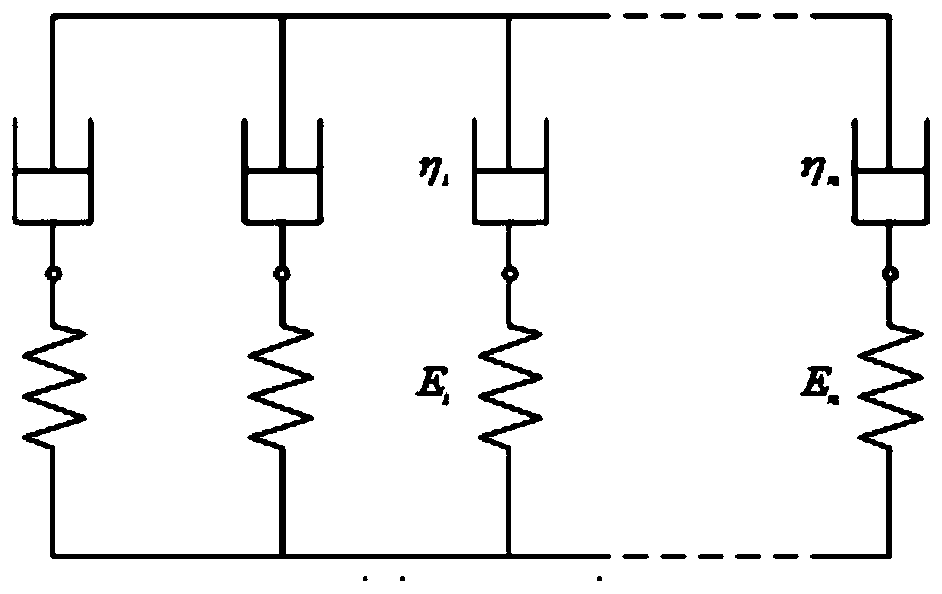

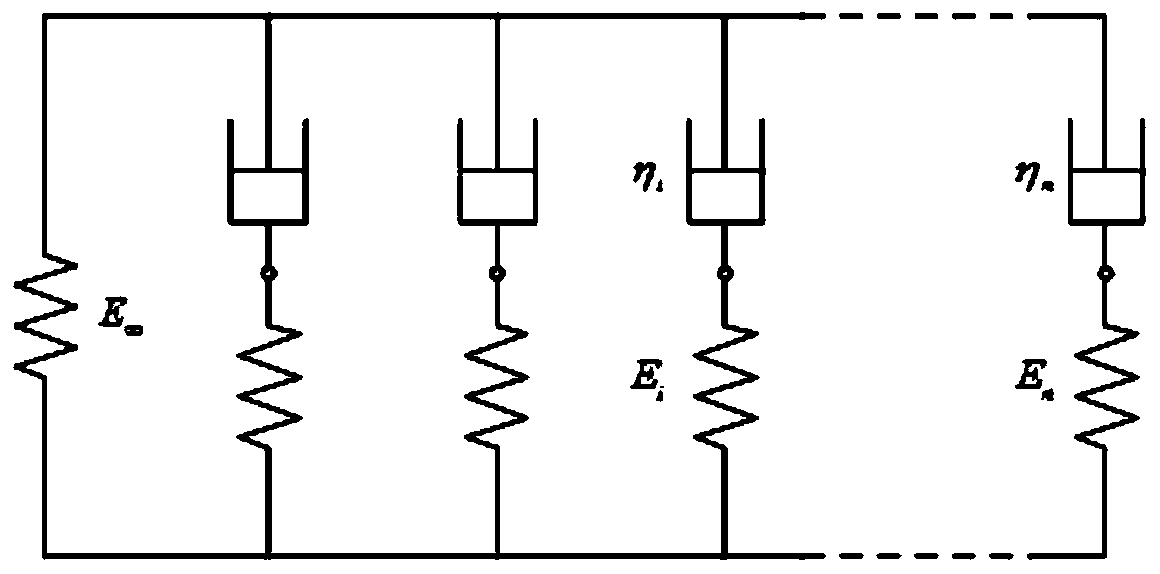

Construction and application method of epoxy glue constitutive model for inertial device

InactiveCN109783985AAccurately reflect mechanical behaviorReflect mechanical behaviorSpecial data processing applicationsEpoxyAdhesive glue

The invention discloses a construction and application method of an epoxy glue constitutive model for an inertial device. The construction and application method comprises the following steps: establishing a linear thermoviscoelasticity constitutive equation, solving an aging development equation and a damage development equation, calculating cross-linking density, conversion time and damage variables, and establishing the epoxy glue constitutive model containing thermal aging and damage. The invention further discloses an application method of the epoxy glue constitutive model for the inertial device. According to the constitutive model construction method, the mechanical behavior of the viscoelastic material under the extreme external environment temperature change and the influence mechanism of the adhesive glue layer on the static output of the inertial device can be reflected more accurately. Accurate numerical simulation and mechanical analysis can be carried out on the constructed viscoelastic constitutive model in finite element software, and the model can be used as a theoretical basis and an application means for temperature change characteristic analysis of an inertial device.

Owner:HUNAN UNIV +1

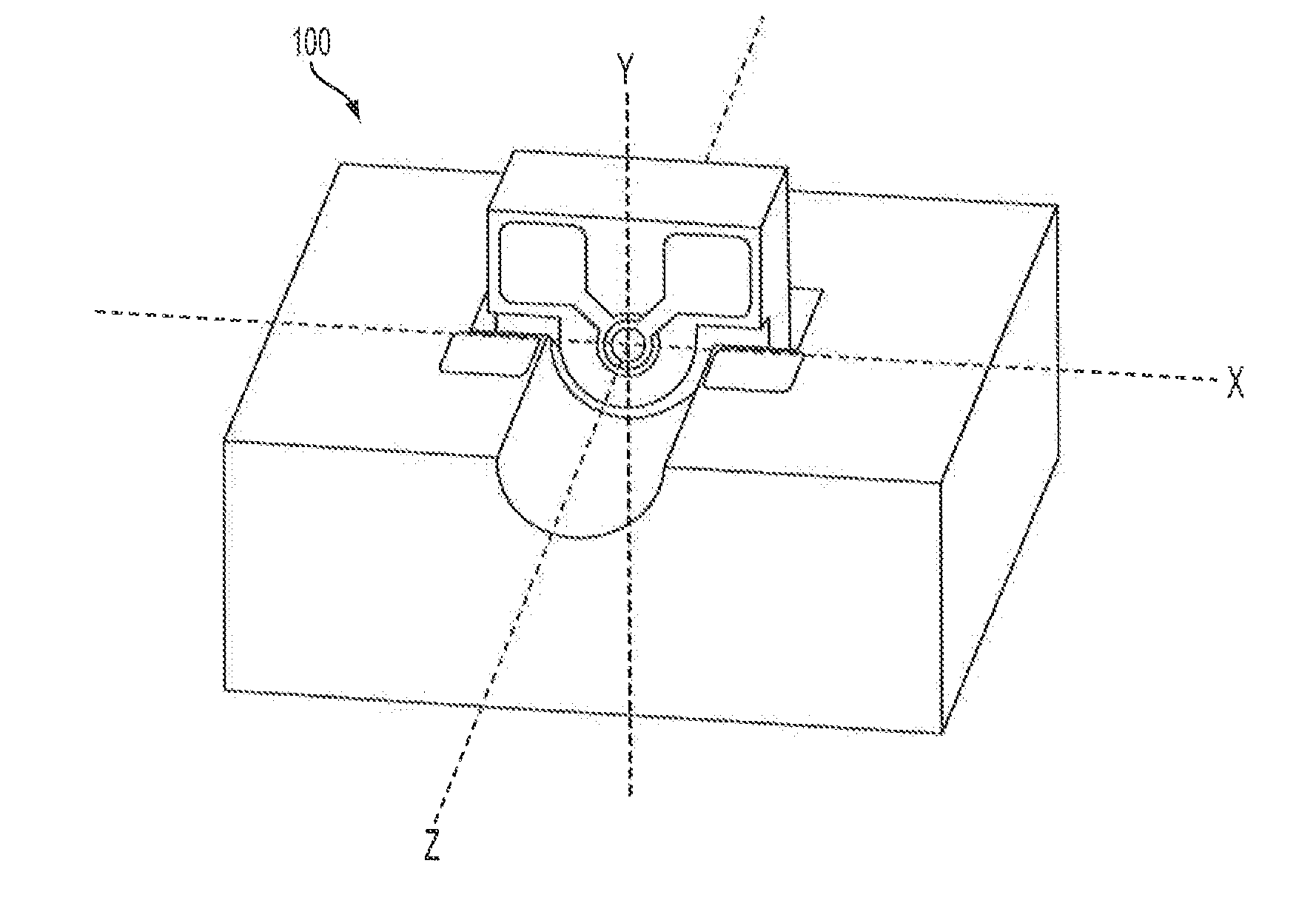

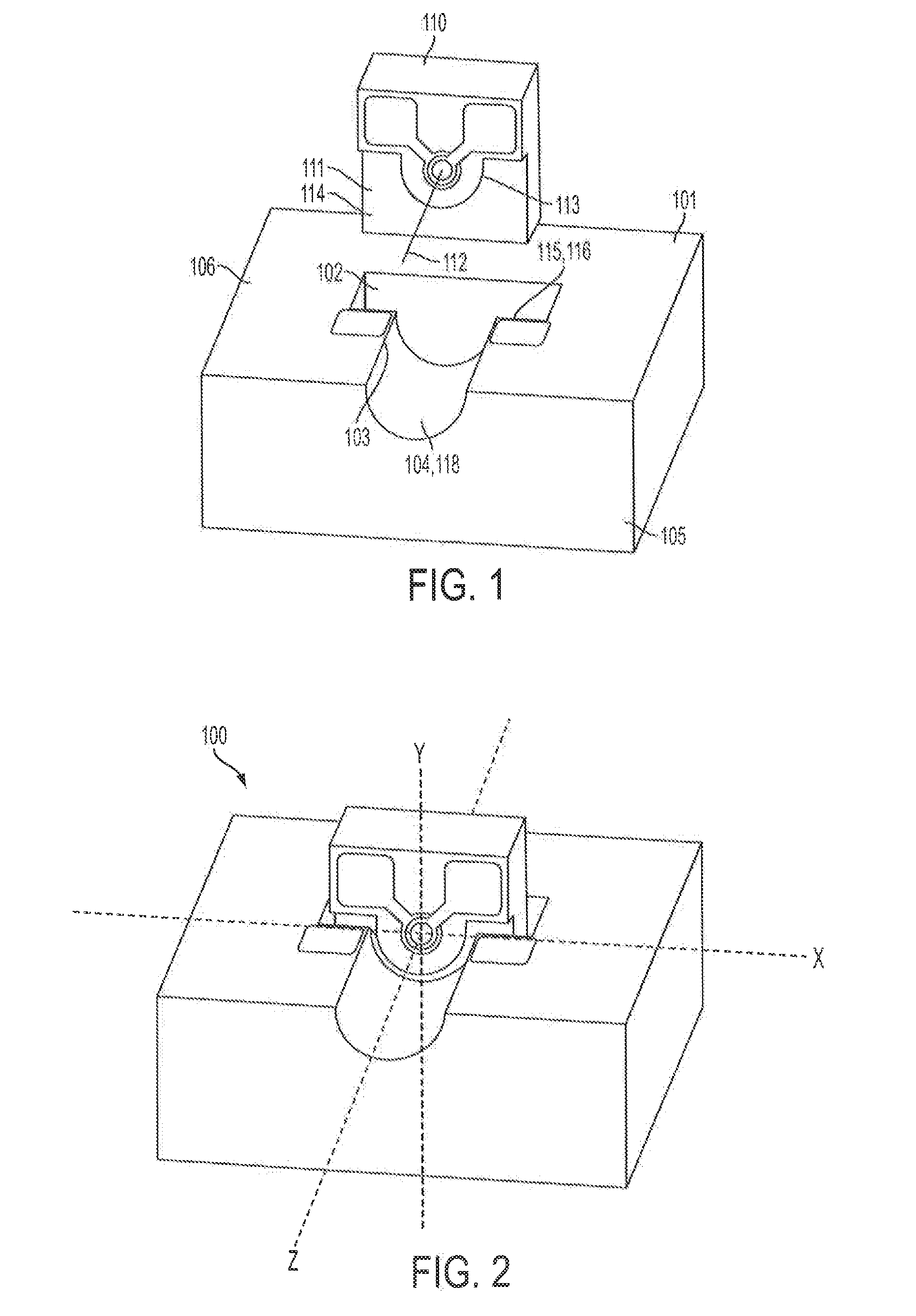

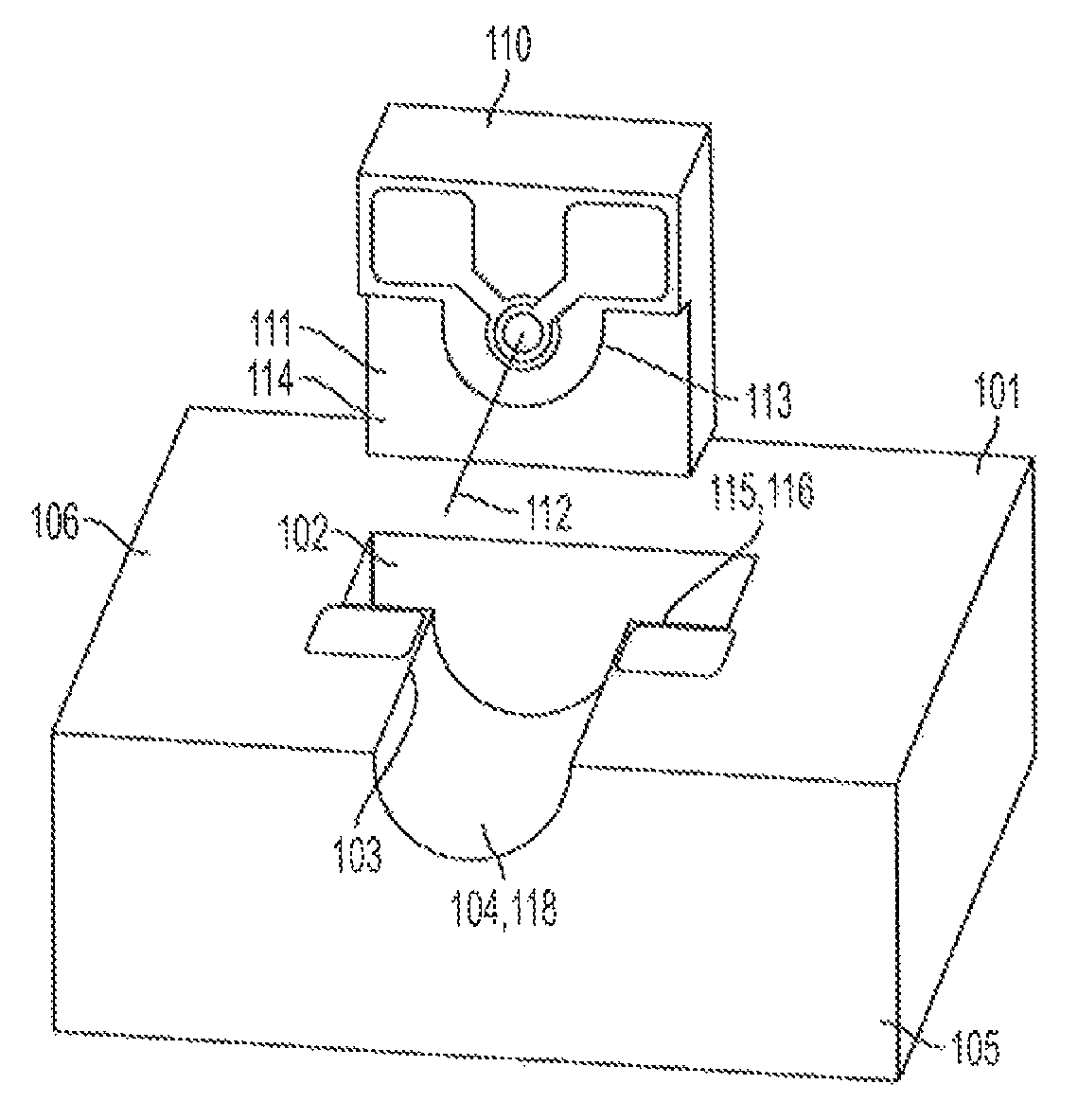

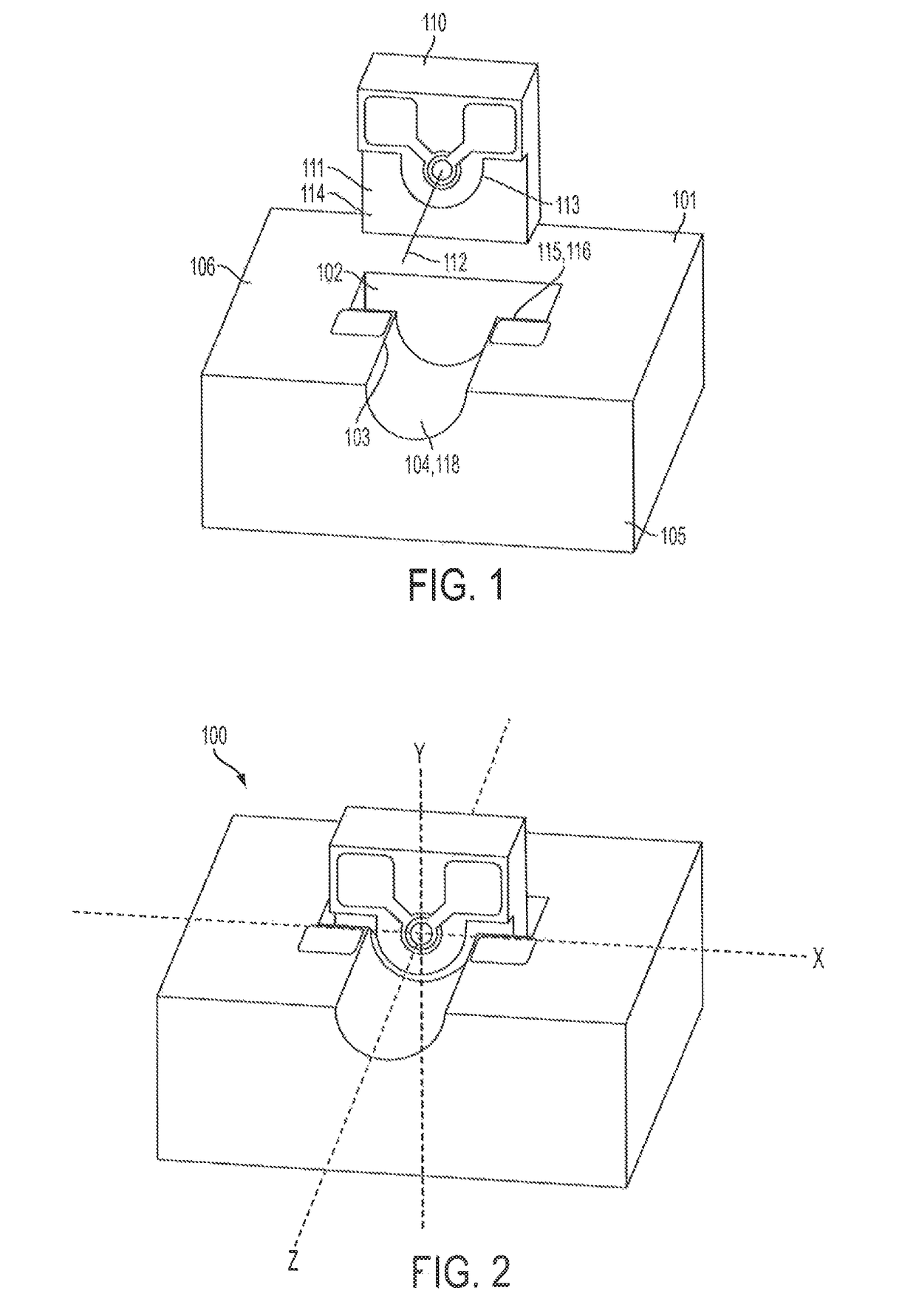

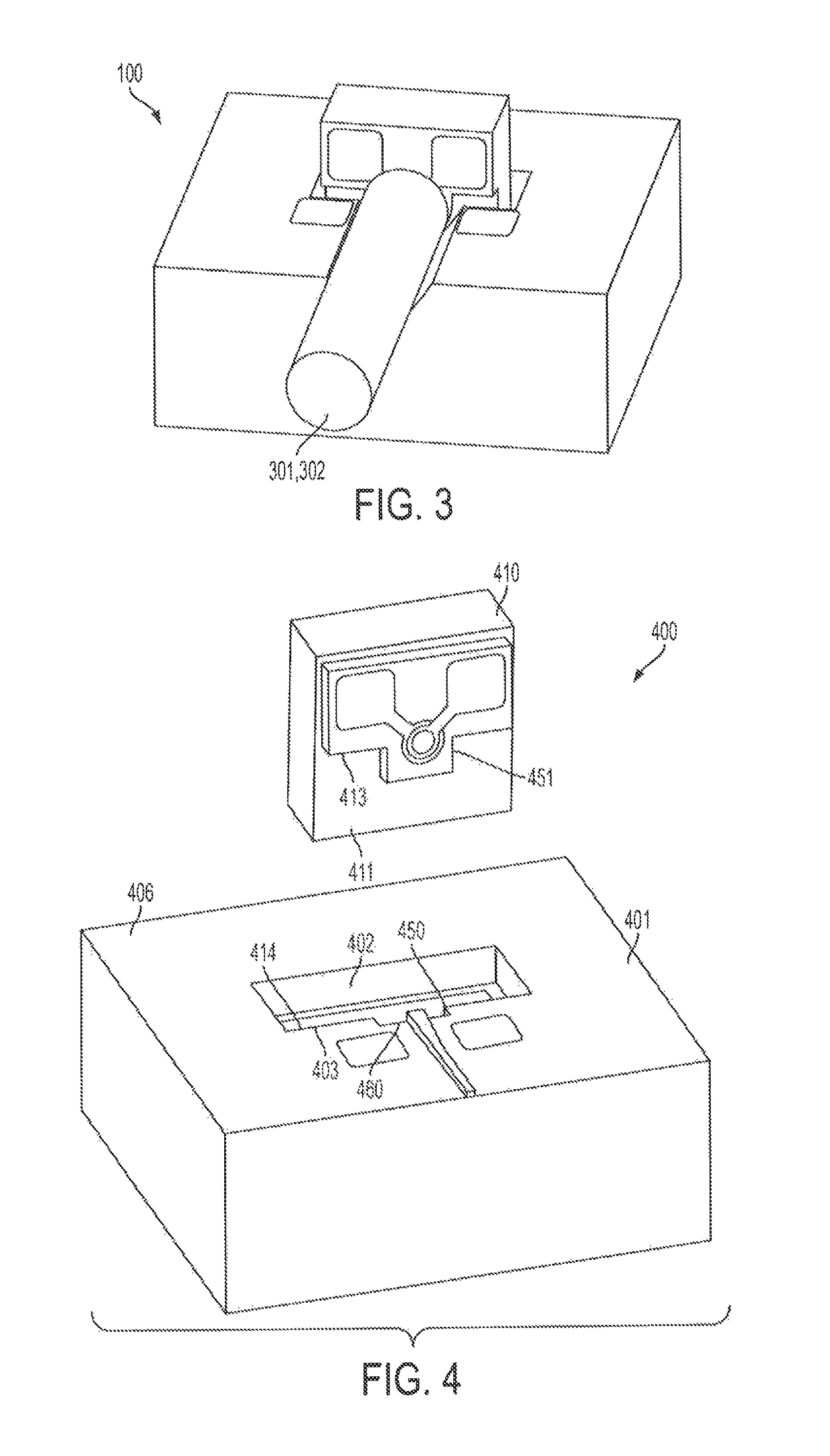

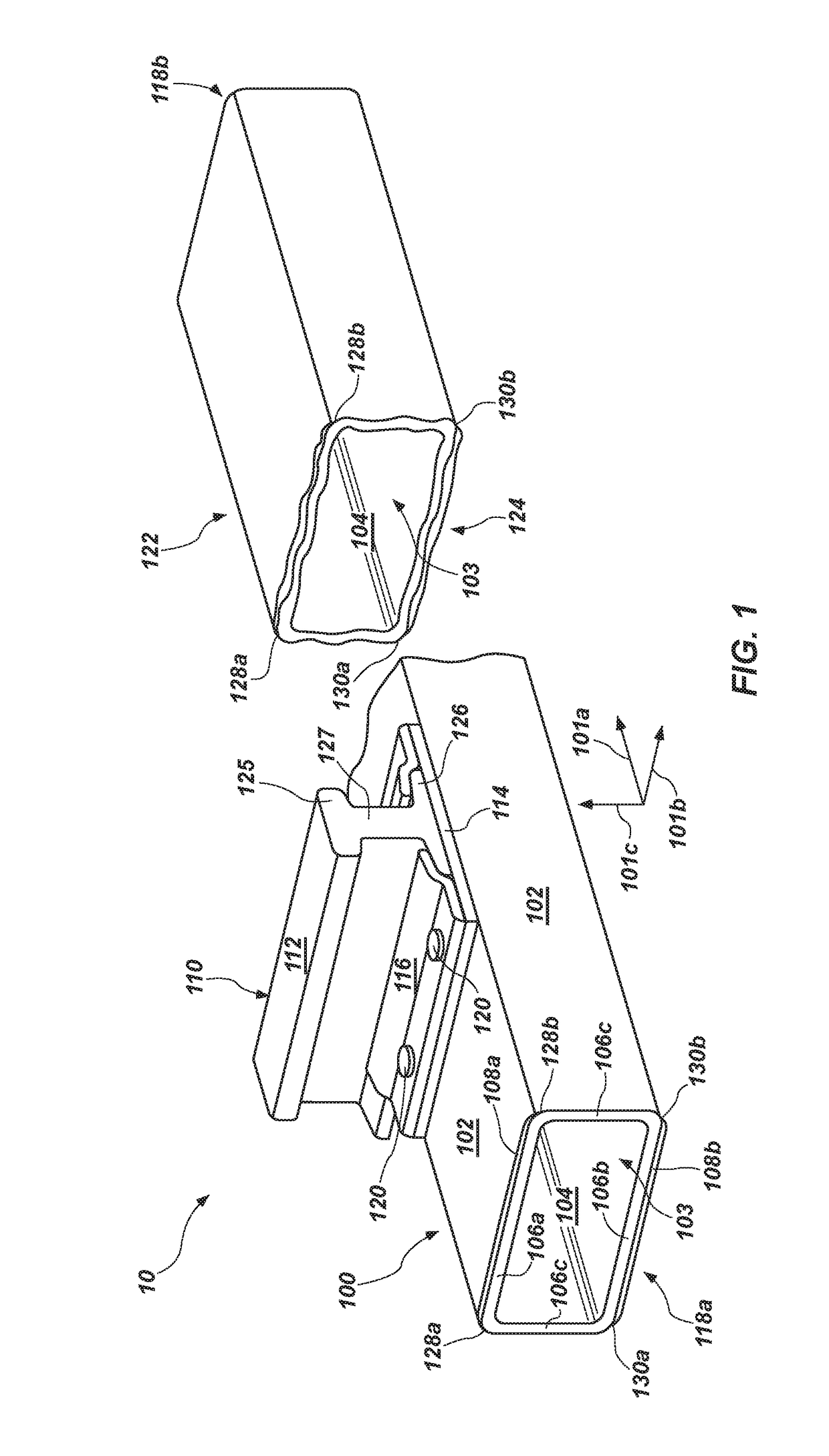

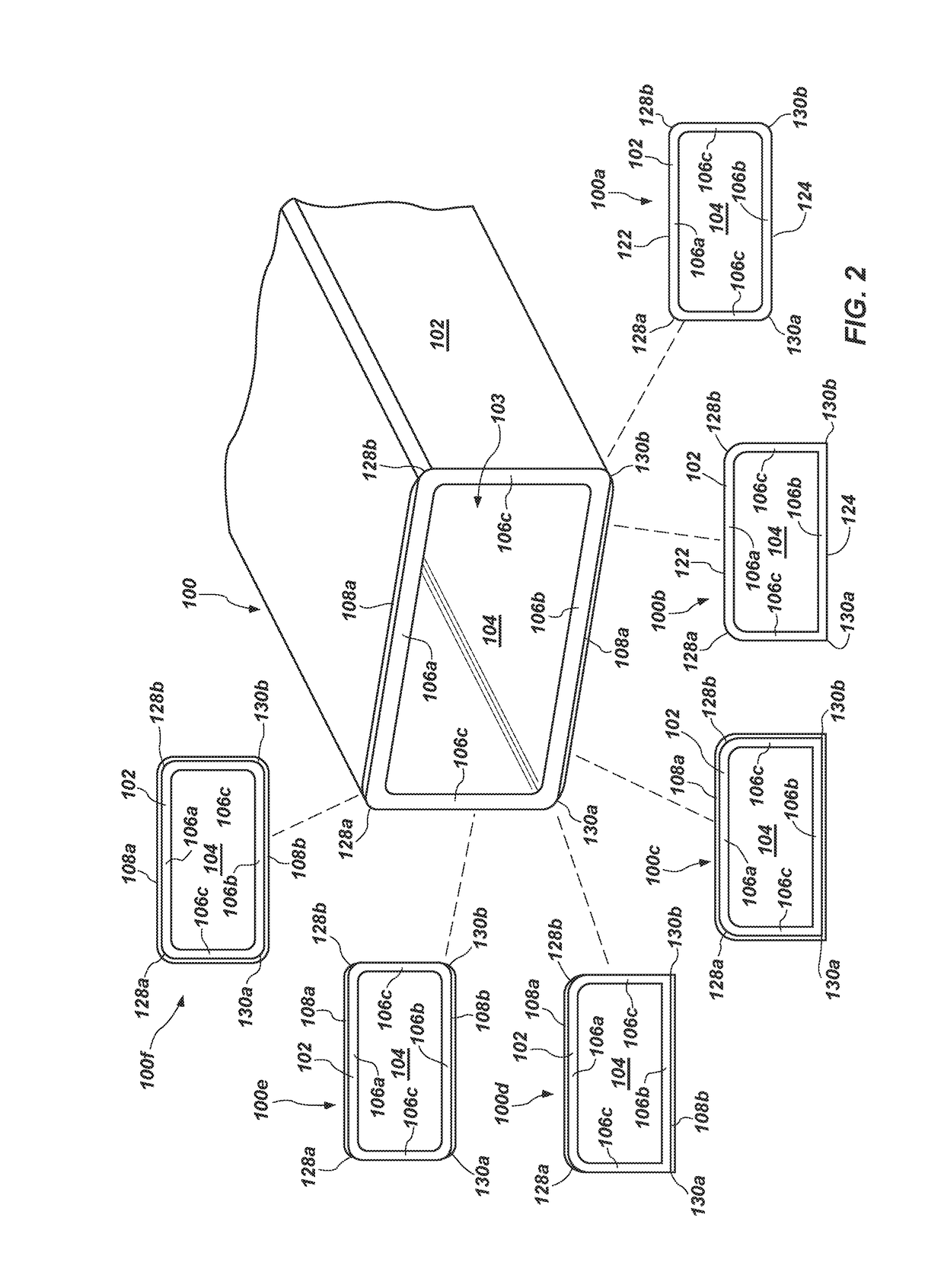

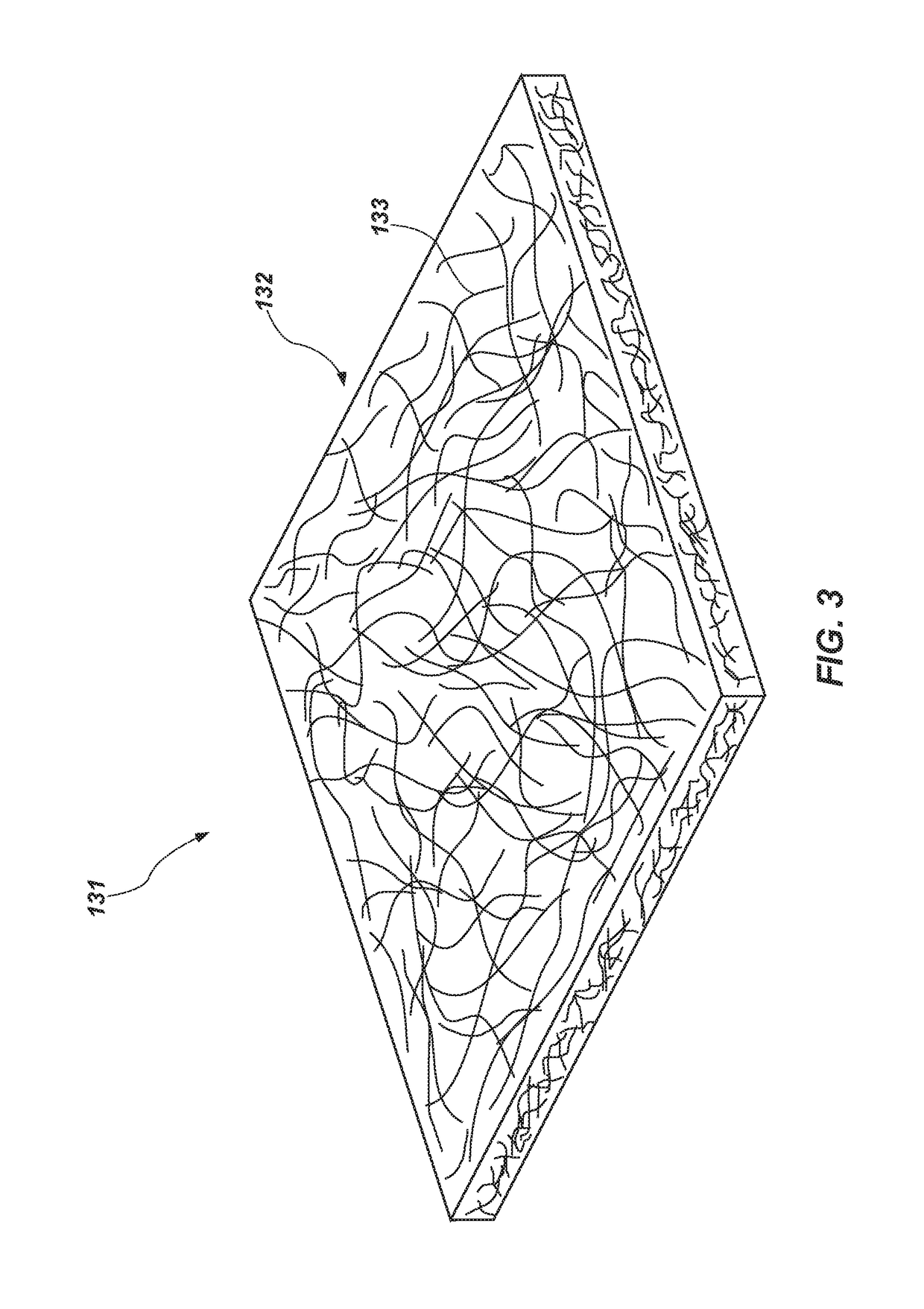

Optical assembly with passive alignment

An optical assembly having x, y and z axes and comprising: (a) a first substrate having a planar surface, a first wall adjacent and substantially perpendicular to the planar surface, a first register surface adjacent the first wall, at least one foundation to receive an optical element having a first optical axis at least partially along the z axis; (b) an opto-electrical device (OED) having a top surface, an active area on the top surface having a second optical axis normal to the top surface, and a first alignment element defined on the top surface, the OED mounted to the first wall such that the first alignment element contacts the first register surface to position the OED on the first substrate along at least one of the x or y axes with the second optical axis parallel to the planar surface.

Owner:TE CONNECTIVITY NEDERLAND

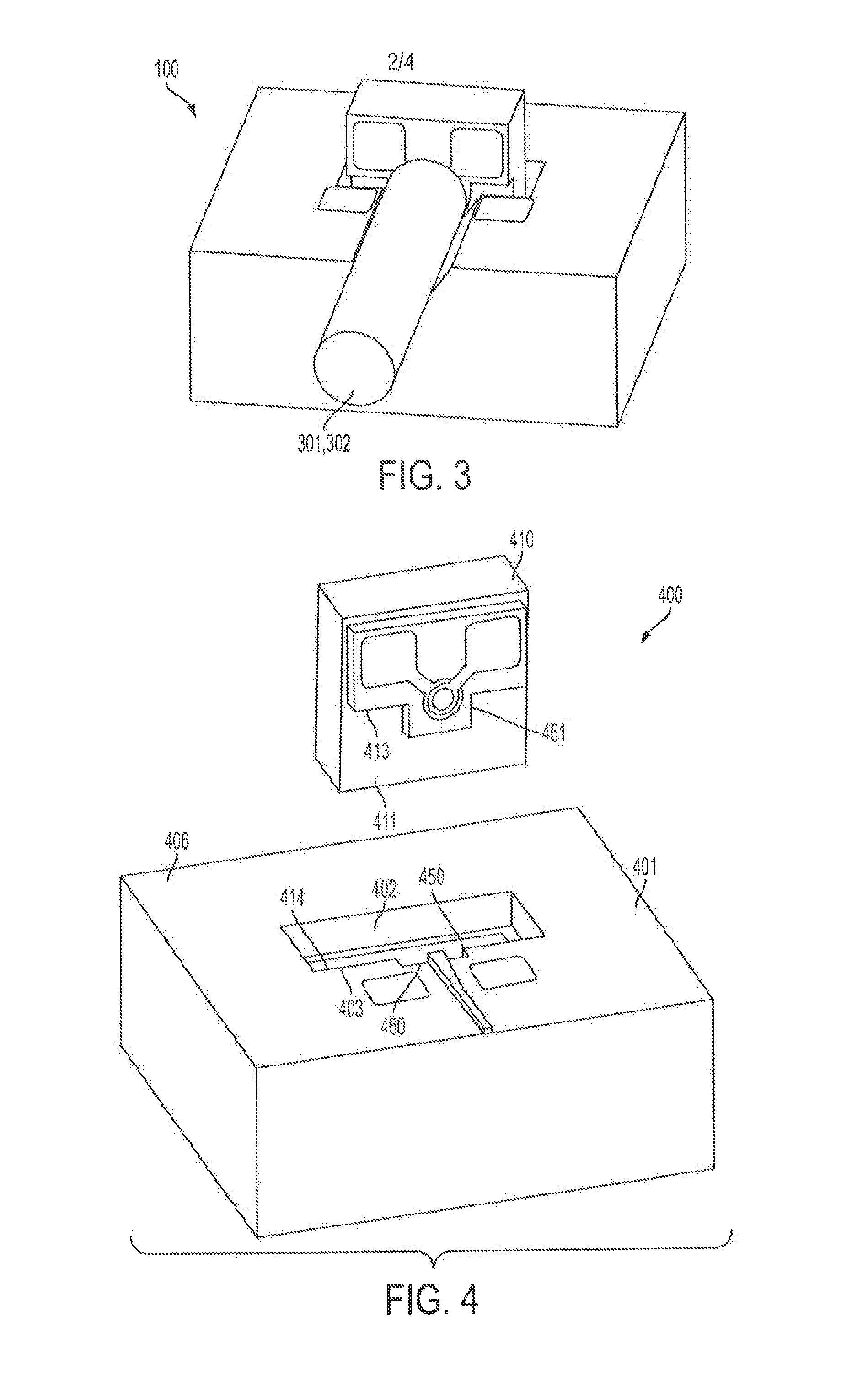

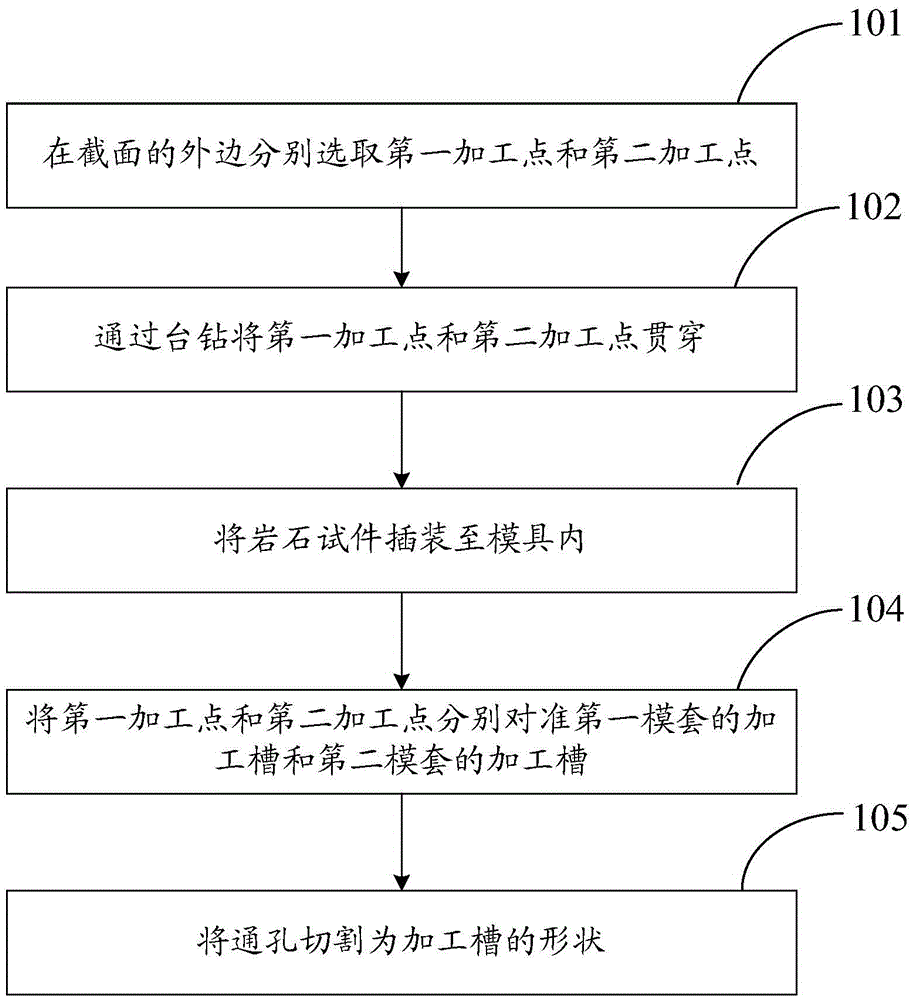

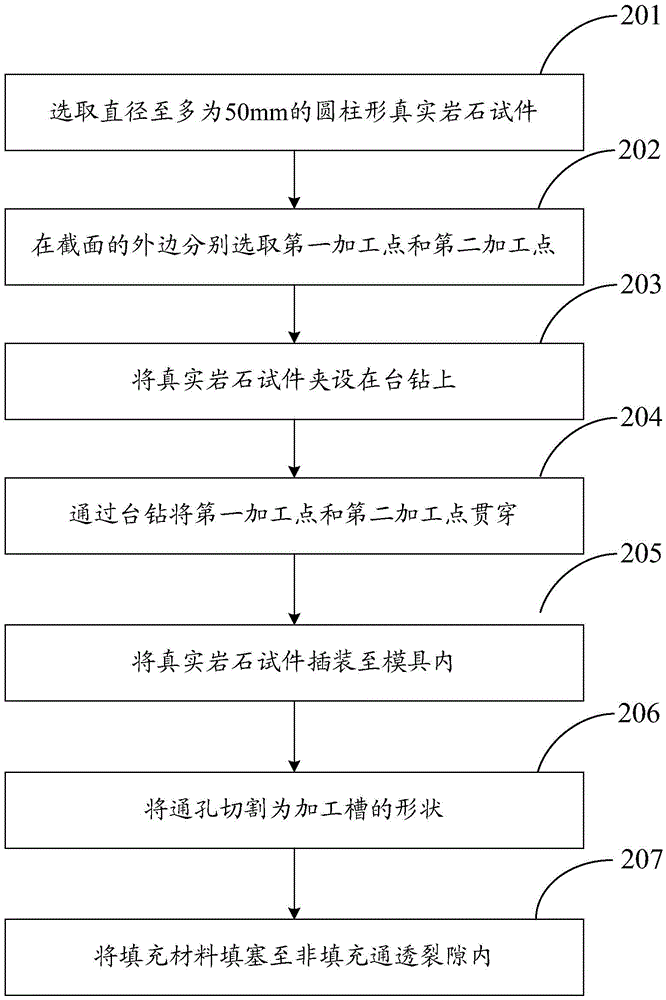

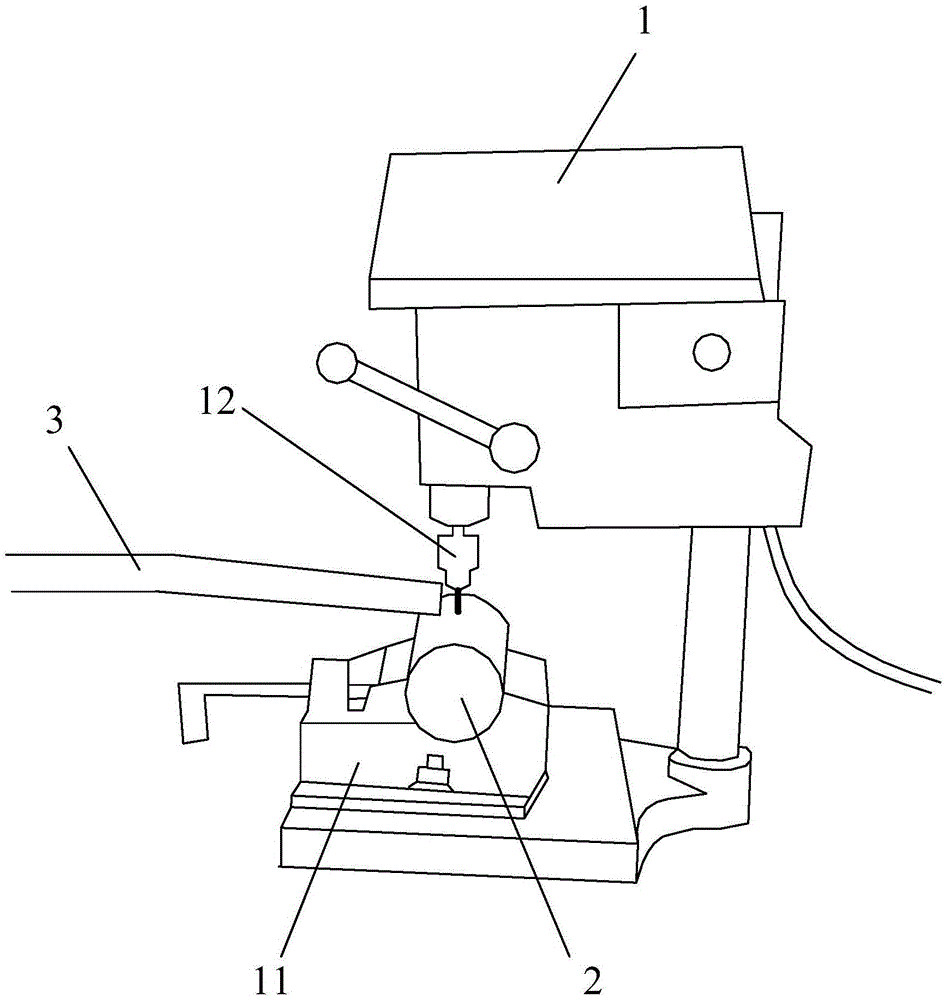

Manufacturing method of real rock specimen having through cracks

InactiveCN105606417AAccurate Mechanical PropertiesThe mechanical properties are accurately obtainedPreparing sample for investigationManufacturing technologyDrill

The invention discloses a manufacturing method of a real rock specimen having through cracks, belonging to the technical field of rock specimen manufacture. The method comprises the steps of selecting a cross section on the cylindrical real rock specimen, wherein the selected cross section is parallel to the bottom surface; respectively selecting a first processing point and a second processing point at the outer side of the cross section, wherein the connecting line between the first processing point and the second processing point passes through the center of a circle of the cross section; enabling the real rock specimen to be clamped on a bench drill, and penetrating the first processing point and the second processing point by using the bench drill to form through holes; inserting the real rock specimen into a mould, wherein the mould comprises a first die sleeve and a second die sleeve, and two processing grooves are respectively formed in the first die sleeve and the second die sleeve; enabling the first processing point and the second processing point to be respectively aligned with the processing groove of the first die sleeve and the processing groove of the second die sleeve; cutting the through holes to enable the shapes of the through holes to be the same as those of the processing grooves, and forming the non-filling through cracks in the real rock specimen. The method can be used for manufacturing the real rock specimen having the through cracks.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

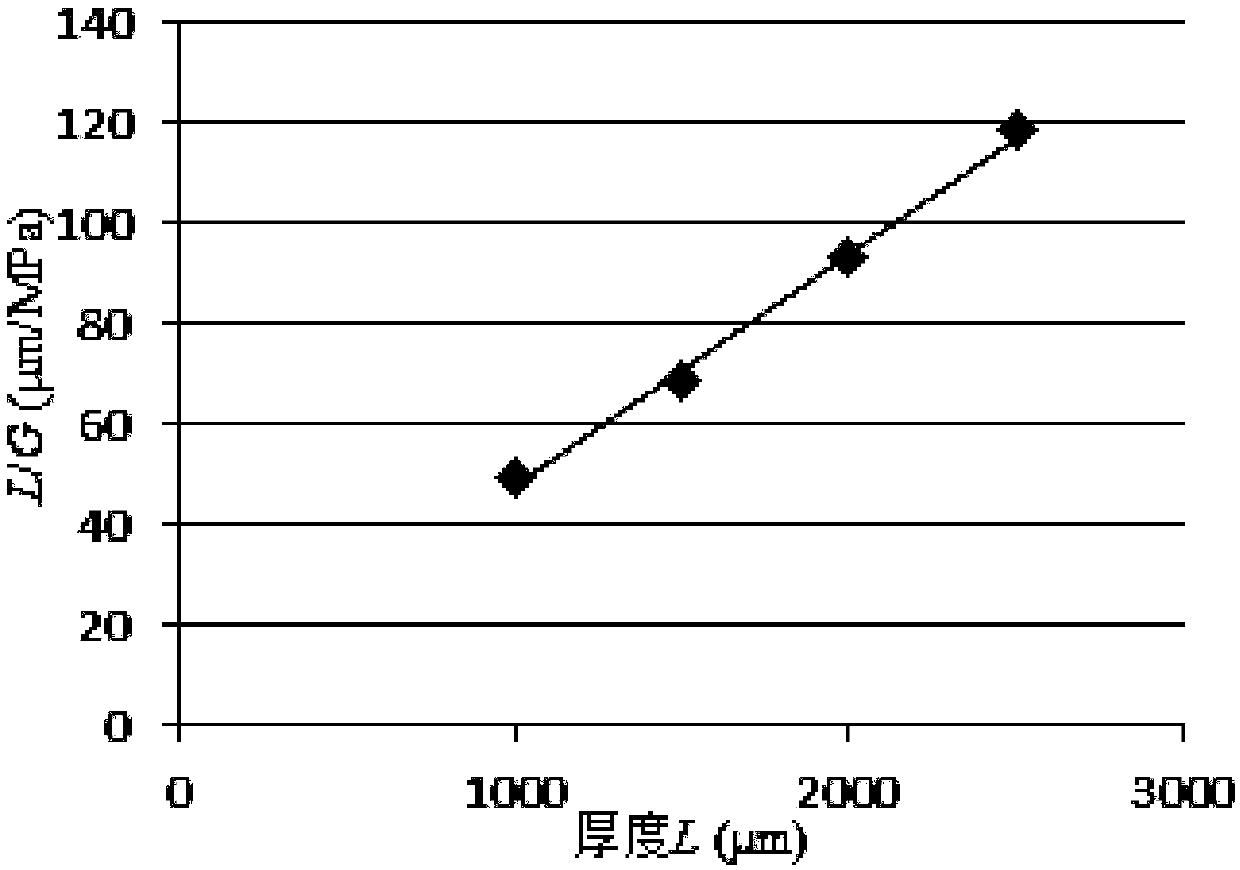

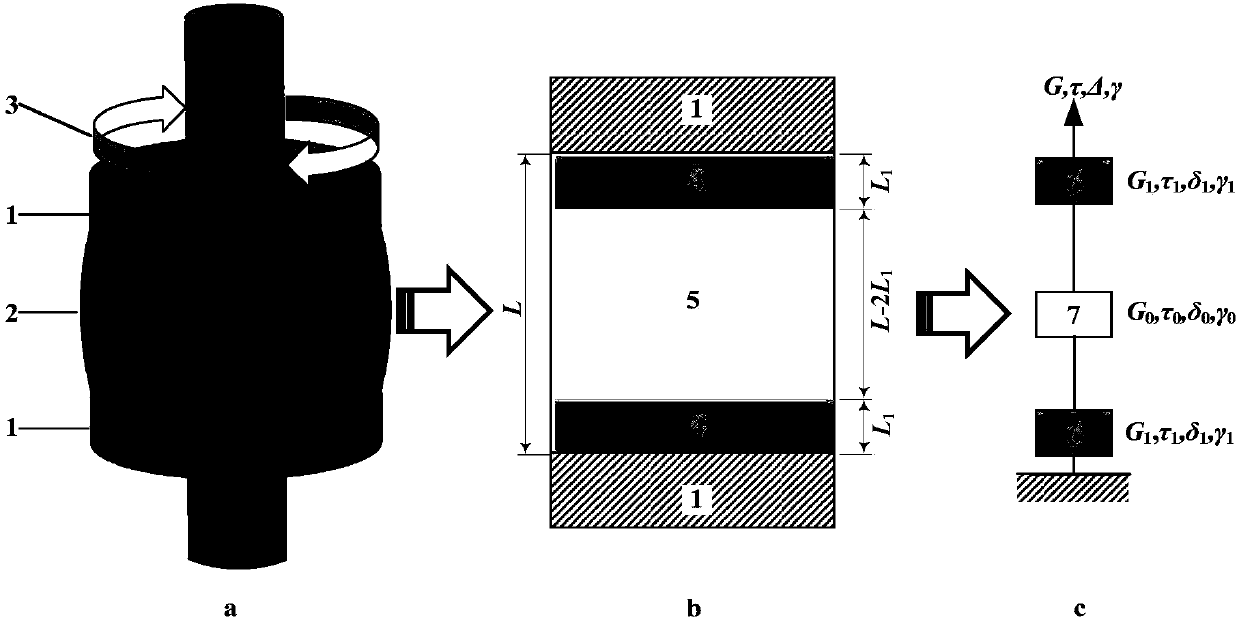

Testing method for dynamic shear complex modulus of bulk-phase asphalt rubber paste by considering substrate-adhesive cement interaction effect

ActiveCN107817174ATest accurateAccurate acquisitionFlow propertiesMaterial strength using steady shearing forcesAdhesive cementAsphalt

The invention provides a testing method for dynamic shear complex modulus of bulk-phase asphalt rubber paste by considering a substrate-adhesive cement interaction effect, and relates to a dynamic shear complex modulus testing method, aiming at solving the problems that the tested dynamic shear complex modulus of the bulk-phase asphalt adhesive cement has errors, caused by the fact that the substrate-adhesive cement interaction effect is ignored by the dynamic shear complex modulus, tested by an existing method, of the bulk-phase asphalt adhesive cement. The method comprises the following steps: preparing an original asphalt adhesive cement test piece; testing to obtain dynamic shear complex modulus detection values G of the asphalt adhesive cement test piece corresponding to different testing thicknesses L; drawing an L / G-L curve diagram; carrying out linear fitting according to a formula L / G=A+1 / G0L, so as to obtain a fitting linear function gradient 1 / G0; then calculating to obtainbulk-phase asphalt adhesive cement modulus G after considering the substrate-adhesive cement interaction effect. According to the dynamic shear complex modulus testing method provided by the invention, a complicated microcosmic-macroscopic interaction effect spanning mechanism is greatly simplified and the substrate-adhesive cement interaction effect influence is accurately separated to obtain thereal dynamic shear complex modulus of the bulk-phase asphalt adhesive cement.

Owner:HARBIN INST OF TECH

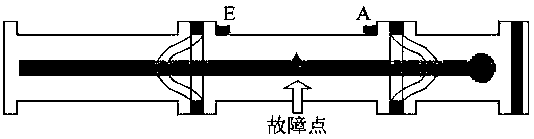

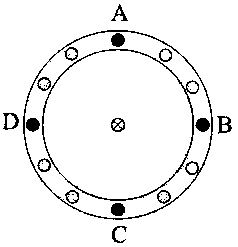

GIS fault accurate positioning method and positioning system thereof based on vibration signals

ActiveCN110018391ASimple structureEasy to operateSubsonic/sonic/ultrasonic wave measurementTesting using acoustic measurementsElectrical connectionData acquisition

The invention discloses a GIS fault accurate positioning method and a positioning system thereof based on vibration signals, wherein a GIS fault accurate positioning system is adopted. The GIS fault accurate positioning system comprises a vibration sensor, a data acquisition instrument and a PC which are connected in sequence, wherein the vibration sensor is fixedly arranged on the shell surface of the GIS device. The GIS fault accurate positioning system based on the vibration signals, provided by the invention, which acquisition of vibration signals has no electrical connection with GIS equipment, has the advantages of simple structure, easy operation, economy and practicability. The GIS fault accurate positioning method based on the vibration signals, provided by the invention, has theadvantages that the mechanical fault and the insulation fault can be accurately positioned at the same time, and the positioning accuracy is higher than that of the prior means and methods.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

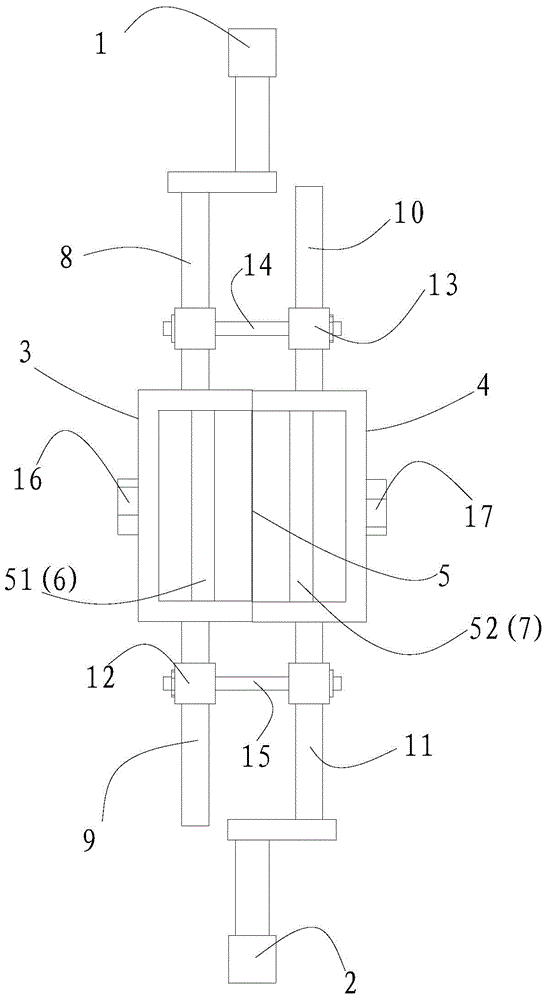

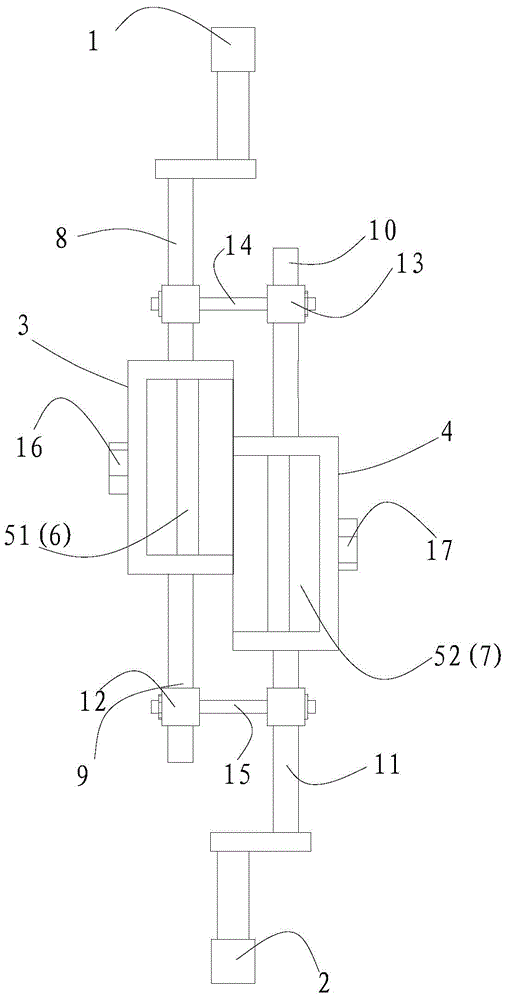

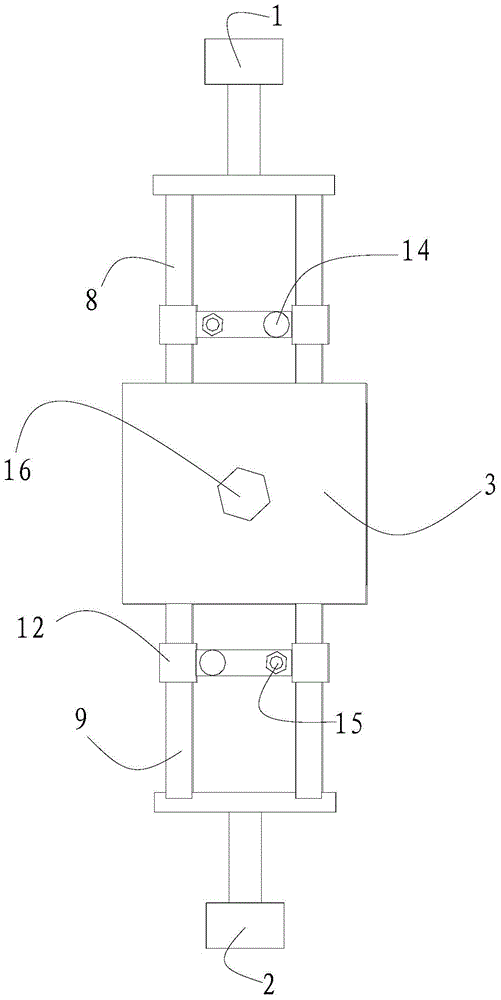

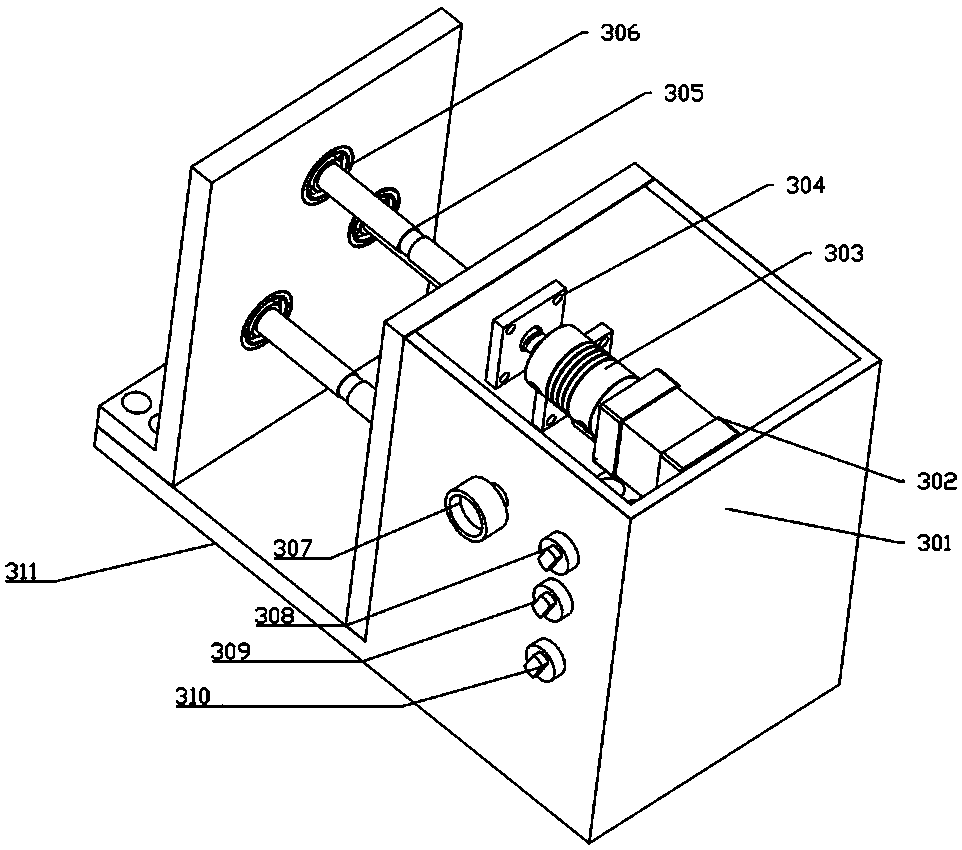

Clamp and method for detecting mechanical property of rolled composite material thermal simulation test sample

The invention discloses a clamp and a method for detecting mechanical property of a rolled composite material thermal simulation test sample. The clamp comprises a first clamp sleeve and a second clamp sleeve which are oppositely arranged, wherein a first containing groove and a second containing groove which can contain a composite material are respectively formed in the first clamp sleeve and the second clamp sleeve; a first vertical guide post and a second vertical guide post are respectively arranged at the upper end and the lower end of the first clamp sleeve; a third vertical guide post and a fourth vertical guide post are respectively arranged at the upper end and the lower end of the second clamp sleeve; the vertical guide post is connected with a second slide block on the third vertical guide post; the fourth vertical guide post is connected with a first slide block on the second vertical guide post; a first clamping head is arranged at the upper end of the first vertical guide post; a second clamping head is arranged at the lower end of the fourth vertical guide post. The related mechanical property of a rolled composite material can be obtained by stretching the first clamping head and the second clamping head by a stretcher to separate the first clamp sleeve from the second clamp sleeve.

Owner:银邦(安徽)新能源材料科技有限公司

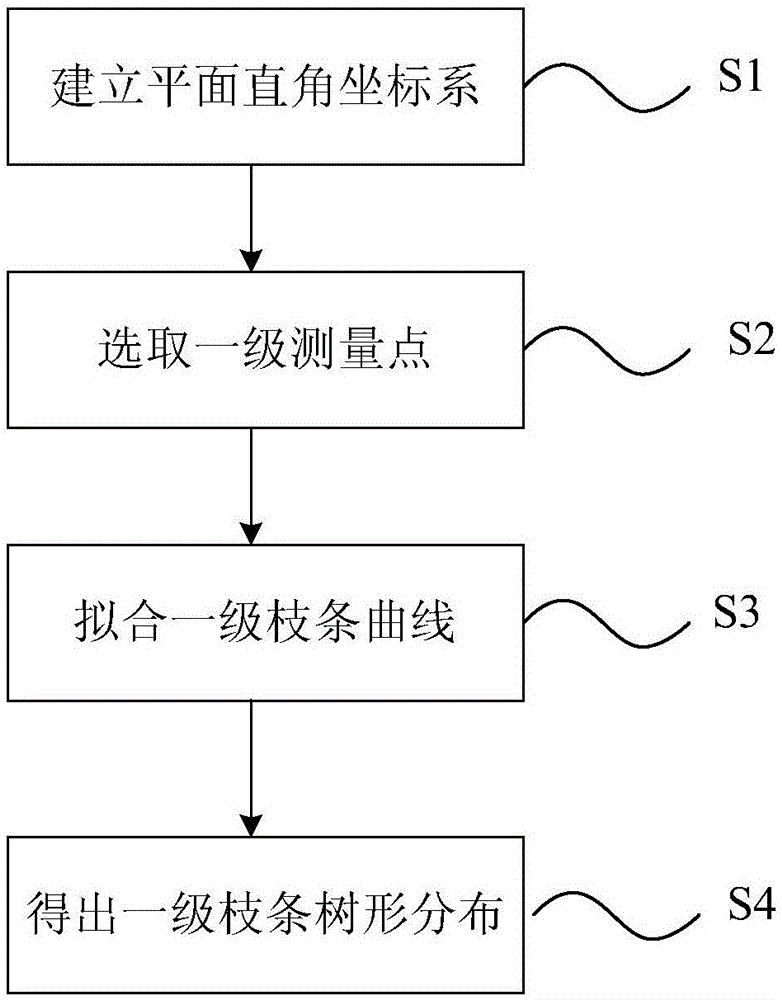

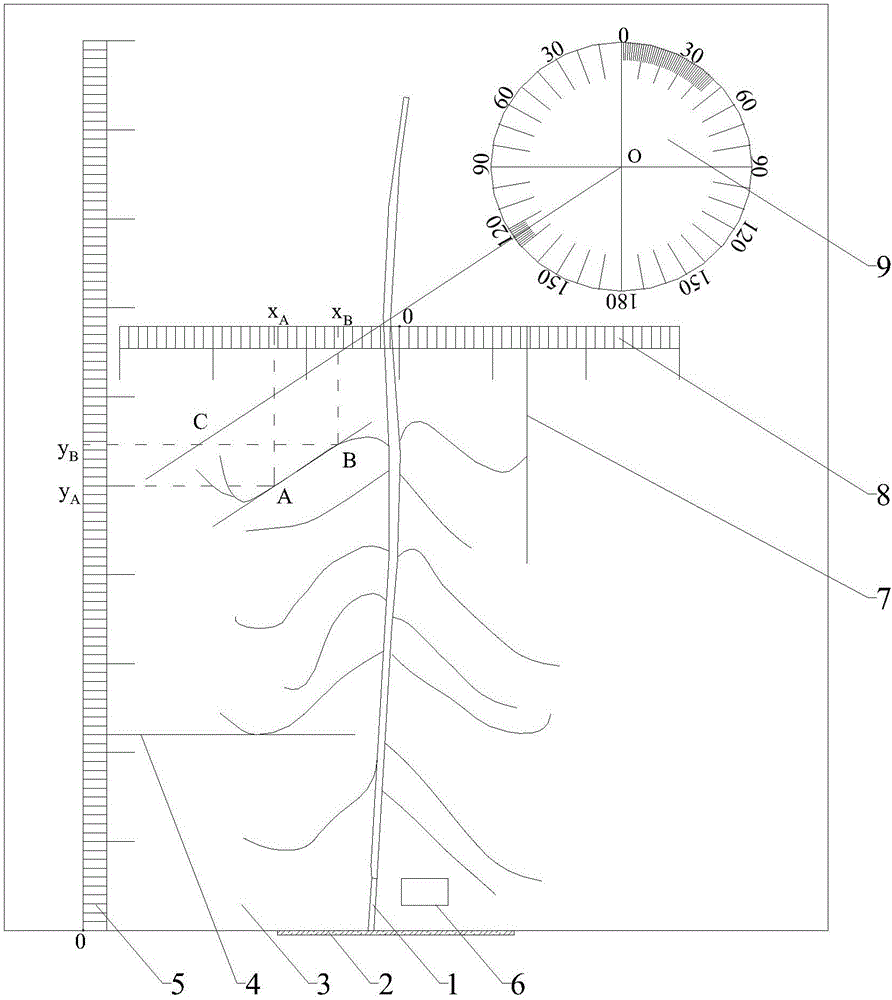

Measurement method and device of tree shape of fruit tree

InactiveCN106441202AAchieve mechanized pruningPrecision medicineMeasurement devicesFruit treeMeasurement device

The invention relates to a measurement method of a tree shape of a fruit tree. The measurement method comprises the following steps: 1) establishing a plane rectangular coordinate system vertical to the ground, wherein in the rectangular coordinate system, a direction parallel to the ground is a horizontal direction and a direction vertical to the ground is a vertical direction; 2) selecting a plurality of first-grade measurement points from one first-grade branch connected with a fruit tree trunk and projecting to the coordinate system; 3) fitting a branch curve of the first-grade branch according to coordinates of the first-grade measurement points on the rectangular coordinate system; and 4) selecting the other first-grade branch and repeating steps 2) and 3) until the first-grade branch is measured so as to obtain the tree shape of the first-grade branch of the fruit tree. The tree shape of each fruit tree at a phenological period is measured and a fruit tree growth parameter database can be formed, so that theoretical data support is provided for mechanical pruning, accurate pesticide application and mechanical picking. The invention further relates to a measurement device of the tree shape of the fruit tree, which can realize the measurement method.

Owner:HEBEI AGRICULTURAL UNIV.

Preparation method and application of skeleton-imitating macromolecular composite material for dummy

The invention belongs to the technical field of bionic macromolecular composite materials, and relates to a preparation method and an application of a skeleton-imitating macromolecular composite material for a dummy. The composite material is prepared by the steps: firstly, treating an inorganic filler with an industrial coupling agent; secondly, fully and uniformly mixing thermosetting resin, theinorganic filler, a cross-linking agent and the like, carrying out pouring low-temperature pre-curing, and then carrying out heating curing; or fully and uniformly mixing thermoplastic resin, the inorganic filler and the like, and carrying out high-temperature casting molding. The macromolecular composite artificial bone material with similar mechanical properties of skeleton at different parts of a human body can be prepared by changing the types, weight fractions and the like of the raw materials. In a three-point bending mechanical test, the bending strength of the composite material is 30-160 MPa, and the bending modulus of the composite material is 5-18 GPa. The prepared macromolecular composite artificial bone material is a bionic material having the mechanical properties highly similar to those of human skeletons at different parts, and can meet the application requirements of developing the dummy with the test requirements of simulating collision, penetration and the like.

Owner:HUNAN UNIV

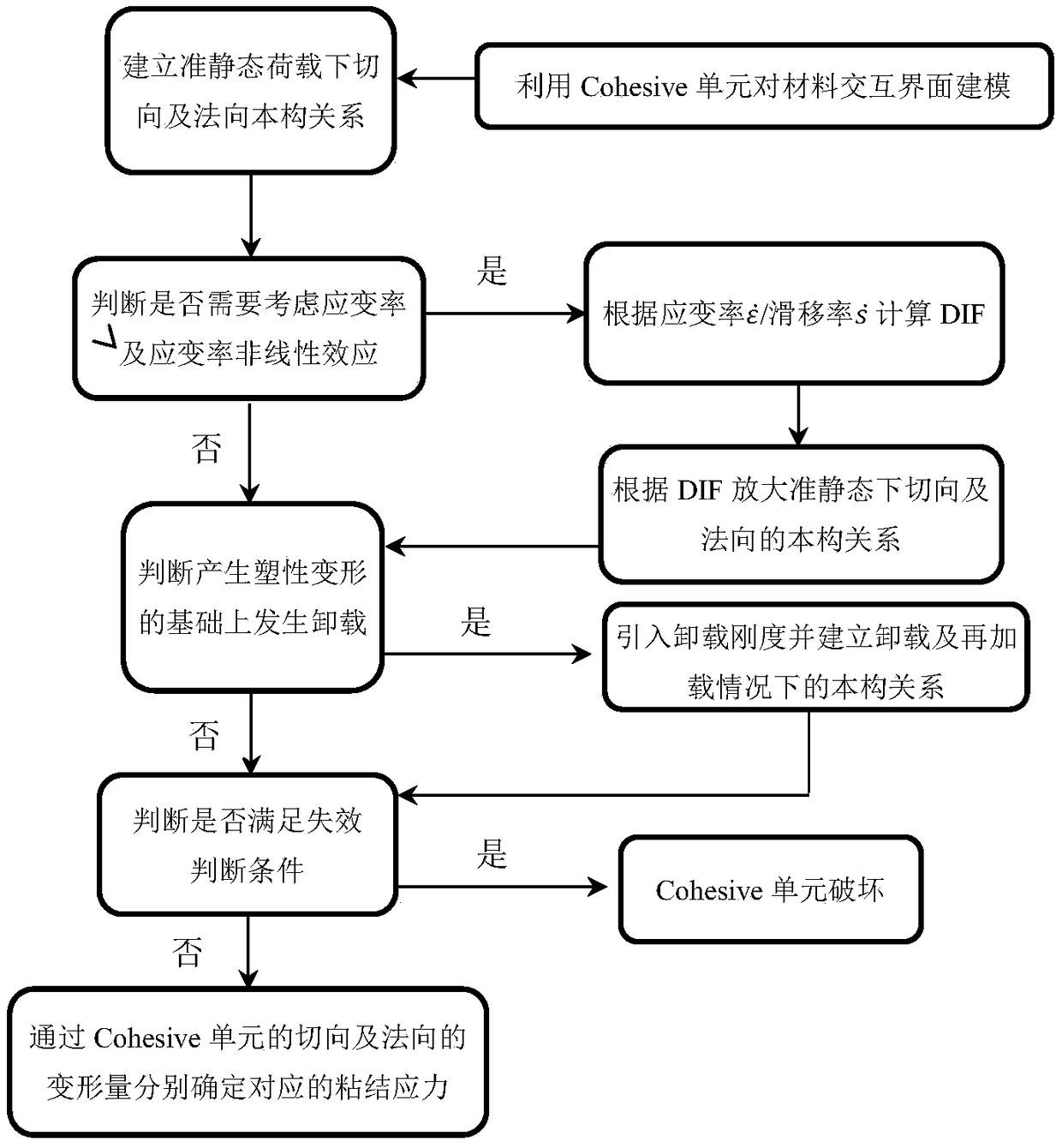

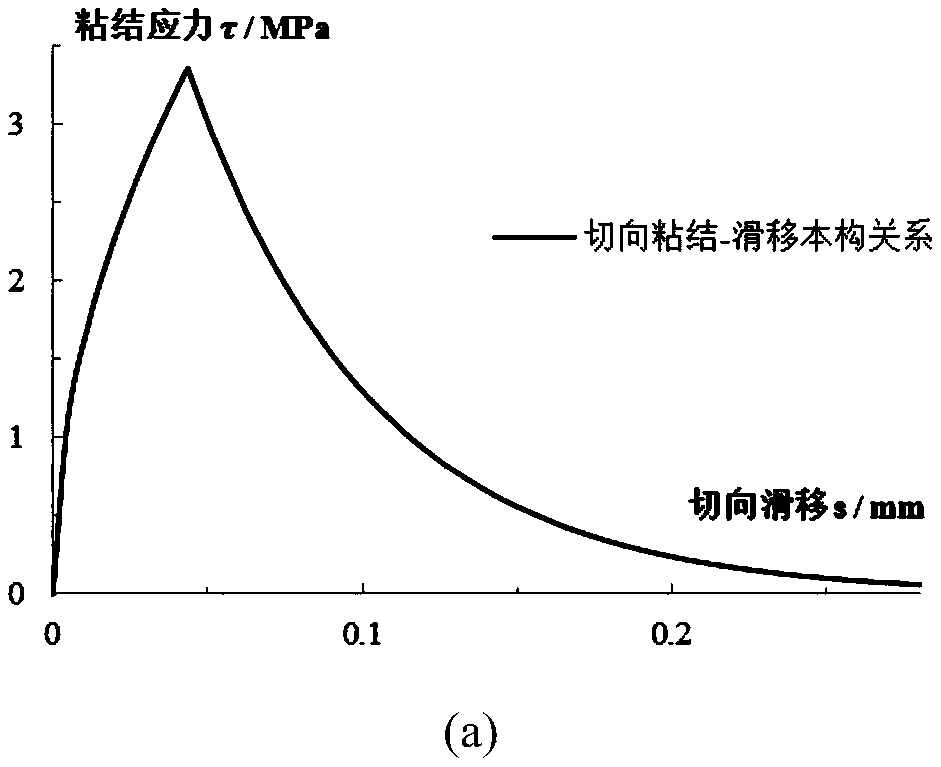

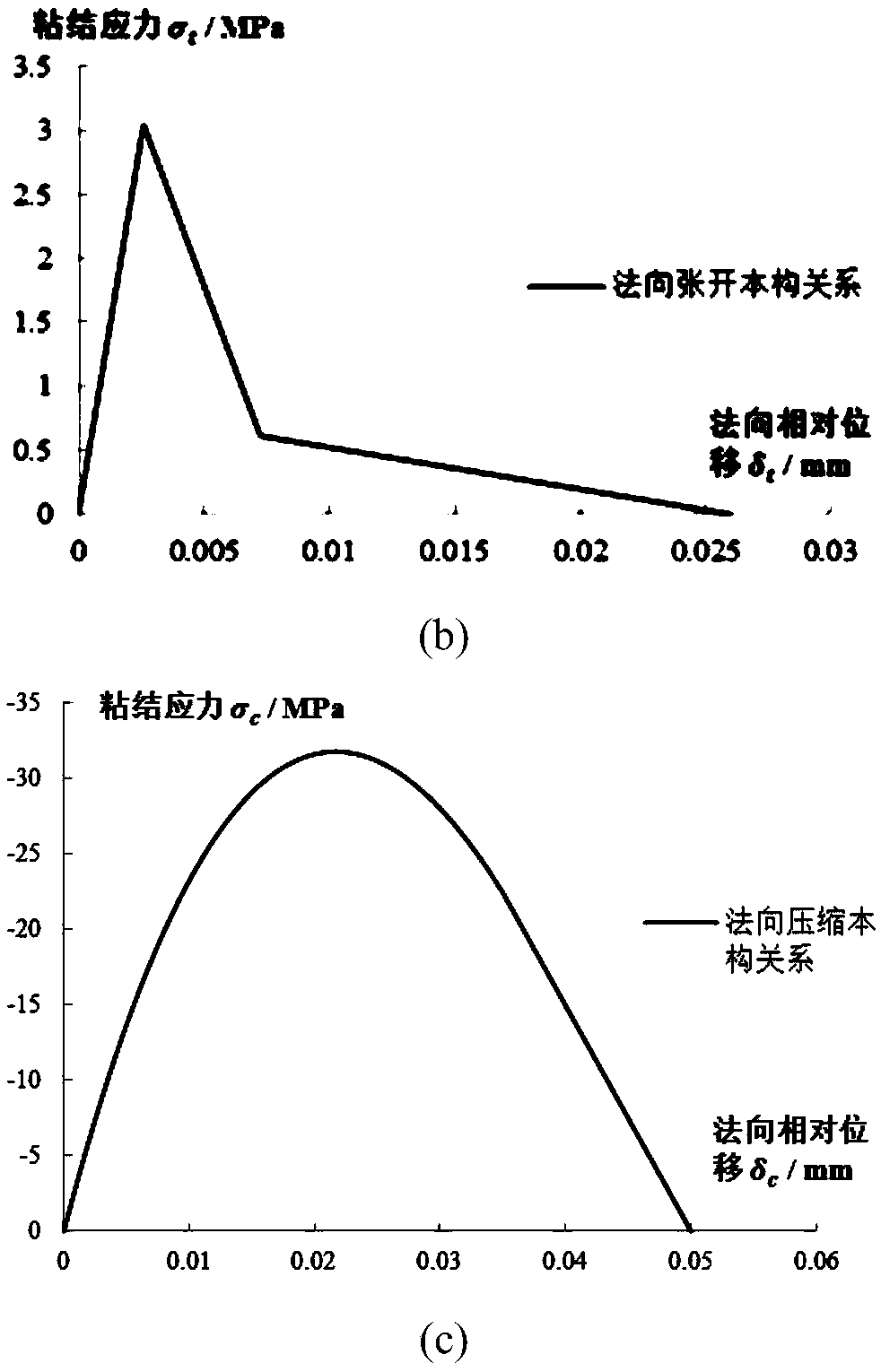

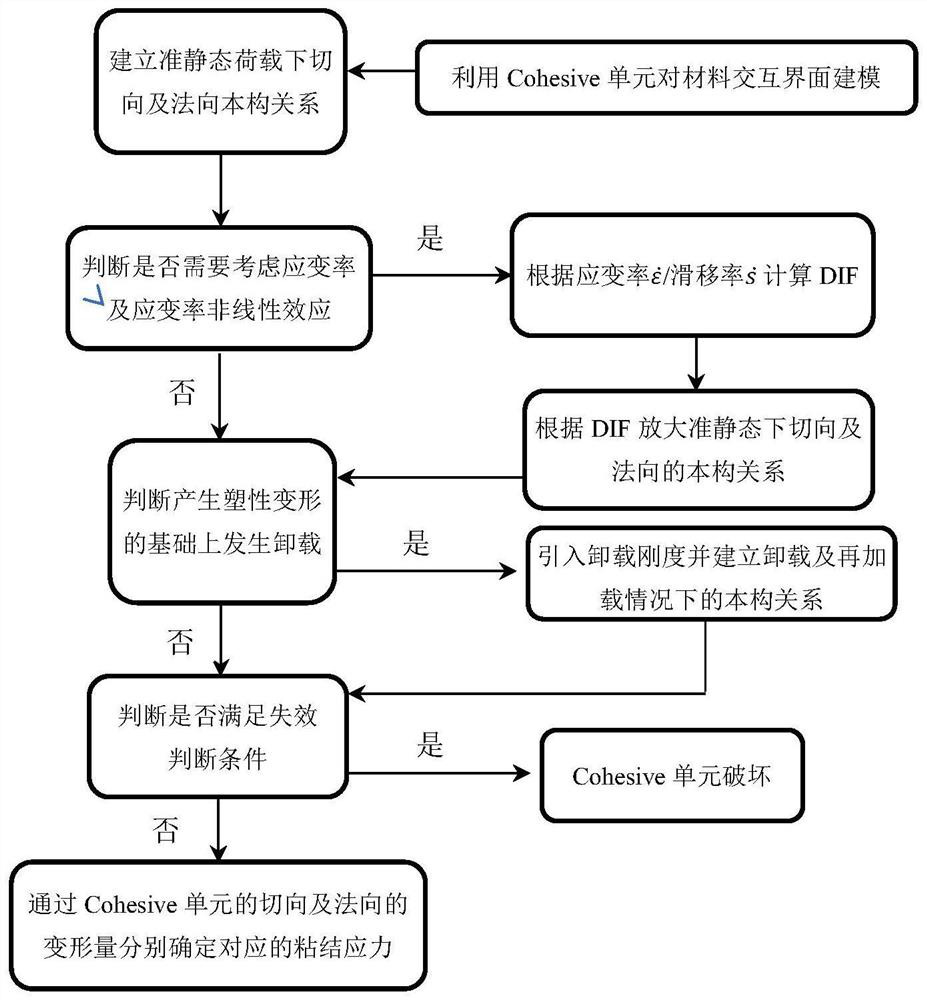

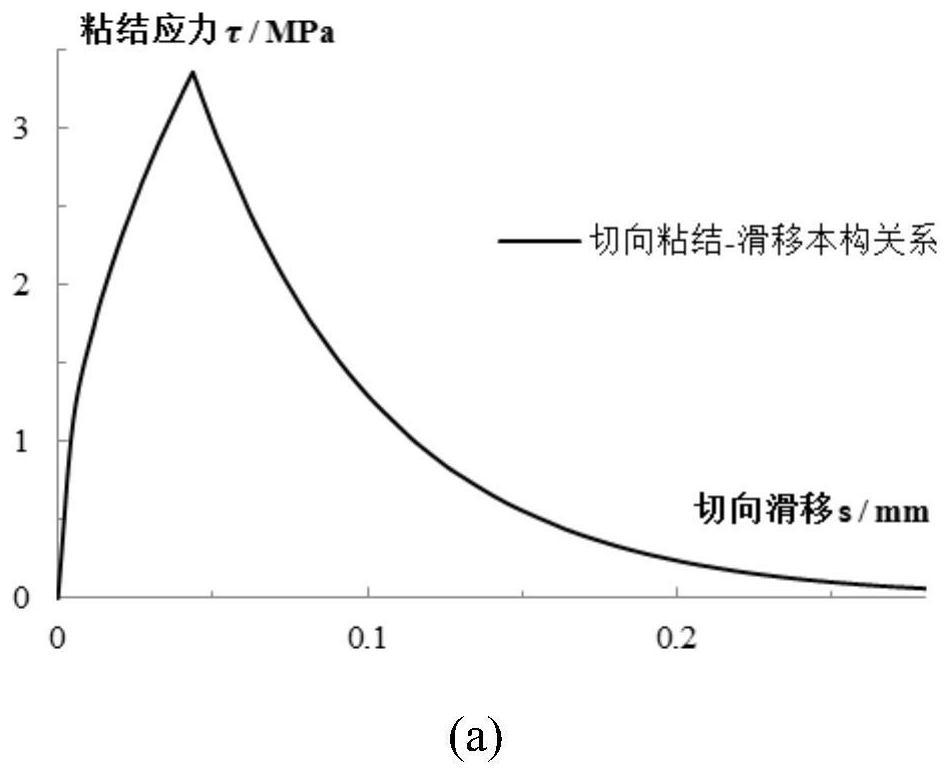

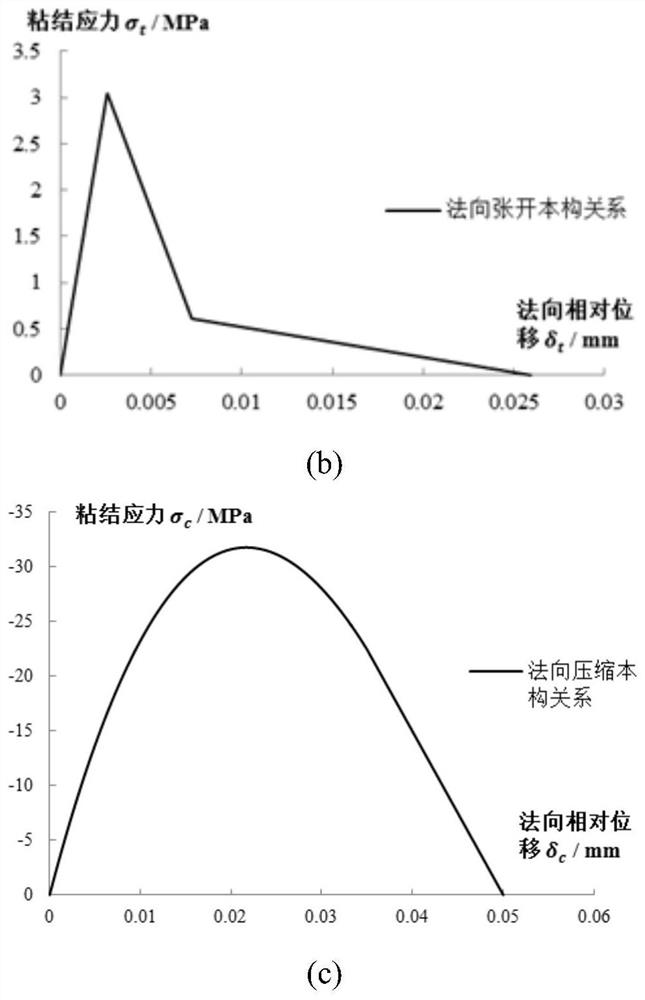

Material interactive interface numerical simulation method considering nonlinearity and strain rate effect

ActiveCN109187334AAccurate Mechanical PropertiesDescribe mechanical propertiesUsing mechanical meansMaterial analysisRelational modelLS-DYNA

The present invention relates to a material interaction interface numerical simulation method considering nonlinearity and strain rate effect. The material interaction interface numerical simulation method considering nonlinearity and strain rate effect comprises the following steps of: establishing a constitutive relation model of tangential bonding-sliding and normal opening / compression nonlinearity of a material interaction interface under the action of a quasi-static load; quantifying the reinforcement effect of the strain rate effect and strain rate nonlinearity on the quasi-static constitutive relation model in the tangent direction and normal direction of the material interactive interface; defining the influence of the plastic damage effect on the tangential and normal constitutiverelation of the material interaction interface; establishing the failure judgment criterion of the material interaction interface in the hybrid mode; and defining a cohesive unit for the numerical simulation of the material interaction interface according to the material interaction interface constitutive relationship formed in the previous step based on LS-DYNA user-defined material module. Thematerial interaction interface numerical simulation method considering nonlinearity and strain rate effect can comprehensively and accurately describe the mechanical properties of the material interaction interface in the first and second modes, and reflects the dynamic performance of the material interaction interface under the strain rate effect and the nonlinearity and the influence of the plastic damage effect on the material interaction interface performance.

Owner:KUNMING UNIV OF SCI & TECH

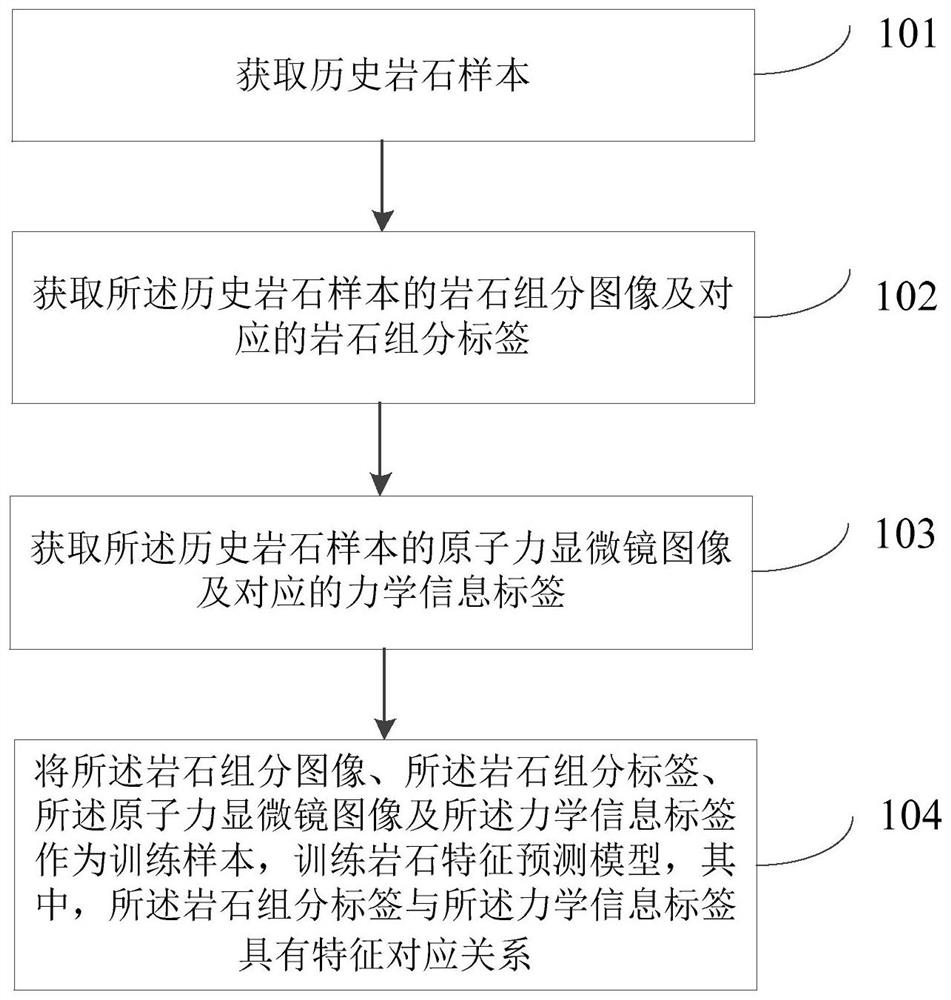

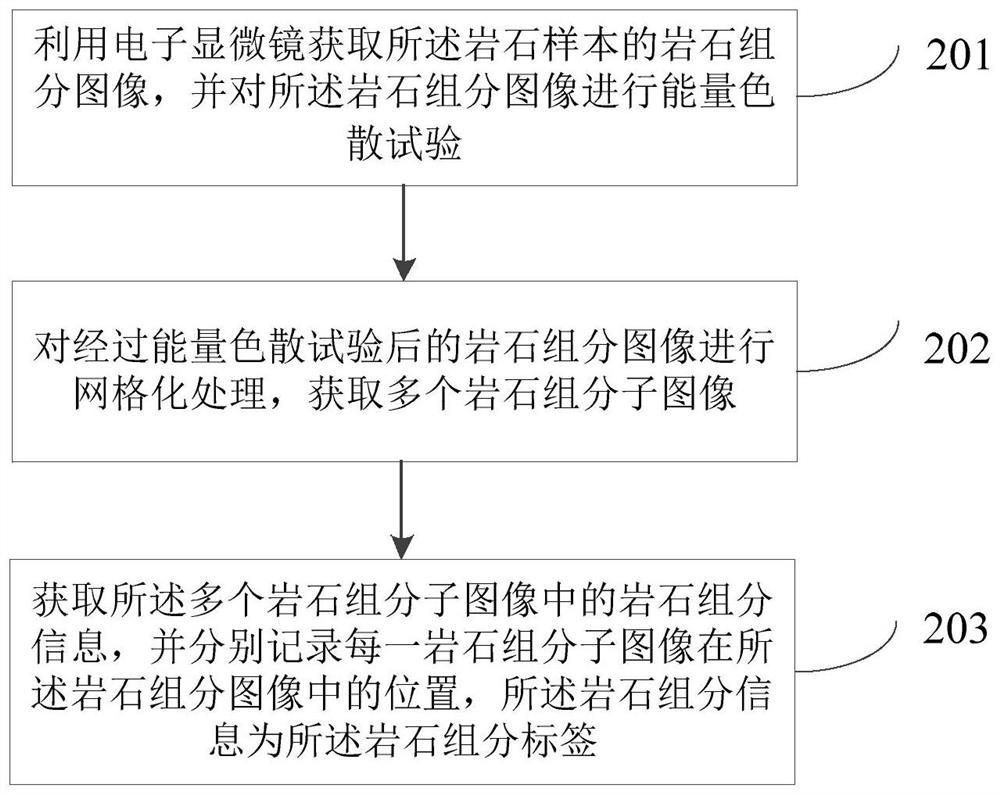

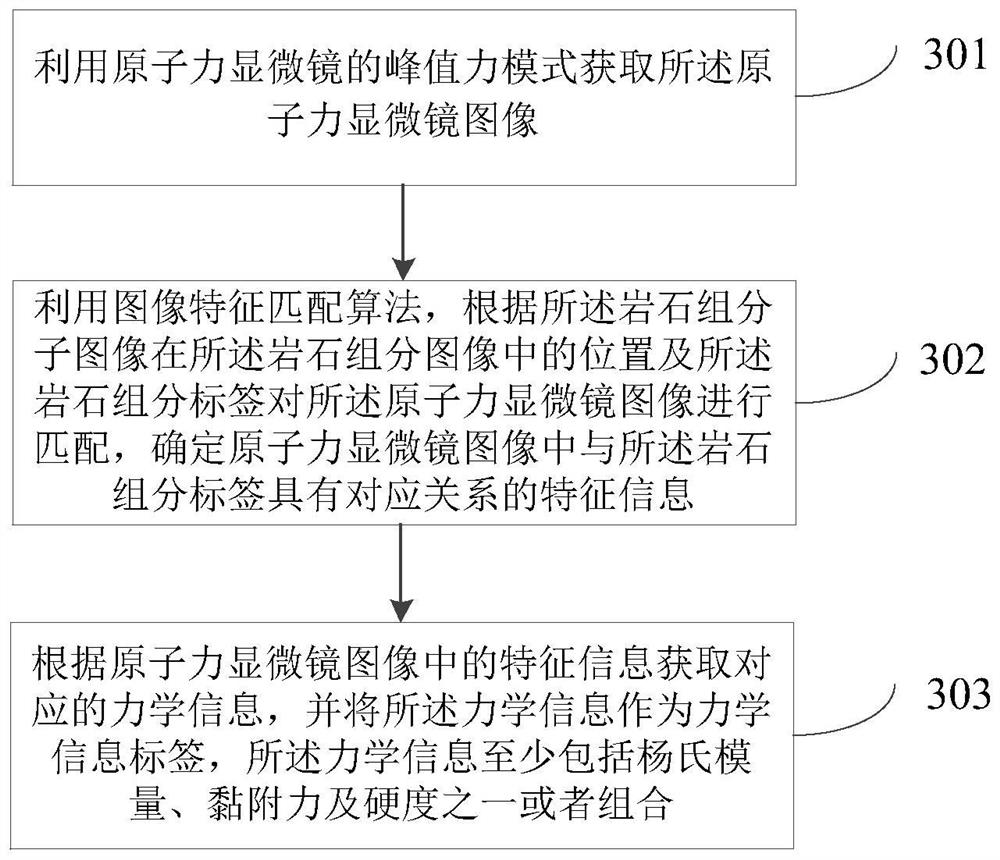

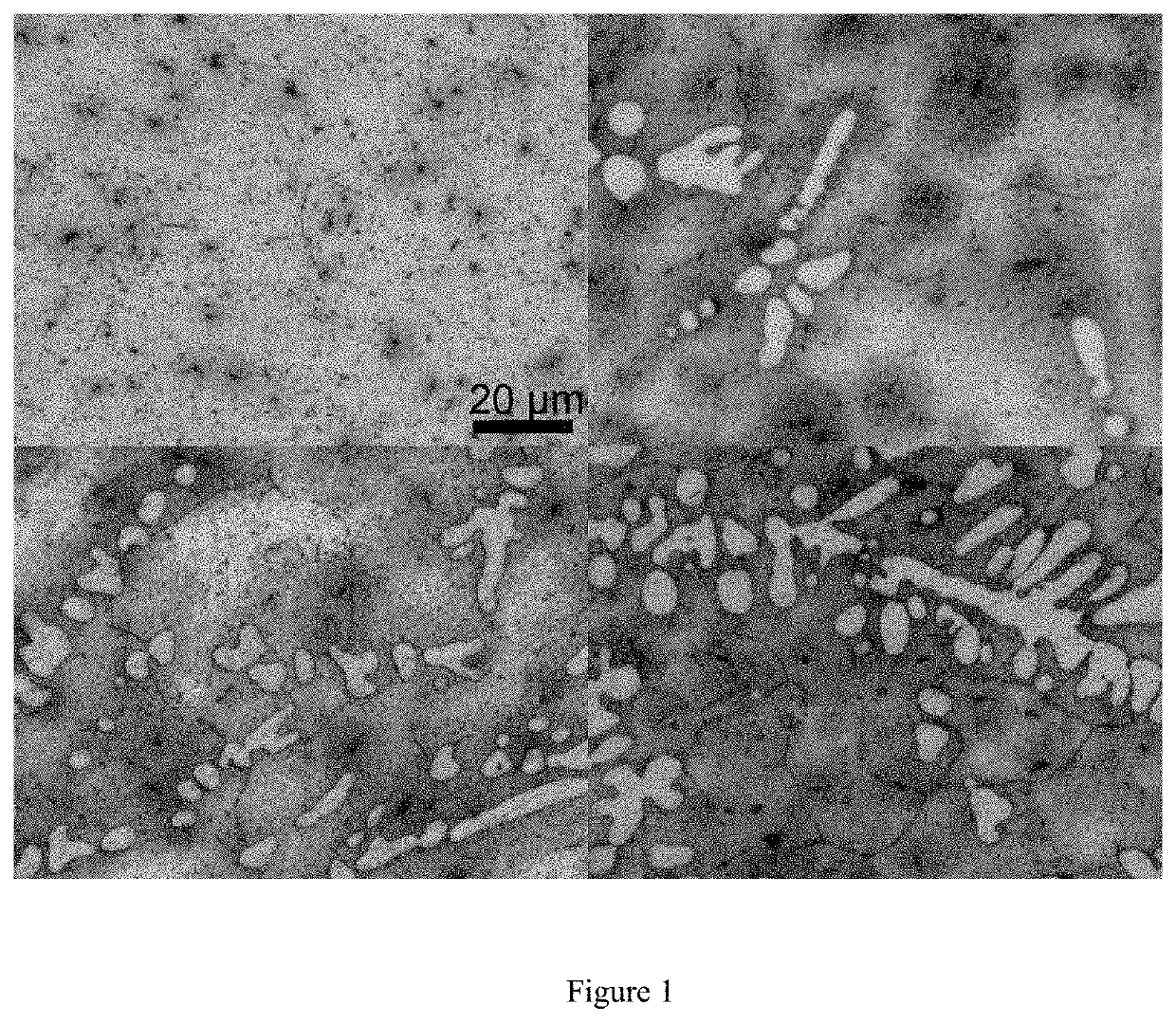

Rock feature prediction model training method and device and rock feature prediction method

PendingCN114582434ARapid positioningAvoid slow recognitionChemical property predictionData processing applicationsPattern recognitionAlgorithm

The invention relates to the field of oil-gas exploration and development, in particular to a rock feature prediction model training method and device and a rock feature prediction method. Comprises: acquiring a historical rock sample; acquiring a rock component image of the historical rock sample and a corresponding rock component label; obtaining an atomic force microscope image of the historical rock sample and a corresponding mechanical information label; the rock component image, the rock component label, the atomic force microscope image and the mechanical information label serve as training samples, a rock feature prediction model is trained, the rock component label and the mechanical information label are different labels at the same position of the same rock, and the rock component label and the mechanical information label are different labels at the same position of the same rock. The rock component label and the mechanical information label have a corresponding relation. According to the scheme, the features in the rock image are rapidly identified, rapid positioning, accurate identification and mechanical property prediction of the rock components in the rock image are realized, the identification precision of the rock components is improved, and the test efficiency is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method and device for measuring isotropic electrical properties in soil body compression process

ActiveCN112485302AImprove test accuracyReliable resultsMaterial strength using tensile/compressive forcesMaterial resistanceAxial displacementTest sample

The invention discloses a device for determining isotropic electrical properties in a soil body compression process, a sample is arranged between an upper bearing plate and a lower bearing plate, an upper electrode plate and a lower electrode plate are respectively arranged at the top and the bottom of the sample, and an axial displacement sensor and a pressure sensor are arranged at the top of the upper bearing plate; radial electrode plate pairs are arranged at different height positions of the sample, and each radial electrode plate corresponds to one radial displacement meter. The invention further discloses a method for determining the isotropic electrical properties in each direction in the soil body compression process. The sectional area of the test sample at any time can be obtained, a result is corrected, the test accuracy is improved, and the result is more reliable. The internal structure change and the isotropic electrical properties of the soil body in the unconfined compression process can be analyzed more comprehensively through multi-path measurement. Resistivity and displacement changes are synchronous real-time data, so that the continuity of the test and the correlation of the data are improved.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

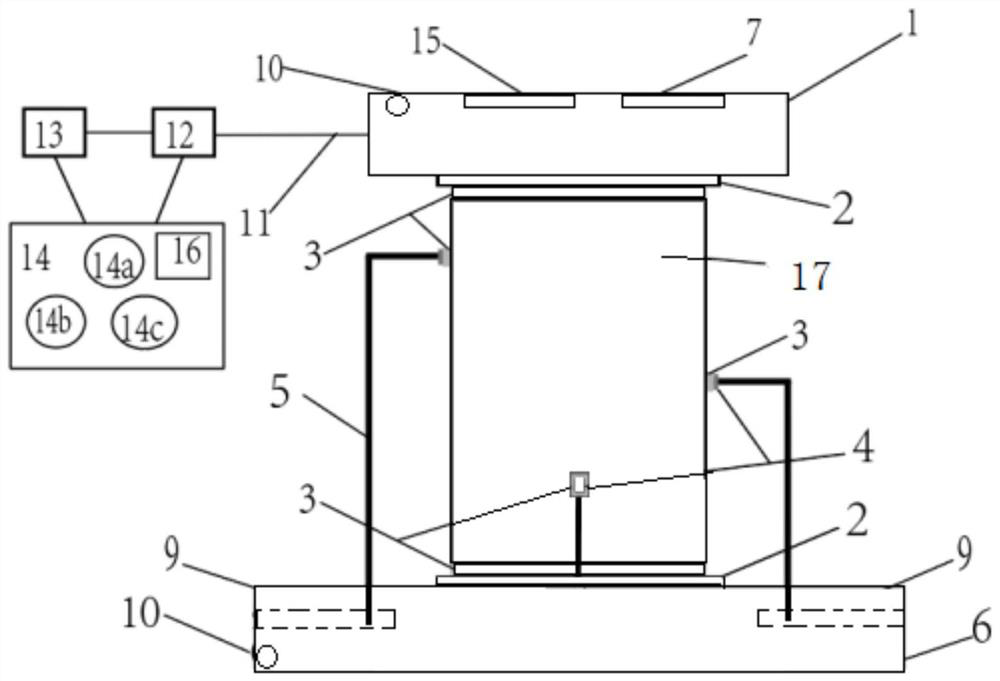

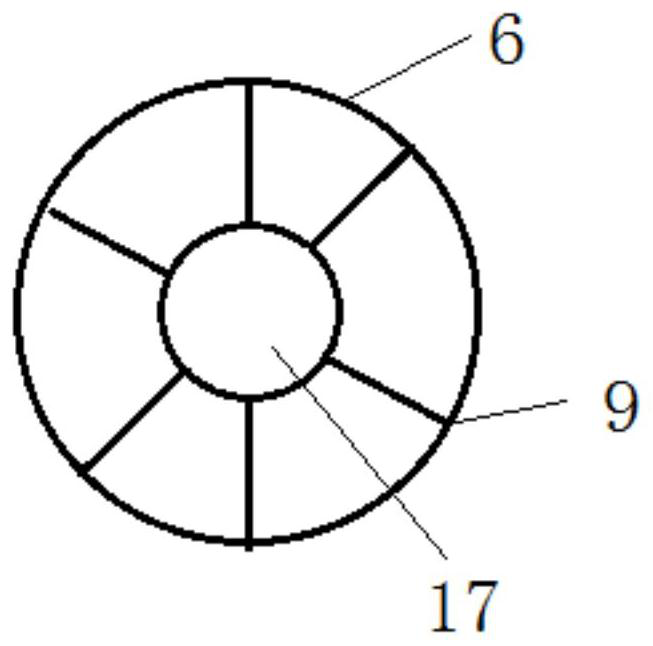

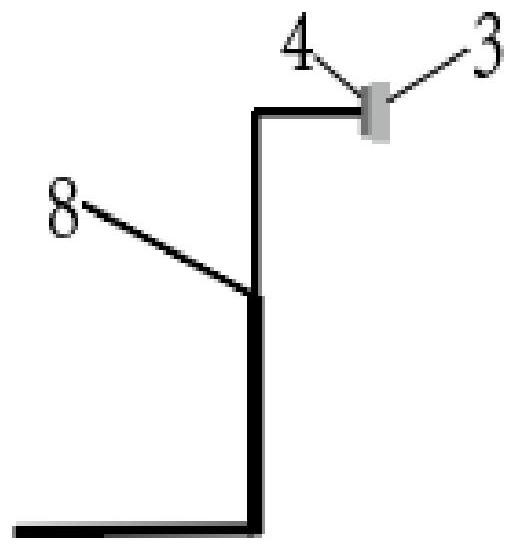

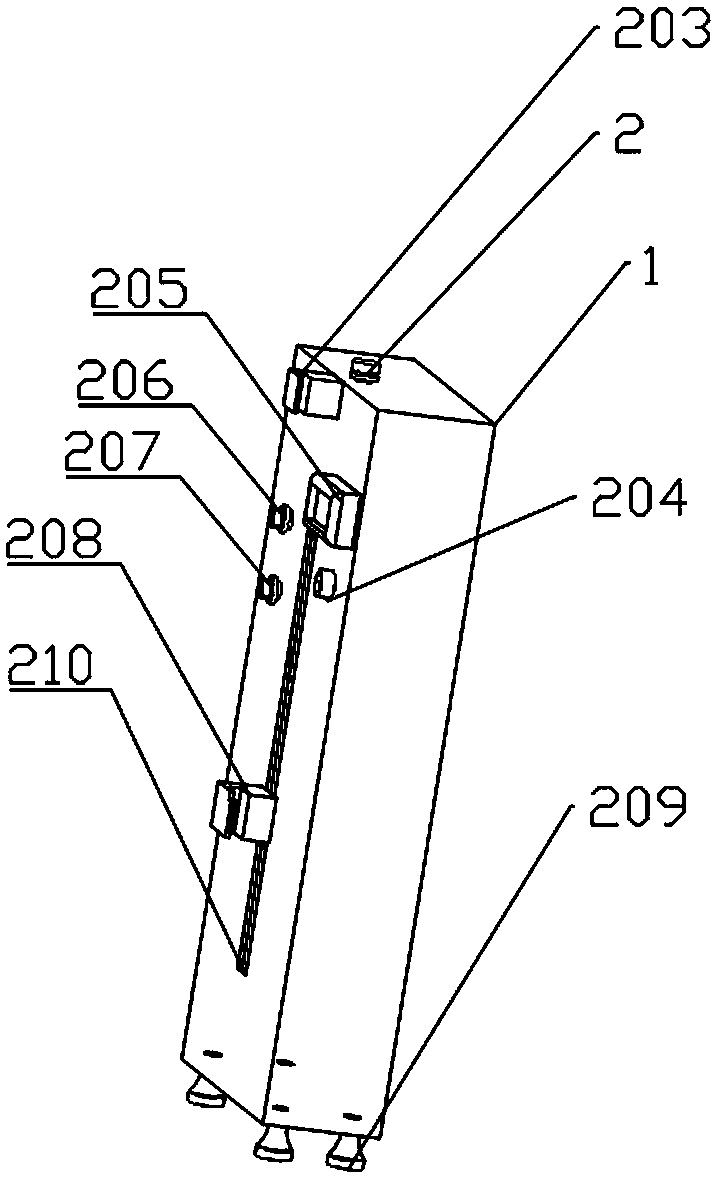

Simulation yarn dynamic breaking strength testing equipment and testing method

ActiveCN111257116AAccurate Mechanical PropertiesSimple structureMaterial strength using tensile/compressive forcesYarnControl system

The invention discloses simulation yarn dynamic breaking strength testing equipment and a testing method. The testing equipment comprises a strength machine case, a microcomputer control system, a power simulation system and a yarn balance block, a yarn fixing device is arranged at the top of the strength machine case, and an upper yarn clamp, a yarn stretching sliding way, a power simulation system, a lower yarn clamp and a yarn balance block are arranged on one side face of the strength machine case. The dynamic simulation system is fixedly arranged on the side surface and is positioned between the upper yarn clamp and the lower yarn clamp; the yarn lower clamp is located in the yarn stretching slide way and provided with a force measuring sensor. The yarn balance block is positioned below the yarn lower clamp; the power simulation system comprises a rack, a motor and a rotating shaft, the rotating shaft is connected with the output shaft of the motor, and the microcomputer control system is connected with the motor and the force transducer. According to the invention, the strength of the yarn at different angles and different rotating speeds can be tested, and the mechanical property of the fabric formed by the yarn can be simulated more accurately. The device is simple in structure, the cost is reduced, and the operation process is simplified.

Owner:HUNAN INSTITUTE OF ENGINEERING

Optical assembly with passive alignment

ActiveUS9709758B2Low insertion lossReduced insertion lossCoupling light guidesOptical axisEngineering

Owner:TE CONNECTIVITY NEDERLAND

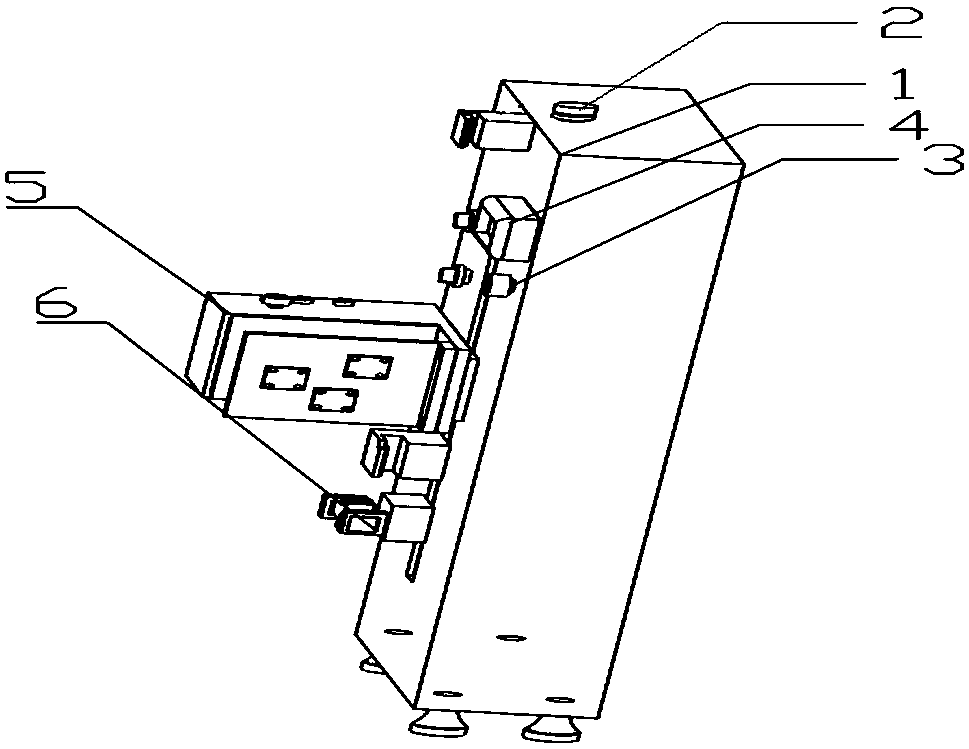

Efficient and automatic detecting and sorting system for cosmetic brushes

The invention discloses an efficient and automatic detecting and sorting system for cosmetic brushes. A cosmetic brush rotating module, a vision detecting module, a sorting module and a controller module are included; the cosmetic brush rotating module comprises an installing plate, a first clamping device rotationally connected to the installing plate, and a rotating driving device driving the first clamping device to rotate; the vision detecting module comprises a camera shooting device with a lens facing one side of the first clamping device; the sorting module comprises a manipulator adjacent to the first clamping device and a second clamping device, and the second clamping device is connected to the hand portion of the manipulator; and the first clamping device, the rotating driving device, the camera shooting device, the manipulator and the second clamping device are all electrically connected with the controller module. The efficient and automatic detecting and sorting system for the cosmetic brushes is high in automation degree, can fast achieve detection on defective products of the cosmetic brushes, and can perform accurate sorting on the defective products, the production efficiency is improved easily, the manpower cost is reduced, and the sorting error rate caused by fatigue of an operator can also be avoided.

Owner:ZHONGSHAN SHANGYANG PRECISION IND

Composite rail tie apparatus and method

Owner:HAWKINS MICHAEL A +1

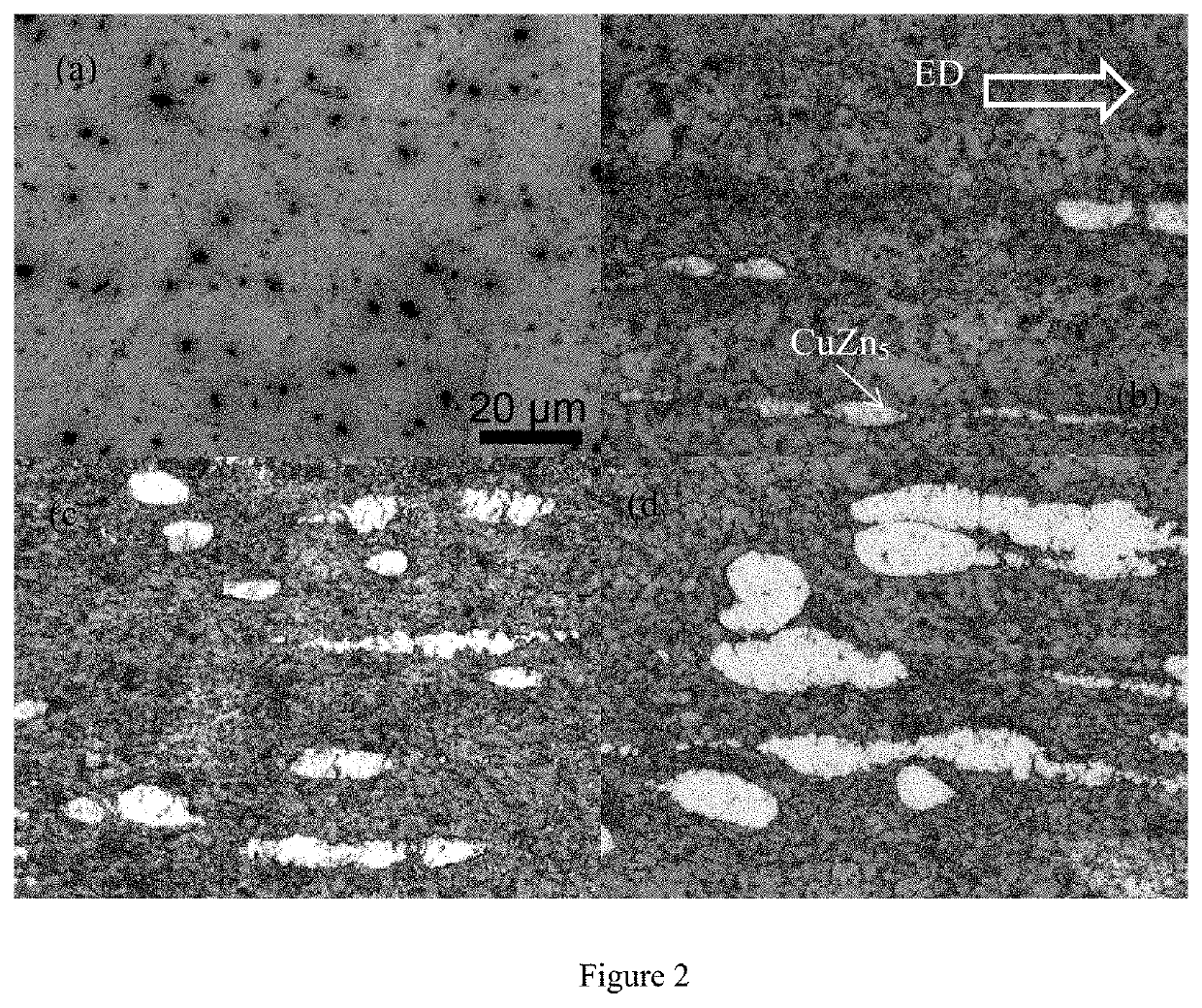

Medical biodegradable zn-cu alloy and its preparation method as well as applications

InactiveUS20200385844A1Accurate Mechanical PropertiesEasy to processStentsBone implantZinc alloysIngot

The present invention relates to the preparation methods and applications of biodegradable zinc-copper alloys, which can be applied to medical implant materials. The alloy of present invention is mainly composed of copper (1-10 wt. %), the balance of zinc and trace impurity elements. As-cast alloy ingot is homogenized and then hot processed to refine microstructure. The mechanical properties of the alloys are improved due to the refined microstructure. The alloys are capable of being further fabricated into micro-tubes, wires and plates. There are many advantages of these Zn alloys such as excellent mechanical properties, easy to process, appropriate corrosion resistance, good biocompatibility and so on, which correspondingly can be applied to many kinds of biodegradable medical implant devices. With excellent mechanical properties, good biocompatibility and degrading completely in 6-18 months, the Zn alloys meet the requirements of implant materials for mechanical properties and biosafety.

Owner:SHANGHAI JIAO TONG UNIV

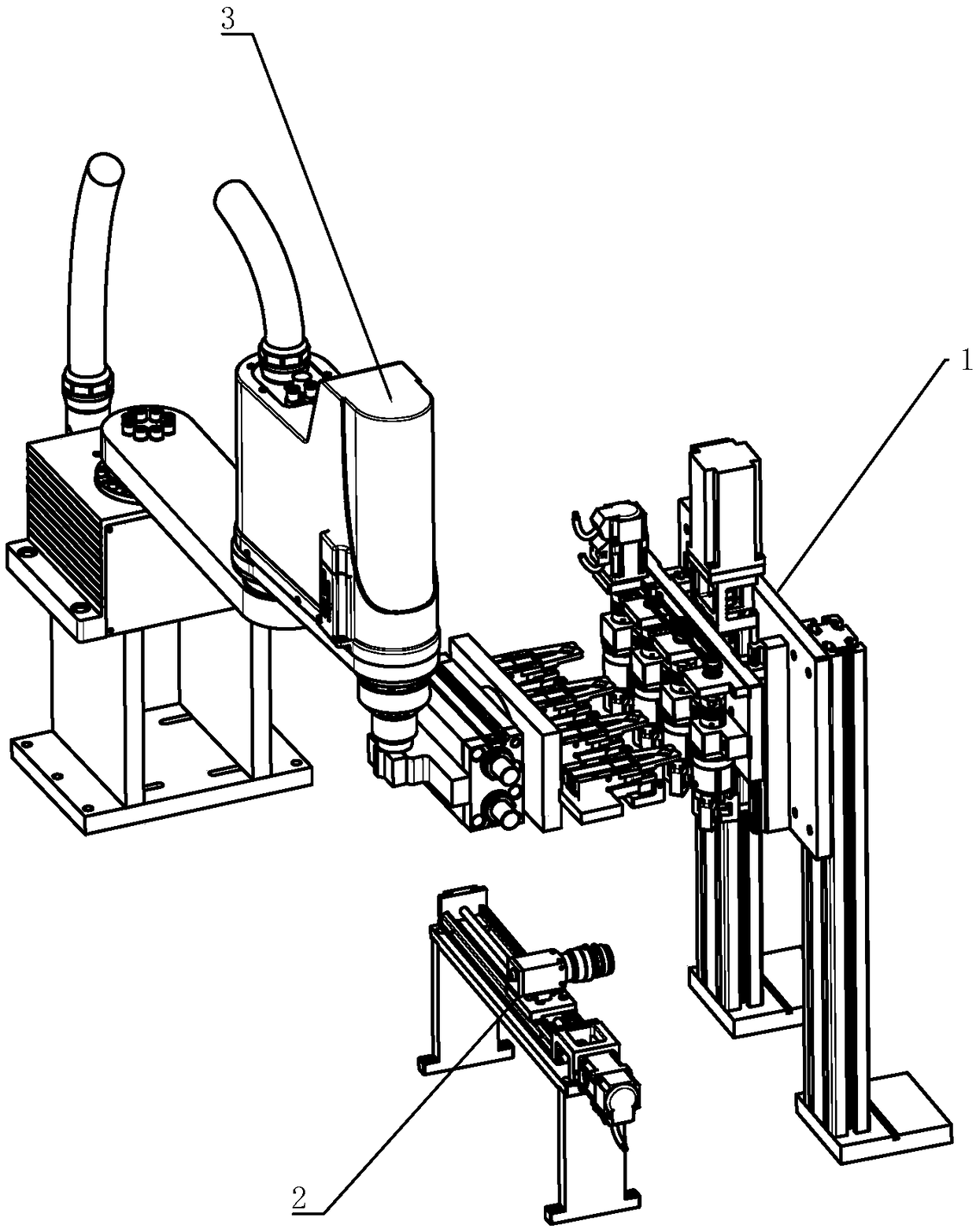

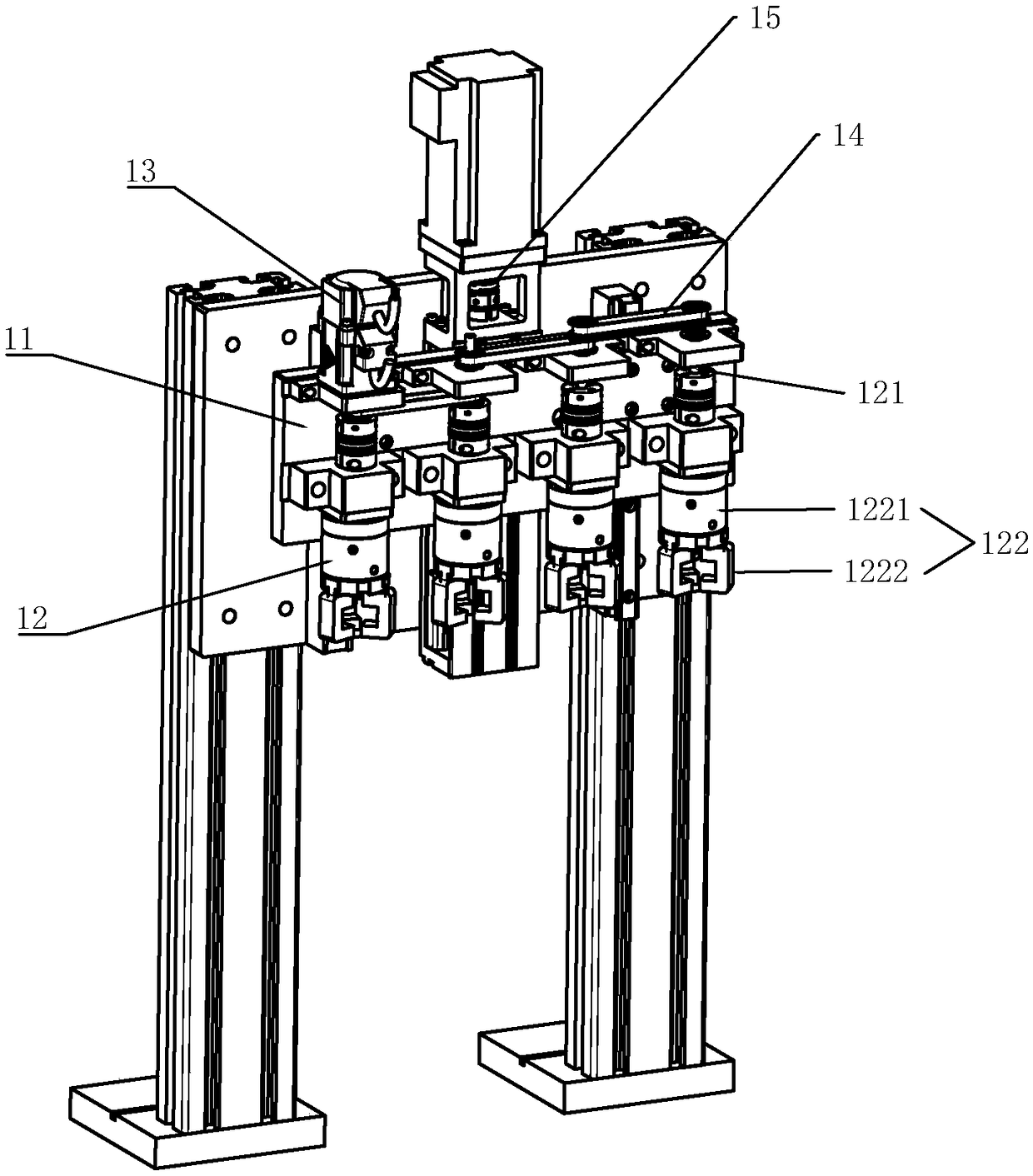

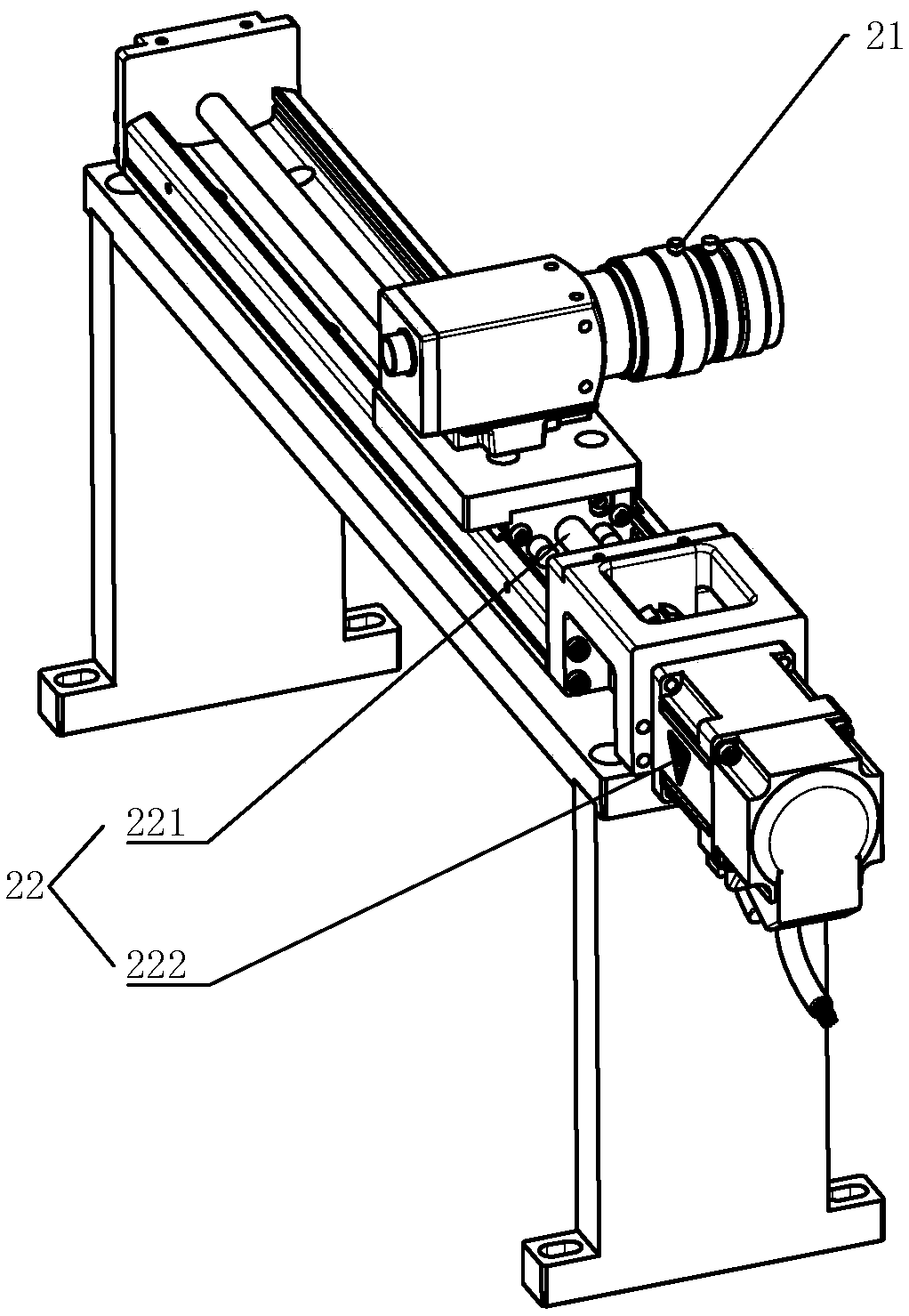

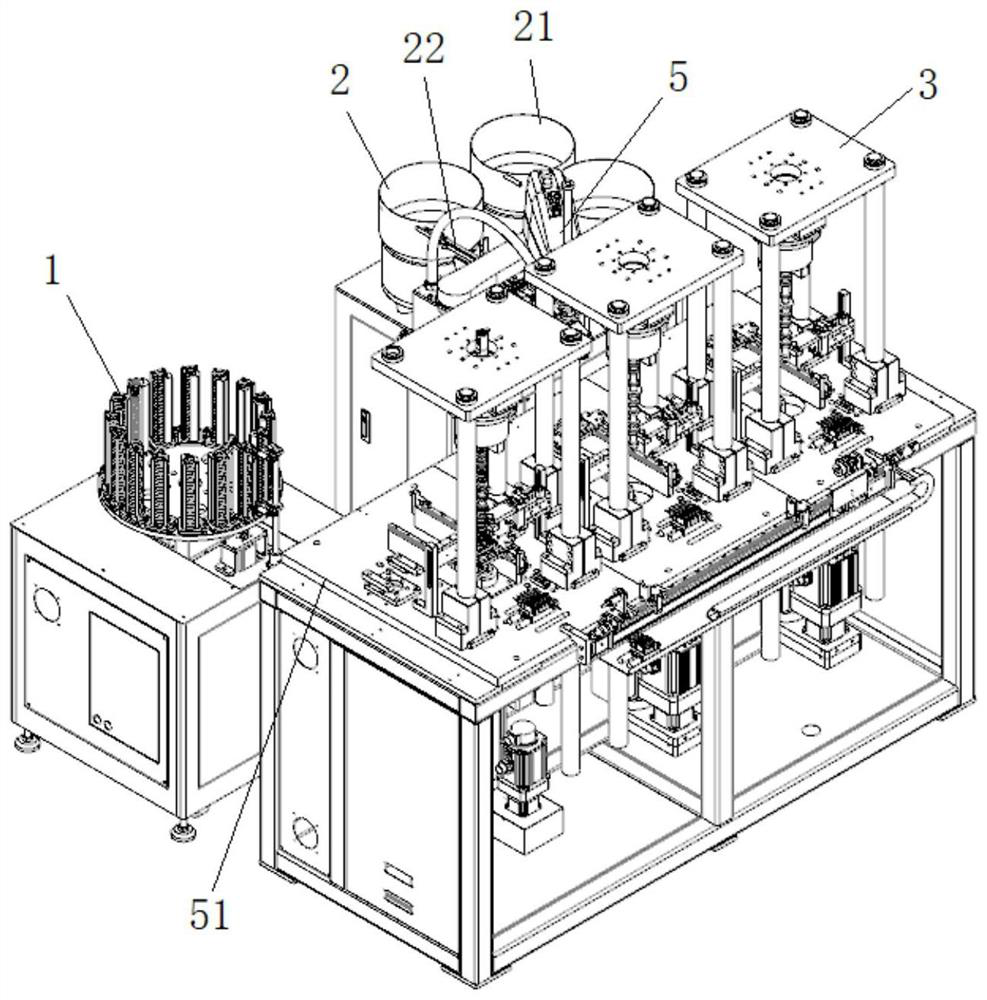

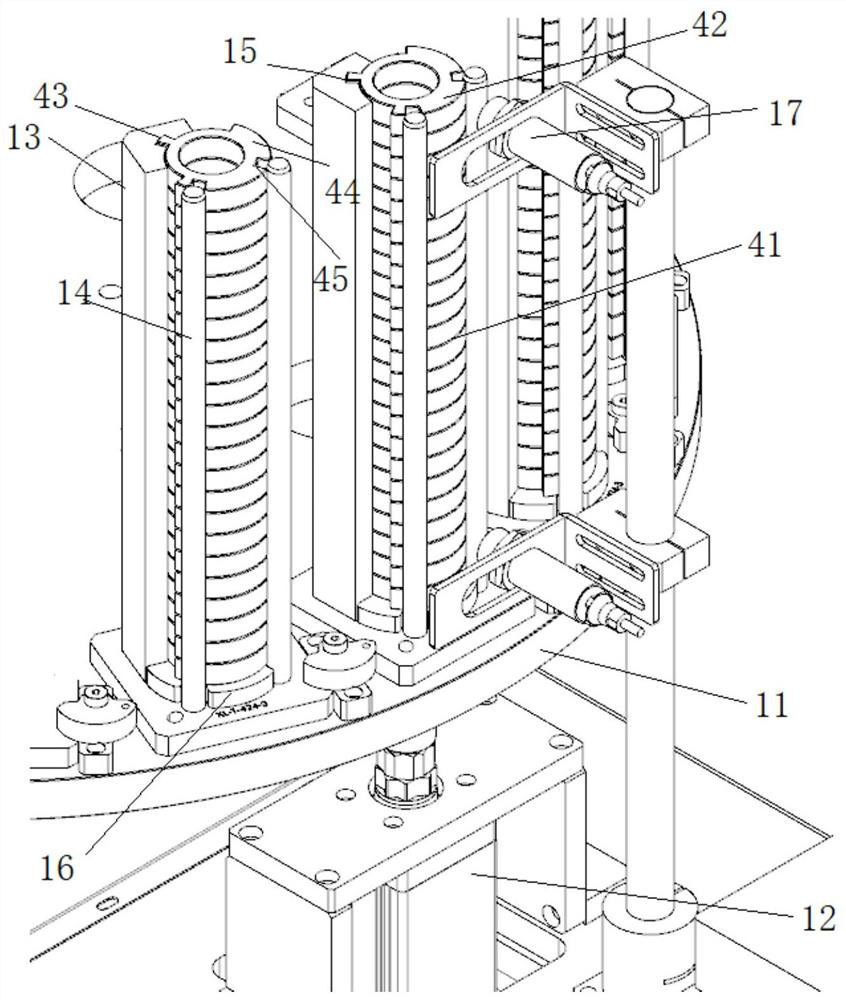

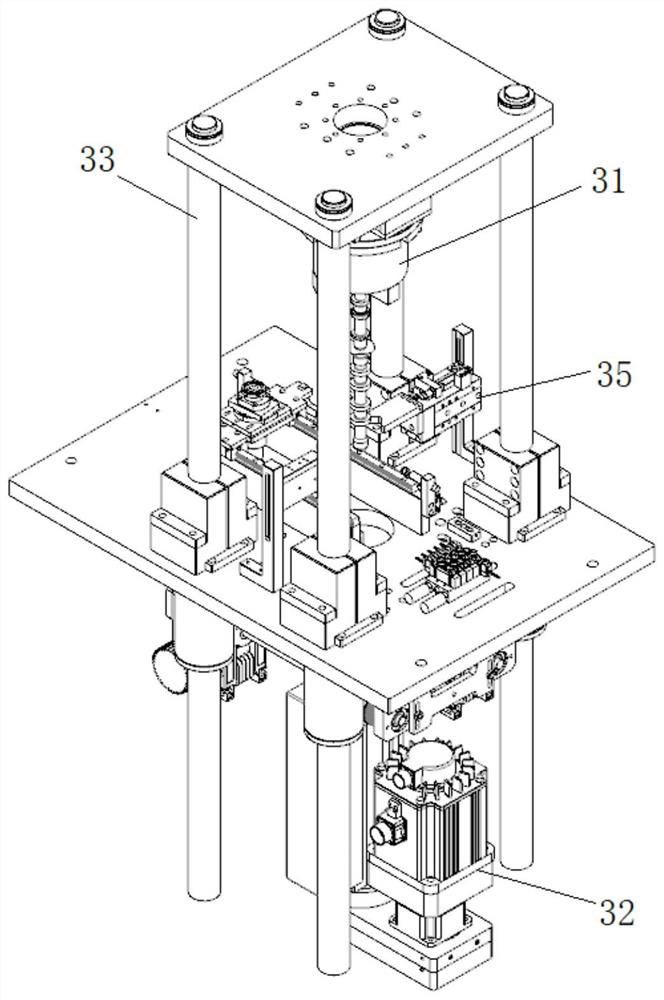

Full-automatic camshaft press-fitting machine

PendingCN113927275APrecise positioningAccurate Mechanical PropertiesMetal working apparatusEngineeringCam

The invention discloses a full-automatic camshaft press-fitting machine. The full-automatic camshaft press-fitting machine comprises a stacking device used for tidying and guiding signal wheels, a feeding device used for feeding cams and a press-fitting device. The press-fitting device comprises a chuck structure, a lateral moving clamping plate assembly, a horizontal moving carrier and a first air cylinder, wherein the chuck structure is arranged in a suspended mode and used for clamping a camshaft, the lateral moving clamping plate assembly is arranged below the chuck structure, used for relatively clamping the camshaft and used for positioning the axis, the horizontal moving carrier is arranged below the lateral moving clamping plate assembly, the first air cylinder is arranged below the alignment chuck structure and used for jacking materials in the horizontal moving carrier to be connected to the camshaft in a sleeving mode, and a mechanical arm takes the materials in the stacking device or the feeding device into the horizontal moving carrier to be positioned. By means of the full-automatic camshaft press-fitting machine, a cam and the signal wheels are accurately pressed on the camshaft, and the pressing efficiency is improved.

Owner:利捷得(苏州)自动化有限公司

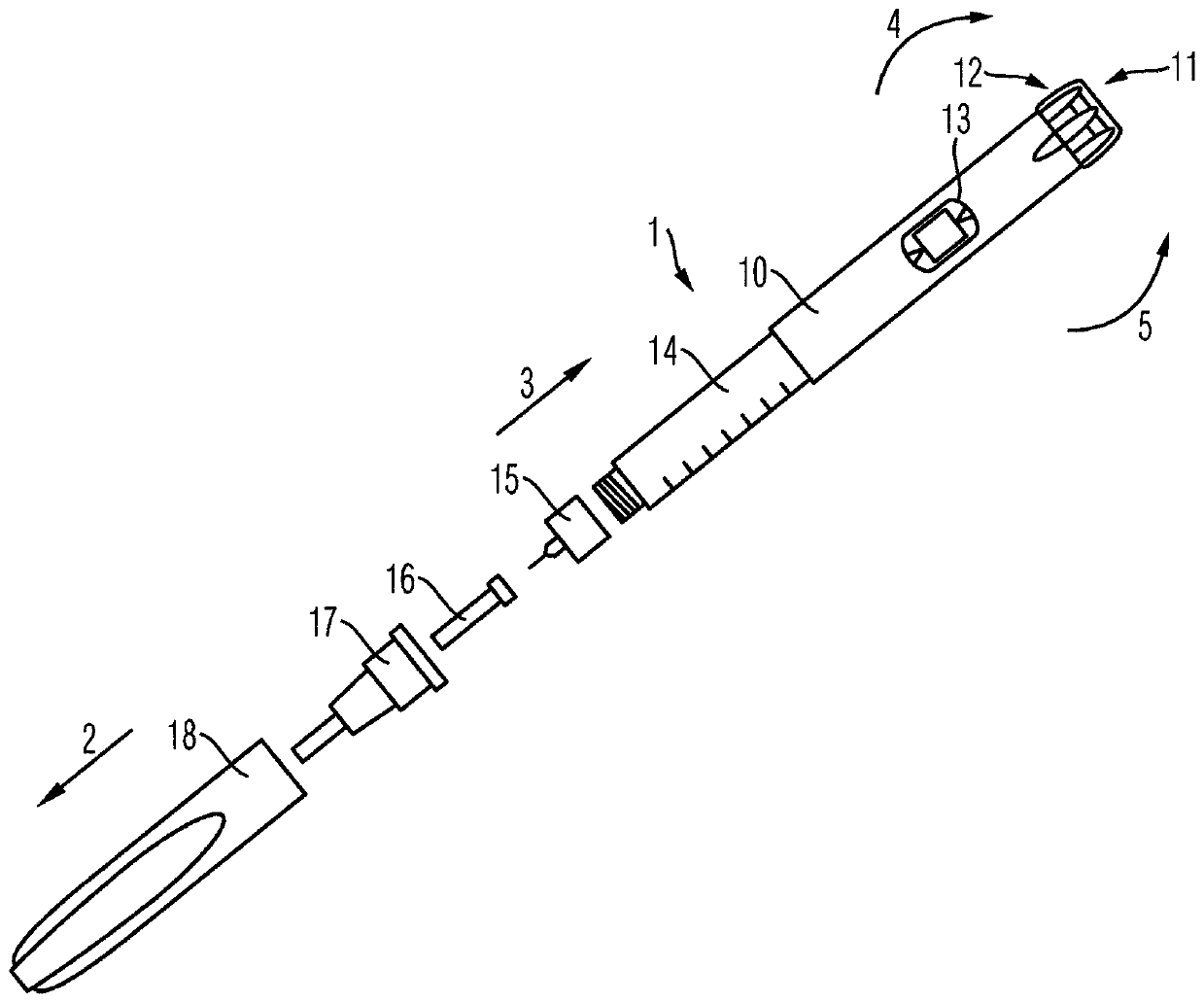

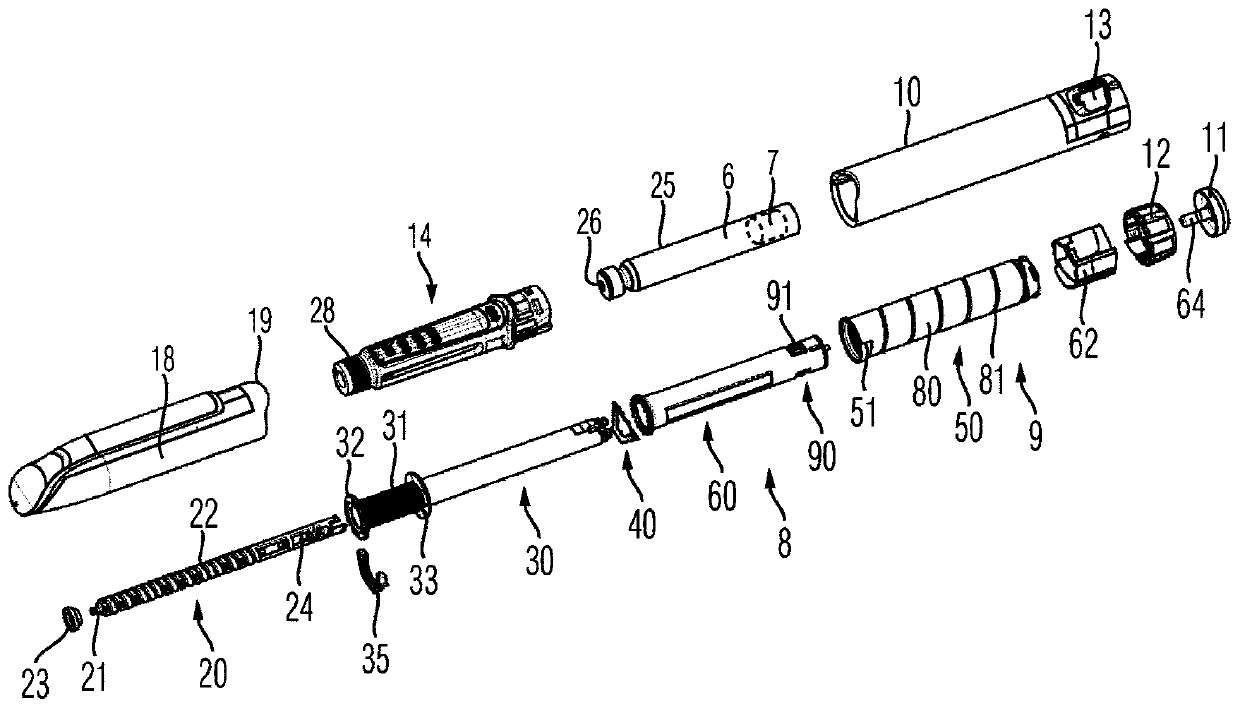

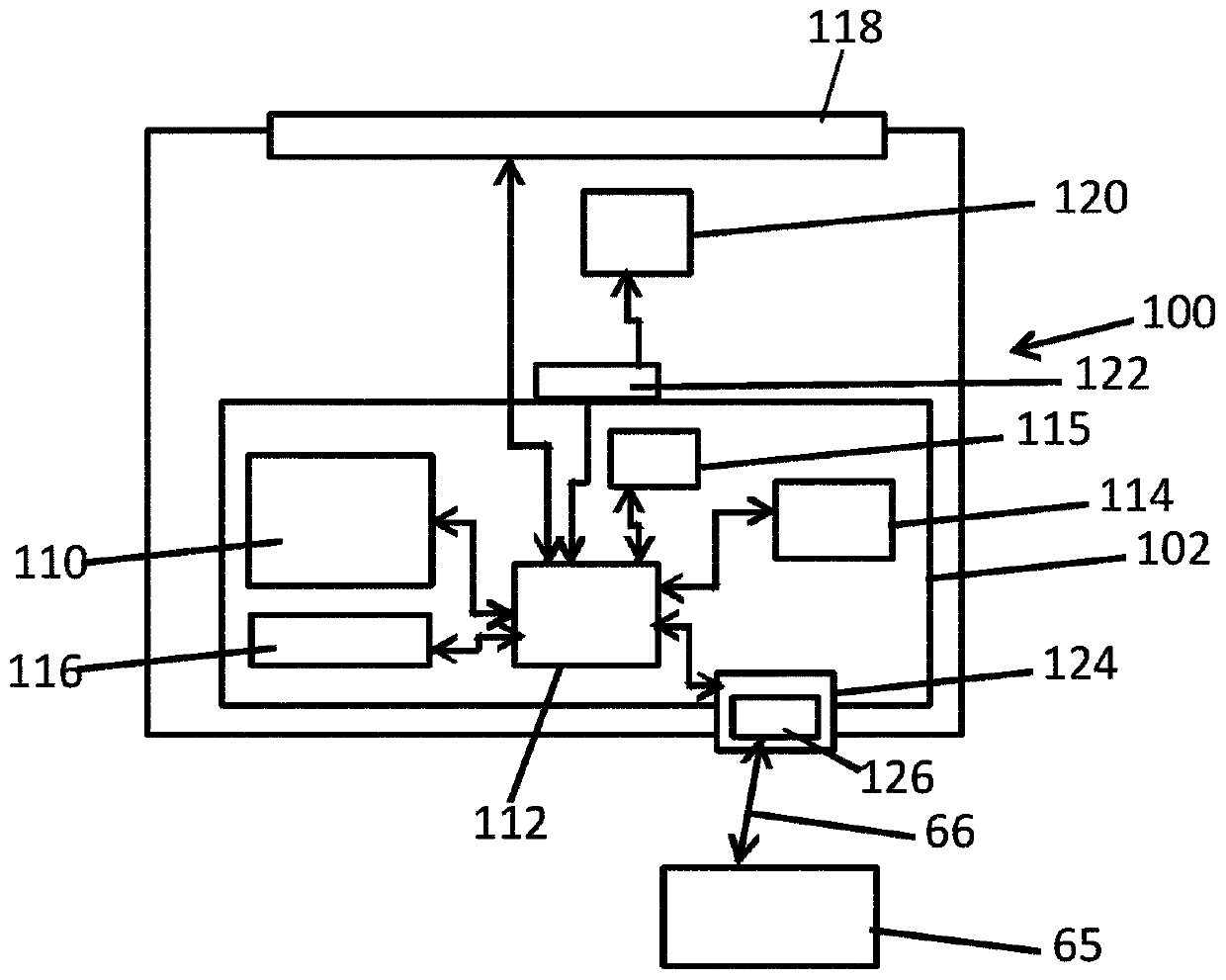

Rotation sensor for injection device

ActiveCN111479602AAccurate Mechanical PropertiesPrecise elasticityAngles/taper measurementsAmpoule syringesRatchetEngineering

The present disclosure relates to a rotation sensor for an injection device (1), the rotation sensor comprising: a rotatable element (201) configured for a mechanical engagement with a ratchet mechanism (90; 190), the rotatable element (201) comprising an outer rim (208) and a hub (210) is configured for transmission of a torque between the outer rim (208) and the hub (210), at least one sensor (220, 222, 224) attached to the rotatable element (201) and configured to measure at least one of a mechanical force, a mechanical pressure or a mechanical strain at a portion of the rotatable element (201) during a rotation of the rotatable element (201), a processor (112) connected to the at least one sensor (220, 222, 224) and configured to calculate an angle of rotation of the rotatable elementon the basis of a sensor output of the at least one sensor (220, 222, 224).

Owner:SANOFI SA

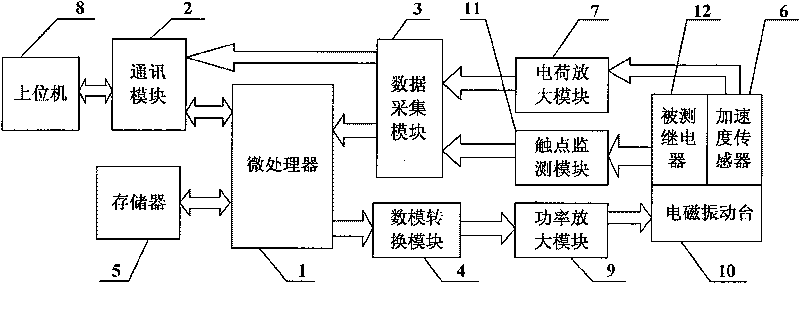

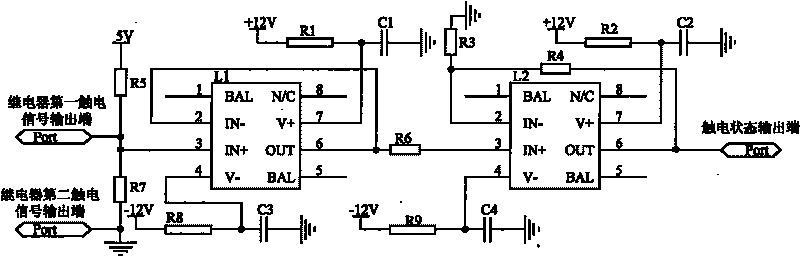

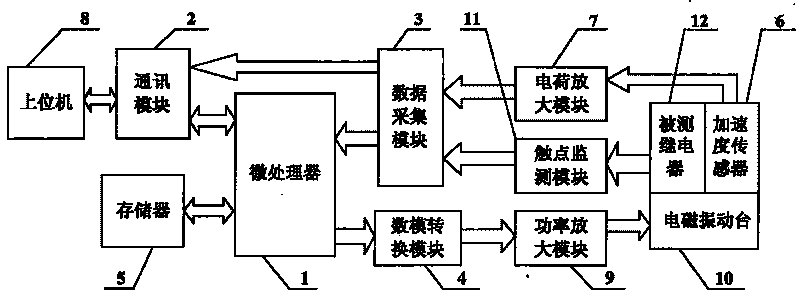

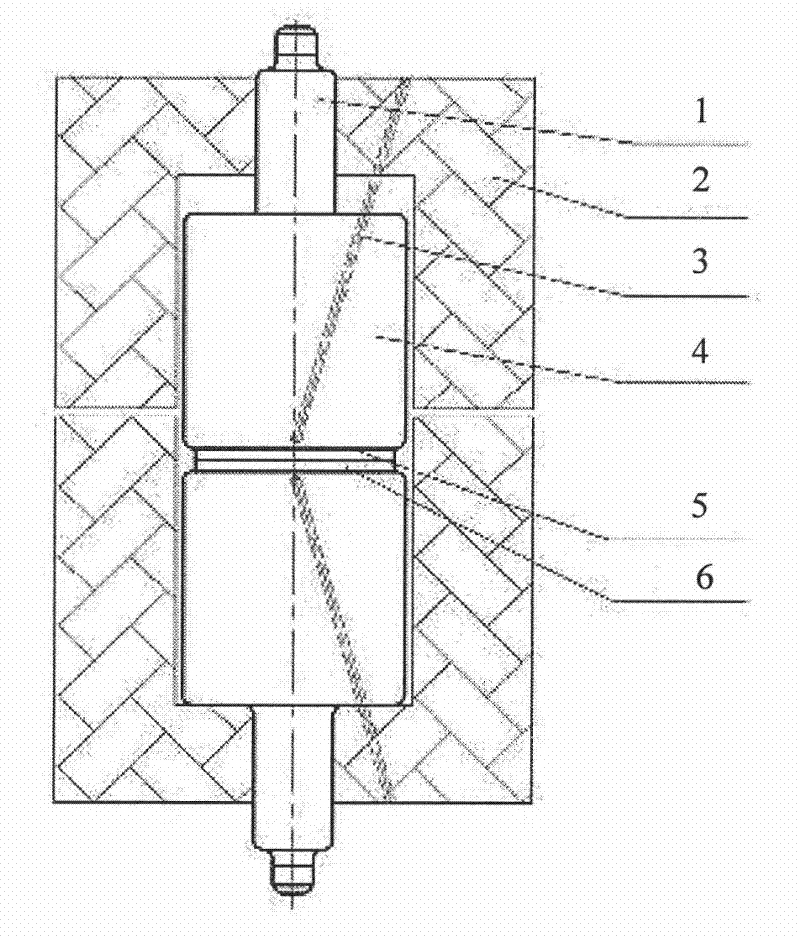

Electromagnetic relay dynamic environmental test system

InactiveCN101261310BAccurate Mechanical PropertiesAccurate recordCircuit interrupters testingClosed loopEngineering

Owner:HARBIN INST OF TECH

Method and device for preparing large-size bulk amorphous composite materials

Owner:UNIV OF SCI & TECH BEIJING

Numerical Simulation Method of Material Interaction Interface Considering Nonlinearity and Strain Rate Effect

ActiveCN109187334BAccurate Mechanical PropertiesDescribe mechanical propertiesUsing mechanical meansMaterial analysisClassical mechanicsMechanical engineering

The present invention relates to a material interaction interface numerical simulation method considering nonlinearity and strain rate effect. The material interaction interface numerical simulation method considering nonlinearity and strain rate effect comprises the following steps of: establishing a constitutive relation model of tangential bonding-sliding and normal opening / compression nonlinearity of a material interaction interface under the action of a quasi-static load; quantifying the reinforcement effect of the strain rate effect and strain rate nonlinearity on the quasi-static constitutive relation model in the tangent direction and normal direction of the material interactive interface; defining the influence of the plastic damage effect on the tangential and normal constitutiverelation of the material interaction interface; establishing the failure judgment criterion of the material interaction interface in the hybrid mode; and defining a cohesive unit for the numerical simulation of the material interaction interface according to the material interaction interface constitutive relationship formed in the previous step based on LS-DYNA user-defined material module. Thematerial interaction interface numerical simulation method considering nonlinearity and strain rate effect can comprehensively and accurately describe the mechanical properties of the material interaction interface in the first and second modes, and reflects the dynamic performance of the material interaction interface under the strain rate effect and the nonlinearity and the influence of the plastic damage effect on the material interaction interface performance.

Owner:KUNMING UNIV OF SCI & TECH

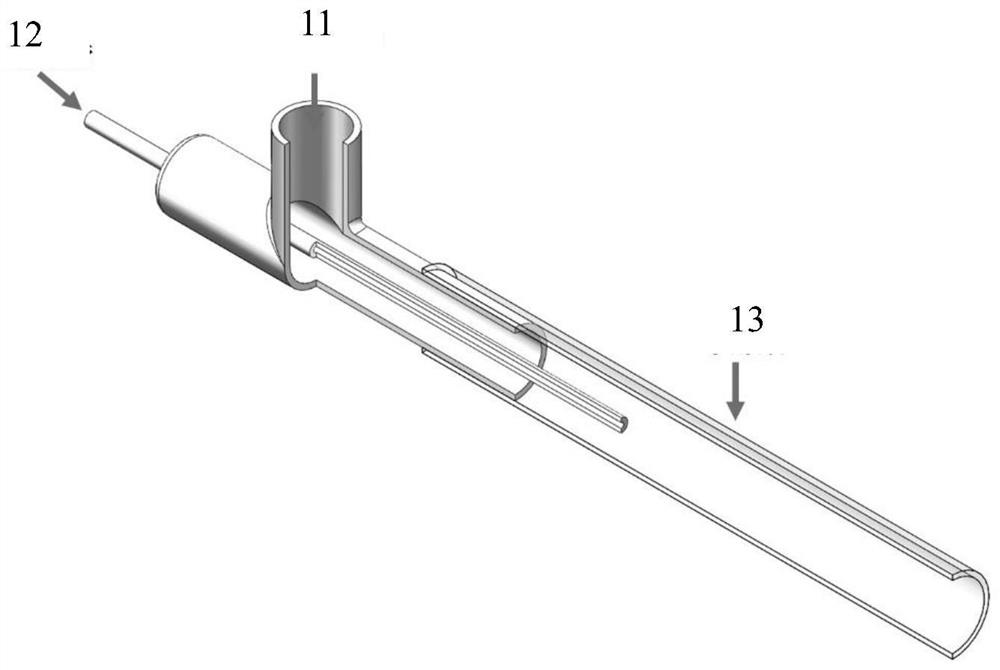

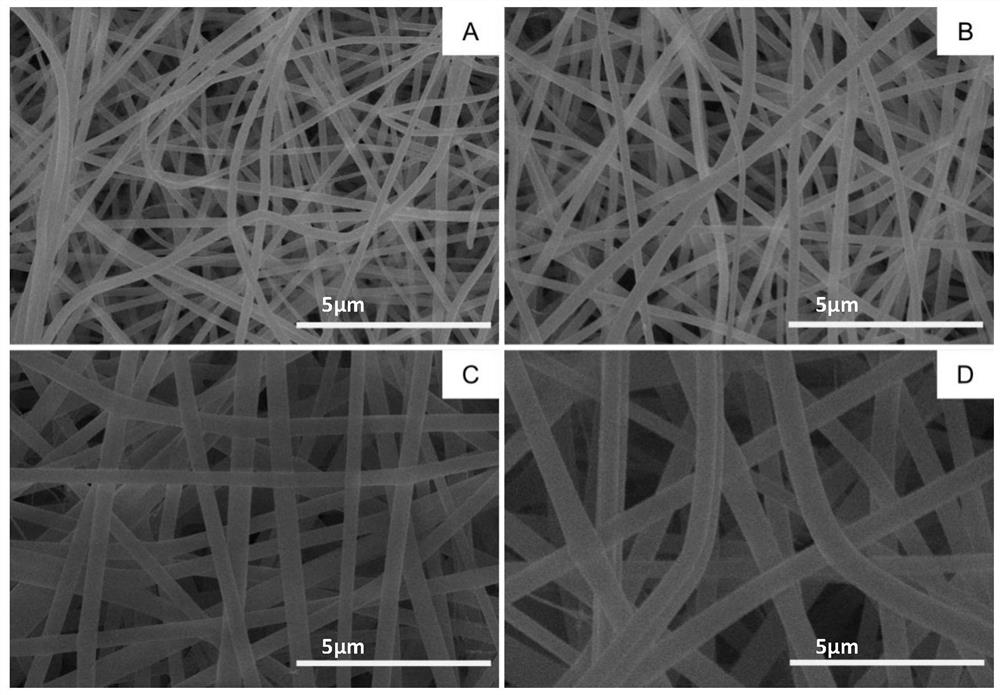

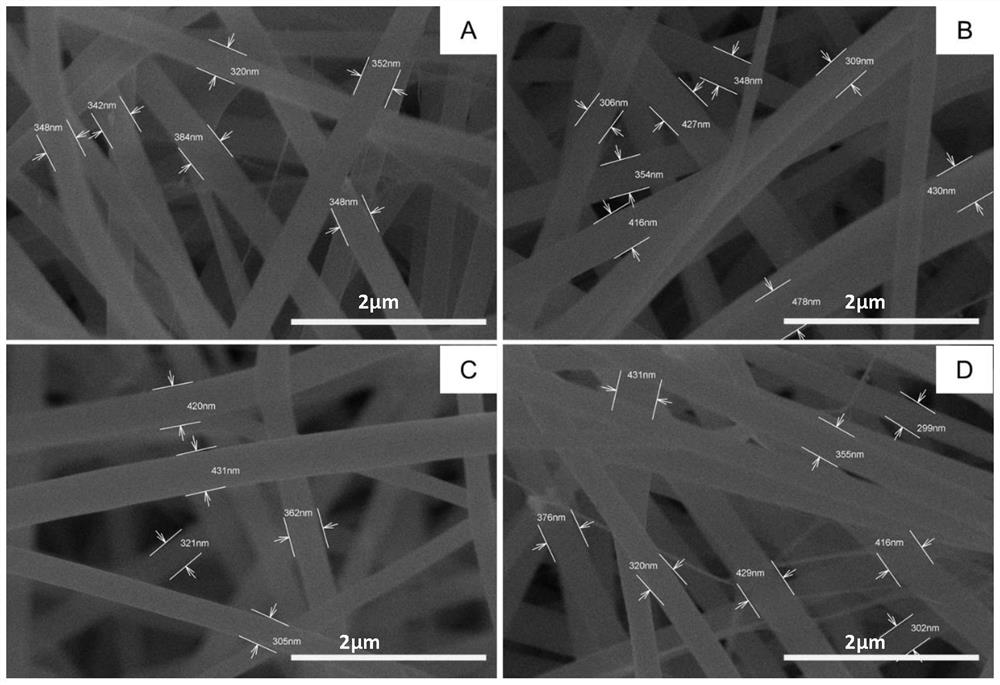

Preparation method of electrostatic spinning membrane for tissue defect repair

PendingCN114541038AStable and controllable viscosityNo loss of spinnabilityElectro-spinningNon-woven fabricsPolymer scienceSpinning

The invention discloses a preparation method of an electrostatic spinning membrane for tissue defect repair, which comprises the following steps: (i) continuously conveying a solution of a high polymer material through a first liquid supply pipe, and continuously conveying a cross-linking agent solution through a second liquid supply pipe; (ii) mixing the high polymer material solution conveyed from the downstream end of the first liquid supply pipe and the cross-linking agent solution conveyed from the downstream end of the second liquid supply pipe in real time in a main liquid supply pipe positioned at the downstream of the first liquid supply pipe and the second liquid supply pipe to form a spinning solution, and then the spinning solution is conveyed to a spinning electrode of electrostatic spinning equipment through the main liquid supply pipe for spinning, and the viscosity of the spinning solution is controlled according to a preset rule to form an electrostatic spinning film with the fiber diameter corresponding to the preset rule. According to the embodiment of the invention, the viscosity of the spinning solution gets rid of the dependence on the crosslinking reaction time and can be stably controlled.

Owner:NEO MODULUS SUZHOU MEDICAL SCI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com