Full-automatic camshaft press-fitting machine

A camshaft and press-fitting machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult product quality assurance, long time-consuming, low efficiency, etc., to avoid positioning deviation, high-efficiency press-fitting, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

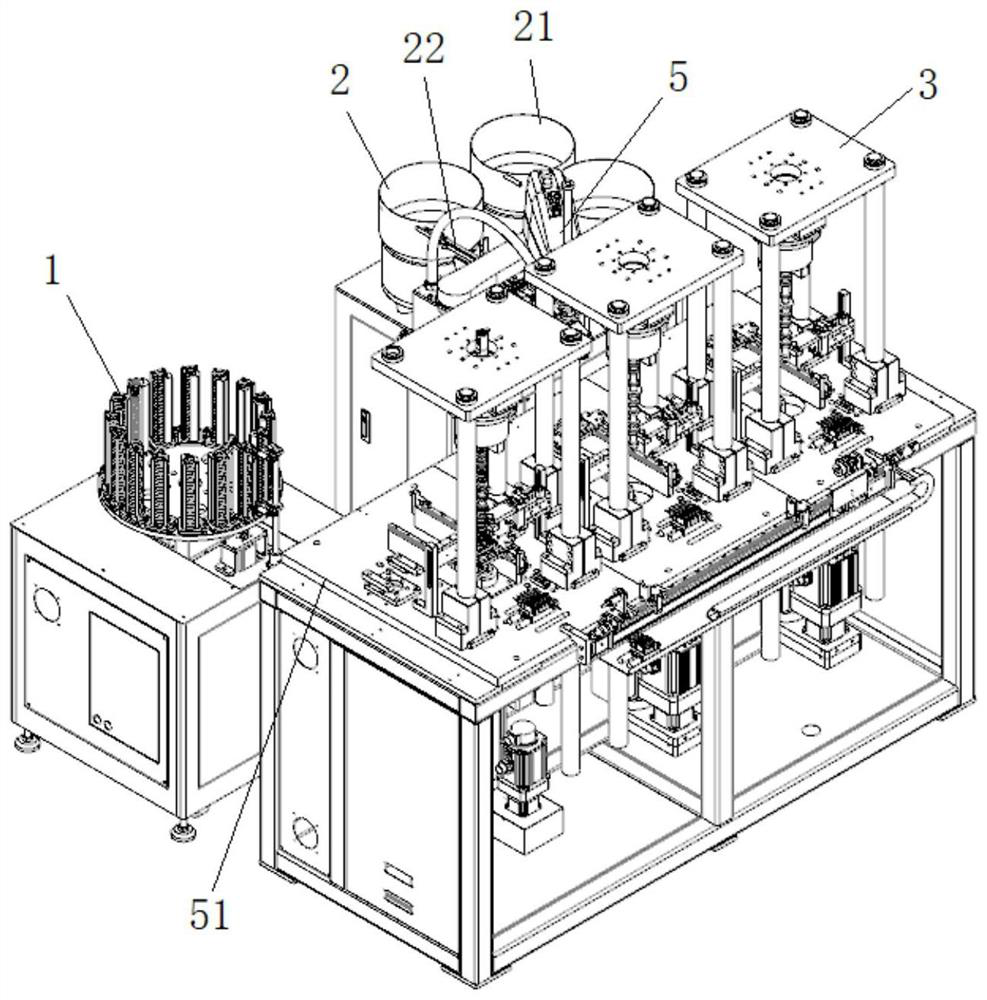

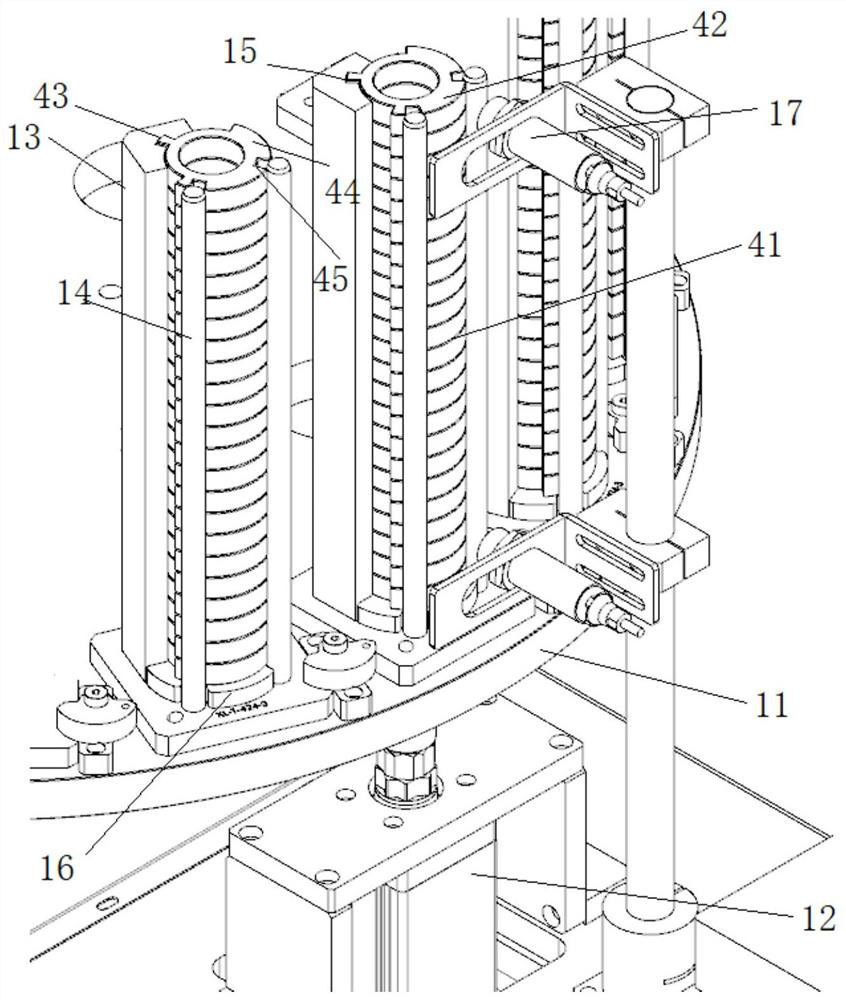

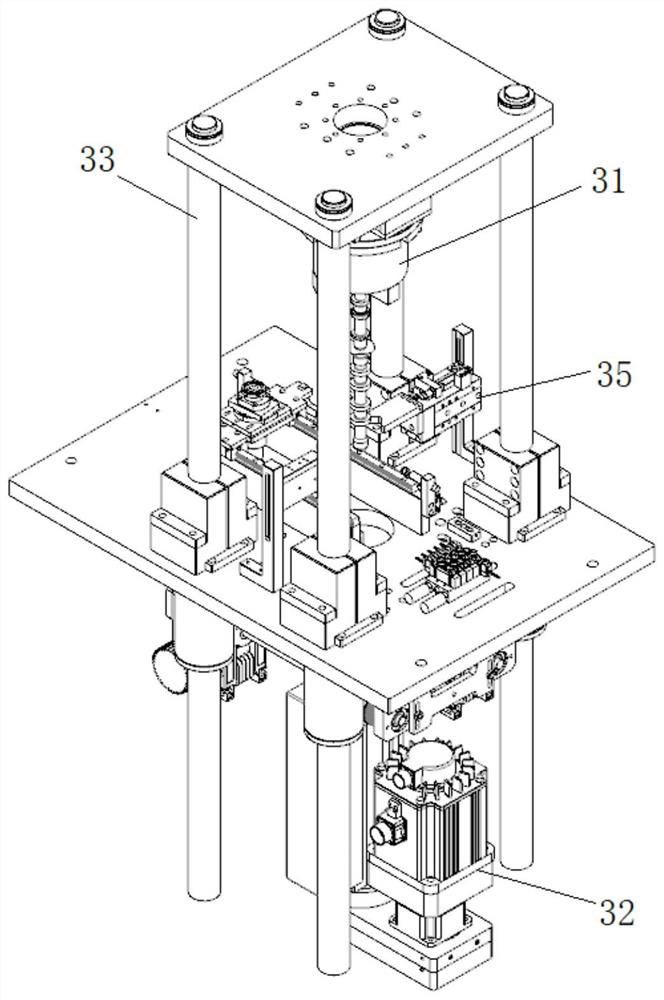

[0029] refer to Figure 1-4 As shown, the present embodiment is a fully automatic camshaft press-fitting machine, including a coding device 1 for regularizing the guide signal wheel, a feeding device 2 for feeding cams, and a press-fitting device 3; the press-fitting device 3 includes a suspension The provided chuck structure 31 for clamping the camshaft 4, the laterally moving splint assembly arranged below the chuck structure 31 for relative clamping of the camshaft 4 for positioning the axis, and the laterally moving splint assembly located below the laterally moving splint assembly The horizontal moving carrier and the first cylinder 32 on the camshaft 4 are used to lift the material in the horizontal moving carrier under the alignment chuck structure, and the manipulator 5 takes the material into the material loading device 1 or the feeding device 2 The material is positioned in the horizontal moving carrier.

[0030] The coding device 1 includes a rotating disk 11 , sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com